A Study On Effects of Silica Fume On Mechanical Properties of Light Weight Coconut Shell Concrete PDF

Diunggah oleh

esatjournalsJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

A Study On Effects of Silica Fume On Mechanical Properties of Light Weight Coconut Shell Concrete PDF

Diunggah oleh

esatjournalsHak Cipta:

Format Tersedia

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

A STUDY ON EFFECTS OF SILICA FUME ON MECHANICAL

PROPERTIES OF LIGHT WEIGHT COCONUT SHELL CONCRETE

Shaik.Aliimran Tippu1, Vr.Prasanth Kumar2

1

Post Graduate Student, SRM University, Kattankulathur, Chennai

2

Faculty, SRM University, Kattankulathur, Chennai

Abstract

The rising value of construction materials in many countries needs to research and implement of different alternative materials in

civil engineering construction .In India, concerning 890 million tonnes of solid wastes are being generated annually as byproducts throughout industrial and agricultural. The Above wastes can be used as aggregate in concrete for the production of

light weight concrete. Amid this study, coconut shell is utilized as light-weight mix in concrete. The undertaking paper goes for

examining split tensile strength and compressive strength characteristics with complete replacement of coarse combination with

coconut shell to supply light-weight concrete and to exchange cement by exploitation silica fume as admixtures with completely

different percentages (0%, 10%, 15%, 20%, 25% and 30%) to urge smart strength like standard concrete. Concrete 63 cubes and

63 cylinders are casted with mix proportion (1:1.47:0.65) and their mechanical properties are determined and compared with

standard concrete. The employment of coconut shells as for standard aggregates ought to be inspired as an environmental

protection and construction value reduction measure.

Keywords: Coconut shell (CS), light weight concrete (LWC), Light Weight Aggregate (LWA), Surface Saturated Dry

(SSD), Normal Weight Concrete (NWC), NC Normal Concrete

--------------------------------------------------------------------***-----------------------------------------------------------------1. INTRODUCTION

Light weight concrete has less self weight of concrete

.Density of LWC concrete varies from 330 kg/m3 to 1850

kg/m3.It has many advantage when compared to normal

concrete, less dead load ,fasten the construction progress of

building ,less handling cost of materials, flexible in design

adaptable in weak soil. Another main characteristic of light

weight concrete is low thermal conductivity which improves

decreasing density. Light weight concrete has become more

popular in recent years owning to tremendous advantages it

offers over conventional concrete. Many research attempts

have been done on light weight concrete and many new

technologies have also helped much in use lightweight

concrete.

The main characteristic of this light-weight mixture is its

high consistency which ends in a very low relative density

makes an attempt are created to use the agriculture wastes

like rice husk ash, palm nut shell and coconut shell saw

mud, ground shell and feather palm shell as building

materials within the past few decades in an exceedingly

analysis study shows that the agriculture waste specifically

feather palm shell used as coarse mixture satisfies the

strength demand of structural lightweight weight concrete.

In India, one among agricultural wastes coconut shell (CS),

is made in abundance and has the potential to be used as

coarse mixture in concrete. Utilization of CS as mixture to

supply LWC could be a comparatively new field of

application. This could be a vital achievement for society in

our attempts towards maintainable improvements.

The bulk density of coconut shell is concerning five hundred

and 600 kg/m that make them light-weight weight. Its been

found that coconut shell concrete simply attains the strength

of quite seventeen MPa that is demand for structural lightweight weight concrete as per ASTM C330. the utilization

of light weight concrete within the industry has gaining

quality within the past few decades. Though there are

several works done on the structural performance of lightweight concrete, these are largely confined to present

aggregates, factory-made aggregates and aggregates from

industrial by product. This experimental study aims to

research the quality of coconut shell as complete

replacement for coarse combination. The objectives and

scope of present study are

a) To relate mechanical properties between control

specimens and coconut shell specimens.

b) To provide economical construction material

2. EXPERIMENTAL PROGRAM

2.1 Materials Descriptions

2.1.1 Cement

The cement used for the present experimental investigation

was ordinary Portland cement of 53 grade, conforming to IS:

122691987. The various characteristics of cement were

tested as per the Indian Standards IS: 4031 1988. Specific

Gravity of the cement was 3.15.

_______________________________________________________________________________________

Volume: 04 Issue: 04 | Apr-2015, Available @ http://www.ijret.org

392

IJRET: International Journal of Research in Engineering and Technology

Table 1 Chemical Analysis for cement

eISSN: 2319-1163 | pISSN: 2321-7308

presented over the shells. The Coconut Shell aggregate were

soaked for 24 hours in water and then taken from water, to

allow dry under room temperature. The aggregate used were

in saturated surface dry (SSD) condition throughout

admixture to stop absorption happening throughout mixing.

The coconut shells are pulverized a mini crusher developed

in the Coconut Shell Concrete Research Center at SRM

University. After crushing the coconut shell, they were

sieved and the aggregate passing 12.5mm sieve size was

used in this investigation.

Composition

Test results

SiO2

21.81

Al2O3

6.90

Fe2O3

3.71

Cao

58.61

Mgo

4.77

K 20

Na20

SO3

0.40

Table 4 Physical Properties of CS Aggregate

Physical Properties

Coconut shell

Specific gravity

2.85

LOI

2.00

Bulk density (Loose) (kg/m)

470

Bulk density (compacted) (kg/m)

Fineness

Bulk age (%)

595

4.00

54

2.1.2 Silica Fume

In this investigation, Silica fume was sourced from Astrra

Chemicals, Chennai, Tamil Nadu was used in this investigation Specific gravity of silica fume was 2.12. Silica fume

commonly used mineral admixtures which replace the

cement by its fineness property. Silica fume is general

passes through 75 microns and which is finer than cement.

Table 2 Chemical Analysis for Silica Fume

Chemical composition

SiO2

94.3

Al2O3

0.09

Fe2O3

0.10

Cao

0.30

Mgo

0.43

K20

0.83

Table 5 Chemical Properties of CS Aggregate

Chemical properties

Coconut Shell

Carbon (C) (%)

49.80

Silica fume (SiO2) (%)

64.20

Alumina (Al2O3) (%)

6.51

Iron (Fe2O3) (%)

6.98

Calcium (CaO) (%)

10.56

Sulphuric Anhydride (SO3)

1.05

(%)

Glucose (%)

0.1

Fructose (%)

0.1

Sucrose (%)

0.1

2.1.3 Fine Aggregate

Characteristic sand according to IS:383-1987 was utilized.

Generally accessible River and having bulk density 1860

kg/m3 was utilized the properties of fine aggregate are

indicated in Table 3

Sl.No

1

2

3

Table 3 Properties of Fine Aggregate

Property

Results

Specific gravity

Fineness

modulus

Grading zone

2.56

2.23

II

Fig 1: Collection of Coconut Shell

2.1.4 Coconut Shells

Large quantity of coconut shells is available in coconut oil

mills. One tone of coconut shells were purchased from

industries of coconut oils mills at Pollachi town .the

collected coconut shells were stacked in the SRM University

campus and well seasoned manually by removing the fibers

_______________________________________________________________________________________

Volume: 04 Issue: 04 | Apr-2015, Available @ http://www.ijret.org

393

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

2.3 Batching and Mixing

For each combine, the specified quantities of the

constituents were batched by weight. Concrete was mixed

during a fifty metric weight unit capability drum sort mixer

within the laboratory. Before staring mixer machine, the

mixer drum was absolutely washed and allowed for couple

of minutes to dry the drum. Coconut shell aggregates were

initial placed and mixed with four-hundredth of the entire

calculated water for one minute. Then the stream sand and

half-hour of water is value-added with coconut shell coarse

mixture. the blending was continued for 2 minutes. Finally

the cement and also the remaining water were value-added

and intermixture continued till the contemporary concrete

becomes homogeneous.

2.4 Casting and Curing

All the specimens were cast in steel moulds. During

collection of the mould to be used, the joints between the

sections of mould were thinly coated with crude oil was

applied between the contact surfaces of rock bottom of the

mould and therefore the base plates as to confirm that no

water escapes throughout filling of concrete

Fig 2: Coconut Shell Drying

2.1.5 Water

Portable tap water has been used for the concrete

preparation and curing of specimen Water is an imperative

element of cement as it effectively takes an interest in

synthetic response with cement. Water conforming IS 4562000 was used, the water used in the preparation of motor

should not necessary be distilled water, but must be free of

all acids, bases and other distilled salts.

2.2 Mix Proportion

Mix design which are applied for conventional concrete

cannot be used for light weight concrete due to deficiency of

water absorption of aggregate ,specific gravity of aggregate

and moisture content.mix design are generally obtained from

trail mixes.

Table 6 Mix Proportion

MIX

Replacement % of Silica

Fume

Mix 1

OPC 100%

Mix 2

OPC 90%+S.F 10%

Mix 3

OPC 85%+S.F 15%

Mix 4

OPC 80%+S.F 20%

Mix 5

OPC 75%+S.F 25%

Mix 6

OPC 70%+S.F 30%

Test samples were made when practicable in the wake of

mixing, thus as to convey full compaction of the concrete

with neither detachment nor unnecessary laitance.

Compaction was done by technique for an electric vibrating

table .after top layer has been compacted; the surface of the

concrete was done level with top of the mould using a

trowel. They were de-moulded after 24 hours and cured in

water at the room temperature of 25

2.5 Test Programme

The cubes of 100100100 mm size and cylinders of 100

mm dia200 mm diameter were tested for Compression and

Split Tensile. Tests were done as per following codes of

Bureau of Indian Standards. The test for Compressive

Strength and split strength on cubes were measured at 7,

14and 28 days of curing as per IS: 516-1959.

3. RESULTS AND DISCUSSIONS

3.1 Compressive Strength

The results of compressive strength were conferred in table

no 7. The test was carried out conforming to IS 516-1959 to

get compressive strength at the age of seven, fourteen and

twenty eight days. The cubes were tested exploitation

Compression Testing (CTM) of capability 1500 kN. it had

been found that the 28-day compressive strength of concrete

varied within the vary of twenty.17 N/mm2 to twenty

four.13 N/mm2. The most compressive strength is optimised

at 25 % replacement of silicon dioxide fume with cement.

it's terminated that the concrete strength depends on the

strength, stiffness and density of coarse aggregates. The

compressive strength obtained for the cement content 510

kg/m3 at seventh day, fourteenth day and twenty eighth day

of the coconut shell concrete is suitable to be employed in

the assembly of non-load support panels it needs the

_______________________________________________________________________________________

Volume: 04 Issue: 04 | Apr-2015, Available @ http://www.ijret.org

394

IJRET: International Journal of Research in Engineering and Technology

30

25

20

15

7th day

10

14th day

28th day

The results of split tensile strength were presented in table 8.

The optimum silica fume replacement 25% percentages for

tensile strengths have been found to be a function of W/c

ratio of the mix.

Table 8 Average Split tensile strength for Coconut Shell

Concrete (N/mm)

Replacement Age of Curing

MIX

% of Silica 7th

14th

28th

Fume

day

day

day

1.223

1.797

2.587

NC

0%

0.819

1.91

2.095

Mix 1

0%

0.946

1.297

2.256

Mix 2

10%

1.053

1.467

2.371

Mix 3

15%

1.095

1.191

2.393

Mix 4

20%

1.117

1.138

2.488

Mix 5

25%

Mix 6

0.787

1.063

2.180

30%

0

NC

MIX 1

MIX 2

MIX 3

MIX 4

MIX 5

MIX 6

Avg. compressive strength

N/mm2

Table 7 Average Compressive Strength for Coconut Shell

Concrete (N/mm)

Replacement Age of Curing

MIX

% of Silica

14th

28th

7th day

Fume

day

day

14.83

19.77

22.21

NC

0%

11.61

16.52

20.17

Mix 1

0%

13.07

17.16

22.12

Mix 2

10%

14.79

19.91

23.12

Mix 3

15%

16.91

20.86

23.63

Mix 4

20%

17.64

21.45

24.13

Mix 5

25%

12.45

18.14

21.31

Mix 6

30%

3.2 Split Tensile Strength

Avg.Split tensile strength N/mm2

strength of 3.45 N/mm2 at 28-day , ASTM C129-85. From

the results, coconut shell combination shows some promise

to be used in building construction. Within the perspective

of this, coconut shell have to be compelled to be thought of

as coarse total within the creation of light weight concrete

for the auxiliary and non basic elements. It should, in any

case, be seen that any analysis have to be compelled to be

done before it may be used as building materials.

MIX PROPORTIONS

eISSN: 2319-1163 | pISSN: 2321-7308

3

2.5

2

1.5

7th Day

14th Day

0.5

28th Day

0

NC Mix Mix Mix Mix Mix Mix

1 2 3 4 5 6

Mix proportions

Fig 5: Split Tensile Strength graph for Coconut shell

concrete

Fig 3: Compressive Strength Graph for Coconut shell

concrete

Fig 4 Tested CSC Cube

Fig 6: Tested CSC Cylinder

_______________________________________________________________________________________

Volume: 04 Issue: 04 | Apr-2015, Available @ http://www.ijret.org

395

IJRET: International Journal of Research in Engineering and Technology

4. CONCLUSION

This study presents the effective way of utilizing crushed

coconut shell aggregate in concrete. Presently, coconut shell

is available at low price in most tropical countries. Also the

concrete obtained using coconut shell aggregates satisfy the

minimum requirements of light weight concrete. Hence it is

possible to made light weight concrete making use of

coconut shells as an aggregate in concrete.

Based on the investigation, the following conclusions were

made

It was observed that the compressive strength of the

light weight concrete using coconut shell aggregate

increases with increasing age, but compressive

strength decrease at 30% replacement of silica

fume with cement.

It was observed that split tensile strength decreases

at, 30% of replacement of Silica Fume with cement

The compressive strength for Coconut Shell

Concrete with replacement of 25% silica fume at

7th, 14th and 28th day varies in the range of 17.64,

21.45 and 24.13N/mm2 respectively.

The Split Tensile strength for Coconut Shell

Concrete with replacement of 25% silica fume at

7th, 14th and 28th day varies in the range of

1.117,1.138 and2.488 N/mm2 respectively.

The maximum compressive strength and split

tensile strength is observed at 25% replacement of

silica fume with cement.

The light weight concrete design mix partial

replacement with 25% of silica fume with cement

has achieved compressive strength 24.13 N/mm2 at

28th day age with 98 % compared to that of Normal

concrete with several advantages over Normal

concrete.

The optimum 28th day split tensile strength and

compressive strength has been obtained in the

range of 20-25% silica fume replacement level.

eISSN: 2319-1163 | pISSN: 2321-7308

[5]. J. Olumuyiwa Agunsoye, Talabi S. Isaac, Sanni O.

Samuel Department of Metallurgical and Materials

Engineering, University of Lagos, Lagos, Nigeria August

2012 study of mechanical behaviour of coconut shell

reinforced polymer matrix composite

[6]. Vishwas P. Kukarni, Sanjay kumar B. Gaikwad

Volume 2, Issue 12, June 2013 Comparative Study on

Coconut Shell Aggregate with Conventional Concrete.

BIOGRAPHY

Shaik.Aliimran Tippu, Post Graduate

Student, SRM University, Kattankulathur,

chennai

REFERENCES

[1]. Abdulfatah Abubakar and Muhammed Saleh Abubakar

Department of Civil Engineering Kaduna Polytechnic,

Kaduna Volume 3, December 2011 on exploratory study of

coconut shell as coarse aggregate in concrete.

[2]. Akshay S. Shelke, Kalyani R. Ninghot, Pooja P.

Kunjekar, Shraddha P. Gaikwad Civil Engineering

Department, Prof. Ram Meghe College of Engineering and

Management, Amravati, Maharashtra, India. Volume 5,

Number 3 (2014) Coconut Shell as partial replacement for

coarse aggregate.

[3]. Amarnath Yerramala, Ramachandrudu Structures and

Materials laboratory Department of Civil Engineering, Intell

Engineering College, Anantapur, India Volume 1, Issue 6

(October2012) Properties of Concrete with Coconut Shells

as Aggregate Replacement.

[4]. Daniel Yaw Osei Department of Civil Engineering Cape

Coast Polytechnic, Cape Coast, Ghana. Volume 2 Issue 5

May. 2013 experimental assessment on coconut shells as

aggregate in concrete.

_______________________________________________________________________________________

Volume: 04 Issue: 04 | Apr-2015, Available @ http://www.ijret.org

396

Anda mungkin juga menyukai

- PTE 3 Week Study ScheduleDokumen3 halamanPTE 3 Week Study ScheduleesatjournalsBelum ada peringkat

- Analysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFDokumen7 halamanAnalysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFesatjournalsBelum ada peringkat

- Analysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFDokumen4 halamanAnalysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFesatjournalsBelum ada peringkat

- Analysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFDokumen6 halamanAnalysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFesatjournalsBelum ada peringkat

- Analysis of Cylindrical Shell Structure With Varying Parameters PDFDokumen6 halamanAnalysis of Cylindrical Shell Structure With Varying Parameters PDFesatjournalsBelum ada peringkat

- A Servey On Wireless Mesh Networking ModuleDokumen5 halamanA Servey On Wireless Mesh Networking ModuleesatjournalsBelum ada peringkat

- A Review Paper On Smart Health Care System Using Internet of ThingsDokumen5 halamanA Review Paper On Smart Health Care System Using Internet of ThingsesatjournalsBelum ada peringkat

- A Survey On Identification of Ranking Fraud For Mobile ApplicationsDokumen6 halamanA Survey On Identification of Ranking Fraud For Mobile ApplicationsesatjournalsBelum ada peringkat

- A Review On Fake Biometric Detection System For Various ApplicationsDokumen4 halamanA Review On Fake Biometric Detection System For Various ApplicationsesatjournalsBelum ada peringkat

- A Study and Survey On Various Progressive Duplicate Detection MechanismsDokumen3 halamanA Study and Survey On Various Progressive Duplicate Detection MechanismsesatjournalsBelum ada peringkat

- A Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesDokumen9 halamanA Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesesatjournalsBelum ada peringkat

- A Women Secure Mobile App For Emergency Usage (Go Safe App)Dokumen3 halamanA Women Secure Mobile App For Emergency Usage (Go Safe App)esatjournalsBelum ada peringkat

- A Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemDokumen8 halamanA Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemesatjournalsBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Materials and Design: P.F. Liu, J.Y. Zheng, B.J. Zhang, P. ShiDokumen8 halamanMaterials and Design: P.F. Liu, J.Y. Zheng, B.J. Zhang, P. Shi123habib123fikriBelum ada peringkat

- (Doi 10.1115 - gt2012-69103) Swaminathan, V. P. (Swami) Dean, Gil J. Scheibel, John R. - (ASME ASME Turbo Expo 2012 - Turbine Technical Conference and Exposition - Copenhagen, Denmark (Monday 11 JunDokumen11 halaman(Doi 10.1115 - gt2012-69103) Swaminathan, V. P. (Swami) Dean, Gil J. Scheibel, John R. - (ASME ASME Turbo Expo 2012 - Turbine Technical Conference and Exposition - Copenhagen, Denmark (Monday 11 JunpeymanBelum ada peringkat

- Chen, W. F. - Lui, E. M - Stability Design of Steel Frames-CRC Press (1991)Dokumen395 halamanChen, W. F. - Lui, E. M - Stability Design of Steel Frames-CRC Press (1991)fahmi aballiBelum ada peringkat

- ETA Bonded Fasteners For Use in ConcreteDokumen59 halamanETA Bonded Fasteners For Use in ConcreteJianhua WuBelum ada peringkat

- RTR PDFDokumen5 halamanRTR PDFMoacyr Salles Neto100% (1)

- Lanturi GallDokumen88 halamanLanturi GallNicoleta IacobBelum ada peringkat

- Beam Analysis With CATIA V5Dokumen7 halamanBeam Analysis With CATIA V5beanjoeBelum ada peringkat

- En 12004 2001 Adhessives For Tiles Definitions and Specifica PDFDokumen26 halamanEn 12004 2001 Adhessives For Tiles Definitions and Specifica PDFthietbimoitruongBelum ada peringkat

- JTOSRDadvertisement 04082010Dokumen24 halamanJTOSRDadvertisement 04082010rvjcdl460Belum ada peringkat

- Reliability-Based Design of RC Water Tank Structures Under Seismic ActionDokumen14 halamanReliability-Based Design of RC Water Tank Structures Under Seismic ActionRAKSHITH NBelum ada peringkat

- Structural Analysis of Multi Storey Steel FramesDokumen17 halamanStructural Analysis of Multi Storey Steel FramesAlem LoajnerBelum ada peringkat

- TSwift CometDokumen63 halamanTSwift CometRoberto LopezBelum ada peringkat

- Vancouver Geotechnical Society: Critical State Soil Mechanics: NotesDokumen57 halamanVancouver Geotechnical Society: Critical State Soil Mechanics: Notesa4abhirawatBelum ada peringkat

- Material Allowables Material AllowablesDokumen35 halamanMaterial Allowables Material AllowablesElzainie ShehabBelum ada peringkat

- SDI-C-2011 Standard For Composite Steel Floor Deck-SlabsDokumen36 halamanSDI-C-2011 Standard For Composite Steel Floor Deck-SlabsDiego Torres100% (1)

- 15ME745 Smart Materials Module 3Dokumen18 halaman15ME745 Smart Materials Module 3Yogananda Bangalore ShanthamurthyBelum ada peringkat

- Astm C 1609 - 2019Dokumen9 halamanAstm C 1609 - 2019김기준100% (1)

- CpedDokumen6 halamanCpedJeanne Roselle Dulatre CortezBelum ada peringkat

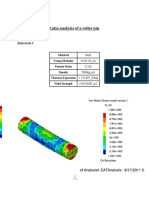

- Catia Analysis of A Roller PinDokumen15 halamanCatia Analysis of A Roller Pinanteneh tesfayeBelum ada peringkat

- Chapter 2 Outline: NSCP Strength and Serviceability RequirementsDokumen7 halamanChapter 2 Outline: NSCP Strength and Serviceability RequirementsYo FangirlsBelum ada peringkat

- The Effect of Zirconia Sintering Temperature On Flexural Strength, Grain Size, and Contrast RatioDokumen6 halamanThe Effect of Zirconia Sintering Temperature On Flexural Strength, Grain Size, and Contrast RatioFrontiersBelum ada peringkat

- Contact Stress Analysis For A Pair of Mating GearsDokumen10 halamanContact Stress Analysis For A Pair of Mating Gearsanmol6237Belum ada peringkat

- Nimonic Alloy 80ADokumen24 halamanNimonic Alloy 80AdharmatejakademBelum ada peringkat

- Design Methods: Types of BeamsDokumen9 halamanDesign Methods: Types of BeamsSyazaa SalimBelum ada peringkat

- نسخة من 224.2R-92 Cracking of Concrete Members in Direct TensionDokumen12 halamanنسخة من 224.2R-92 Cracking of Concrete Members in Direct TensionwalidkcBelum ada peringkat

- Strength of Materialspretest Assignment1Dokumen2 halamanStrength of Materialspretest Assignment1Nellai VprBelum ada peringkat

- ASTM A615M - 16 - Standard Specification For Deformed and Plain Carbon-Steel Bars For Concrete ReinforcementDokumen8 halamanASTM A615M - 16 - Standard Specification For Deformed and Plain Carbon-Steel Bars For Concrete ReinforcementLuis QuispeBelum ada peringkat

- Finglow N7Dokumen2 halamanFinglow N7RobinReyndersBelum ada peringkat

- Jetting ConductorsDokumen10 halamanJetting Conductorszerocool2kBelum ada peringkat

- Structural Design of Reinforced Concrete U Shaped Channels Basins and Drop Structures PDFDokumen39 halamanStructural Design of Reinforced Concrete U Shaped Channels Basins and Drop Structures PDFuntel untelBelum ada peringkat