Alloy Master Links

Diunggah oleh

Anonymous 48jYxR1C0%(1)0% menganggap dokumen ini bermanfaat (1 suara)

117 tayangan1 halamanalloy master link

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Inialloy master link

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0%(1)0% menganggap dokumen ini bermanfaat (1 suara)

117 tayangan1 halamanAlloy Master Links

Diunggah oleh

Anonymous 48jYxR1Calloy master link

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 1

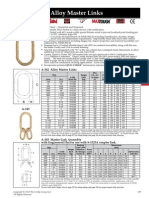

Alloy Master Links

A-342

Alloy Steel Quenched and Tempered.

Individually Proof Tested to values shown, with certification.

Proof Tested with 60% inside width special fixtures sized to prevent localized point loading per

ASME A-952 , reference page 269.

Meets or exceeds all requirements of ASME B30.26 including identification, ductility, design

factor, proof load and temperature requirements. Importantly, these links meet other critical

performance requirements including fatigue life, impact properties and material traceability, not

addressed by ASME B30.26.

Forgings have a Product Identification Code (PIC) for material traceability, along with the size,

the name Crosby and USA in raised lettering.

Selected sizes designated with W in the size column have enlarged inside dimensions to allow

additional room for sling hardware and crane hook.

Crosby 32mm to 51mm 342/345 master links are type approved to DNV Certification Notes

2.7-1- Offshore Containers. These Crosby master links are 100% proof tested, MPI and impact

tested. The tests are conducted by Crosby and 3.1 test certification is available upon request.

Refer to page 161 for Crosby COLD TUFF master links that meet the additional requirements of

DNV rules for certification of lifting applications - Loose Gear.

Incorporates patented QUIC-CHECK deformation indicators.

Dimensions

WLL

(mm)

Weight

S.F.= 5/1

Proof

A-342

Each

for Rope

Load

Deformation

(mm)

(in.)

Stock No.

(kg)

(t)*

(kN)**

A

B

C

Indicator

13W

1/2W

1014266

0.59

3.40

77

13

71.1

127

89

16

5/8

1014280

0.69

4.00

80

16

76.2

152

89

19W

3/4W

1014285

0.91

5.60

126

19

81.3

152

102

22W

7/8W

1014319

1.50

6.90

157

22

95.3

162

114

26W

1W

1014331

2.77

11.8

267

26

109

191

140

32W

1-1/4W

1014348

5.44

17.7

402

32

140

241

178

38W

1-1/2W

1014365

8.44

27.7

628

38

150

267

191

44

1-3/4

1014388

11.4

38.5

944

44

152

305

191

51

2

1014404

16.8

46.5

1141

51

178

356

229

57

2-1/4

1014422

24.5

64.9

1287

57

203

406

254

63

2-1/2

1014468

31.1

72.6

1423

63

213

406

279

70

2-3/4

1014440

42.6

98.4

1930

70

251

457

318

76

3

1014486

52.0

103

2029

76

251

457

330

83

3-1/4

1014501

66.0

119

2332

83

254

508

343

89

3-1/2

1014529

91.0

126

2483

89

305

610

394

95

3-3/4

1015051

90.0

152

2990

95

254

508

343

102

4

1015060

120

169

3319

102

305

610

406

108

4-1/4

1015067

137

160

3150

108

305

610

114

4-1/2

1015079

156

163

3202

114

356

711

121

4-3/4

1015088

198

176

3460

121

356

711

127

5

1015094

234

179

3515

127

381

762

*Ultimate Load is 5 times the Working Load Limit. Based on single leg sling (in-line load), or resultant load on multiple legs with

an included angle less than or equal to 120 degrees. Applications with wire rope and synthetic sling generally require a design

factor of 5. ** Proof Test Load equals or exceeds the requirement of ASTM A952(8.1) and ASME B30.9. Welded Master Link.

For use with chain slings, refer to page 237 for sling ratings and page 234 for proper master link selection.

Size

A-345

A-345 Master Link Assembly

with Engineered Flat for use with S-1325A coupler link.

Working

Dimensions

Load Limit

(mm)

Weight Based on

Proof

A-345

Each

5:1 Design Load

Deformation

(mm)

(in.)

Stock No.

(kg)

Factor (t)

(kN)**

A

B

C

D

E

F

G

Indicator

19W

3/4W

1014739

1.59

5.6

126

19 81.3 152 14.2 85.1 45.0 7.62

102

22W

7/8W

1014742

2.18

6.9

157

22 95.3 162 14.2 85.1 45.0 7.62

114

26W

1W

1014766

4.22

11.8

267

26 109 191 19.1 100 59.9 8.38

140

32W

1-1/4W

1014779

7.17

17.7

402

32

140 241 25.4 160 89.9 13.0

178

38W

1-1/2W 1014807

15.47

27.7

628

38 150 267 31.8 180 100 16.5

191

44

1-3/4

1014814

20.9

38.5

944

44

152 305 35.1 203 127 18.5

191

51

2

1014832

30.4

46.5

1141

51

178 356 38.1 229 146

229

64

2-1/2

1014855

93.4

72.6

1423

64

213 406 63.5 406 213

279

70

2-3/4

1014864

128

98.4

1929

70

251 457 69.9 457 251

318

102

4

1014999

303

169

3319

102 305 610 89.0 610 305

394***

*Ultimate Load is 5 times the Working Load Limit. The maximum individual sublink working load limit is 75% of the assembly

working load limit except for 2-1/2and 2-3/4, which are 100% of assembly working load limit. Applications with wire

rope and synthetic sling generally require a design factor of 5. ** Proof Test Load equals or exceeds the requirement of ASTM

A952(8.1) and ASME B30.9.

For use with chain slings, refer to page 237 for sling ratings and page 234 for proper master link selection.

Size

Copyright 2013 The Crosby Group LLC

All Rights Reserved

159

Rigging

Accessories

A-342 Alloy Master Links

Anda mungkin juga menyukai

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Sling Load Stress Calculations PDFDokumen14 halamanSling Load Stress Calculations PDFJohn Vincent Macatangay CleofeBelum ada peringkat

- York Chiller YcivDokumen80 halamanYork Chiller Ycivatiq100% (1)

- Crane and Hoist Safety TrainingDokumen13 halamanCrane and Hoist Safety TrainingMAHEBOOB PASHABelum ada peringkat

- Pveng: Pressure Vessel Engineering LTDDokumen5 halamanPveng: Pressure Vessel Engineering LTDBruno TrujilloBelum ada peringkat

- Jib Cranes 20875644 Colour CatalogueDokumen30 halamanJib Cranes 20875644 Colour Cataloguepsingh1996Belum ada peringkat

- Metric and Standard Flange Slide RuleDokumen1 halamanMetric and Standard Flange Slide RuleAnonymous 48jYxR1C100% (1)

- Rong ShengDokumen45 halamanRong ShengAnonymous 48jYxR1C0% (1)

- 4 EyeBolts-HoistRings-LiftingSlings - US PricingDokumen5 halaman4 EyeBolts-HoistRings-LiftingSlings - US PricingJohn MuellerBelum ada peringkat

- DNV Standards For Certification No 2.7-1 Offshore ContainersDokumen60 halamanDNV Standards For Certification No 2.7-1 Offshore ContainersMichael CovillBelum ada peringkat

- Marriot StandarsDokumen409 halamanMarriot StandarsJose Buitrago100% (10)

- API FlangeDokumen3 halamanAPI FlangeAnonymous 48jYxR1C100% (1)

- TurnbuckleDokumen6 halamanTurnbuckleAbi Latiful HakimBelum ada peringkat

- Sheave Design 10tDokumen1 halamanSheave Design 10tSubratBelum ada peringkat

- Crosby ShackleDokumen1 halamanCrosby Shacklecaner_kurtoglu-1Belum ada peringkat

- Eqpt Check List-Pre InspectionDokumen51 halamanEqpt Check List-Pre Inspectionarifayee-1Belum ada peringkat

- Lyrics of Nirvana/ Atma Shatakam With Translation..... Shivoham ! Shivoham !Dokumen2 halamanLyrics of Nirvana/ Atma Shatakam With Translation..... Shivoham ! Shivoham !Kellie RamosBelum ada peringkat

- Rd8100 Cable Pipe and RD Marker Brochure en v4Dokumen12 halamanRd8100 Cable Pipe and RD Marker Brochure en v4mubarak khanBelum ada peringkat

- HTCC Room padeye calculations sheetDokumen28 halamanHTCC Room padeye calculations sheetghoshamit4100% (5)

- BS EN 12079 Vs ISO10855Dokumen6 halamanBS EN 12079 Vs ISO10855milindsmeher100% (1)

- Twenty Five Ton Padeye - SpreadsheetDokumen4 halamanTwenty Five Ton Padeye - Spreadsheetoluomo1Belum ada peringkat

- Rubber Manufacturing Process ReportDokumen17 halamanRubber Manufacturing Process ReportAriel GamboaBelum ada peringkat

- Marine Operations During Removal of Offshore Installations: Recommended Practice DNV-RP-H102Dokumen22 halamanMarine Operations During Removal of Offshore Installations: Recommended Practice DNV-RP-H102leelarama100% (1)

- Engine performance dataDokumen1 halamanEngine performance dataAnonymous 48jYxR1C100% (2)

- Norbar HandTorque KitsDokumen2 halamanNorbar HandTorque KitsnoormanmubarakBelum ada peringkat

- Jib Crane Design and ParametersDokumen5 halamanJib Crane Design and ParametersNicole DavisBelum ada peringkat

- ShacklesDokumen16 halamanShacklesJerzy RistujczinBelum ada peringkat

- American Traveling BlockDokumen1 halamanAmerican Traveling BlockAnonymous 48jYxR1CBelum ada peringkat

- A. Check For Compression: DESIGN USING ASME BTH1-2005 - Code For LiftingDokumen5 halamanA. Check For Compression: DESIGN USING ASME BTH1-2005 - Code For LiftingDhanraj VasanthBelum ada peringkat

- Master Link CatalogueDokumen1 halamanMaster Link CatalogueHafizi HZnumismatic50% (2)

- GL Pers Transfer Basket Inspection PDFDokumen26 halamanGL Pers Transfer Basket Inspection PDFSteve Morrison100% (1)

- Stepped Couplings OD355.6 - 1222: Large DiameterDokumen1 halamanStepped Couplings OD355.6 - 1222: Large DiameterAnonymous 48jYxR1CBelum ada peringkat

- Crosby ShacklesDokumen18 halamanCrosby ShacklesAnjar DarundriyaBelum ada peringkat

- Crosby Shackles G-2130 PDFDokumen2 halamanCrosby Shackles G-2130 PDFBolarinwaBelum ada peringkat

- EN 12079-1:2006 (E) Forklift Pocket DimensionsDokumen3 halamanEN 12079-1:2006 (E) Forklift Pocket Dimensionsdsn_sarmaBelum ada peringkat

- Bridon Offshore ExplorationDokumen44 halamanBridon Offshore ExplorationAthox QhurienBelum ada peringkat

- Heavy Hex NutsDokumen3 halamanHeavy Hex NutsAhmadreza AminianBelum ada peringkat

- LEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories Non Fixed Load Lifting Attachments - Version 2 - Feb 2015Dokumen17 halamanLEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories Non Fixed Load Lifting Attachments - Version 2 - Feb 2015Ulviyye ElesgerovaBelum ada peringkat

- Piping Engineering All Codes and StandardDokumen17 halamanPiping Engineering All Codes and Standardomkar parabBelum ada peringkat

- Litewalk Steel GratingDokumen2 halamanLitewalk Steel GratingDr Bugs TanBelum ada peringkat

- Cables para Izaje Diepa IngevalDokumen60 halamanCables para Izaje Diepa IngevalOscar ValderramaBelum ada peringkat

- Welding SymbolsDokumen12 halamanWelding SymbolsrsrtnjBelum ada peringkat

- Rollgliss InstructionsDokumen28 halamanRollgliss InstructionsCarlos Ernesto Flores AlbinoBelum ada peringkat

- Iso 3874 1997Dokumen87 halamanIso 3874 1997ferruxo69Belum ada peringkat

- Securing Straps & RatchetsDokumen2 halamanSecuring Straps & RatchetsKhurram S. MuzammilBelum ada peringkat

- Pipe Size and Trim Angle CalculatorDokumen4 halamanPipe Size and Trim Angle CalculatorThennarasu PanneerselvamBelum ada peringkat

- Mordec-Catalogue 2011 MayDokumen83 halamanMordec-Catalogue 2011 Maykiiru88100% (1)

- Copie de Standards Check ListDokumen7 halamanCopie de Standards Check ListAbakar MahamatBelum ada peringkat

- Stainless Steel PropertiesDokumen3 halamanStainless Steel Propertieskiwanis_lamBelum ada peringkat

- Example of Ferrule Selection ChartDokumen1 halamanExample of Ferrule Selection ChartKyi HanBelum ada peringkat

- DOC. No. Revision Date by E6DPA-WEIGHT-003 01 18.02.2015 1 of 2 Flora Braoh TitleDokumen1 halamanDOC. No. Revision Date by E6DPA-WEIGHT-003 01 18.02.2015 1 of 2 Flora Braoh TitleNasrul AdliBelum ada peringkat

- Metric Fine Screw Threads Taper Pipe ThreadsDokumen1 halamanMetric Fine Screw Threads Taper Pipe Threadsmanuelq9100% (1)

- Asme Pipe Wall ThicknessDokumen3 halamanAsme Pipe Wall ThicknessYoke ShuBelum ada peringkat

- Working Load Limits For SlingsDokumen11 halamanWorking Load Limits For Slingstolis-gefBelum ada peringkat

- Grating1 1Dokumen32 halamanGrating1 1amachmouchiBelum ada peringkat

- Metric screw thread parameters and gaugesDokumen5 halamanMetric screw thread parameters and gaugesnoe juarezBelum ada peringkat

- Structural Equivalency SheetDokumen73 halamanStructural Equivalency Sheetboim1234Belum ada peringkat

- Catalogo 511Dokumen4 halamanCatalogo 511Luis Oswaldo R PBelum ada peringkat

- PT Bhaita Wire Rope Inspection ProcedureDokumen4 halamanPT Bhaita Wire Rope Inspection ProcedureSugianto TanBelum ada peringkat

- SDLINC NDT Level II Certification CourseDokumen8 halamanSDLINC NDT Level II Certification CourseNkwor AndersonBelum ada peringkat

- Is-5372-Taper Washer For ChannelDokumen2 halamanIs-5372-Taper Washer For ChannelSurendra Kumar ChordiaBelum ada peringkat

- Taglineuse PEERREVIEWDOCDokumen56 halamanTaglineuse PEERREVIEWDOCMohamed Said0% (1)

- Calculate volume and surface areas of a hollow cylinderDokumen4 halamanCalculate volume and surface areas of a hollow cylindershiel175Belum ada peringkat

- RR C 271FDokumen45 halamanRR C 271Fm_naderasliBelum ada peringkat

- A-344, A-347 Master LinkDokumen1 halamanA-344, A-347 Master LinkAekJayBelum ada peringkat

- Crosby Alloy Screw Pin Shackles: All Rights Reserved 72Dokumen1 halamanCrosby Alloy Screw Pin Shackles: All Rights Reserved 72theCrosbyGroupBelum ada peringkat

- A 928 - A 928M - 04 Qtkyoc9boti4tqDokumen6 halamanA 928 - A 928M - 04 Qtkyoc9boti4tqsachinguptachdBelum ada peringkat

- VideoDokumen1 halamanVideopothirajkalyanBelum ada peringkat

- Vents and StacksDokumen5 halamanVents and Stacksadel rihanaBelum ada peringkat

- TAPER GRIP-TWIST Brochure - RevB-red PDFDokumen4 halamanTAPER GRIP-TWIST Brochure - RevB-red PDFGonzalo AbarcaBelum ada peringkat

- MMX6 WebDokumen2 halamanMMX6 WebAnonymous 48jYxR1CBelum ada peringkat

- M3036 Block 5861Dokumen21 halamanM3036 Block 5861Gregory StewartBelum ada peringkat

- 6 1 2 p1458 1473 Sya3000 - enDokumen16 halaman6 1 2 p1458 1473 Sya3000 - enMurali SambandanBelum ada peringkat

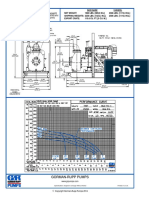

- PumpDokumen1 halamanPumpAnonymous 48jYxR1CBelum ada peringkat

- 6 1 2 p1458 1473 Sya3000 - enDokumen16 halaman6 1 2 p1458 1473 Sya3000 - enMurali SambandanBelum ada peringkat

- Hydril - GK Annular r2Dokumen2 halamanHydril - GK Annular r2Anonymous 48jYxR1CBelum ada peringkat

- MISC006B Anchorage StrengthDokumen2 halamanMISC006B Anchorage StrengthAnonymous 48jYxR1CBelum ada peringkat

- G:/Marketing/Public Data/Printed Materials/Advantage Booklet/Contractor Advantage Booklet - PDF Last Revision: Dec 1, 2009Dokumen12 halamanG:/Marketing/Public Data/Printed Materials/Advantage Booklet/Contractor Advantage Booklet - PDF Last Revision: Dec 1, 2009Anonymous 48jYxR1CBelum ada peringkat

- Sealed-Blok Bro REV G English LRDokumen8 halamanSealed-Blok Bro REV G English LRAnonymous 48jYxR1CBelum ada peringkat

- LS ManridersDokumen8 halamanLS ManridersAnonymous 48jYxR1CBelum ada peringkat

- 1 Make Colliding Pattern of Device ClearDokumen4 halaman1 Make Colliding Pattern of Device ClearAnonymous 48jYxR1CBelum ada peringkat

- A01LADSAFTENDokumen4 halamanA01LADSAFTENAnonymous 48jYxR1CBelum ada peringkat

- Material Conversion TableDokumen1 halamanMaterial Conversion TableAnonymous 48jYxR1CBelum ada peringkat

- Crosby CatalogDokumen1 halamanCrosby CatalogShammika1986Belum ada peringkat

- 15 10 Sat Chit Ananda 10Dokumen5 halaman15 10 Sat Chit Ananda 10Anonymous 48jYxR1CBelum ada peringkat

- EJ Overhanging - Monorails 3rd - Q 1985 Tanner PDFDokumen6 halamanEJ Overhanging - Monorails 3rd - Q 1985 Tanner PDFAnonymous 48jYxR1CBelum ada peringkat

- 52 259Dokumen2 halaman52 259Anonymous 48jYxR1CBelum ada peringkat

- Articulated Choke & Kill LinesDokumen3 halamanArticulated Choke & Kill LinesAnonymous 48jYxR1CBelum ada peringkat

- NutDokumen1 halamanNutAnonymous 48jYxR1CBelum ada peringkat

- The Vedanta Kesari June 2016 Issue Highlights Ramakrishna Temple in TamlukDokumen56 halamanThe Vedanta Kesari June 2016 Issue Highlights Ramakrishna Temple in TamlukAnonymous 48jYxR1CBelum ada peringkat

- Creusabro 4800 Steel Offers Improved Wear ResistanceDokumen3 halamanCreusabro 4800 Steel Offers Improved Wear ResistanceAnonymous 48jYxR1CBelum ada peringkat

- Vedanta Kesari 3Dokumen56 halamanVedanta Kesari 3Anonymous 48jYxR1CBelum ada peringkat

- Assignment No 2 2020Dokumen2 halamanAssignment No 2 2020ROHIT SHRESTHABelum ada peringkat

- CG-2016284-02 CHEMGUARD Pre-Piped Vertical Bladder Tanks PDFDokumen6 halamanCG-2016284-02 CHEMGUARD Pre-Piped Vertical Bladder Tanks PDFJitheesh SahadevanBelum ada peringkat

- Jonas 2009Dokumen15 halamanJonas 2009Deepika RajamBelum ada peringkat

- CS2 H2S SO2 analyzer sample line calculationDokumen4 halamanCS2 H2S SO2 analyzer sample line calculationKevin PratyatamaBelum ada peringkat

- Luneta MirillaDokumen2 halamanLuneta MirillaJeefBelum ada peringkat

- Experimental studies on utilization of shredded plastic waste in hardened concrete mixDokumen52 halamanExperimental studies on utilization of shredded plastic waste in hardened concrete mixShashi KumarBelum ada peringkat

- Preparatory steps for painting projectDokumen8 halamanPreparatory steps for painting projectNicholas GawanBelum ada peringkat

- Development of An Inexpensive Labview Based Refrigeration Cycle LaboratoryDokumen5 halamanDevelopment of An Inexpensive Labview Based Refrigeration Cycle Laboratoryvinicius schwabBelum ada peringkat

- (Clivet-2003-5C2001) Water Cooled Screw ChillerDokumen19 halaman(Clivet-2003-5C2001) Water Cooled Screw Chillerajun madana putraBelum ada peringkat

- IS 4985 (2000) - Unplasticized PVC Pipes For Potable Water SuppliesDokumen37 halamanIS 4985 (2000) - Unplasticized PVC Pipes For Potable Water SuppliesRajguru MoreBelum ada peringkat

- MC-Color T 21 DE DE EN TDSDokumen2 halamanMC-Color T 21 DE DE EN TDSY TingBelum ada peringkat

- Tang2015 PDFDokumen19 halamanTang2015 PDFLuky HandokoBelum ada peringkat

- SB Sway Brace AttachmentDokumen2 halamanSB Sway Brace Attachmentrvalentino2012Belum ada peringkat

- Asiam Games VillageDokumen18 halamanAsiam Games Villageriddhi patel100% (1)

- Reference Data: Schedule 40 Steel Pipe DataDokumen2 halamanReference Data: Schedule 40 Steel Pipe DataKareem HelalBelum ada peringkat

- Apcolite Premium Gloss Enamel PDFDokumen2 halamanApcolite Premium Gloss Enamel PDFAnand Chavan Projects-QualityBelum ada peringkat

- Material Handling Valves For Dust Collection - AerodyneDokumen2 halamanMaterial Handling Valves For Dust Collection - AerodyneKyle ChandlerBelum ada peringkat

- Is 1570 7Dokumen18 halamanIs 1570 7Raj K Sharma100% (1)

- Ressure Elief Alves: Model 7000 Model 7200 For Fire Sprinkler SystemsDokumen1 halamanRessure Elief Alves: Model 7000 Model 7200 For Fire Sprinkler SystemsrajeshBelum ada peringkat

- Vestige of Bitumen With and Without Sasobit On MaturingDokumen4 halamanVestige of Bitumen With and Without Sasobit On MaturingadithyaBelum ada peringkat

- 1.7027 (Germany / WN)Dokumen2 halaman1.7027 (Germany / WN)farhadBelum ada peringkat

- We Deliver Ice Builders (Latent Heat Storage Units) To The HVAC, Dairy, and Food Processing IndustriesDokumen4 halamanWe Deliver Ice Builders (Latent Heat Storage Units) To The HVAC, Dairy, and Food Processing IndustriesArlex Ricardo Guillen PetitBelum ada peringkat

- Tower Internals Hardware and ServicesDokumen36 halamanTower Internals Hardware and ServicesRondinelli CandidoBelum ada peringkat

- Chapter 3Dokumen15 halamanChapter 3Bheemesh GudelliBelum ada peringkat

- ColumnsDokumen5 halamanColumnsayalwBelum ada peringkat

- Traffic Light Cable: Typical Section of Rigid Pavement at JunctionDokumen1 halamanTraffic Light Cable: Typical Section of Rigid Pavement at JunctiongeobyunBelum ada peringkat

- ORMOCERIDokumen6 halamanORMOCERIBogdanBelum ada peringkat