22 - Outlet Works Through Dams and River Intakes

Diunggah oleh

DeroHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

22 - Outlet Works Through Dams and River Intakes

Diunggah oleh

DeroHak Cipta:

Format Tersedia

_22

Outlet Works Through Dams and River Intakes

22.1. Sluicesways or Dam Outlets

The most of the water which is stored in a reservoir for irrigation, water supply or

power generation purposes, is stored below the spillway crest level: The spillway is

provided at normal pool level, such that the floods are discharged safely above the

spillway. But, in order to draw water from the reservoir as and when needed, for

irrigation, water supply, navigation or power purposes, it is absolutely necessary that

outlet works are provided either through the body of the dam or adjacent to it through

some hill side at one end of the dam. This water may be discharged into the downstream

channel below the dam or may be transported at distances where required (to some

power house, etc.) through pipes or canals. The opening, i.e. a pipe or a tunnel provided

for this withdrawal of water is known as a dam outlet or a sluiceway.

The outlets of most of the dams consist of one or more sluiceways with their inlets

at about minimum pool level. In most of the cases, a number of outlets are generally

provided at different levels ; as a single large capacity outlet may be structurally

unsatisfactory or difficult to construct. Moreover, by having more number of smaller

capacity outlets, greater control on discharge can be obtained, which can be varied as

and when desired. Hence, when wider fluctuations in the demand are anticipated, it is

always, advisable to go in for more number of small capacity sluiceways, although it

may prove to be somewhat costlier as compared to a few large capacity sluiceways.

___A sluiceway is a pipe or_a tunATE

nel, circular or rectangular in section, that passes through the body of __ _ _

the dam or through some hillside at

one end. of the dam ancLdischarges

into the stream below. For masonry

or concrete gravity dams, these

sluiceways can easily pass through

the body of the dam or the spillway

(Fig. 22.1) ; but for earthen dams, it

is preferred to place them outside

the limits of the embankments. But,

if no such adjacent hill site is avail_able arid there is no alternative left

but to pass the sluiceway through

the dam, projecting collars must be

Fig. 22.1. Typical outlet arrangements through

a concrete gravity dam.

provided so as to reduce- seepage

along the outside of the conduit as

shown in Fig. 22.2. The seepage is thus, reduced by increasing the length of the seepage

path by at least 25 per cent.

1155

1156

IRRIGATION ENGINEERING AND HYDRAULIC STRUCTURES

EARTHEN DAM

'

.

'

LI

\SLUICE PIPE OR

RECTANGULAR

TUNNEL

i-------------

L ------------

Fig. 22.2. Typical outlet arrangement through an earthen dam.

I.

In Fig. 22.2; if L is the total length of sluiceway from upstream to downstream, the

length of the seepage path will be given as :

=L+(2x)N

where x is the projection of each collar ; and

N is the number of collars.

The increase in seepage path, i.e. 2 N x must generally be greater than L/4.

The interior of sluiceway tunnel or pipe, must be smooth, without any projections

or cavities. The projections or cavities, etc. if at all present, may cause separation of

flow from the boundary of the conduit,. causing development of negative pressures and

the consequent danger qf cavitation*. The entrance of the sluiceway is also very impor-

111

1":11

,1

;I

!

SEPARATION OF

OCCURS HERE

(a) Square edged entrance

(b)

FLOW

Bell-mouthed entrance.

--~--~ ---- . - -'- }<ig. _22.3

tant, since a square edged entrance [Fig. 22.3 (a)] is likely to cause more separation of

flow ~nd more danger of consequent cavitation as compared to a bell mouthed or some

other type of entrance. There have been several such cases where large scale damages

have occurred due .to cavitation in the vicinity of square-edged entrances. A bellmouthed entrance [Fig. 22.3 (b)] is much better and superior to any other type, and the

. "' Explained earlier in Chapter 21.

OUTLET WORKS THROUGH DAMS AND RIVER INTAKES

1157

extra cost involved in shaping this entrance is usually justified except for small projects

under low heads.

The shape of the bell mouth is generally elliptical, and Douma has suggested the

following equations for it :

(i) For circular conduits.

4X2 + 44.4 Y2 = d2

.. (22.1)

where X, Y are the co-ordinates of any point on the

curve as definediJ:! Fig'. 22.2 (b) ; and

d is diameter of the circular conduit.

(ii) For rectangular tunnels or conduits

xz + IO .4 yz =dz

... (22.2)

where X and Y have same meaning as above ; and

d is the width or height of the conduit,

depending on whether the sides or top

and bottom curves are being designed.

22.2. Hydraulics of Outlet W orlcs

The discharge passing through the. dam outlet can be calculated easily, be using the

equation :

... [22.3(a)]

where Q = Discharge

A = Area of outlet sluice

H = Differential head causing flow, i.e. the

difference of u/s and d/s water levels.

Cd= Coefficient of discharge, whose value

=-c- . -depends upon various factors such as the

type of gate and trash rack provided, conduit friction, transitions etc.

For precise designs, the total head losses encountered in the outlet conduits may

be calculated. These losses include those caused by trash racks, conduit entrance,

conduit friction, gates and valves, transitions and bends. The entrance loss may be

taken as 0.5

vz

y2

g for square edged entrance, and equal to 0.04 g for bell mouthed

entrance, where V is the flow velocity through the conduit. Head losses caused by

conduit friction may be calculated by standard pipe formulas, such as :

hL =:

or

f' LV2

hL =

2gci c.=c

nz. yz. L

R4/3

The head loss through the gate depends upon the type of gate and valve provided.

vz

A loss of about 0.2 - g may be taken for fully open

. gate and butterfly valves. This head

2

loss is taken as nil for ring follower gates. The head loss through the trash rack depends

upon the velocity, and may be taken as shown in Table 22.1. -

IRRIGATION ENGINEERING AND HYDRAULIC STRUCTURES

1158

Table 22.1. Head Loss through Trash Racks

Ve loci throu h trash rack in m/sec

0.15

0.30

0.45

0.62

Head loss in metres

0.006

0.03

0.09

0.15

The net effective head which is responsible for flow, should then be taken as

= Heff= Differential head (H)-Head losses. The discharge can then be calculated easily, using

Q = A.Y2g Reff

... [22:3 (b)]

22.3. River Intakes

When water is withdrawn through a conduit from a river or a reservoir independently, and as such the entrance of the conduit is not an integral part of the dam or

any other related structure, then an intake structure must be constructed at the entrance

of the conduit. An intake structure may vary from a simple concrete block supporting

the end of the conduit pipe to huge concrete towers, depending upon various factors

such as, reservoir characteristics, capacity and discharge requirements, climatic conditions, etc. The basic function of an intake structure is to help in safely withdrawing water

from the reservoir over a predetermined range of pool levels, and thus to protect the

conduit from being damaged or clogged by ice, trash, debris, waves, etc.

Various types of intake structures are discussed below :

(1) Simple Submerged Intakes. A simple submerged intake consists of a simple

concrete block, or a rock filled timber crib supporting the starting end of the withdrawal

pipe, as shown in Figs. 22.4 (a) and (b).

BARSCREEN (SUCH AS 12mmX.50mmt/>

......-r....M-~~ STEEL BARS@ 15cm APART)

CONCRETE

BLOCK

.

...

FLEXIBLE JOINT

CONDUIT PIPE

Fig. 22.4. (a) Simple concrete block submerged intake.

BAR SCREEN

Fig. 22.4. (b) Rock-filled timber-crib submerged intake.

Such intake structures should be placed in the river or the reservoir at a place where

they may not get buried under the sediment. These submerged intakes are very economi-

OUTLET WORKS THROUGH DAMS AND RIVER INTAKES

1159

cal and donot obstruct navigation, and are, therefore, widely used on small works, and

are particularly suitable as water-supply intakes from small rivers*. They are sometimes

used as intakes to sluiceways of earthen dams with hydraulically operated gates for flow

regulation. These intakes are not used on bigger projects as their main disadvantage is

the fact that they are not easily accessible for repairing of their gates, etc.

(2) Intake Towers. Intake towers are generally used on large projects and where

there are large fluctuations of water level. Openings at various levels, called ports are

generally provided in these concrete towers, which may help in regulating the flow

through the towers -and permit some selection of the quality ofwater to be withdrawn,

If the_ ports are submerged at all levels, then there is no problem of any clogging or

damage by ice or debris, etc. However, the level of the lowest port should be high

enough above the reservoir bed, so that the sediment is not drawn into them. There are

two major types of intake towers, viz.

(i) Wet intake towers ; and

(ii) Dry intake towers.

(i) Wet intake towers. A typical section of a wet intake tower is shown in Fig. 22.5 (a).

It consists of a concrete circular shell filled with water' upto the reservoir level, and has

ROOF TRUSS

RESERVOIR LEVEL

GATE CONTROLLED

OPENING IN

THE SHAFT

WITHDRAWAL CONDUIT

:. _,,,.,. ' -. . .'

.... .

.'':

,,,. ,'<CJ_.

..

. ........

. '

I

....

..... '<

'

..

.. ~f-

- .

..~ -

- . - . - ...... ......

. ' .. '-. ~):~ , ... '.-q, ...

-

Fig. 22.5. (a) Wet Intake tower.

More detailed description of river and canal intakes is given in "Water Supply Engineering" by the same author.

1160

IRRIGATION ENGINEERING AND HYDRAULIC STRUCTURES

a vertical inside shaft which is connected to the withdrawal pipe. Openings are made

into the inside shaft also. Gates are usually placed on the shaft, so as to control the flow

of water into the shaft and the withdrawal conduit.

(ii) Dry Intake Towers. The essential. difference between a wet intake tower and a

dry intake tower is that, whereas in a wet intake tower, the water enters from .. the entry

ports into the tower and then it enters into the conduit pipe through separate gate

controlled openings ; in a dry intake tower, the water is directly drawn into the

withdrawal c::onduit through the gated entry ports as shown in Fig. 22.5 (b). A dry intake

tower will, therefore, have no. water inside the tower if its gates are closed, whereas th-e

RESERVOIR LEVEL

~ ENTRY -PORTS

! .

CYLINDER GATE

,_

iii

!ii

'

""+----! -

_ _ _...,.....

..

,I,

=-

:1

,,. P

...

r

~

1\

A

--

.. .

i. .

-~ -

. .

. : : ...

--- - - -- --

_.,..

WITHDRAWAL

CONDUIT

-===.. -

..

11!

,1:11

Fig. 22.5 (b ). Dry Intake Tower.

'i:

,1,

'.~-_w.etintake-tower-will-b-fuU-ofwater even if its gates-are-closed. When the-entry ports

are closed, a dry intake tower will be subjected to additional buoyant forces and hence,

must be of heavier construction than the wet intake towers. However, the dry intake

towers are useful and beneficial in the sense that water can be withdrawn from any

selected level of the reservoir by opening the port at that level.

Intake towers are huge structures standing in the river, and hence should be located

so as not to interfere with navigation, and must be properly designed so as to withstand

the worst possible combination of various forces, such as hydrostatic pressures, wind

and earthquake forces, and forces caused by waves, ice and debris, etc.

OUTLET WORKS THROUGH DAMS AND RIVER INTAKES

1161

22.4. Trash Racks

The entrances to intakes and dam outlets. are generally covered with trash racks so

as to prevent the entry of debris, ice, etc, into the conduit. These racks are generally

nothing but bar

screens, made from

steel bars spaced at

I

. - - -I

5 to 1.5 cm_centre to

centre (in both

HOISTING

CABLE

directions) depending upon the maximum size of the

debris required to

be excluded from

entering the conduit.The velocity of

A

flow through the

trash rack is kept

low (generally less

than 0.62 m/sec), so

as to minimise losses. This is someTRASH RACK

times accomplished

by constructing the

trash rack in the

form of a half

cylinder, as shown in Fig. 22.6.

SLUICEWAY

CONDUIT

The floating

debris, ice, etc.

which are stopped

by the racks and

thus get collected

SECTION A A

on

them,

are

removed by manual

Fig. 22.6. Half Cylinder-Trash rack and Tractor gate installation.

labour when required ; but on large projects, where much debris are expected, automatic

power-driven racks are used. Steam or electrically heated racks are preferred in cold

countries, so as to prevent ice formation on trash racks.

Ill

1111

r- I l l

II

PROBLEMS

1. (a) What is meant by a 'Dam sluice' ? Why are such sluices necessary in dam construction ?

(b) Show with neat sketches, the provision of sluiceways in

(i) an earth dam.

(ii) a concrete gravity dam.

2. Write short notes on :

(i) Sluiceways in dams.

(ii) River intakes.

(iii) Trash Racks.

Anda mungkin juga menyukai

- 527 538Dokumen7 halaman527 538smaajBelum ada peringkat

- DHS - Module I - Presentation - S6C1 - 12 April 2021Dokumen65 halamanDHS - Module I - Presentation - S6C1 - 12 April 2021Nf ZBelum ada peringkat

- Types of OutletsDokumen9 halamanTypes of OutletsS GBelum ada peringkat

- Chapter 8Dokumen27 halamanChapter 8Fuad Ahmedin100% (1)

- CENG 6606 HSII - 2 Diversion Head WorksDokumen29 halamanCENG 6606 HSII - 2 Diversion Head WorksKenenisa BultiBelum ada peringkat

- Bottom OutletsDokumen36 halamanBottom OutletsNikom Kraitud100% (3)

- Final Report (Hydrolic Structure 2)Dokumen30 halamanFinal Report (Hydrolic Structure 2)Ahmed AmediBelum ada peringkat

- Intakes PDFDokumen12 halamanIntakes PDFaggrey noah100% (1)

- Chapter Four: Spillways & Energy DissipatorDokumen84 halamanChapter Four: Spillways & Energy Dissipatorzelalemniguse100% (1)

- Gates and Valves in Hydraulic StructuresDokumen13 halamanGates and Valves in Hydraulic StructuresMuler DiribaBelum ada peringkat

- Culvert and Bridge Material - 1 and 2Dokumen116 halamanCulvert and Bridge Material - 1 and 2Tulu SenaBelum ada peringkat

- Guidelines For Design of SpillwayDokumen8 halamanGuidelines For Design of Spillwayrvkumar3619690Belum ada peringkat

- IntakesDokumen9 halamanIntakesThe ConquerorBelum ada peringkat

- Irrigation Outlets Guide: Types, Requirements & DesignDokumen9 halamanIrrigation Outlets Guide: Types, Requirements & DesignMazharBelum ada peringkat

- IDE Lec10 Regulatorand FallsDokumen34 halamanIDE Lec10 Regulatorand FallsFortiter FysproBelum ada peringkat

- Regulators Guide Canal Water DistributionDokumen11 halamanRegulators Guide Canal Water DistributionM.E.T EC CIVIL DEPARTMENTBelum ada peringkat

- Lecturenote - 271069403HS-II, CH-6 (Cross Drainage & Drop Structures)Dokumen22 halamanLecturenote - 271069403HS-II, CH-6 (Cross Drainage & Drop Structures)Yu Oscar KpariongoBelum ada peringkat

- SPILLWAYS, GATES AND OUTLET WORKS: KEY COMPONENTS AND DESIGNSDokumen47 halamanSPILLWAYS, GATES AND OUTLET WORKS: KEY COMPONENTS AND DESIGNSSohailKhanBelum ada peringkat

- 21 - Spillways Energy Dissipators and Spillway GatesDokumen56 halaman21 - Spillways Energy Dissipators and Spillway GatesBilal MzhrBelum ada peringkat

- Canal Outlets Students 2017Dokumen46 halamanCanal Outlets Students 2017Top5 foryouBelum ada peringkat

- Handout - HS-II, CH-6 (Cross Drainage & Drop Structures)Dokumen22 halamanHandout - HS-II, CH-6 (Cross Drainage & Drop Structures)abdata wakjiraBelum ada peringkat

- Conduits, Intake, Power House and AccessoriesDokumen29 halamanConduits, Intake, Power House and Accessorieshussen belewBelum ada peringkat

- Spillways, Gates and Outlet WorksDokumen47 halamanSpillways, Gates and Outlet WorksKieth LadimoBelum ada peringkat

- Dam From: Safety Valve For A DamDokumen28 halamanDam From: Safety Valve For A DamRashmi SahooBelum ada peringkat

- Chute Spillway 2Dokumen6 halamanChute Spillway 2Fasil GeberemeskelBelum ada peringkat

- Regulating Structures: StructureDokumen12 halamanRegulating Structures: Structuregurumurthy38Belum ada peringkat

- CANAL (T) - Water Control Structures PDFDokumen20 halamanCANAL (T) - Water Control Structures PDFMIKHA2014Belum ada peringkat

- Lecture 20 - Spillways 03.04.2021Dokumen5 halamanLecture 20 - Spillways 03.04.2021Morio MosoroBelum ada peringkat

- SPILL WAYSmodDokumen22 halamanSPILL WAYSmodhailishBelum ada peringkat

- Ce 405 Module 2 IntakesDokumen27 halamanCe 405 Module 2 IntakesHarikrishnan PsBelum ada peringkat

- SSC-JE, AE(PSC), RRB Irrigation Hydrology Objective QuestionsDokumen35 halamanSSC-JE, AE(PSC), RRB Irrigation Hydrology Objective QuestionsSuvendu ParidaBelum ada peringkat

- Other Canal Structures: Regulation WorksDokumen56 halamanOther Canal Structures: Regulation WorkskkodgeBelum ada peringkat

- Chapter 10 Canal OutletsDokumen65 halamanChapter 10 Canal OutletsUMAR FAROOQ67% (3)

- Pumphouse: Station Design and LayoutDokumen34 halamanPumphouse: Station Design and LayoutAswindana Ibnu SenaBelum ada peringkat

- Conveyence StructureDokumen14 halamanConveyence StructureNiiteSajoBelum ada peringkat

- Hydraulic Structure - 2 Chapter-4Dokumen43 halamanHydraulic Structure - 2 Chapter-4Debela Kebede Kera100% (1)

- River Diversion Headworks ExplainedDokumen18 halamanRiver Diversion Headworks ExplainedYu Oscar KpariongoBelum ada peringkat

- Lec#10 Cross Drainage Works, Regulators & FallsDokumen66 halamanLec#10 Cross Drainage Works, Regulators & FallsNoman Tariq MalkaniBelum ada peringkat

- Culvert Design PDFDokumen12 halamanCulvert Design PDFSouliman AlkhoderBelum ada peringkat

- Surface Water DrainageDokumen8 halamanSurface Water DrainageronyBelum ada peringkat

- Irrigation Structures - Diversion Head Works ComponentsDokumen13 halamanIrrigation Structures - Diversion Head Works Componentslakumas15Belum ada peringkat

- Level Crossing in RailsDokumen6 halamanLevel Crossing in RailsezequilBelum ada peringkat

- Canal Outlets - Updated-2023Dokumen52 halamanCanal Outlets - Updated-2023Ali RazaBelum ada peringkat

- Bottom OutletsDokumen3 halamanBottom OutletsJezylu Jireh Lasola AnitoBelum ada peringkat

- MiscellaneousDokumen6 halamanMiscellaneousBehar AbdurahemanBelum ada peringkat

- CH 5 Cross DrinageDokumen40 halamanCH 5 Cross DrinageAbuye HDBelum ada peringkat

- Lecturenote - 489027965chapter 3 SpillwayDokumen26 halamanLecturenote - 489027965chapter 3 SpillwayJemera TeshomeBelum ada peringkat

- Stilling WellDokumen9 halamanStilling WellEdinson Vargas CharajaBelum ada peringkat

- Chapter One Spillways and Its Design Principle: Essential Requirements of A SpillwayDokumen21 halamanChapter One Spillways and Its Design Principle: Essential Requirements of A SpillwayMaulidBelum ada peringkat

- Gate Slot LossesDokumen13 halamanGate Slot LossesRex ImperialBelum ada peringkat

- Design of Pipe CulvertsDokumen24 halamanDesign of Pipe Culvertsnour100% (1)

- Chapter Number Design SyphonDokumen21 halamanChapter Number Design SyphonIssa Drdr0% (1)

- Chapter9 CulvertsDokumen92 halamanChapter9 CulvertsVictor OmotoriogunBelum ada peringkat

- Hs 2 CH - 1Dokumen25 halamanHs 2 CH - 1asimamaw100% (1)

- Sewage Disposal Works: Their Design and ConstructionDari EverandSewage Disposal Works: Their Design and ConstructionBelum ada peringkat

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Dari EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Penilaian: 5 dari 5 bintang5/5 (2)

- Scientific American Supplement, No. 497, July 11, 1885Dari EverandScientific American Supplement, No. 497, July 11, 1885Belum ada peringkat

- Scientific American Supplement, No. 470, January 3, 1885Dari EverandScientific American Supplement, No. 470, January 3, 1885Belum ada peringkat

- A199Dokumen2 halamanA199DeroBelum ada peringkat

- ET Water SurfDokumen27 halamanET Water SurfprevrtljivacBelum ada peringkat

- Gate Design ProcedureDokumen42 halamanGate Design ProcedureNoppadol Ariyakrua92% (13)

- About Chute SpillwayDokumen15 halamanAbout Chute SpillwayPrem Singh RawatBelum ada peringkat

- ET Water SurfDokumen27 halamanET Water SurfprevrtljivacBelum ada peringkat

- Climate: Factors That Affect PrecipitationDokumen12 halamanClimate: Factors That Affect PrecipitationDeroBelum ada peringkat

- A284890 Self AerationDokumen112 halamanA284890 Self AerationDeroBelum ada peringkat

- Fema484 Conduit Through e DamDokumen614 halamanFema484 Conduit Through e Damrgscribd61Belum ada peringkat

- Cavitation in Chouts and SpillwaysDokumen164 halamanCavitation in Chouts and SpillwaysDeroBelum ada peringkat

- PAP-0012 Morning Glory DetailsDokumen39 halamanPAP-0012 Morning Glory DetailsDeroBelum ada peringkat

- Rainfall Analysis (1) : HydrologyDokumen64 halamanRainfall Analysis (1) : Hydrologymrs_minalBelum ada peringkat

- A284890 Self AerationDokumen112 halamanA284890 Self AerationDeroBelum ada peringkat

- ET Water SurfDokumen27 halamanET Water SurfprevrtljivacBelum ada peringkat

- 231 0eDokumen5 halaman231 0eDeroBelum ada peringkat

- ForemanDokumen2 halamanForemanmikeBelum ada peringkat

- Acquisition and Management of Spatial DataDokumen18 halamanAcquisition and Management of Spatial DataDeroBelum ada peringkat

- Some Relations Between Air Temperatures and The Surface Water Temperatures of LakesDokumen7 halamanSome Relations Between Air Temperatures and The Surface Water Temperatures of LakesDeroBelum ada peringkat

- Piche Evaporimeter ManualDokumen4 halamanPiche Evaporimeter ManualDeroBelum ada peringkat

- 232Dokumen10 halaman232DeroBelum ada peringkat

- 15 3 PDFDokumen19 halaman15 3 PDFDeroBelum ada peringkat

- Evaporation Pan: Operating InstructionsDokumen3 halamanEvaporation Pan: Operating InstructionsAsem A. HassanBelum ada peringkat

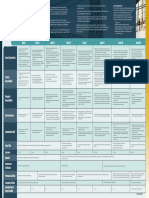

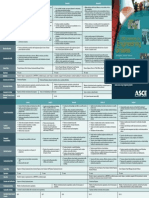

- Asce Eng Grades Chart PDFDokumen1 halamanAsce Eng Grades Chart PDFDeroBelum ada peringkat

- ASCE Engineering Grades BrochureDokumen2 halamanASCE Engineering Grades Brochuregeo_unoBelum ada peringkat

- Hess 19 2145 2015Dokumen17 halamanHess 19 2145 2015DeroBelum ada peringkat

- Dutta - Ten Commandments of ReviewingDokumen5 halamanDutta - Ten Commandments of ReviewingDeroBelum ada peringkat

- Understanding the Hydrologic CycleDokumen6 halamanUnderstanding the Hydrologic CycleRaman LuxBelum ada peringkat

- Measurement and Processing of Streamflow DataDokumen22 halamanMeasurement and Processing of Streamflow DataDeroBelum ada peringkat

- RANS solver predicts propeller hull vortexDokumen7 halamanRANS solver predicts propeller hull vortexHayderAlSamawiBelum ada peringkat

- Blakeborough X-Stream Brochure PWDokumen12 halamanBlakeborough X-Stream Brochure PWAnderson SiqueiraBelum ada peringkat

- Hydraulic Design of Francis TurbineDokumen108 halamanHydraulic Design of Francis Turbinenurettin100% (1)

- Cardinal Pump - Unifin PresentationDokumen226 halamanCardinal Pump - Unifin PresentationManibalanBelum ada peringkat

- Marine Propulsors Symposium DesignDokumen7 halamanMarine Propulsors Symposium DesignThibault HugBelum ada peringkat

- Engineering Design Guideline Static Mixer Rev02webDokumen23 halamanEngineering Design Guideline Static Mixer Rev02webWilfredo Suarez Torres50% (2)

- Pump Handbook CSIDokumen257 halamanPump Handbook CSIMrinmoy Das100% (2)

- Homonizer PDFDokumen8 halamanHomonizer PDFGopalVarthyaBelum ada peringkat

- Two Main Types of Mechanical Seals: Balanced and UnbalancedDokumen3 halamanTwo Main Types of Mechanical Seals: Balanced and UnbalancedmasoodkamalBelum ada peringkat

- Cat Piston Pump Service ManualDokumen8 halamanCat Piston Pump Service ManualMiguel Angel Santos PintadoBelum ada peringkat

- 1 s2.0 S2092678223000195 MainDokumen17 halaman1 s2.0 S2092678223000195 Main장영훈Belum ada peringkat

- ChokesBrochure ENG v01Dokumen12 halamanChokesBrochure ENG v01ermaiezBelum ada peringkat

- Robert E. Henry and Hans K. Fauske - A Different Approach To Fragmentation in Steam ExplosionsDokumen13 halamanRobert E. Henry and Hans K. Fauske - A Different Approach To Fragmentation in Steam ExplosionsPelaggioBelum ada peringkat

- DNV PropellerDokumen20 halamanDNV PropellerTay Chu YenBelum ada peringkat

- Rec Erc 77 14 PDFDokumen46 halamanRec Erc 77 14 PDFAdelmo FilhoBelum ada peringkat

- Basic Theory of PumpDokumen19 halamanBasic Theory of PumpJoon Eeo100% (4)

- Iso 14692-3-2017Dokumen44 halamanIso 14692-3-2017sachin100% (2)

- Pump & Pump Piping PresentationDokumen55 halamanPump & Pump Piping PresentationEduard Gonzalo Rojas Cervantes100% (1)

- Trilliumflow Brochure - Formerly Weir GlobalDokumen7 halamanTrilliumflow Brochure - Formerly Weir GlobalAndry HermawanBelum ada peringkat

- Sample HAZOP Study Worksheet (P&ID 100-002)Dokumen5 halamanSample HAZOP Study Worksheet (P&ID 100-002)Mikee Felipe88% (8)

- Transportation and Metering of FluidsDokumen34 halamanTransportation and Metering of FluidsPRAJWAL RASTOGIBelum ada peringkat

- Pumps Selection LectureDokumen59 halamanPumps Selection Lectureshicardinal100% (2)

- Ultrasonic CleaningDokumen14 halamanUltrasonic CleaningAbhilash FulkarBelum ada peringkat

- Flow Control May 2019Dokumen39 halamanFlow Control May 2019Alberto Fernández MarínBelum ada peringkat

- Abrasion of Concrete-FinalDokumen31 halamanAbrasion of Concrete-FinalHemin ZZBelum ada peringkat

- Advanced Fluid Mechanics (AFM) : Pakistan Navy Engineering College, PNEC, NUST KarachiDokumen8 halamanAdvanced Fluid Mechanics (AFM) : Pakistan Navy Engineering College, PNEC, NUST KarachiHammad PervezBelum ada peringkat

- Improve Pumps Performance With Composite Wear ComponentsDokumen0 halamanImprove Pumps Performance With Composite Wear ComponentsDelfinshBelum ada peringkat

- Gas/Steam Gas/Steam Medium MediumDokumen7 halamanGas/Steam Gas/Steam Medium MediumAaron BirhanuBelum ada peringkat

- Discharge Recirculation and CavitationDokumen2 halamanDischarge Recirculation and Cavitationdk4monjure100% (1)