Tracing Steam For Vessel

Diunggah oleh

Jonathan Arboleda GenesJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

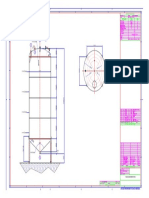

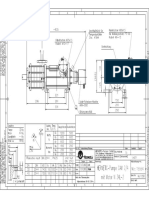

Tracing Steam For Vessel

Diunggah oleh

Jonathan Arboleda GenesHak Cipta:

Format Tersedia

PRODUCT / APPLICATION INFORMATION

HeetSheet Tank & Vessel

Heating Unit Characteristics

How are HeetSheet units constructed?

HeetSheet units are plate-type heating units made of

two sheets of 20 or 26 gauge 304 stainless steel conforming to ASTM-A240. The sheets are seam-welded to

define the fluid holding portion. Interrupted seam welds

are arranged to provide a variety of parallel passageways

for steam or other heat transfer fluids to pass through

the HeetSheet unit.

HeetSheet units internal volumes are below the ASME

limits 5 ft3 at 250# (0.14m3 at 1720 kPa) that would

require certification. So, HeetSheet units

can withstand relatively high pressures

and temperatures, but still be lightweight

and pliable.

How do HeetSheet units work?

HeetSheet units may be installed on flat or

curved surfaces. Each unit is designed for

a specific tank and includes tubing inlet

and outlet connections. The 26 gauge

units also include a special non-hardening

heat transfer compound applied to the

surface that will contact the tank wall. This

eliminates all air pockets and creates an uninterrupted

path for the heat through the tank wall, and into the

product being heated within the vessel.

What is the efficiency of HeetSheet units?

Heat is transferred to the tank wall at a rate of 114 to

227 W/m2-K (20 to 40 Btu/hr-F-ft2) For comparison,

typical externally installed plate-type tank heating coils

deliver heat at a rate of approximately 17 to 28 w/

m2-K. For this reason, 2 to 3 times more surface area

can be required for conventional external plate-typeheating coils to maintain the same temperatures with

HeetSheet units.

By comparison, two workers can easily install a HeetSheet unit of the largest 20 gauge size. Then, simplified

banding methods and lesser coverage combines to

permit the installation of HeetSheet units in minutes

compared to hours for other methods.

Where are HeetSheet units typically installed?

HeetSheet units can be an economical heating or cooling method on most process plant tanks and vessels.

They may be used in a wide variety of applications

where other types of internal or external

plate heating coils are typically used.

Common applications include temperature maintenance for: caustic soda,

phthalic anhydride, soap, paraffin, syrup,

sulfur, asphalt and heavy ends materials, naphthalene, malaic anhydride and

many food products.

What are the ratings

for HeetSheet units?

HeetSheet units are rated for use with

10.34 bar g (150 psig) steam pressure

at temperatures of 186C (366F) when used with NH

(Non-hardening) heat transfer compound. Higher pressures with correspondingly higher temperatures may be

designed if the NH material is not employed. Product

temperatures to 177C (350F) can be maintained in

tanks, vats, or other types of vessels.

What are the sizes for HeetSheet units?

HeetSheet units are available in standard external dimensions of 0.61 m (2 ft) in width and lengths of 0.61

m (2 ft); 1.22 m (4 ft); and 2.44 m (8 ft). Special lengths

of 0.91 m (3 ft) and 1.83 m (6 ft) are available upon

request, as are special widths of 0.3 m (1 ft).

How can HeetSheet units be safer?

HeetSheet units are applied to the external wall of a

tank; therefore, no danger of cross-contamination

between the process fluid and the steam exists. Crosscontamination is a concern with internal steam heating

coils and jacketed tanks and vessels.

Why are HeetSheet units more economical?

The fast and simple installation of HeetSheet units

makes them more economical. Each 26 gauge unit

weighs only about 9.8 kg/m2 (2 lb/ft2) compared to

almost 40 kg/m2 (8 lb/ft2) for a typical external platetype-heating coil. Heavy coils often require lifting equipment for handling, with difficult mounting techniques

resulting in higher labor cost.

Unit

THERMON . . . The Heat Tracing Specialists

www.thermon.com

Form PAF0035-1008 Thermon Manufacturing Co. Subject to change without prior notice.

Anda mungkin juga menyukai

- Npsa in Pumps Ansi Hi 9 6-3-1997Dokumen18 halamanNpsa in Pumps Ansi Hi 9 6-3-1997Luis Garrido Marín100% (4)

- Kitchen Ventilation Systeme Design Green Heck)Dokumen56 halamanKitchen Ventilation Systeme Design Green Heck)sbragdon0% (1)

- EDTA 40 Solution-SDS PDFDokumen8 halamanEDTA 40 Solution-SDS PDFRopy Rachmat AjiBelum ada peringkat

- EDTA 40 Solution-SDS PDFDokumen8 halamanEDTA 40 Solution-SDS PDFRopy Rachmat AjiBelum ada peringkat

- TCV 40 m3 Grow Chemical Group-Modelo PDFDokumen1 halamanTCV 40 m3 Grow Chemical Group-Modelo PDFJonathan Arboleda GenesBelum ada peringkat

- HVAC - Demand Control VentilationDokumen60 halamanHVAC - Demand Control VentilationEnis IvkovićBelum ada peringkat

- Fibreglass Tank PDFDokumen56 halamanFibreglass Tank PDFdadan yupi andika100% (1)

- Ansys Fluent 18 Tutorial Guide PDFDokumen1.052 halamanAnsys Fluent 18 Tutorial Guide PDFaliafsin100% (1)

- 1 Articulo Recycling of Electric Arc Furnace (EAF) Dust For Use PDFDokumen6 halaman1 Articulo Recycling of Electric Arc Furnace (EAF) Dust For Use PDFJonathan Arboleda GenesBelum ada peringkat

- Catalogo Filtros EspecialesDokumen88 halamanCatalogo Filtros EspecialesJonathan Arboleda GenesBelum ada peringkat

- Fume Exhaust Duct Catalog 10 12 8 PDFDokumen86 halamanFume Exhaust Duct Catalog 10 12 8 PDFJonathan Arboleda GenesBelum ada peringkat

- Chemical and Physical Properties of Refined Petroleum ProductsDokumen36 halamanChemical and Physical Properties of Refined Petroleum Productskanakarao1Belum ada peringkat

- 1 Articulo Analisis Termodinamico Horno de Fundicion de Arco PDFDokumen16 halaman1 Articulo Analisis Termodinamico Horno de Fundicion de Arco PDFJonathan Arboleda GenesBelum ada peringkat

- All Ny Ls Ump San Series ElementsDokumen1 halamanAll Ny Ls Ump San Series ElementsJonathan Arboleda GenesBelum ada peringkat

- Filtros VariosDokumen40 halamanFiltros VariosAbraham2211Belum ada peringkat

- Manual de CloroDokumen61 halamanManual de CloroJonathan Arboleda GenesBelum ada peringkat

- Chlorine Safety Scrubbing SystemsDokumen47 halamanChlorine Safety Scrubbing SystemsMaswady Bin Maskin100% (1)

- P1628 Informacion Filtro Combustible Diesel A Los Quemadores PreferredDokumen2 halamanP1628 Informacion Filtro Combustible Diesel A Los Quemadores PreferredJonathan Arboleda GenesBelum ada peringkat

- Chemical and Physical Properties of Refined Petroleum ProductsDokumen36 halamanChemical and Physical Properties of Refined Petroleum Productskanakarao1Belum ada peringkat

- Cavs-T-S-Pc1-0001 Rev D Jonathan Arboleda Genes CPVCDokumen56 halamanCavs-T-S-Pc1-0001 Rev D Jonathan Arboleda Genes CPVCJonathan Arboleda GenesBelum ada peringkat

- P1628 Catalogo Set Filtracion CombustiblesDokumen3 halamanP1628 Catalogo Set Filtracion CombustiblesJonathan Arboleda GenesBelum ada peringkat

- P1628 Brochure Quemadores PreferredDokumen4 halamanP1628 Brochure Quemadores PreferredJonathan Arboleda GenesBelum ada peringkat

- Chemical and Physical Properties of Refined Petroleum ProductsDokumen36 halamanChemical and Physical Properties of Refined Petroleum Productskanakarao1Belum ada peringkat

- Sample Dimensional With Bearing Wear Monitor (Old)Dokumen1 halamanSample Dimensional With Bearing Wear Monitor (Old)Jonathan Arboleda GenesBelum ada peringkat

- WEB Fuel Oil No. 2Dokumen3 halamanWEB Fuel Oil No. 2Jonathan Arboleda GenesBelum ada peringkat

- WEB Fuel Oil No. 2Dokumen3 halamanWEB Fuel Oil No. 2Jonathan Arboleda GenesBelum ada peringkat

- 1 Caso de Estudio para Proteccion CI Del Bagaso PDFDokumen4 halaman1 Caso de Estudio para Proteccion CI Del Bagaso PDFJonathan Arboleda GenesBelum ada peringkat

- Handbook of Chemical Process Hazardous Material. (Object XMLDocument)Dokumen93 halamanHandbook of Chemical Process Hazardous Material. (Object XMLDocument)amo100% (1)

- 2 Storage of Sugar Cane BagasseDokumen29 halaman2 Storage of Sugar Cane BagasseJonathan Arboleda GenesBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Grade 8 Mathematics Checkpoint Booklet AY 23-24Dokumen270 halamanGrade 8 Mathematics Checkpoint Booklet AY 23-24Arta riaBelum ada peringkat

- Digital ThermometerDokumen12 halamanDigital Thermometershahpatel19Belum ada peringkat

- Simple Love Spells That WorkDokumen14 halamanSimple Love Spells That Workagg24ankitBelum ada peringkat

- WHITE TOWN GROUP-4 FinalDokumen112 halamanWHITE TOWN GROUP-4 Finalaswath manojBelum ada peringkat

- No Experience ResumeDokumen2 halamanNo Experience ResumeNatalia PantojaBelum ada peringkat

- Day 1 Training Material FlowDokumen200 halamanDay 1 Training Material FlowGhazouani AymenBelum ada peringkat

- Review Systems of Linear Equations All MethodsDokumen4 halamanReview Systems of Linear Equations All Methodsapi-265647260Belum ada peringkat

- Hazop Close Out ReportDokumen6 halamanHazop Close Out ReportKailash PandeyBelum ada peringkat

- Advancement of SGDokumen2 halamanAdvancement of SGkailasasundaramBelum ada peringkat

- Loan Agreement: Acceleration ClauseDokumen2 halamanLoan Agreement: Acceleration ClauseSomething SuspiciousBelum ada peringkat

- PROP CASES OUTLINE 7 - Right of Way - Light & ViewDokumen108 halamanPROP CASES OUTLINE 7 - Right of Way - Light & ViewKringle Lim - DansalBelum ada peringkat

- Advanced Packaging Polymers: Product Selection GuideDokumen12 halamanAdvanced Packaging Polymers: Product Selection GuideDKBelum ada peringkat

- AMX Prodigy Install ManualDokumen13 halamanAMX Prodigy Install Manualsundevil2010usa4605Belum ada peringkat

- QLD Plan Draft Review Raw DataDokumen242 halamanQLD Plan Draft Review Raw DataRohit Jain100% (1)

- Hybrid Neural-Network - Genetic Algorithm Technique For Aircraft Engine Performance Diagnostics Developed and DemonstratedDokumen4 halamanHybrid Neural-Network - Genetic Algorithm Technique For Aircraft Engine Performance Diagnostics Developed and Demonstratedmohamad theibechBelum ada peringkat

- (AVA Academia) Lorraine Farrelly - The Fundamentals of architecture-AVA Academia (2012) - Trang-137-161Dokumen25 halaman(AVA Academia) Lorraine Farrelly - The Fundamentals of architecture-AVA Academia (2012) - Trang-137-161Thảo VyBelum ada peringkat

- Movie Review of THORDokumen8 halamanMovie Review of THORSiva LetchumiBelum ada peringkat

- Calculate Breakeven Point in Units and Revenue Dollars: Intermediate Cost Analysis and ManagementDokumen52 halamanCalculate Breakeven Point in Units and Revenue Dollars: Intermediate Cost Analysis and ManagementNavice Kie100% (1)

- JHS Integrated Science Preamble, Jan 2012 - FinalDokumen15 halamanJHS Integrated Science Preamble, Jan 2012 - Finalfrank adamsBelum ada peringkat

- Norma Geral Astm Bronze Alumínio - b150b150m.19198Dokumen7 halamanNorma Geral Astm Bronze Alumínio - b150b150m.19198EduardoBelum ada peringkat

- About TableauDokumen22 halamanAbout TableauTarun Sharma67% (3)

- Maryam Ejaz Sec-A Marketing Assignment (CHP #15)Dokumen3 halamanMaryam Ejaz Sec-A Marketing Assignment (CHP #15)MaryamBelum ada peringkat

- Esp Kelompok 2Dokumen19 halamanEsp Kelompok 2Taufiq DiBelum ada peringkat

- Grange Fencing Garden Products Brochure PDFDokumen44 halamanGrange Fencing Garden Products Brochure PDFDan Joleys100% (1)

- EPA NCP Technical Notebook PDFDokumen191 halamanEPA NCP Technical Notebook PDFlavrikBelum ada peringkat

- E Commerce and Its Influence in Changing in Purchasing Behavior of Modern ConsumersDokumen13 halamanE Commerce and Its Influence in Changing in Purchasing Behavior of Modern ConsumersRichard VillanuevaBelum ada peringkat

- Machine DesignDokumen627 halamanMachine DesignlucarBelum ada peringkat

- Construction of Perimeter Fence of BFP NHQ PDFDokumen133 halamanConstruction of Perimeter Fence of BFP NHQ PDFYalla ChaitanyaBelum ada peringkat

- H I Ôn Thi Aptis & Vstep - Tài Liệu - Anna MaiDokumen4 halamanH I Ôn Thi Aptis & Vstep - Tài Liệu - Anna Maihanh.mt2022Belum ada peringkat

- Why Do Kashmiris Need Self-Determination?: UncategorizedDokumen16 halamanWhy Do Kashmiris Need Self-Determination?: UncategorizedFarooq SiddiqiBelum ada peringkat