Other 1294491

Diunggah oleh

noneJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Other 1294491

Diunggah oleh

noneHak Cipta:

Format Tersedia

L1084 32 Abingdon Villas

APPENDIX D

STRUCTURAL CALCULATIONS

Page 34 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

Page 35 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

Page 36 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

Loading For The Structure:

LOADING

Roof (Existing):

Dead Loads:

-

Tiles

= 0.75kN/m

Timber Structure

= 0.25 kN/m

Ceiling & Services

= 0.50 kN/m

= 1.50 kN/m

Live Loads:

-

Limited access roof

= 0.75 kN/m

Second, First & Upper Ground Floor (Existing):

Dead Loads:

-

Finishes

= 0.25 kN/m

Timber structure

= 0.25 kN/m

Ceiling & Services

= 0.50 kN/m

= 1.00 kN/m

Live Loads:

-

Domestic

= 1.50 kN/m

Lower Ground Floor (New):

Dead Loads:

-

50mm screed

= 1.10 kN/m

150mm RC Slab

= 3.60 kN/m

Ceiling & Services

= 0.50 kN/m

= 5.20 kN/m

Live Loads:

-

Domestic

= 1.50 kN/m

Basement Floor (New):

Dead Loads:

-

50mm screed

= 1.10 kN/m

350m RC slab

= 8.60 kN/m

= 9.70 kN/m

Live Loads:

-

Page 37 of 70

Domestic

= 1.50 kN/m

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

Page 38 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

Page 39 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

BEAM BB01

STEEL BEAM ANALYSIS & DESIGN (BS5950)

Unfactored dead load reaction at support B;

RB_Dead = 29.3 kN

Unfactored imposed load reaction at support B;

RB_Imposed = 8.1 kN

Section details

In accordance with BS5950-1:2000 incorporating Corrigendum No.1

Section type;

UKC 203x203x46 (Corus Advance);

Steel grade;

S275

TEDDS calculation version 3.0.04

Load Envelope - Com bination 1

17.393

0.0

mm

A

6200

1

Classification of cross sections - Section 3.5

Tensile strain coefficient;

= 1.00;

Section classification;

Compact

Fv = 53.9 kN;

Design shear resistance;

Pv = 241.4 kN

Shear capacity - Section 4.2.3

Design shear force;

PASS - Design shear resistance exceeds design shear force

Moment capacity - Section 4.2.5

Design bending moment;

M = 83.6 kNm;

Moment capacity low shear;

Mc = 136.8 kNm

PASS - Moment capacity exceeds design bending moment

Check vertical deflection - Section 2.5.2

Consider deflection due to dead and imposed loads

Limiting deflection;

lim = 24.8 mm;

Maximum deflection;

= 24.763 mm

PASS - Maximum deflection does not exceed deflection limit

Support conditions

Support A

Vertically restrained

Rotationally free

Support B

Vertically restrained

Rotationally free

Applied loading

Beam loads

Dead self weight of beam 1

Dead full UDL 9 kN/m

Imposed full UDL 2.6 kN/m

Analysis results

Maximum moment;

Mmax = 83.6 kNm;

Mmin = 0 kNm

Maximum shear;

Vmax = 53.9 kN;

Vmin = -53.9 kN

Deflection;

max = 24.8 mm;

min = 0 mm

Maximum reaction at support A;

RA_max = 53.9 kN;

RA_min = 53.9 kN

Unfactored dead load reaction at support A;

RA_Dead = 29.3 kN

Unfactored imposed load reaction at support A;

RA_Imposed = 8.1 kN

Maximum reaction at support B;

RB_max = 53.9 kN;

RB_min = 53.9 kN

Page 40 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

BEAM BB02

STEEL BEAM ANALYSIS & DESIGN (BS5950)

In accordance with BS5950-1:2000 incorporating Corrigendum No.1

Maximum reaction at support B;

RB_max = 17.2 kN;

Unfactored dead load reaction at support B;

RB_Dead = 11.1 kN

Unfactored imposed load reaction at support B;

RB_Imposed = 1 kN

RB_min = 17.2 kN

Section details

TEDDS calculation version 3.0.04

Section type;

UKB 203x133x25 (Corus Advance);

Steel grade;

S275

Load Envelope - Com bination 1

28.685

0.0

mm

A

1200

1

5.7

133.2

Classification of cross sections - Section 3.5

Tensile strain coefficient;

= 1.00;

Section classification;

Plastic

Design shear resistance;

Pv = 191.1 kN

Shear capacity - Section 4.2.3

Design shear force;

Fv = 17.2 kN;

PASS - Design shear resistance exceeds design shear force

Moment capacity - Section 4.2.5

Design bending moment;

M = 5.2 kNm;

Moment capacity low shear;

Mc = 70.9 kNm

PASS - Moment capacity exceeds design bending moment

Check vertical deflection - Section 2.5.2

Consider deflection due to dead and imposed loads

Limiting deflection;

lim = 4.8 mm;

Maximum deflection;

= 0.114 mm

PASS - Maximum deflection does not exceed deflection limit

Support conditions

Support A

Vertically restrained

Rotationally free

Support B

Vertically restrained

Rotationally free

Applied loading

Beam loads

Dead self weight of beam 1

Dead full UDL 16 kN/m

Imposed full UDL 1.7 kN/m

Dead full UDL 2.3 kN/m

Analysis results

Maximum moment;

Mmax = 5.2 kNm;

Mmin = 0 kNm

Maximum shear;

Vmax = 17.2 kN;

Vmin = -17.2 kN

Deflection;

max = 0.1 mm;

min = 0 mm

Maximum reaction at support A;

RA_max = 17.2 kN;

RA_min = 17.2 kN

Unfactored dead load reaction at support A;

RA_Dead = 11.1 kN

Unfactored imposed load reaction at support A;

RA_Imposed = 1 kN

Page 41 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

BEAM LGB2

MOMENT FRAME 2

LGB2

C1

C2

BB05

BEAM BB05

Page 42 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

COLUMN C1

COLUMN C2

Page 43 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

MOMENT FRAME 1

BEAM BB06

LGB03

C3

C4

BB06

C11

COLUMN C3

BEAM LGB03

Page 44 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

COLUMN C4

COLUMN C11

Page 45 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

BEAM BB07

STEEL BEAM ANALYSIS & DESIGN (BS5950)

Unfactored dead load reaction at support B;

RB_Dead = 24 kN

Unfactored imposed load reaction at support B;

RB_Imposed = 6.7 kN

Section details

In accordance with BS5950-1:2000 incorporating Corrigendum No.1

Section type;

UKC 203x203x46 (Corus Advance);

Steel grade;

S275

TEDDS calculation version 3.0.04

Load Envelope - Com bination 1

23.893

0.0

mm

A

3700

1

Classification of cross sections - Section 3.5

Tensile strain coefficient;

= 1.00;

Section classification;

Compact

Fv = 44.2 kN;

Design shear resistance;

Pv = 241.4 kN

Shear capacity - Section 4.2.3

Design shear force;

PASS - Design shear resistance exceeds design shear force

Moment capacity - Section 4.2.5

Design bending moment;

M = 40.9 kNm;

Moment capacity low shear;

Mc = 136.8 kNm

PASS - Moment capacity exceeds design bending moment

Check vertical deflection - Section 2.5.2

Consider deflection due to dead and imposed loads

Limiting deflection;

lim = 14.8 mm;

Maximum deflection;

= 4.314 mm

PASS - Maximum deflection does not exceed deflection limit

Support conditions

Support A

Vertically restrained

Rotationally free

Support B

Vertically restrained

Rotationally free

Applied loading

Beam loads

Dead self weight of beam 1

Dead full UDL 12.5 kN/m

Imposed full UDL 3.6 kN/m

Analysis results

Maximum moment;

Mmax = 40.9 kNm;

Mmin = 0 kNm

Maximum shear;

Vmax = 44.2 kN;

Vmin = -44.2 kN

Deflection;

max = 4.3 mm;

min = 0 mm

Maximum reaction at support A;

RA_max = 44.2 kN;

RA_min = 44.2 kN

Unfactored dead load reaction at support A;

RA_Dead = 24 kN

Unfactored imposed load reaction at support A;

RA_Imposed = 6.7 kN

Maximum reaction at support B;

RB_max = 44.2 kN;

RB_min = 44.2 kN

Page 46 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

BEAM BB08

STEEL BEAM ANALYSIS & DESIGN (BS5950)

Unfactored dead load reaction at support B;

RB_Dead = 7.8 kN

Unfactored imposed load reaction at support B;

RB_Imposed = 2.2 kN

Section details

In accordance with BS5950-1:2000 incorporating Corrigendum No.1

Section type;

UKC 203x203x46 (Corus Advance);

Steel grade;

S275

TEDDS calculation version 3.0.04

Load Envelope - Com bination 1

23.893

0.0

mm

1200

1

Classification of cross sections - Section 3.5

Tensile strain coefficient;

= 1.00;

Section classification;

Compact

Fv = 14.3 kN;

Design shear resistance;

Pv = 241.4 kN

Shear capacity - Section 4.2.3

Design shear force;

PASS - Design shear resistance exceeds design shear force

Moment capacity - Section 4.2.5

Design bending moment;

M = 4.3 kNm;

Moment capacity low shear;

Mc = 136.8 kNm

PASS - Moment capacity exceeds design bending moment

Check vertical deflection - Section 2.5.2

Consider deflection due to dead and imposed loads

Limiting deflection;

lim = 4.8 mm;

Maximum deflection;

= 0.048 mm

PASS - Maximum deflection does not exceed deflection limit

Support conditions

Support A

Vertically restrained

Rotationally free

Support B

Vertically restrained

Rotationally free

Applied loading

Beam loads

Dead self weight of beam 1

Dead full UDL 12.5 kN/m

Imposed full UDL 3.6 kN/m

Analysis results

Maximum moment;

Mmax = 4.3 kNm;

Mmin = 0 kNm

Maximum shear;

Vmax = 14.3 kN;

Vmin = -14.3 kN

Deflection;

max = 0 mm;

min = 0 mm

Maximum reaction at support A;

RA_max = 14.3 kN;

RA_min = 14.3 kN

Unfactored dead load reaction at support A;

RA_Dead = 7.8 kN

Unfactored imposed load reaction at support A;

RA_Imposed = 2.2 kN

Maximum reaction at support B;

RB_max = 14.3 kN;

RB_min = 14.3 kN

Page 47 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

BEAM BB09

STEEL BEAM ANALYSIS & DESIGN (BS5950)

Unfactored dead load reaction at support B;

RB_Dead = 29.3 kN

Unfactored imposed load reaction at support B;

RB_Imposed = 8.1 kN

Section details

In accordance with BS5950-1:2000 incorporating Corrigendum No.1

Section type;

UKC 203x203x46 (Corus Advance);

Steel grade;

S275

TEDDS calculation version 3.0.04

Load Envelope - Com bination 1

17.393

0.0

mm

A

6200

1

Classification of cross sections - Section 3.5

Tensile strain coefficient;

= 1.00;

Section classification;

Compact

Fv = 53.9 kN;

Design shear resistance;

Pv = 241.4 kN

Shear capacity - Section 4.2.3

Design shear force;

PASS - Design shear resistance exceeds design shear force

Moment capacity - Section 4.2.5

Design bending moment;

M = 83.6 kNm;

Moment capacity low shear;

Mc = 136.8 kNm

PASS - Moment capacity exceeds design bending moment

Check vertical deflection - Section 2.5.2

Consider deflection due to dead and imposed loads

Limiting deflection;

lim = 24.8 mm;

Maximum deflection;

= 24.763 mm

PASS - Maximum deflection does not exceed deflection limit

Support conditions

Support A

Vertically restrained

Rotationally free

Support B

Vertically restrained

Rotationally free

Applied loading

Beam loads

Dead self weight of beam 1

Dead full UDL 9 kN/m

Imposed full UDL 2.6 kN/m

Analysis results

Maximum moment;

Mmax = 83.6 kNm;

Mmin = 0 kNm

Maximum shear;

Vmax = 53.9 kN;

Vmin = -53.9 kN

Deflection;

max = 24.8 mm;

min = 0 mm

Maximum reaction at support A;

RA_max = 53.9 kN;

RA_min = 53.9 kN

Unfactored dead load reaction at support A;

RA_Dead = 29.3 kN

Unfactored imposed load reaction at support A;

RA_Imposed = 8.1 kN

Maximum reaction at support B;

RB_max = 53.9 kN;

RB_min = 53.9 kN

Page 48 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

BEAM BB12

STEEL BEAM ANALYSIS & DESIGN (BS5950)

In accordance with BS5950-1:2000 incorporating Corrigendum No.1

TEDDS calculation version 3.0.04

Unfactored imposed load reaction at support A;

RA_Imposed = 5 kN

Maximum reaction at support B;

RB_max = 210.9 kN;

Unfactored dead load reaction at support B;

RB_Dead = 142.2 kN

Unfactored imposed load reaction at support B;

RB_Imposed = 7.4 kN

RB_min = 210.9 kN

Section details

Section type;

UKC 203x203x60 (Corus Advance);

Steel grade;

S275

Load Envelope - Com bination 1

132.823

0.0

mm

A

2700

1

Classification of cross sections - Section 3.5

Tensile strain coefficient;

= 1.00;

Section classification;

Plastic

Design shear resistance;

Pv = 325.1 kN

Shear capacity - Section 4.2.3

Design shear force;

Fv = 210.9 kN;

PASS - Design shear resistance exceeds design shear force

Moment capacity - Section 4.2.5

Design bending moment;

M = 143.3 kNm;

Moment capacity high shear;

Mc = 177.9 kNm

PASS - Moment capacity exceeds design bending moment

Check vertical deflection - Section 2.5.2

Consider deflection due to dead and imposed loads

Limiting deflection;

lim = 7.5 mm;

Maximum deflection;

= 6.128 mm

PASS - Maximum deflection does not exceed deflection limit

Support conditions

Support A

Vertically restrained

Rotationally free

Support B

Vertically restrained

Rotationally free

Applied loading

Beam loads

Dead self weight of beam 1

Dead full UDL 92 kN/m

Imposed full UDL 2 kN/m

Dead point load 25.8 kN at 1800 mm

Imposed point load 7 kN at 1800 mm

Analysis results

Maximum moment;

Mmax = 143.3 kNm;

Mmin = 0 kNm

Maximum shear;

Vmax = 195.1 kN;

Vmin = -210.9 kN

Deflection;

max = 6.1 mm;

min = 0 mm

Maximum reaction at support A;

RA_max = 195.1 kN;

RA_min = 195.1 kN

Unfactored dead load reaction at support A;

RA_Dead = 133.6 kN

Page 49 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

BEAM BB13

STEEL BEAM ANALYSIS & DESIGN (BS5950)

Unfactored dead load reaction at support B;

RB_Dead = 83.2 kN

Unfactored imposed load reaction at support B;

RB_Imposed = 1.8 kN

Section details

In accordance with BS5950-1:2000 incorporating Corrigendum No.1

Section type;

UKC 203x203x46 (Corus Advance);

Steel grade;

S275

TEDDS calculation version 3.0.04

Load Envelope - Com bination 1

132.633

0.0

mm

A

1800

1

Classification of cross sections - Section 3.5

Tensile strain coefficient;

= 1.00;

Section classification;

Compact

Fv = 119.4 kN;

Design shear resistance;

Pv = 241.4 kN

Shear capacity - Section 4.2.3

Design shear force;

PASS - Design shear resistance exceeds design shear force

Moment capacity - Section 4.2.5

Design bending moment;

M = 53.7 kNm;

Moment capacity low shear;

Mc = 136.8 kNm

PASS - Moment capacity exceeds design bending moment

Check vertical deflection - Section 2.5.2

Consider deflection due to dead and imposed loads

Limiting deflection;

lim = 5 mm;

Maximum deflection;

= 1.379 mm

PASS - Maximum deflection does not exceed deflection limit

Support conditions

Support A

Vertically restrained

Rotationally free

Support B

Vertically restrained

Rotationally free

Applied loading

Beam loads

Dead self weight of beam 1

Dead full UDL 92 kN/m

Imposed full UDL 2 kN/m

Analysis results

Maximum moment;

Mmax = 53.7 kNm;

Mmin = 0 kNm

Maximum shear;

Vmax = 119.4 kN;

Vmin = -119.4 kN

Deflection;

max = 1.4 mm;

min = 0 mm

Maximum reaction at support A;

RA_max = 119.4 kN;

RA_min = 119.4 kN

Unfactored dead load reaction at support A;

RA_Dead = 83.2 kN

Unfactored imposed load reaction at support A;

RA_Imposed = 1.8 kN

Maximum reaction at support B;

RB_max = 119.4 kN;

RB_min = 119.4 kN

Page 50 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

BEAM BB16

STEEL BEAM ANALYSIS & DESIGN (BS5950)

In accordance with BS5950-1:2000 incorporating Corrigendum No.1

TEDDS calculation version 3.0.04

Unfactored imposed load reaction at support A;

RA_Imposed = 7 kN

Maximum reaction at support B;

RB_max = 48.7 kN;

Unfactored dead load reaction at support B;

RB_Dead = 26.8 kN

Unfactored imposed load reaction at support B;

RB_Imposed = 7 kN

RB_min = 48.7 kN

Section details

Section type;

UKC 203x203x46 (Corus Advance);

Steel grade;

S275

Load Envelope - Com bination 1

50.680

0.0

mm

A

4800

1

Classification of cross sections - Section 3.5

Tensile strain coefficient;

= 1.00;

Section classification;

Compact

Fv = 95.2 kN;

Design shear resistance;

Pv = 241.4 kN

Shear capacity - Section 4.2.3

Design shear force;

PASS - Design shear resistance exceeds design shear force

Moment capacity - Section 4.2.5

Design bending moment;

M = 61.1 kNm;

Moment capacity low shear;

Mc = 136.8 kNm

PASS - Moment capacity exceeds design bending moment

Check vertical deflection - Section 2.5.2

Consider deflection due to dead and imposed loads

Limiting deflection;

lim = 13.333 mm;

Maximum deflection;

= 11.044 mm

PASS - Maximum deflection does not exceed deflection limit

Support conditions

Support A

Vertically restrained

Rotationally free

Support B

Vertically restrained

Rotationally free

Applied loading

Beam loads

Dead self weight of beam 1

Dead full UDL 10.1 kN/m

Imposed full UDL 2.9 kN/m

Dead point load 18.1 kN at 200 mm

Dead point load 18.1 kN at 200 mm

Analysis results

Maximum moment;

Mmax = 61.1 kNm;

Mmin = 0 kNm

Maximum shear;

Vmax = 95.2 kN;

Vmin = -48.7 kN

Deflection;

max = 11 mm;

min = 0 mm

Maximum reaction at support A;

RA_max = 95.2 kN;

RA_min = 95.2 kN

Unfactored dead load reaction at support A;

RA_Dead = 60 kN

Page 51 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

BEAM BB17

STEEL BEAM ANALYSIS & DESIGN (BS5950)

Unfactored dead load reaction at support B;

RB_Dead = 25.8 kN

Unfactored imposed load reaction at support B;

RB_Imposed = 7 kN

Section details

In accordance with BS5950-1:2000 incorporating Corrigendum No.1

Section type;

UKC 203x203x46 (Corus Advance);

Steel grade;

S275

TEDDS calculation version 3.0.04

Load Envelope - Com bination 1

19.693

0.0

mm

A

4800

1

Classification of cross sections - Section 3.5

Tensile strain coefficient;

= 1.00;

Section classification;

Compact

Fv = 47.3 kN;

Design shear resistance;

Pv = 241.4 kN

Shear capacity - Section 4.2.3

Design shear force;

PASS - Design shear resistance exceeds design shear force

Moment capacity - Section 4.2.5

Design bending moment;

M = 56.7 kNm;

Moment capacity low shear;

Mc = 136.8 kNm

PASS - Moment capacity exceeds design bending moment

Check vertical deflection - Section 2.5.2

Consider deflection due to dead and imposed loads

Limiting deflection;

lim = 19.2 mm;

Maximum deflection;

= 10.077 mm

PASS - Maximum deflection does not exceed deflection limit

Support conditions

Support A

Vertically restrained

Rotationally free

Support B

Vertically restrained

Rotationally free

Applied loading

Beam loads

Dead self weight of beam 1

Dead full UDL 10.3 kN/m

Imposed full UDL 2.9 kN/m

Analysis results

Maximum moment;

Mmax = 56.7 kNm;

Mmin = 0 kNm

Maximum shear;

Vmax = 47.3 kN;

Vmin = -47.3 kN

Deflection;

max = 10.1 mm;

min = 0 mm

Maximum reaction at support A;

RA_max = 47.3 kN;

RA_min = 47.3 kN

Unfactored dead load reaction at support A;

RA_Dead = 25.8 kN

Unfactored imposed load reaction at support A;

RA_Imposed = 7 kN

Maximum reaction at support B;

RB_max = 47.3 kN;

RB_min = 47.3 kN

Page 52 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

Section details

BEAM BB18 & BB19

Section type;

UKC 203x203x46 (Corus Advance);

Steel grade;

S275

STEEL BEAM ANALYSIS & DESIGN (BS5950)

In accordance with BS5950-1:2000 incorporating Corrigendum No.1

TEDDS calculation version 3.0.04

Load Envelope - Com bination 1

34.233

0.0

mm

A

1900

1

Classification of cross sections - Section 3.5

Tensile strain coefficient;

= 1.00;

Section classification;

Compact

Design shear resistance;

Pv = 241.4 kN

Shear capacity - Section 4.2.3

Design shear force;

Fv = 25.4 kN;

PASS - Design shear resistance exceeds design shear force

Moment capacity - Section 4.2.5

Design bending moment;

M = 9.4 kNm;

Moment capacity low shear;

Mc = 136.8 kNm

PASS - Moment capacity exceeds design bending moment

Check vertical deflection - Section 2.5.2

Consider deflection due to dead and imposed loads

Limiting deflection;

lim = 5.278 mm;

Maximum deflection;

= 0.245 mm

PASS - Maximum deflection does not exceed deflection limit

Support conditions

Support A

Vertically restrained

Rotationally free

Support B

Vertically restrained

Rotationally free

Applied loading

Beam loads

Dead self weight of beam 1

Dead partial UDL 24 kN/m from 900 mm to 1900 mm

Analysis results

Maximum moment;

Mmax = 9.4 kNm;

Mmin = 0 kNm

Maximum shear;

Vmax = 9.4 kN;

Vmin = -25.4 kN

Deflection;

max = 0.2 mm;

min = 0 mm

Maximum reaction at support A;

RA_max = 9.4 kN;

RA_min = 9.4 kN

Unfactored dead load reaction at support A;

RA_Dead = 6.7 kN

Maximum reaction at support B;

RB_max = 25.4 kN;

Unfactored dead load reaction at support B;

RB_Dead = 18.1 kN

RB_min = 25.4 kN

Page 53 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

BEAM BB20

STEEL BEAM ANALYSIS & DESIGN (BS5950)

In accordance with BS5950-1:2000 incorporating Corrigendum No.1

TEDDS calculation version 3.0.04

Maximum reaction at support A;

RA_max = 64.9 kN;

Unfactored dead load reaction at support A;

RA_Dead = 34.8 kN

Unfactored imposed load reaction at support A;

RA_Imposed = 10.1 kN

Maximum reaction at support B;

RB_max = 64.9 kN;

Unfactored dead load reaction at support B;

RB_Dead = 34.8 kN

Unfactored imposed load reaction at support B;

RB_Imposed = 10.1 kN

RA_min = 64.9 kN

RB_min = 64.9 kN

Section details

Load Envelope - Com bination 1

Section type;

UKC 203x203x52 (Corus Advance);

Steel grade;

S275

12.5

17.400

0.0

mm

6200

1

12.5

206.2

Classification of cross sections - Section 3.5

Tensile strain coefficient;

= 1.00;

Section classification;

Plastic

Fv = 64.9 kN;

Design shear resistance;

Pv = 268.8 kN

Shear capacity - Section 4.2.3

Design shear force;

PASS - Design shear resistance exceeds design shear force

Moment capacity - Section 4.2.5

Design bending moment;

M = 77.1 kNm;

Moment capacity low shear;

Mc = 156 kNm

PASS - Moment capacity exceeds design bending moment

Check vertical deflection - Section 2.5.2

Consider deflection due to dead and imposed loads

Limiting deflection;

lim = 24.8 mm;

Maximum deflection;

= 20.004 mm

PASS - Maximum deflection does not exceed deflection limit

Support conditions

Support A

Vertically restrained

Rotationally free

Support B

Vertically restrained

Rotationally free

Applied loading

Beam loads

Dead self weight of beam 1

Dead full UDL 7.8 kN/m

Imposed full UDL 2.3 kN/m

Dead point load 9 kN at 200 mm

Imposed point load 3 kN at 200 mm

Dead point load 9 kN at 6000 mm

Imposed point load 3 kN at 6000 mm

Analysis results

Maximum moment;

Mmax = 77.1 kNm;

Mmin = 0 kNm

Maximum shear;

Vmax = 64.9 kN;

Vmin = -64.9 kN

Deflection;

max = 20 mm;

min = 0 mm

Page 54 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

BEAM BB23

STEEL BEAM ANALYSIS & DESIGN (BS5950)

Unfactored dead load reaction at support B;

RB_Dead = 7.9 kN

Unfactored imposed load reaction at support B;

RB_Imposed = 2.3 kN

Section details

In accordance with BS5950-1:2000 incorporating Corrigendum No.1

Section type;

UKB 203x133x25 (Corus Advance);

Steel grade;

S275

TEDDS calculation version 3.0.04

Load Envelope - Com bination 1

24.625

5.7

0.0

mm

A

1200

1

133.2

Classification of cross sections - Section 3.5

Tensile strain coefficient;

= 1.00;

Section classification;

Plastic

Fv = 14.8 kN;

Design shear resistance;

Pv = 191.1 kN

Shear capacity - Section 4.2.3

Design shear force;

PASS - Design shear resistance exceeds design shear force

Moment capacity - Section 4.2.5

Design bending moment;

M = 4.4 kNm;

Moment capacity low shear;

Mc = 70.9 kNm

PASS - Moment capacity exceeds design bending moment

Check vertical deflection - Section 2.5.2

Consider deflection due to dead and imposed loads

Limiting deflection;

lim = 4.8 mm;

Maximum deflection;

= 0.096 mm

PASS - Maximum deflection does not exceed deflection limit

Support conditions

Support A

Vertically restrained

Rotationally free

Support B

Vertically restrained

Rotationally free

Applied loading

Beam loads

Dead self weight of beam 1

Dead full UDL 13 kN/m

Imposed full UDL 3.8 kN/m

Analysis results

Maximum moment;

Mmax = 4.4 kNm;

Mmin = 0 kNm

Maximum shear;

Vmax = 14.8 kN;

Vmin = -14.8 kN

Deflection;

max = 0.1 mm;

min = 0 mm

Maximum reaction at support A;

RA_max = 14.8 kN;

RA_min = 14.8 kN

Unfactored dead load reaction at support A;

RA_Dead = 7.9 kN

Unfactored imposed load reaction at support A;

RA_Imposed = 2.3 kN

Maximum reaction at support B;

RB_max = 14.8 kN;

RB_min = 14.8 kN

Page 55 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

COLUMN C2 PAD FOUNDATION

PAD FOOTING ANALYSIS AND DESIGN (BS8110-1:1997)

TEDDS calculation version 2.0.05.06

750

144.9 kN/m

144.9 kN/m

750

144.9 kN/m

144.9 kN/m

Partial safety factors for loads

1800

Dead loads;

fG = 1.40;

Wind loads;

fW = 0.00

Imposed loads;

fQ = 1.60

Ult. horizontal load in y dir;

HyuA = 0.0 kN

Ultimate axial loading on column

Pad footing details

Ultimate axial load on column; PuA = 567.6 kN

Length of pad footing;

L = 1800 mm;

Width of pad footing;

Depth of pad footing;

h = 450 mm;

Depth of soil over pad footing; hsoil = 0 mm

B = 1800 mm

Density of concrete;

conc = 23.6 kN/m

Ultimate foundation loads

Ultimate foundation load;

Ultimate horizontal loading on column

Column details

Ult.horizontal load in x dir;

Column base length;

lA = 300 mm;

Column base width;

bA = 300 mm

Column eccentricity in x;

ePxA = 0 mm;

Column eccentricity in y;

ePyA = 0 mm

Density of soil;

soil = 20.0 kN/m

Depth of soil over pad footing; hsoil = 0 mm;

Pbearing = 150 kN/m

Ult.moment on column in x dir; MxuA = 0.000 kNm;

Axial loading on column (From Moment Frame 2 Analysis)

PGA = 370.0 kN;

Imposed axial load;

PQA = 31.0 kN

Wind axial load;

PWA = 34.0 kN;

Total axial load;

PA = 435.0 kN

Imposed surcharge load;

FQsur = 0.000 kN/m

Total foundation load;

F = 34.4 kN

Pad footing self weight;

Fswt = 10.620 kN/m

Soil self weight;

Fsoil = 0.000 kN/m ;

Minimum ult.base pressure;

Ultimate moment in x dir;

Minimum base pressure;

qminu = 190.053 kN/m ;

Mx = 127.710 kNm;

q2 = 144.879 kN/m ;

q3 = 144.879 kN/m ;

2

qmin = 144.879 kN/m ;

Maximum base pressure;

q4 = 144.879 kN/m

q3u = 190.053 kN/m ;

q4u = 190.053 kN/m

Maximum ult.base pressure;

qmaxu = 190.053 kN/m

Ultimate moment in y dir;

My = 127.710 kNm

Char.strength of reinft;

fy = 500 N/mm

Char.strength of concrete;

fcu = 30 N/mm ;

Char.strength of shear reinft;

fyv = 500 N/mm ;

Nom.cover to reinforcement;

cnom = 40 mm

xB = 16 mm;

Tens.reinforcement depth;

dx = 402 mm

Kx = 0.015;

Kx = 0.156

Tens.reinforcement diameter;

Design formula for rectangular beams (cl 3.4.4.4);

Calculate pad base pressures

q1 = 144.879 kN/m ;

q2u = 190.053 kN/m ;

Moment design in x direction

Base reaction eccentricity in y; eTy = 0 mm

Base reaction acts within middle third of base

eTyu = 0 mm

Material details

T = 469.4 kN

Base reaction eccentricity in x; eTx = 0 mm;

Ecc.of ult.base reaction in y;

Library item: Ultimate pressures summaryUltimate moments

Calculate pad base reaction

Total base reaction;

eTxu = 0 mm;

Tu = 615.8 kN

Ecc.of ult.base reaction in x;

q1u = 190.053 kN/m ;

Foundation loads

2

Ultimate base reaction;

Calculate ultimate pad base pressures

Dead axial load;

FGsur = 0.000 kN/m ;

Ult.moment on column in y dir; MyuA = 0.000 kNm

Ultimate pad base reaction

Dead surcharge load;

HxuA = 0.0 kN;

Ultimate moment on column

Soil details

Allowable bearing pressure;

Fu = 48.2 kN

Kx < Kx' compression reinforcement is not required

2

qmax = 144.879 kN/m

PASS - Maximum base pressure is less than allowable bearing pressure

Tens.reinforcement required;

As_x_req = 769 mm ;

Minimum tens.reinforcement;

Tens.reinforcement provided;

12 No. 16 dia. bars btm;

As_xB_prov = 2413 mm

As_x_min = 1053 mm

PASS - Tension reinforcement provided exceeds tension reinforcement required

Moment design in y direction

Tens.reinforcement diameter;

Page 56 of 70

yB = 16 mm;

Tens.reinforcement depth;

dy = 386 mm

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

Design formula for rectangular beams (cl 3.4.4.4);

Ky = 0.016;

Ky = 0.156

Ky < Ky' compression reinforcement is not required

Tens.reinforcement required;

Tens.reinforcement provided;

As_y_req = 801 mm ;

Minimum tens.reinforcement;

12 No. 16 dia. bars btm;

As_yB_prov = 2413 mm

As_y_min = 1053 mm

PASS - Tension reinforcement provided exceeds tension reinforcement required

Calculate ultimate shear force at d from top face of column

Ult.pressure for shear;

Area loaded for shear;

qsu = 190.053 kN/m

As = 0.655 m ;

Ult.shear force;

Vsu = 114.781 kN

Shear stresses at d from top face of column (cl 3.5.5.2)

Design shear stress;

vsu = 0.165 N/mm

Design concrete shear stress; vc = 0.471 N/mm ;

Allowable design shear stress; vmax = 4.382 N/mm

PASS - vsu < vc - No shear reinforcement required

Calculate ultimate punching shear force at face of column

Ult.press.for punching shear;

qpuA = 190.053 kN/m ;

Avg.effective reinf.depth;

d = 394 mm

Area loaded;

ApA = 0.090 m ;

Length of shear perimeter;

upA = 1200 mm

Ult.punching shear force;

VpuA = 551.833 kN;

Eff.punching shear force;

VpuAeff = 551.833 kN

Punching shear stresses at face of column (cl 3.7.7.2)

Design shear stress;

vpuA = 1.167 N/mm

PASS - Design shear stress is less than allowable design shear stress

Calculate ultimate punching shear force at perimeter of 1.5 d from face of column

Ult.press.for punching shear;

qpuA1.5d = 190.053 kN/m ;

Avg.effective reinf.depth;

d = 394 mm

Area loaded;

ApA1.5d = 2.668 m ;

Length of shear perimeter;

upA1.5d = 3600 mm

Ult.punching shear force;

VpuA1.5d = 100.276 kN;

Eff.punching shear force;

VpuA1.5deff = 125.345 kN

Punching shear stresses at perimeter of 1.5 d from face of column (cl 3.7.7.2)

Design shear stress;

vpuA1.5d = 0.088 N/mm

PASS - vpuA1.5d < vc - No shear reinforcement required

Page 57 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

Page 58 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

RAFT SLAB DESIGN AT COLUMN C1

RAFT FOUNDATION DESIGN (BS8110 : PART 1 : 1997)

Tedds calculation version 1.0.09;

Asslabtop

A sedgetop

A sedgelink

hedge

Overall depth;

hedge = 450 mm

Width;

bedge = 1000 mm

Angle of chamfer to horizontal;

edge = 45 deg

Strength of main bar reinforcement;

fy = 500 N/mm

Strength of link reinforcement;

fys = 500 N/mm

Reinforcement provided in top;

6 H20 bars (Asedgetop = 1885 mm )

Reinforcement provided in bottom;

6 H20 bars (Asedgebtm = 1885 mm )

Link reinforcement provided;

3 H12 legs at 100 ctrs (Asv/sv = 3.393 mm)

Bottom cover to links;

cbeam = 35 mm

2

2

2

Effective depth of top reinforcement;

dedgetop = hedge - ctop - slabtop -edgelink - edgetop/2 = 398 mm

hslab

Effective depth of bottom reinforcement;

dedgebtm = hedge - cbeam - edgelink - edgebtm/2 = 393 mm

hhcoreslab

Internal slab design checks

Basic loading

aedge

A sslabbtm

hhcorethick

Slab self weight;

wslab = 24 kN/m hslab = 6.0 kN/m

Hardcore;

whcoreslab = hcore hhcoreslab = 0.0 kN/m

2

2

Applied loading

Asedgebtm

bedge

Uniformly distributed dead load;

Uniformly distributed live load;

wDudl = 1.5 kN/m

wLudl = 1.5 kN/m

Internal slab bearing pressure check

Total uniform load at formation level;

Soil and raft definition

wudl = wslab + whcoreslab + wDudl + wLudl = 9.0 kN/m

PASS - wudl <= qallow - Applied bearing pressure is less than allowable

Soil definition

Internal slab bending and shear check

2

Allowable bearing pressure;

qallow = 40.0 kN/m

Number of types of soil forming sub-soil;

One type only

Soil density;

Firm to loose

Depth of hardcore beneath slab;

hhcoreslab = 0 mm; (Dispersal allowed for bearing pressure check)

Depth of hardcore beneath thickenings;

hhcorethick = 0 mm; (Dispersal allowed for bearing pressure check)

Density of hardcore;

hcore = 20.0 kN/m

Basic assumed diameter of local depression;

Applied bending moments

Span of slab;

lslab = depslab + dtslabav = 2220 mm

Ultimate self weight udl;

wswult = 1.4 wslab = 8.4 kN/m

Self weight moment at centre;

Mcsw = wswult lslab (1 + ) / 64 = 0.8 kNm/m

Self weight moment at edge;

Mesw = wswult lslab / 32 = 1.3 kNm/m

depbasic = 2000mm

Self weight shear force at edge;

Vsw = wswult lslab / 4 = 4.7 kN/m

Diameter under slab modified for hardcore;

depslab = depbasic - hhcoreslab = 2000 mm

Moments due to applied uniformly distributed loads

Diameter under thickenings modified for hardcore;

depthick = depbasic - hhcorethick = 2000 mm

Ultimate applied udl;

wudlult = 1.4 wDudl + 1.6 wLudl = 4.5 kN/m

Moment at centre;

Mcudl = wudlult

Moment at edge;

Meudl = wudlult lslab / 32 = 0.7 kNm/m

Shear force at edge;

Vudl = wudlult lslab / 4 = 2.5 kN/m

Raft slab definition

Max dimension/max dimension between joints;

lmax = 6.200 m

Slab thickness;

hslab = 250 mm

Concrete strength;

fcu = 40 N/mm

Poissons ratio of concrete;

= 0.2

Slab mesh reinforcement strength;

fyslab = 500 N/mm

Partial safety factor for steel reinforcement;

s = 1.15

2

lslab

(1 + ) / 64 = 0.4 kNm/m

Resultant moments and shears

2

From C&CA document Concrete ground floors Table 5

Total moment at edge;

Me = 2.0 kNm/m

Total moment at centre;

Mc = 1.2 kNm/m

Total shear force;

V = 7.2 kN/m

Reinforcement required in top

Minimum mesh required in top for shrinkage;

A142;

Actual mesh provided in top;

A393 (Asslabtop = 393 mm /m)

Mesh provided in bottom;

A393 (Asslabbtm = 393 mm /m)

Top mesh bar diameter;

slabtop = 10 mm

Bottom mesh bar diameter;

slabbtm = 10 mm

Cover to top reinforcement;

ctop = 20 mm

Cover to bottom reinforcement;

cbtm = 35 mm

Average effective depth of top reinforcement;

dtslabav = hslab - ctop - slabtop = 220 mm

Reinforcement required in bottom

Average effective depth of bottom reinforcement;

dbslabav = hslab - cbtm - slabbtm = 205 mm

K factor;

Kslabbtm = Mc/(fcu dbslabav ) = 0.001

Overall average effective depth;

dslabav = (dtslabav + dbslabav)/2 = 213 mm

Lever arm;

zslabbtm = dbslabav min(0.95, 0.5 + (0.25 - Kslabbtm/0.9)) = 194.7 mm

Minimum effective depth of top reinforcement;

dtslabmin = dtslabav - slabtop/2 = 215 mm

Area of steel required for bending;

Asslabbtmbend = Mc/((1.0/s) fyslab zslabbtm) = 14 mm /m

Minimum effective depth of bottom reinforcement;

dbslabmin = dbslabav - slabbtm/2 = 200 mm

Area of steel required;

K factor;

Kslabtop = Me/(fcu dtslabav ) = 0.001

Lever arm;

zslabtop = dtslabav min(0.95, 0.5 + (0.25 - Kslabtop/0.9)) = 209.0 mm

Area of steel required for bending;

Asslabtopbend = Me/((1.0/s) fyslab zslabtop) = 22 mm /m

Minimum area of steel required;

Asslabmin = 0.0013 hslab = 325 mm /m

Area of steel required;

Asslabtopreq = max(Asslabtopbend, Asslabmin) = 325 mm /m

PASS - Asslabtopreq <= Asslabtop - Area of reinforcement provided in top to span local depressions is adequate

2

Asslabbtmreq = max(Asslabbtmbend, Asslabmin) = 325 mm /m

PASS - Asslabbtmreq <= Asslabbtm - Area of reinforcement provided in bottom to span local depressions is adequate

Edge beam definition

Page 59 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

Shear check

2

Applied shear stress;

v = V/dtslabmin = 0.033 N/mm

Tension steel ratio;

= 100 Asslabtop/dtslabmin = 0.183

From BS8110-1:1997 - Table 3.8;

Design concrete shear strength;

vc = 0.490 N/mm

Limiting max dispersal to say 6 x beam depth;

ppoint = min(ppointmom, 6 hedge) = 2700 mm

Total dispersal width of point loads;

lpoint = 2 ppoint + bpoint = 5700 mm

Equivalent ultimate udl of edge load 1;

wedgeudl1 = wultedge1/lpoint = 54.4 kN/m

Equivalent unfactored udl of edge load 1;

wedgeudl1sls = wedgeudl1 (wDedge1 + wLedge1)/wultedge1 = 38.2 kN/m

Centroid of longitudinal and equivalent line loads from outside face of raft

PASS - v <= vc - Shear capacity of the slab is adequate

Internal slab deflection check

Basic allowable span to depth ratio;

Ratiobasic = 26.0

Moment factor;

Mfactor = Mc/dbslabav = 0.028 N/mm

Steel service stress;

fs = 2/3 fyslab Asslabbtmbend/Asslabbtm = 11.941 N/mm

Modification factor;

MFslab = min(2.0, 0.55 + [(477N/mm - fs)/(120 (0.9N/mm + Mfactor))])

Load x distance for edge load 1;

Moment1 = wedgeudl1 xedge1 = 24.5 kN

Load x distance for edge load 2;

Moment2 = wultedge2 xedge2 = 25.0 kN

Sum of ultimate longitudl and equivalent line loads; UDL = 220.8 kN/m

2

Sum of load x distances;

Moment = 49.4 kN

Centroid of loads;

xbar = Moment/UDL = 224 mm

Initially assume no moment transferred into slab due to load/reaction eccentricity

MFslab = 2.000

Modified allowable span to depth ratio;

Ratioallow = Ratiobasic MFslab = 52.000

Actual span to depth ratio;

Ratioactual = lslab/ dbslabav = 10.829

Sum of unfactored longitudl and efftive line loads; UDLsls = 155.2 kN/m

PASS - Ratioactual <= Ratioallow - Slab span to depth ratio is adequate

Allowable bearing width;

ballow = 2 xbar + 2 hhcoreslab tan(30) = 448 mm

Bearing pressure due to line/point loads;

qlinepoint = UDLsls/ ballow = 346.7 kN/m

Total applied bearing pressure;

qedge = qlinepoint + wudledge = 360.1 kN/m

Edge beam design checks

qedge > qallow - The slab is required to resist a moment due to eccentricity

Basic loading

Hardcore;

Now assume moment due to load/reaction eccentricity is resisted by slab

whcorethick = hcore hhcorethick = 0.0 kN/m

Edge beam

Bearing width required;

breq = UDLsls/(qallow - wudledge) = 5836 mm

Effective bearing width at u/s of slab;

wbeam = 24 kN/m hedge bedge = 10.8 kN/m

breqeff = breq - 2 hhcoreslab tan(30) = 5836 mm

Rectangular beam element;

Load/reaction eccentricity;

e = breqeff/2 - xbar = 2694 mm

Chamfer element;

wchamfer = 24 kN/m (hedge - hslab) /(2 tan(edge)) = 0.5 kN/m

Ultimate moment to be resisted by slab;

Mecc = UDL e = 594.9 kNm/m

Slab element;

wslabelmt = 24 kN/m hslab (hedge - hslab)/tan(edge) = 1.2 kN/m

From slab bending check

Edge beam self weight;

wedge = wbeam + wchamfer + wslabelmt = 12.5 kN/m

Moment due to depression under slab (hogging);

Me = 2.0 kNm/m

Total moment to be resisted by slab top steel;

Mslabtop = Mecc + Me = 596.9 kNm/m

K factor;

Kslab = Mslabtop/(fcu dtslabmin ) = 0.323

Edge load number 1

Load type;

Point load

Dead load;

wDedge1 = 194.0 kN (From Moment Frame 2 Analysis)

Live load;

wLedge1 = 24.0 kN (From Moment Frame 2 Analysis)

Ultimate load;

wultedge1 = 1.4 wDedge1 + 1.6 wLedge1 = 310.0 kN

Plan dimension parallel to edge of raft;

b1edge1 = 300 mm

Plan dimension perpendicular to edge of raft;

b2edge1 = 300 mm

Centroid of load from outside face of raft;

xedge1 = 450 mm

K > 0.156 - Therefore compression reinforcement is required

The design is outside the scope of this calculation

Hand calculation:

M = 596.9kNm

Slab thickness = 350mm

[Raft analysis software only allows slab depths up to 250mm, actual depth is 350mm]

Top cover = 25mm

Bar = 25mm

d = 350-25-25/2 = 312.5mm

fck = 40N/mm2

Edge load number 2

Load type;

Longitudinal line load

Dead load;

wDedge2 = 103.9 kN/m (From Load Takedown)

Live load;

wLedge2 = 13.2 kN/m(From Load Takedown)

Ultimate load;

wultedge2 = 1.4 wDedge2 + 1.6 wLedge2 = 166.4 kN/m

Longitudinal line load width;

bedge2 = 300 mm

Centroid of load from outside face of raft;

xedge2 = 150 mm

k = 596.9 x106/1000x312.52x40 = 0.153<0.156

z = 312.5x[0.5 + (0.25-0.153/0.9) ] = 245mm

Edge beam bearing pressure check

Effective bearing width of edge beam;

bbearing = bedge + (hedge - hslab)/tan(edge) = 1200 mm

Total uniform load at formation level;

wudledge = wDudl+wLudl+wedge/bbearing+whcorethick = 13.4 kN/m

As reqd = 596.9x106/(0.87x500x245) = 5600mm2

Total dead point load;

wDpoint = 194.0 kN

Use H25 @ 100mm centres and H12 @ 150mm centres locally at Column C1

Total live point load;

wLpoint = 24.0 kN

Total ultimate point load;

wultpoint = 310.0 kN

Min width of point loads parallel to edge of raft;

bpoint = 300 mm

Edge beam bending check

Approx moment capacity of bottom steel;

Medgebtm = (1.0/s) fy 0.9 dedgebtm Asedgebtm = 289.9 kNm

Divider for moments due to udls;

udl = 10.0

Divider for moments due to point loads;

point = 6.0

Longitudinal dispersal of point loads

As prov = 5663mm2

No transverse line loads therefore:Moment in edge beam due to transverse line loads; Mtrans = 0 kNm

Residual moment capacity of beam;

Mresid = Medgebtm - Mtrans = 289.9 kNm

Max allow beam dispersal based on mt cap;

ppointmom=[2 Mresid + (4 Mresid + 2 wultpoint Mresid bpoint)]/wultpoint

Applied bending moments

Span of edge beam;

Ultimate self weight udl;

ppointmom = 3885 mm

Ultimate slab udl (approx);

Page 60 of 70

ledge = depthick + dedgetop = 2398 mm

wedgeult = 1.4 wedge = 17.5 kN/m

wedgeslab = max(0 kN/m,1.4wslab((depthick/23/4)-(bedge+(hedge-hslab)/tan(edge))))

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

wedgeslab = 0.0 kN/m

Self weight and slab bending moment;

Medgesw = (wedgeult + wedgeslab) ledge /udl = 10.0 kNm

Self weight shear force;

Vedgesw = (wedgeult + wedgeslab) ledge/2 = 20.9 kN

Moments due to applied uniformly distributed loads

Ultimate udl (approx);

wedgeudl = wudlult depthick/2 3/4 = 3.4 kN/m

Bending moment;

Medgeudl = wedgeudl ledge /udl = 1.9 kNm

Shear force;

Vedgeudl = wedgeudl ledge/2 = 4.0 kN

Moment and shear due to load number 1

Bending moment;

Medge1 = wultedge1 ledge/point = 123.9 kNm

Shear force;

Vedge1 = wultedge1 = 310.0 kN

Moment and shear due to load number 2

Bending moment;

Medge2 = wultedge2 ledge /udl = 95.7 kNm

Shear force;

Vedge2 = wultedge2 ledge/2 = 199.5 kN

Resultant moments and shears

Total moment (hogging and sagging);

Medge = 231.6 kNm

Maximum shear force;

Vedge = 534.5 kN

Reinforcement required in top

Width of section in compression zone;

Average web width;

K factor;

bedgetop = bedge = 1000 mm

bw = bedge + (hedge/tan(edge))/2 = 1225 mm

2

Kedgetop = Medge/(fcu bedgetop dedgetop ) = 0.037

Lever arm;

zedgetop = dedgetop min(0.95, 0.5 + (0.25 - Kedgetop/0.9)) = 378 mm

Area of steel required for bending;

Asedgetopbend = Medge/((1.0/s) fy zedgetop) = 1409 mm

Minimum area of steel required;

Asedgetopmin = 0.0013 1.0 bw hedge = 717 mm

Area of steel required;

Asedgetopreq = max(Asedgetopbend, Asedgetopmin) = 1409 mm

2

2

PASS - Asedgetopreq <= Asedgetop - Area of reinforcement provided in top of edge beams is adequate

Reinforcement required in bottom

Width of section in compression zone;

bedgebtm = bedge + (hedge - hslab)/tan(edge) + 0.1 ledge = 1440 mm

K factor;

Kedgebtm = Medge/(fcu bedgebtm dedgebtm ) = 0.026

Lever arm;

zedgebtm = dedgebtm min(0.95, 0.5 + (0.25 - Kedgebtm/0.9)) = 373 mm

Area of steel required for bending;

Asedgebtmbend = Medge/((1.0/s) fy zedgebtm) = 1427 mm

Minimum area of steel required;

Asedgebtmmin = 0.0013 1.0 bw hedge = 717 mm

Area of steel required;

Asedgebtmreq = max(Asedgebtmbend, Asedgebtmmin) = 1427 mm

2

2

PASS - Asedgebtmreq <= Asedgebtm - Area of reinforcement provided in bottom of edge beams is adequate

Edge beam shear check

Applied shear stress;

vedge = Vedge/(bw dedgetop) = 1.096 N/mm

Tension steel ratio;

edge = 100 Asedgetop/(bw dedgetop) = 0.387

From BS8110-1:1997 - Table 3.8

Design concrete shear strength;

vcedge = 0.539 N/mm

2

2

vedge > vcedge + 0.4N/mm - Therefore designed links required

Link area to spacing ratio required;

Asv_upon_svreqedge = (vedge - vcedge) bw/((1.0/s) fys) = 1.570 mm

Link area to spacing ratio provided;

Asv_upon_svprovedge = Nedgelinkedgelink /(4svedge) = 3.393 mm

2

PASS - Asv_upon_svreqedge <= Asv_upon_svprovedge - Shear reinforcement provided in edge beams is adequate

Corner design checks

Basic loading

Corner bearing pressure check

Total uniform load at formation level;

wudlcorner = wDudl+wLudl+wedge/bbearing+whcorethick = 13.4 kN/m

PASS - wudlcorner <= qallow - Applied bearing pressure is less than allowable

Page 61 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

RAFT SLAB DESIGN (TYPICAL)

RAFT FOUNDATION DESIGN (BS8110 : PART 1 : 1997)

Tedds calculation version 1.0.09;

Asslabtop

A sedgetop

A sedgelink

hedge

Overall depth;

hedge = 450 mm

Width;

bedge = 1000 mm

Angle of chamfer to horizontal;

edge = 45 deg

Strength of main bar reinforcement;

fy = 500 N/mm

Strength of link reinforcement;

fys = 500 N/mm

Reinforcement provided in top;

6 H20 bars (Asedgetop = 1885 mm )

Reinforcement provided in bottom;

6 H20 bars (Asedgebtm = 1885 mm )

Link reinforcement provided;

3 H12 legs at 100 ctrs (Asv/sv = 3.393 mm)

Bottom cover to links;

cbeam = 35 mm

2

2

2

Effective depth of top reinforcement;

dedgetop = hedge - ctop - slabtop -edgelink - edgetop/2 = 398 mm

hslab

Effective depth of bottom reinforcement;

dedgebtm = hedge - cbeam - edgelink - edgebtm/2 = 393 mm

hhcoreslab

Internal slab design checks

Basic loading

aedge

A sslabbtm

hhcorethick

Slab self weight;

wslab = 24 kN/m hslab = 6.0 kN/m

Hardcore;

whcoreslab = hcore hhcoreslab = 0.0 kN/m

2

2

Applied loading

Asedgebtm

bedge

Uniformly distributed dead load;

Uniformly distributed live load;

wDudl = 1.5 kN/m

wLudl = 1.5 kN/m

Internal slab bearing pressure check

Total uniform load at formation level;

Soil and raft definition

wudl = wslab + whcoreslab + wDudl + wLudl = 9.0 kN/m

PASS - wudl <= qallow - Applied bearing pressure is less than allowable

Soil definition

Internal slab bending and shear check

2

Allowable bearing pressure;

qallow = 40.0 kN/m

Number of types of soil forming sub-soil;

One type only

Soil density;

Firm to loose

Depth of hardcore beneath slab;

hhcoreslab = 0 mm; (Dispersal allowed for bearing pressure check)

Depth of hardcore beneath thickenings;

hhcorethick = 0 mm; (Dispersal allowed for bearing pressure check)

Density of hardcore;

hcore = 20.0 kN/m

Basic assumed diameter of local depression;

Applied bending moments

Span of slab;

lslab = depslab + dtslabav = 2220 mm

Ultimate self weight udl;

wswult = 1.4 wslab = 8.4 kN/m

Self weight moment at centre;

Mcsw = wswult lslab (1 + ) / 64 = 0.8 kNm/m

Self weight moment at edge;

Mesw = wswult lslab / 32 = 1.3 kNm/m

depbasic = 2000mm

Self weight shear force at edge;

Vsw = wswult lslab / 4 = 4.7 kN/m

Diameter under slab modified for hardcore;

depslab = depbasic - hhcoreslab = 2000 mm

Moments due to applied uniformly distributed loads

Diameter under thickenings modified for hardcore;

depthick = depbasic - hhcorethick = 2000 mm

Ultimate applied udl;

wudlult = 1.4 wDudl + 1.6 wLudl = 4.5 kN/m

Moment at centre;

Mcudl = wudlult

Moment at edge;

Meudl = wudlult lslab / 32 = 0.7 kNm/m

Shear force at edge;

Vudl = wudlult lslab / 4 = 2.5 kN/m

Raft slab definition

Max dimension/max dimension between joints;

lmax = 6.200 m

Slab thickness;

hslab = 250 mm

Concrete strength;

fcu = 40 N/mm

Poissons ratio of concrete;

= 0.2

Slab mesh reinforcement strength;

fyslab = 500 N/mm

Partial safety factor for steel reinforcement;

s = 1.15

2

lslab

(1 + ) / 64 = 0.4 kNm/m

Resultant moments and shears

2

From C&CA document Concrete ground floors Table 5

Total moment at edge;

Me = 2.0 kNm/m

Total moment at centre;

Mc = 1.2 kNm/m

Total shear force;

V = 7.2 kN/m

Reinforcement required in top

Minimum mesh required in top for shrinkage;

A142;

Actual mesh provided in top;

A393 (Asslabtop = 393 mm /m)

Mesh provided in bottom;

A393 (Asslabbtm = 393 mm /m)

Top mesh bar diameter;

slabtop = 10 mm

Bottom mesh bar diameter;

slabbtm = 10 mm

Cover to top reinforcement;

ctop = 20 mm

Cover to bottom reinforcement;

cbtm = 35 mm

Average effective depth of top reinforcement;

dtslabav = hslab - ctop - slabtop = 220 mm

Reinforcement required in bottom

Average effective depth of bottom reinforcement;

dbslabav = hslab - cbtm - slabbtm = 205 mm

K factor;

Kslabbtm = Mc/(fcu dbslabav ) = 0.001

Overall average effective depth;

dslabav = (dtslabav + dbslabav)/2 = 213 mm

Lever arm;

zslabbtm = dbslabav min(0.95, 0.5 + (0.25 - Kslabbtm/0.9)) = 194.7 mm

Minimum effective depth of top reinforcement;

dtslabmin = dtslabav - slabtop/2 = 215 mm

Area of steel required for bending;

Asslabbtmbend = Mc/((1.0/s) fyslab zslabbtm) = 14 mm /m

Minimum effective depth of bottom reinforcement;

dbslabmin = dbslabav - slabbtm/2 = 200 mm

Area of steel required;

K factor;

Kslabtop = Me/(fcu dtslabav ) = 0.001

Lever arm;

zslabtop = dtslabav min(0.95, 0.5 + (0.25 - Kslabtop/0.9)) = 209.0 mm

Area of steel required for bending;

Asslabtopbend = Me/((1.0/s) fyslab zslabtop) = 22 mm /m

Minimum area of steel required;

Asslabmin = 0.0013 hslab = 325 mm /m

Area of steel required;

Asslabtopreq = max(Asslabtopbend, Asslabmin) = 325 mm /m

PASS - Asslabtopreq <= Asslabtop - Area of reinforcement provided in top to span local depressions is adequate

2

Asslabbtmreq = max(Asslabbtmbend, Asslabmin) = 325 mm /m

PASS - Asslabbtmreq <= Asslabbtm - Area of reinforcement provided in bottom to span local depressions is adequate

Edge beam definition

Page 62 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

Shear check

2

Applied shear stress;

v = V/dtslabmin = 0.033 N/mm

Tension steel ratio;

= 100 Asslabtop/dtslabmin = 0.183

Total moment to be resisted by slab top steel;

Mslabtop = Mecc + Me = 453.0 kNm/m

K factor;

Kslab = Mslabtop/(fcu dtslabmin ) = 0.245

2

K > 0.156 - Therefore compression reinforcement is required

The design is outside the scope of this calculation

From BS8110-1:1997 - Table 3.8;

Design concrete shear strength;

vc = 0.490 N/mm

Hand calculation:

PASS - v <= vc - Shear capacity of the slab is adequate

M = 453.0kNm

Slab thickness = 350mm

[Raft analysis software only allows slab depths up to 250mm, actual depth is 350mm]

Top cover = 25mm

Bar = 25mm

d = 350-25-25/2 = 312.5mm

fck = 40N/mm2

Internal slab deflection check

Basic allowable span to depth ratio;

Ratiobasic = 26.0

Moment factor;

Mfactor = Mc/dbslabav = 0.028 N/mm

Steel service stress;

fs = 2/3 fyslab Asslabbtmbend/Asslabbtm = 11.941 N/mm

Modification factor;

MFslab = min(2.0, 0.55 + [(477N/mm - fs)/(120 (0.9N/mm + Mfactor))])

2

2

MFslab = 2.000

Modified allowable span to depth ratio;

Ratioallow = Ratiobasic MFslab = 52.000

Actual span to depth ratio;

Ratioactual = lslab/ dbslabav = 10.829

k = 453.0x106/1000x312.52x40 = 0.116<0.156

z = 312.5x[0.5 + (0.25-0.116/0.9) ] = 265mm

PASS - Ratioactual <= Ratioallow - Slab span to depth ratio is adequate

Edge beam design checks

As reqd = 453.0x106/(0.87x500x265) = 3929mm2

Basic loading

Hardcore;

whcorethick = hcore hhcorethick = 0.0 kN/m

Use H25 @ 150mm centres & H12 @ 150mm centres

Edge beam

Rectangular beam element;

wbeam = 24 kN/m hedge bedge = 10.8 kN/m

Chamfer element;

wchamfer = 24 kN/m (hedge - hslab) /(2 tan(edge)) = 0.5 kN/m

Slab element;

wslabelmt = 24 kN/m hslab (hedge - hslab)/tan(edge) = 1.2 kN/m

Edge beam self weight;

wedge = wbeam + wchamfer + wslabelmt = 12.5 kN/m

As prov = 4026mm2

Edge beam bending check

Divider for moments due to udls;

Edge load number 1

udl = 12.0

Load type;

Longitudinal line load

Applied bending moments

Dead load;

wDedge1 = 116.9 kN/m(From Load Takedown)

Span of edge beam;

ledge = depthick + dedgetop = 2398 mm

Live load;

wLedge1 = 16.9 kN/m(From Load Takedown)

Ultimate self weight udl;

wultedge1 = 1.4 wDedge1 + 1.6 wLedge1 = 190.7 kN/m

wedgeult = 1.4 wedge = 17.5 kN/m

Ultimate load;

Ultimate slab udl (approx);

Longitudinal line load width;

bedge1 = 300 mm

Centroid of load from outside face of raft;

xedge1 = 150 mm

wedgeslab = 0.0 kN/m

Edge beam bearing pressure check

Effective bearing width of edge beam;

bbearing = bedge + (hedge - hslab)/tan(edge) = 1200 mm

Total uniform load at formation level;

wudledge = wDudl+wLudl+wedge/bbearing+whcorethick = 13.4 kN/m

Self weight and slab bending moment;

Medgesw = (wedgeult + wedgeslab) ledge /udl = 8.4 kNm

Self weight shear force;

Vedgesw = (wedgeult + wedgeslab) ledge/2 = 20.9 kN

Moments due to applied uniformly distributed loads

Centroid of longitudinal and equivalent line loads from outside face of raft

Load x distance for edge load 1;

wedgeslab = max(0 kN/m,1.4wslab((depthick/23/4)-(bedge+(hedge-hslab)/tan(edge))))

Moment1 = wultedge1 xedge1 = 28.6 kN

Sum of ultimate longitudl and equivalent line loads; UDL = 190.7 kN/m

Ultimate udl (approx);

wedgeudl = wudlult depthick/2 3/4 = 3.4 kN/m

Bending moment;

Medgeudl = wedgeudl ledge /udl = 1.6 kNm

Shear force;

Vedgeudl = wedgeudl ledge/2 = 4.0 kN

Moment and shear due to load number 1

Sum of load x distances;

Moment = 28.6 kN

Bending moment;

Medge1 = wultedge1 ledge /udl = 91.4 kNm

Centroid of loads;

xbar = Moment/UDL = 150 mm

Shear force;

Vedge1 = wultedge1 ledge/2 = 228.6 kN

Initially assume no moment transferred into slab due to load/reaction eccentricity

Resultant moments and shears

Sum of unfactored longitudl and efftive line loads; UDLsls = 133.8 kN/m

Total moment (hogging and sagging);

Medge = 101.4 kNm

Allowable bearing width;

ballow = 2 xbar + 2 hhcoreslab tan(30) = 300 mm

Maximum shear force;

Vedge = 253.6 kN

Bearing pressure due to line/point loads;

qlinepoint = UDLsls/ ballow = 446.0 kN/m

Reinforcement required in top

Total applied bearing pressure;

qedge = qlinepoint + wudledge = 459.4 kN/m

Width of section in compression zone;

qedge > qallow - The slab is required to resist a moment due to eccentricity

Now assume moment due to load/reaction eccentricity is resisted by slab

Average web width;

K factor;

bedgetop = bedge = 1000 mm

bw = bedge + (hedge/tan(edge))/2 = 1225 mm

2

Kedgetop = Medge/(fcu bedgetop dedgetop ) = 0.016

Bearing width required;

breq = UDLsls/(qallow - wudledge) = 5030 mm

Lever arm;

zedgetop = dedgetop min(0.95, 0.5 + (0.25 - Kedgetop/0.9)) = 378 mm

Effective bearing width at u/s of slab;

breqeff = breq - 2 hhcoreslab tan(30) = 5030 mm

Area of steel required for bending;

Asedgetopbend = Medge/((1.0/s) fy zedgetop) = 617 mm

Load/reaction eccentricity;

e = breqeff/2 - xbar = 2365 mm

Minimum area of steel required;

Asedgetopmin = 0.0013 1.0 bw hedge = 717 mm

Ultimate moment to be resisted by slab;

Mecc = UDL e = 451.0 kNm/m

Area of steel required;

Asedgetopreq = max(Asedgetopbend, Asedgetopmin) = 717 mm

2

2

PASS - Asedgetopreq <= Asedgetop - Area of reinforcement provided in top of edge beams is adequate

From slab bending check

Moment due to depression under slab (hogging);

Me = 2.0 kNm/m

Reinforcement required in bottom

Page 63 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

Width of section in compression zone;

bedgebtm = bedge + (hedge - hslab)/tan(edge) + 0.1 ledge = 1440 mm

K factor;

Kedgebtm = Medge/(fcu bedgebtm dedgebtm ) = 0.011

Lever arm;

zedgebtm = dedgebtm min(0.95, 0.5 + (0.25 - Kedgebtm/0.9)) = 373 mm

Area of steel required for bending;

Asedgebtmbend = Medge/((1.0/s) fy zedgebtm) = 625 mm

Minimum area of steel required;

Asedgebtmmin = 0.0013 1.0 bw hedge = 717 mm

Area of steel required;

Asedgebtmreq = max(Asedgebtmbend, Asedgebtmmin) = 717 mm

2

2

PASS - Asedgebtmreq <= Asedgebtm - Area of reinforcement provided in bottom of edge beams is adequate

Edge beam shear check

Applied shear stress;

vedge = Vedge/(bw dedgetop) = 0.520 N/mm

Tension steel ratio;

edge = 100 Asedgetop/(bw dedgetop) = 0.387

From BS8110-1:1997 - Table 3.8

Design concrete shear strength;

vcedge = 0.539 N/mm

2

2

vedge <= vcedge + 0.4N/mm - Therefore minimum links required

Link area to spacing ratio required;

Asv_upon_svreqedge = 0.4N/mm bw/((1.0/s) fys) = 1.127 mm

Link area to spacing ratio provided;

Asv_upon_svprovedge = Nedgelinkedgelink /(4svedge) = 3.393 mm

PASS - Asv_upon_svreqedge <= Asv_upon_svprovedge - Shear reinforcement provided in edge beams is adequate

Page 64 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

PROPPED RETAINING WALL DESIGN

RETAINING WALL ANALYSIS (BS 8002:1994)

450

1700

3150

2700

TEDDS calculation version 1.2.01.06

Wall details

Retaining wall type;

Cantilever

Height of wall stem;

hstem = 2700 mm;

Wall stem thickness;

twall = 200 mm

Length of toe;

ltoe = 1000 mm;

Length of heel;

lheel = 0 mm

Overall length of base;

lbase = 1200 mm;

Base thickness;

tbase = 450 mm

Height of retaining wall;

hwall = 3150 mm

Depth of downstand;

dds = 0 mm;

Thickness of downstand;

tds = 450 mm

Position of downstand;

lds = 750 mm

Depth of cover in front of wall; dcover = 0 mm;

Unplanned excavation depth;

dexc = 0 mm

Height of ground water;

hwater = 1700 mm;

Density of water;

water = 9.81 kN/m

Density of wall construction;

wall = 23.6 kN/m ;

Density of base construction;

base = 23.6 kN/m

Angle of soil surface;

= 0.0 deg;

Effective height at back of wall; heff = 3150 mm

Mobilisation factor;

M = 1.5

Moist density;

m = 18.0 kN/m ;

Saturated density;

s = 21.0 kN/m

Design shear strength;

' = 24.2 deg;

Angle of wall friction;

= 18.6 deg

Design shear strength;

'b = 24.2 deg;

Design base friction;

b = 18.6 deg

Moist density;

mb = 18.0 kN/m ;

Allowable bearing;

Pbearing = 150 kN/m

Active pressure;

Ka =0.369;

Passive pressure;

Kp = 4.187

At-rest pressure;

K0 = 0.590

Using Coulomb theory

Loading details

Page 65 of 70

Surcharge load;

Surcharge = 0.0 kN/m

Vertical dead load;

W dead = 116.9 kN/m;

Vertical live load;

W live = 16.9 kN/m

Horizontal dead load;

Fdead = 0.0 kN/m;

Horizontal live load;

Flive = 0.0 kN/m

Position of vertical load;

lload = 1100 mm;

Height of horizontal load;

hload = 0 mm

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

134

0

Prop

Prop

32.1

9.1

132.7

6.7

16.7

132.7

Loads shown in kN/m, pressures shown in kN/m2

Calculate propping force

Propping force;

Fprop = 0.0 kN/m

Check bearing pressure

Total vertical reaction;

R = 159.3 kN/m;

Eccentricity of reaction;

e = 0 mm

Distance to reaction;

xbar = 600 mm

Reaction acts within middle third of base

Bearing pressure at toe;

ptoe = 132.7 kN/m ;

Bearing pressure at heel;

pheel = 132.7 kN/m

PASS - Maximum bearing pressure is less than allowable bearing pressure

Calculate propping forces to top and base of wall

Propping force to top of wall;

Fprop_top = -5.404 kN/m;

Propping force to base of wall; Fprop_base = 5.404 kN/m

Page 66 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

RETAINING WALL DESIGN (BS 8002:1994)

TEDDS calculation version 1.2.01.06

Ultimate limit state load factors

Dead load factor;

f_d = 1.4;

Earth pressure factor;

f_e = 1.4

f_l = 1.6

Live load factor;

Calculate propping force

Propping force to top of wall;

Fprop_top_f = -7.527 kN/m;

200

Calculate propping forces to top and base of wall

Propping force to base of wall; Fprop_base_f = 15.806 kN/m

164

Fprop = 0.0 kN/m

154

Propping force;

Design of reinforced concrete retaining wall toe (BS 8002:1994)

Material properties

2

Strength of concrete;

fcu = 40 N/mm ;

Strength of reinforcement;

fy = 500 N/mm

k = 0.13 %;

Cover in toe;

ctoe = 40 mm

Base details

Minimum reinforcement;

Design of retaining wall stem

Shear at base of stem;

Vstem = 48.3 kN/m;

Moment at base of stem;

Mstem = 23.4 kNm/m

Compression reinforcement is not required

Reinforcement provided;

12 mm dia.bars @ 150 mm centres

Area required;

As_stem_req = 367.4 mm /m;

404

450

Check wall stem in bending

2

Area provided;

As_stem_prov = 754 mm /m

PASS - Reinforcement provided at the retaining wall stem is adequate

Check shear resistance at wall stem

2

Design shear stress;

vstem = 0.313 N/mm ;

Allowable shear stress;

Concrete shear stress;

vc_stem = 0.740 N/mm

vadm = 5.000 N/mm

PASS - Design shear stress is less than maximum shear stress

2

vstem < vc_stem - No shear reinforcement required

Design of retaining wall at mid height

Moment at mid height;

Mwall = 11.8 kNm/m

Reinforcement provided;

12 mm dia.bars @ 150 mm centres

Area required;

As_wall_req = 260.0 mm /m;

Compression reinforcement is not required

Design of retaining wall toe

Shear at heel;

Vtoe = 173.8 kN/m;

Moment at heel;

Mtoe = 105.1 kNm/m

Compression reinforcement is not required

Area required;

As_wall_prov = 754 mm /m

PASS - Reinforcement provided to the retaining wall at mid height is adequate

Check toe in bending

Reinforcement provided;

Area provided;

Check retaining wall deflection

12 mm dia.bars @ 150 mm centres

2

As_toe_req = 629.7 mm /m;

Max span/depth ratio;

Area provided;

As_toe_prov = 754 mm /m

PASS - Reinforcement provided at the retaining wall toe is adequate

ratiomax = 38.80;

Actual span/depth ratio;

ratioact = 17.53

PASS - Span to depth ratio is acceptable

Check shear resistance at toe

2

Design shear stress;

vtoe = 0.430 N/mm ;

Concrete shear stress;

vc_toe = 0.422 N/mm

Allowable shear stress;

vadm = 5.000 N/mm

PASS - Design shear stress is less than maximum shear stress

2

vtoe > vc_toe - Shear reinforcement required

Design of reinforced concrete retaining wall stem (BS 8002:1994)

Material properties

Strength of concrete;

fcu = 40 N/mm ;

Strength of reinforcement;

fy = 500 N/mm

Cover in wall;

cwall = 30 mm

Wall details

Minimum reinforcement;

k = 0.13 %

Cover in stem;

cstem = 40 mm;

Page 67 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

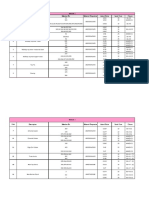

CONTINUOUS BEAM ANALYSIS - RESULTS

Unfactored support reactions

Page 68 of 70

Dead

(kN)

Imposed

(kN)

Support A;

1.7

-1.6

0.0

0.0

0.0

0.0

0.0

0.0

Support B;

-27.0

-6.8

0.0

0.0

0.0

0.0

0.0

0.0

Support C;

-20.4

-2.3

0.0

0.0

0.0

0.0

0.0

0.0

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

Area of outer tension steel provided sufficient to resist sagging

RETAINING WALL DESIGN (TEMPORARY CONDITION)

TRANSVERSE BOTTOM STEEL - INNER

RC SLAB DESIGN (BS8110:PART1:1997)

TEDDS calculation version 1.0.04

Provide 12 dia bars @ 150 centres

2

Asy_prov = Asy = 754 mm /m

CONTINUOUS ONE WAY SPANNING SLAB DEFINITION

;

;;Inner layer of transverse steel;

Overall depth of slab; h = 200 mm

Sagging steel

MAXIMUM DESIGN MOMENTS OVER SUPPORT

Cover to tension reinforcement resisting sagging; c sag = 25 mm

Trial bar diameter; Dtryx = 12 mm

CONCRETE SLAB DESIGN HOGGING OUTER LAYER OF STEEL (CL 3.5.4)

Depth to tension steel (resisting sagging)

dx = h - csag - Dtryx/2 = 169 mm

Hogging steel

Design hogging moment (per m width of slab); m sxhog = 8.1 kNm/m

Design hogging moment (per m width of slab); msxhog = 8.1 kNm/m

Moment Redistribution Factor; bx = 1.0

Area of reinforcement required

Cover to tension reinforcement resisting hogging; c hog = 40 mm

Trial bar diameter; Dtryxhog = 12 mm

;;

Kxhog = abs(msxhog) / ( dxhog fcu ) = 0.009

2

K'x = min (0.156 , (0.402 (bx - 0.4)) - (0.18 (bx - 0.4) )) = 0.156

2

Depth to tension steel (resisting hogging)

Outer compression steel not required to resist hogging

dxhog = h - chog - Dtryxhog/2 = 154 mm

Slab requiring outer tension steel only - bars (hogging)

Materials

;

;

;;

2

Characteristic strength of reinforcement; fy = 500 N/mm

Characteristic strength of concrete; fcu = 40 N/mm

Neutral axis depth; xxhog = (dxhog - zxhog) / 0.45 = 17 mm

Area of tension steel required

;;;

Asyhog

dx

Asy

Nominal 1 m width

Asxhog_req = abs(msxhog) / (1/ms fy zxhog) = 127 mm /m

2

Tension steel

Asxhog

;;Provide 10 dia bars @ 150 centres; outer tension steel resisting hogging

2

Asxhog_prov = Asxhog = 524 mm /m

dxhog

Area of outer tension steel provided sufficient to resist hogging

Asx

Nominal 1 m width

zxhog = min (( 0.95 dxhog),(dxhog(0.5+0.25-Kxhog/0.9)))) = 146 mm

(hogging)

(sagging)

TRANSVERSE TOP STEEL - INNER

One-way spanning slab

;;Inner layer of transverse steel;

(continuous)

Provide 12 dia bars @ 150 centres

ONE WAY SPANNING SLAB (CL 3.5.4)

Asyhog_prov = Asyhog = 754 mm /m

Check min and max areas of steel resisting sagging

2

;Total area of concrete; Ac = h = 200000 mm /m

MAXIMUM DESIGN MOMENTS IN SPAN

;

Design sagging moment (per m width of slab); m sx = 9.6 kNm/m

Minimum % reinforcement; k = 0.13 %

CONCRETE SLAB DESIGN SAGGING OUTER LAYER OF STEEL (CL 3.5.4)

Ast_min = k Ac = 260 mm /m

Design sagging moment (per m width of slab); m sx = 9.6 kNm/m

Ast_max = 4 % Ac = 8000 mm /m

Moment Redistribution Factor; bx = 1.0

Steel defined:

Area of reinforcement required

;;

Kx = abs(msx) / (

2

dx

Outer steel resisting sagging; Asx_prov = 754 mm /m

fcu ) = 0.008

Area of outer steel provided (sagging) OK

K'x = min (0.156 , (0.402 (bx - 0.4)) - (0.18 (bx - 0.4) )) = 0.156

2

Inner steel resisting sagging; Asy_prov = 754 mm /m

Outer compression steel not required to resist sagging

Slab requiring outer tension steel only - bars (sagging)

;;

Area of inner steel provided (sagging) OK

Check min and max areas of steel resisting hogging

2

;Total area of concrete; Ac = h = 200000 mm /m

zx = min (( 0.95 dx),(dx(0.5+0.25-Kx/0.9)))) = 161 mm

Neutral axis depth; xx = (dx - zx) / 0.45 = 19 mm

Area of tension steel required

;;;

Minimum % reinforcement; k = 0.13 %

Ast_min = k Ac = 260 mm /m

2

Asx_req = abs(msx) / (1/ms fy zx) = 138 mm /m

2

Ast_max = 4 % Ac = 8000 mm /m

2

Tension steel

Steel defined:

;;Provide 12 dia bars @ 150 centres; outer tension steel resisting sagging

Asx_prov = Asx = 754 mm /m

Outer steel resisting hogging; Asxhog_prov = 524 mm /m

Area of outer steel provided (hogging) OK

Page 69 of 70

Pringuer-James Consulting Engineers Ltd

L1084 32 Abingdon Villas

;

Inner steel resisting hogging ; Asyhog_prov = 754 mm /m

Area of inner steel provided (hogging) OK

SHEAR RESISTANCE OF CONCRETE SLABS (CL 3.5.5)

Outer tension steel resisting sagging moments

;

Depth to tension steel from compression face; dx = 169 mm

Area of tension reinforcement provided (per m width of slab); A sx_prov = 754 mm /m

Design ultimate shear force (per m width of slab); V x = 33 kN/m

Characteristic strength of concrete; fcu = 40 N/mm

Applied shear stress