CIRED2013 1219 Final

Diunggah oleh

downloadizJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CIRED2013 1219 Final

Diunggah oleh

downloadizHak Cipta:

Format Tersedia

CIRED

22nd International Conference on Electricity Distribution

Stockholm, 10-13 June 2013

Paper 1219

COMBINED INSULATION BUSHING

First Name Carlo Carollo

ABB SPA Italy

carlo.carollo@it.abb.com

First Name Francesco Viaro

ABB SPA Italy

francesco.viaro@it.abb.com

First Name Michela Marchetto

ABB SPA Italy

michela.marchetto@it.abb.com

INTRODUCTION

One of the major current trends in the transformer

industry is dry bushing insulating technologies, combined

with silicon outer insulators to provide the safest service

conditions.

STATE OF THE ART

A conventional non-condenser core bushing in lowervoltage voltage range is typically composed of a

conductor bolt (usually brass or copper), a porcelain

insulating part and oil as the primary insulation. These

so-called conventional porcelain bushings are low-cost

components in comparison to the valuable assets in

which they are used. Bushing failure after either an

internal breakdown in the main transformer unit

(bushing then acts like an exploding "plug") or an

internal bushing failure can have dramatic

consequences not only for the transformer itself, but also

for its immediate surroundings. Shattered porcelain

projectiles are likely to cause secondary damage to other

equipment or any human presence in the vicinity.

Additionally, after such a dramatic failure, the insulating

oil spreads out in small droplets, and combined with a

secondary arcing can easily ignite and caused further

collateral damage. Atmospheric contamination build-up on

electrical apparatus generated from industrial plants

contribute heavily to black-outs and brown-outs. This

contamination builds up on insulators and bushings.

Depending on the resistance values associated with said

contamination, tracking, and in extreme circumstances,

arcing takes place usually during periods of light to

moderate rainfall. When this contamination make a bridge

of conductive material over your porcelain non-conductor

(insulator) the high voltage electricity finds a path to ground

(phase-to-ground fault) resulting in a number of possible

inconveniences for your firm including, but not limited to:

insulator explosion, insulator etching, insulator chipping,

circuit-trip, exposed live-lines, damage to transformers and

breakers, loss of production, injury to personnel, exposure

to electrocution risks to personnel, expensive and timeconsuming repairs, and fires. [1]

CIRED2013 Session 1

Paper No 1219

Picture 1 Conventional porcelain bushing

SILICON RUBBER: A BETTER OPTION

Silicone rubber has been in use as outdoor insulation for

suspension insulator and in other applications from more

than 25 years. Today silicone rubber is the most used

polymeric material for medium and high voltage outdoor

insulator.

The need for cleaning the insulator is almost eliminated

when using silicon rubber. Porcelain, on the other hand,

might have to be cleaned more often in medium polluted

areas as well. The leakage current level along the insulator

is very low compared to porcelain. A typical value for

porcelain is 10 mA and for silicone < 1 mA. This property

also reduces the risk for flash-overs and thus increases the

reliability of the product and eliminates the disturbances in

the power grid resulting from such events. [2]

CIRED

22nd International Conference on Electricity Distribution

Stockholm, 10-13 June 2013

Paper 1219

While start our project we have been focusing on the

weakest performances of a convention porcelain

bushing, which are:

Weakness insulation material

High maintenance

Low partial discharge level

Leakages

Poor prevention of vandalism act

Explosion risk

Low creepage distance

High tolerances

Poor thermal performances

Picture 2 (Silicon rubber)

EPOXY RESIN: HIGH PERFORMANCES

Epoxy resin is well reputed in electro technical field

since 40 years. It is a special insulating material that can

be shaped according to specific need and use. Thanks to

its electrical features in the past years it has been used

for bushings for both transformers and switchgear

applications. Resin material is also having excellent

dielectric and mechanical properties. Thanks to the

perfect molding performance, the epoxy resin became

the perfect solution to in globe electrical screen.

Our challenge was to minimize all these poor performances

in a new high performing bushing.

We have been combining our know how in 50 years of

experience in the transformer components.

The epoxy resin was the best option for the core. This was

immediately evaluated for the following aspects:

Easy to shape

Enabling to insert a simple cylinder electrical

screen (to grant a low partial discharge level)

Good insulation level

High prevention of oil leakages

The silicone rubber was the best option for the housing for

the following reasons:

Thanks to the simple shaping, the creepage

distance can be designed much higher

Non fragmental material

Self-cleaning

High prevention of vandalism act

Minimizing the risk of explosion

Reduced tolerances thank to the molding process

It was a matter of evidence that the combination of the here

above describe insulating material was the solution of the

poor porcelain insulation bushing performances.

We immediately start with the distribution of the electrical

field evaluation in order to design the electrical screen.

Picture 3 (Epoxy resin)

THE PERFECT COMBINATION OF HIGH

PERFORMANCES INSULATION MATERIALS

Today the combined insulation bushing can provide the

needed performances.

Maximizing cast resin and silicon rubber now-how, we

have been developing a new highly performing

insulation bushing.

CIRED2013 Session 1

Paper No 1219

CIRED

22nd International Conference on Electricity Distribution

Stockholm, 10-13 June 2013

Paper 1219

The risk for transport damage is almost eliminated as well.

The safety of personnel is increased due to the non

shattering material in the case of an unexpected failure on

site.

Picture no. 4 - Fem 3D electrical field

Having design the perfect electrical screen, we were ready

to start with mechanical design using a 3D FEM analysis.

This bushing has its conductor directly molded in a

primary organic resin insulation layer, which is in turn

protected by a shed-formed silicone rubber overcoat.

This unique combination of insulation layers eliminates

shattered bushing fragments (no porcelain) and

drastically reduces the risk of fire (no oil), greatly

mitigating the risk of collateral damage after failure,

while also providing excellent insulation properties in

harsh environments (silicone rubber housing).

A COMPLETE FAMILY OF BUSHINGS

The new bushing consists of a full range of standardized

transformer bushings up to

72.5 kV AC applications,

up to 6300 A , with a level of partial discharges meeting

the IEC60137 and IEEE C57.19.01-2000 and IEEE

C57.19.00-2004 standard specifications thanks to an

embedded internal capacitance screen.

With its

exclusive combination of superior materials and robust

construction, this bushing addresses modern insulation

requirements while simultaneously providing a safer and

easier solution for handling, transporting and assembling

bushing units.

Picture no. 5 (Load point and fixations)

Picture no. 6 (Results)

At this stage our bushing was shaped and our project was

ready to because a prototype ready for all testing approval.

We performed successfully all tests required by

international standard IEC 60137.

CIRED2013 Session 1

Paper No 1219

Picture 7 (CRS construction)

A. Copper conductor

CIRED

22nd International Conference on Electricity Distribution

Stockholm, 10-13 June 2013

Paper 1219

B. Primary insulation core (epoxy resin) with

embedded electrical shield

C. Outer insulation layer (silicone rubber sheds)

REFERENCES

For a paper citation:

[1] Optimized use of HV composite apparatus insulators:

field experience from coastal and inland test stations

Cigr conference - Session 2004

[2] Comparision between porcelain and silicone rubber

for use as outdoor insulation on high voltage bushings

ABB Power Technology Products AB Components

Picture 8 Combined insulation bushing CRS type

CIRED2013 Session 1

Paper No 1219

Anda mungkin juga menyukai

- HV Diode Tester: Reliable Diode Assessment TestingDokumen2 halamanHV Diode Tester: Reliable Diode Assessment TestingdownloadizBelum ada peringkat

- اختبارات أجهزة الوقاية - م محمد كمال الجويني - Electrical engineering community PDFDokumen97 halamanاختبارات أجهزة الوقاية - م محمد كمال الجويني - Electrical engineering community PDFdownloadiz75% (12)

- Generator In-Situ Inspections - GER3954CDokumen16 halamanGenerator In-Situ Inspections - GER3954Chozipek100% (1)

- GEH-6676C - Power Systems StabilizerDokumen64 halamanGEH-6676C - Power Systems Stabilizerdownloadiz100% (1)

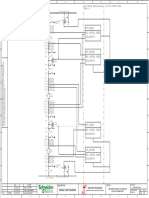

- Power Project Phase II Converting Existing Simple Cycle To Combined Cycle 10069A-CP-106 West DamiettaDokumen1 halamanPower Project Phase II Converting Existing Simple Cycle To Combined Cycle 10069A-CP-106 West DamiettadownloadizBelum ada peringkat

- 10069a 9 V06 Ebb3 00028Dokumen35 halaman10069a 9 V06 Ebb3 00028downloadizBelum ada peringkat

- 426 "5 9 15?!%U3 55%?13U4F ?"W"F ?469 2?4fu) CC?U9?:%1?5b2#37 ?426 "5Dokumen22 halaman426 "5 9 15?!%U3 55%?13U4F ?"W"F ?469 2?4fu) CC?U9?:%1?5b2#37 ?426 "5downloadizBelum ada peringkat

- Bro EX2100Dokumen6 halamanBro EX2100downloadizBelum ada peringkat

- Session 1 (Network Component) PDFDokumen4 halamanSession 1 (Network Component) PDFdownloadizBelum ada peringkat

- Sync SystemDokumen24 halamanSync Systemdownloadiz100% (1)

- Maintenance of Electrical PlantDokumen37 halamanMaintenance of Electrical Plantdownloadiz100% (2)

- FIST 3-31 Transofrmer DiagnosticsDokumen71 halamanFIST 3-31 Transofrmer Diagnosticsjaycarpio100% (1)

- Electrical One Line DiagDokumen5 halamanElectrical One Line DiagdownloadizBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Drainage Master Plan FordelhiDokumen20 halamanDrainage Master Plan FordelhiLovenish BhagatBelum ada peringkat

- Krishna Sie FPT 2000Dokumen33 halamanKrishna Sie FPT 2000Chia Sheng WuBelum ada peringkat

- National Geographic Magazine Volume 1, 1889Dokumen432 halamanNational Geographic Magazine Volume 1, 1889Samina Kosar100% (1)

- (Tamas I. Gombosi) Physics of The Space EnvironmenDokumen357 halaman(Tamas I. Gombosi) Physics of The Space Environmenbrky100% (1)

- Module 2 Week 3 4Dokumen9 halamanModule 2 Week 3 4LeiRne Jo KBahingawan TanGuidBelum ada peringkat

- Physical Chemistry With Formulas and Examples: 1 ThermodynamicDokumen5 halamanPhysical Chemistry With Formulas and Examples: 1 Thermodynamicjkc collegeBelum ada peringkat

- Static Var Generators: DatasheetDokumen4 halamanStatic Var Generators: Datasheethemant kumar0% (1)

- 20 18 1.724 36 T Rtot A Q : Chapter 4 - Heating and Cooling Load CalculationDokumen8 halaman20 18 1.724 36 T Rtot A Q : Chapter 4 - Heating and Cooling Load CalculationdpadrianBelum ada peringkat

- Lesson 16a Earth and Life ScienceDokumen11 halamanLesson 16a Earth and Life ScienceJelai MedinaBelum ada peringkat

- Analysis of Long Term Ecological Monitoring Through Leaf Surface Temperature Parameters in Selected Evergreen and Deciduous Plants of Kodappali.Dokumen29 halamanAnalysis of Long Term Ecological Monitoring Through Leaf Surface Temperature Parameters in Selected Evergreen and Deciduous Plants of Kodappali.Classic PrintersBelum ada peringkat

- UK Brick PlantDokumen47 halamanUK Brick PlantSenthilkumar PragasamBelum ada peringkat

- ZGE 4301 CSAH - M10 Activity No. 1 FT Climate ChangeDokumen10 halamanZGE 4301 CSAH - M10 Activity No. 1 FT Climate ChangeMark Joshua PasicolanBelum ada peringkat

- Life Sciences Grade 11 Practical Task 1.2 DATE: 17 September 2020 Cellular Respiration Marks NAME: .. 30Dokumen5 halamanLife Sciences Grade 11 Practical Task 1.2 DATE: 17 September 2020 Cellular Respiration Marks NAME: .. 30RYAEN RAMBARANBelum ada peringkat

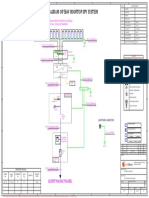

- Single Line Diagram of 5kw Rooftop SPV SystemDokumen1 halamanSingle Line Diagram of 5kw Rooftop SPV SystemArun Sasidharan100% (2)

- Pengumuman DPT Vendor Komponen TrafoDokumen3 halamanPengumuman DPT Vendor Komponen Trafodenny yusufBelum ada peringkat

- NTPC DADRI TrainingDokumen21 halamanNTPC DADRI Trainingpankaj sahuBelum ada peringkat

- Bioplastic Made With Jicama StarchDokumen2 halamanBioplastic Made With Jicama StarchTHE MONSTAAGAMERBelum ada peringkat

- REMF-193 Design and Fabrication of Mini Refrigerator and HeaterDokumen4 halamanREMF-193 Design and Fabrication of Mini Refrigerator and HeaterretechBelum ada peringkat

- Chapter 13Dokumen9 halamanChapter 13drewBelum ada peringkat

- Week - 12 Load CalculationDokumen63 halamanWeek - 12 Load CalculationSuaid Tariq Balghari100% (1)

- Business Plan Majola Recycling V4Dokumen50 halamanBusiness Plan Majola Recycling V4Darlington DhanahBelum ada peringkat

- Experiment 1Dokumen13 halamanExperiment 1許書僑(乂傳說x飛龍乂)Belum ada peringkat

- Development and Validation of A Climate Change Perception ScaleDokumen18 halamanDevelopment and Validation of A Climate Change Perception ScaleJosé Miguel Otazú MejíaBelum ada peringkat

- House Rating SchemesDokumen156 halamanHouse Rating SchemesJanko VukicevicBelum ada peringkat

- QuicksandDokumen3 halamanQuicksandalyssaBelum ada peringkat

- f18 6.11ansDokumen11 halamanf18 6.11ansmina williamBelum ada peringkat

- 7.e.c Evaporation Part 2Dokumen14 halaman7.e.c Evaporation Part 2Sumaya HammoudBelum ada peringkat

- Irrigation Water Requirement For A Model Date Palm (Phoenix Dactylifera) Farm Under Drip Irrigation in The University of MaiduguriDokumen9 halamanIrrigation Water Requirement For A Model Date Palm (Phoenix Dactylifera) Farm Under Drip Irrigation in The University of MaiduguriAZOJETEBelum ada peringkat

- 1st Law of ThermodynamicsDokumen95 halaman1st Law of ThermodynamicsMARUMO_LEVYBelum ada peringkat

- Script (All Mem)Dokumen6 halamanScript (All Mem)Charles CastilloBelum ada peringkat