Composite Integrated Rear Suspension 1986 Composite Structures

Diunggah oleh

jeroldscdHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Composite Integrated Rear Suspension 1986 Composite Structures

Diunggah oleh

jeroldscdHak Cipta:

Format Tersedia

Composite Structures 5 (1986)233-242

Composite Integrated Rear Suspension

C. J. Morris

~, L~ "~Ford Motor Company, Dearborn, Michigan~USA

ABSTRACT

Fiber reinforced plastics are undergoing extensive studies as potential

structural materials for automotive applications. This paper describes the

design, fabrication, weight analysis and testing of a composite integrated

rear suspension in a Ford Escort vehicle. This suspension utilizes a

transverse FRP leaf spring to integrate the functions of the production

Escort stamped steel lower arms and coil springs. The spring was

designed using previously developed composite design procedures. The

results show concept feasibility, a vehicle weight saving of 7 lb, good

ride, noise, vibration and harshness (NVH) characteristics. A reduction

in roll stiffness points out the need for development in the design of the

center clamp attachment to the body structure. This study demonstrates

the viability and potential of fiber reinforced composites in automotive

suspension systems.

1 INTRODUCTION

The efficiency of composites applications in structural applications is

greatly enhanced by the integration of parts wherever feasible. In

evaluating potential composite applications to chassis systems a survey of

commonly used suspension types was made and the potential for composite applications was assessed on a judgemental basis. Of the types

surveyed the Escort type rear suspension (Fig. 1) was judged to have good

potential for integration of parts. The composite integrated suspension

system described in this report, where the steel transverse suspension

arms and coil springs are replaced by a single transverse FRP leaf spring

233

Composite Structures 0263-8223/86/$03.50 O Elsevier Applied Science Publishers Ltd,

England, 1986. Printed in Great Britain

234

C. J. Morris

Fig. 1. E A O / N A A O Escort production rear suspension.

Fig. 2. Experimental integrated FRP rear suspension.

Composite integrated rear suspension

235

(Fig. 2), represents the demonstration of the design, prototype build and

evaluation of such a system.

2 OBJECTIVES

The major goals of the system design were as follows:

(i) Design a composite component utilizing specific composite design

procedures.

(ii) Demonstrate component integration.

(iii) Build concept demonstration vehicle.

(iv) Determine ride and handling issues.

3 SPRING DESIGN

In concept, the combined functions of the two lower arms and two coil

springs are integrated into a single transverse leaf spring mounted at the

center and attached to the wheel spindles at each end (Fig. 2). Each half

of the transverse spring must have the equivalent of the production coil

spring rate to satisfy ride and handling requirements and must geometrically deform to maintain the appropriate wheel camber, etc.

The location of the spring end attachment is fixed by the wheel spindle,

thus determining the spring length. Also the spring rate is fixed. So the

design contains three elements:

(i) Functional spring design.

(ii) Maintenance of acceptable suspension geometry.

(iii) Design of vehicle modifications to package the CIRS.

A design study was made to determine the vehicle changes necessary to

install the concept into the rear of a three-door Escort. The three-door

model was chosen since it requires the lowest spring rate of all Escort

models and generally, within a given package, the spring of lowest rate

generates the highest stress levels in the spring. Concurrently the

configuration of a constant cross-section area FRP leaf spring was

computed to match spring rates and load characteristics of the production

suspension. This spring configuration was accomplished using a

composite leaf spring design program developed by Robertson. t The

236

C. J. Morris

program is user friendly and runs on the Ford CYBER 176 Computer. It

has options for analysis of three types of leaf spring configuration:

(i) Constant cross-section area, tapered in plan and side views,

sometimes called the 'bow-tie' type.

(ii) Constant cross-section, no taper.

(iii) Constant width, tapered in the side view only.

In this case the constant cross-section area tapered type was chosen

(Fig. 3) since it gives the most weight efficient design while allowing all

fibers to run the full length of the spring and is therefore compatible with

existing simple filament winding techniques.

Input data for the program include length, spring rate, design and

jounce loads, suspension travels, width at the center, percentage of

center width at ends, type of fiber (e.g. graphite or glass), and volume

percent of fiber content.

Output data from the program include spring thickness at the center,

maximum composite and fiber stresses, maximum shear stresses and

recommended maximum allowable stresses. Also output are a number of

load/deflection values between zero and full jounce loads. There are a

5 in.

100 mm ~,

~,~ t

5 in.

,,,I

100 mm

Fig. 3. Symmetricsinuousspring-Escort transverse leaf spring.

Composite integrated rear suspension

237

Fig. 4. FRP leaf springs. Filament winding-compressionmoldingprocess.

series of user options for graphic and calcomp plot outputs. Maximum

fiber stress for the computed spring (121 ksi) was very close to the

m a x i m u m r e c o m m e n d e d in 'E' glass (120 ksi).

4 SPRING F A B R I C A T I O N

The springs are fabricated by drawing a bundle of fibers through a bath of

resin and winding them on spindles into a larger bundle, longer than the

finished spring, and laying this bundle into a female die. The male die is

then pressed into the female and heat is applied to initiate the resin cure.

After curing, the spring is removed from the die and trimmed to length

(Fig. 4).

For this project, glass fibers in an epoxy matrix were selected with 50%

volume of glass fiber. Glass fiber was chosen due to its great economic

238

C. J. Morris

advantage over other fibers, e.g. graphite, and the 50% volume is close to

the maximum attainable in practice.

5 VEHICLE AT~'ACHMENT

The geometry characteristics of the production metal lower arms were

approximated by keeping the length of the center attachment clamp as

short as possible, thus producing the longest equivalent link radius in each

cantilever. Design of the center clamp attachment to the vehicle underbody was based on existing designs for steel leaf spring 'isoclamps' used

on the Pinto vehicle. Since it is not desirable to drill a hole in the center of

the FRP spring, as is done in steel leaf springs for positive spring retention,

the clamp system was modified vs. the Pinto design. It was proposed that a

protruding pad be molded to the top and bottom surfaces of the spring

and that the rubber isolators be configured to surround this pad and thus

provide the necessary retention feature. A series of metal shims was also

introduced into the clamp to effect any required ride height changes in the

prototype vehicle. Since the transverse leaf spring would be loading the

rear suspension body crossmember with a large bending moment at the

vehicle centerline it was necessary to substantially reinforce the crossmember. In the prototype build proposal this was accomplished by

adding a 'hat' section doubler to the existing member across its total span.

The design study also showed that the existing routing of the fuel fill pipe

under the crossmember was not feasible since the leaf spring would

interfere over a substantial portion of its vertical travel. This was solved

by raising the fuel fill pipe and routing through a notch formed in the

crossmember for that purpose. The crossmember was further reinforced

locally around the notched area.

Steel end fittings were designed to attach the spring ends to the wheel

spindles in the same manner as the production transverse lower arms.

Since little was known about the variation in spring thickness at the ends

due to the fabrication process, the end fitting design was such that a

generous thickness variation could be accommodated. It was expected

that this would not be necessary in any future production design. Fittings

were designed to be bonded to the FRP spring and also bolted to give a

100% 'fail-safe' feature.

The weight effect of this suspension system was estimated at an overall

vehicle weight saving of approximately 7 lb vs. the production Escort.

Composite integrated rear suspension

239

6 P R O T O T Y P E BUILD AND TESTING

The first springs were installed in the vehicle. The vehicle ride rate was

checked statically by applying load increments to the rear of the vehicle

and measuring the incremental deflection with the wheels resting on a scale

so that accurate wheel loads could be obtained. The ride rate with the first

spring installed was found to be 14% greater than the production vehicle,

but a ride evaluation showed that this greater rate was very difficult to

detect subjectively. It proved to be feasible to reduce the spring rate by

approximately 5% without major tooling changes and all subsequent

springs were made this way.

A second vehicle was completed and the rough road testing initiated.

The rough road durability test consists of 400 cycles of an approximately

18 mile course over a variety of extremely rough surfaces at Dearborn

Proving Ground. These surfaces include cobblestones, belgian block and

square edged potholes. This test is very severe and is designed as an

accelerated test for chassis components to show which components will

typically fail first. At 28 cycles the vehicle was inspected and the spring

was found to have delaminations on the tension side. Closer inspection

showed that these delaminations were due to fiber damage during the

molding process where the center Iocator pad was molded into the spring.

The spring was replaced with another which was manufactured without

the locator pads molded in. This spring was bonded to the rubber isolators

to maintain its location in the vehicle. The vehicle was inspected at

approximately 50 cycle intervals and general repairs made as required.

At 266 cycles the left-hand steel end fitting of the spring developed a crack

located in a bend radius causing a slight sag on the left-hand side of the

vehicle. The composite spring itself showed no evidence of damage. Since

these end fittings were never intended to be representative of a future

production design and the crack was probably a result of poor control of

the bending operation, the fitting was repaired and the test continued. At

353 cycles the spring showed no signs of damage and the repair to the end

fitting showed no degradation. Since the spring now had 325 cycles (81%

of the goal), proof of concept durability was substantially demonstrated

and the test was terminated.

Simultaneously with the durability testing, evaluations were made for

ride, handling, noise, vibration and harshness (NVH) parameters using

the original build vehicle. The vehicle was evaluated by personnel from

various production design and development departments. Generally,

240

C. J. Morris

TABLE 1

Evaluation Summary: Composite Integrated Rear Suspension Escort vs. Standard Escort

Composite integrated

rear suspension

Escort

Standard

Escort

1. Vehicle handling overall

(a) Cornering---Capacity

~-Confidence

--Roll control

(b) Stability--Directional

--Lane change

----Cross wind

6.7

6.9

6.7

6-2

6-7

5-9

6.5

7.0

7.0

7.0

6.5

7.0

7.0

7.5

2. Vehicle ride overall

(a) Smooth roads/boulevard

(b) Rough roads

(c) Control/balance

6.4

7-1

6-3

6-3

7.0

7.0

7.0

7.0

3. Body and chassis NVH overall

(a) Impact harshness--Feel

--Noise

(b) Noise--Interior overall

(c) Shake--Steering wheel/column

--Mid-car

--Front end

--Tyre

(d) Body boom

(e) Rolling feel

6.6

6.3

6.2

6-5

6.5

6.9

7.0

7-0

6-6

7-0

6-6

6.0

6.0

6.0

7.0

7.0

7-0

7.0

6.5

7.0

Characteristic

Comments:

Some loss of cornering capacity.

Less control in transient maneuvers.

Lane changes occur in two distinct steps.

Loss of roll control.

Needs shock absorber development for ride balance.

Some rear impact noise/harshness improvement.

r e s u l t s o f t h e s e e v a l u a t i o n s w e r e in a g r e e m e n t , with f a v o r a b l e ratings f o r

ride a n d N V H , i.e. c o m p a r a b l e to b a s e E s c o r t , a n d criticism f o r roll

c o n t r o l a n d d i r e c t i o n a l stability in s e v e r e h a n d l i n g m a n e u v e r s , i.e. h a r d

c o r n e r i n g a n d l a n e c h a n g e s . T h e s e criticisms f o r h a n d l i n g are a s c r i b e d to

l a c k o f d e v e l o p m e n t in the c e n t e r m o u n t i n g c l a m p a r e a . A r e v i e w o f

p r o d u c t i o n a n d o t h e r p r o p o s e d designs, e.g. 1984 C o r v e t t e a n d 1985

Composite integrated rear suspension

241

Chevrolet 'M' Van suggests that the clamp is too soft for this application.

The data from these other designs were not available at the time the

Escort system was designed. A summary of the vehicle ratings vs. the

production Escort is shown in Table 1. A description of the rating system

used is contained in the Appendix.

7 CONCLUSIONS

All the major goals of the system design were met, i.e.:

(i)

(ii)

(iii)

(iv)

(v)

C o m p o n e n t integration was demonstrated.

A concept demonstration vehicle was built.

Concept durability was demonstrated.

Ride and handling issues were determined.

A system weight saving of 7 lb. was demonstrated.

The major issue remaining was determined to be center attachment

clamp development to improve roll control and vehicle stability to an

acceptable level.

While the center locator pads caused unacceptable performance in the

one sample tested, it cannot be concluded that this type of Iocator should

never be considered for future designs. It is, however, recommended that

an investigation into improved FRP spring fabrication procedures be

carried out prior to future use of this or similar Iocator pad concepts.

ACKNOWLEDGEMENTS

The author is grateful to P. Beardmore and R. A. Jeryan for discussion

and critical evaluation of this manuscript. The author also appreciates the

assistance of N. G. Chavka in carrying out the build and test phases of this

project.

REFERENCE

1. Robertson, R. E., Design of FRP leaf springs, unpublished.

242

('. J. Morris

o~

I'-

,c

ao

p~

./3

#_

.J

ra~

Z

.<

nl

e~

Z

,q

,I I=

u

NI

o,i

Z

D

e~

Anda mungkin juga menyukai

- Design and Analysis of A Propeller Shaft of A Toyoto QualisDokumen118 halamanDesign and Analysis of A Propeller Shaft of A Toyoto QualisSyed Hasan100% (2)

- Design and Fabrication of Race Spec Go-KartDokumen6 halamanDesign and Fabrication of Race Spec Go-KartAJER JOURNALBelum ada peringkat

- MET2013 Hinojosa RicardoDokumen27 halamanMET2013 Hinojosa RicardoAmal GeorgeBelum ada peringkat

- Design and Analysis of A Tubular Space Frame Chassis of A High Performance Race CarDokumen5 halamanDesign and Analysis of A Tubular Space Frame Chassis of A High Performance Race CaresatjournalsBelum ada peringkat

- Baja Rear SuspensionDokumen5 halamanBaja Rear SuspensionArindam MahantaBelum ada peringkat

- Design of A Carbon Fiber Bicycle Stem Using An Internal Bladder and Resin Transfer MoldingDokumen10 halamanDesign of A Carbon Fiber Bicycle Stem Using An Internal Bladder and Resin Transfer MoldingKỹ Sư Cùi BắpBelum ada peringkat

- Composite Rim FSAEDokumen28 halamanComposite Rim FSAEHarry BikasBelum ada peringkat

- Two Seated Buggy Chasis DesignDokumen29 halamanTwo Seated Buggy Chasis Designex4182Belum ada peringkat

- Design and Analysis Multi Purpose Vehicle (MPV) ChassisDokumen15 halamanDesign and Analysis Multi Purpose Vehicle (MPV) ChassisusoppukunBelum ada peringkat

- Design and Analysis of An All Terrain Vehicle: Gaurav S. Chimote, Kartik P. Rajas, Alok Kumar MishraDokumen5 halamanDesign and Analysis of An All Terrain Vehicle: Gaurav S. Chimote, Kartik P. Rajas, Alok Kumar MishraupadhyaysanuBelum ada peringkat

- Complete Design Report Team JaabazDokumen89 halamanComplete Design Report Team JaabazpiyushnsitBelum ada peringkat

- Piyush.C.Chaudhari (M.E Automobile), Prof - Vimal.D.Sonara, DR - Pravin.P.Rathod Government Engineering College, BhujDokumen1 halamanPiyush.C.Chaudhari (M.E Automobile), Prof - Vimal.D.Sonara, DR - Pravin.P.Rathod Government Engineering College, BhujvaniyahareshBelum ada peringkat

- Design & Analysis of Mono Composite Leaf SpringDokumen5 halamanDesign & Analysis of Mono Composite Leaf Springijsret100% (1)

- Rollover Simulation of Bus StructureDokumen13 halamanRollover Simulation of Bus StructureNavas AzeezBelum ada peringkat

- Design and Optimization of Automobile Propeller Shaft With Composite Materials Using Fem AnalysisDokumen17 halamanDesign and Optimization of Automobile Propeller Shaft With Composite Materials Using Fem AnalysisdressfeetBelum ada peringkat

- JETIR21075331Dokumen17 halamanJETIR21075331Vinit TyagiBelum ada peringkat

- Baja Design Report PDFDokumen9 halamanBaja Design Report PDFZubair HussainBelum ada peringkat

- Baja Design ReportDokumen9 halamanBaja Design ReportRishi KumarBelum ada peringkat

- Failure Modes and Failure Mechanisms of Fiber Reinforced Polymer Composite Bridge DecksDokumen10 halamanFailure Modes and Failure Mechanisms of Fiber Reinforced Polymer Composite Bridge Decksalemteka97Belum ada peringkat

- SAE BAJA 2013 Preliminary Design ReportDokumen10 halamanSAE BAJA 2013 Preliminary Design Reportrudey18Belum ada peringkat

- Finite Element Analysis On Hybrid Composite Wheel RimDokumen11 halamanFinite Element Analysis On Hybrid Composite Wheel Rimpramo_dassBelum ada peringkat

- INTRODUCTION The Fender' Called As The Mud-Guard' Is UsedDokumen13 halamanINTRODUCTION The Fender' Called As The Mud-Guard' Is Usedanon-458085Belum ada peringkat

- Best 30 D&A ABSTRACTDokumen30 halamanBest 30 D&A ABSTRACTRajadurai BaskaranBelum ada peringkat

- Proposal On Design Analysis of Composite Leaf Spring of A Light VehicleDokumen13 halamanProposal On Design Analysis of Composite Leaf Spring of A Light Vehiclecobra2919Belum ada peringkat

- Abstract-B Tech LevelDokumen11 halamanAbstract-B Tech LevelDhanish KumarBelum ada peringkat

- Carbon Fiber Subframe CAE Test ResultsDokumen22 halamanCarbon Fiber Subframe CAE Test ResultsAndreea UngureanuBelum ada peringkat

- Structural Analysis of Ladder Chassis for Higher StrengthDokumen7 halamanStructural Analysis of Ladder Chassis for Higher StrengthMohamad FaizBelum ada peringkat

- Analysis of Drive Shaft: Bhirud Pankaj Prakash, Bimlesh Kumar SinhaDokumen6 halamanAnalysis of Drive Shaft: Bhirud Pankaj Prakash, Bimlesh Kumar SinhakumarBelum ada peringkat

- Fall 2013 Final ReportDokumen16 halamanFall 2013 Final ReportPavara RanatungaBelum ada peringkat

- Brake TorontoDokumen65 halamanBrake TorontoMohseen Karche100% (1)

- Seminar 1 EditedDokumen22 halamanSeminar 1 EditedVamsi Badrinadh Naidu VaradaBelum ada peringkat

- Design of Wheel Rim and Tyre AssemblyDokumen26 halamanDesign of Wheel Rim and Tyre AssemblyAbijit Guda100% (2)

- Design Report For SAEDokumen47 halamanDesign Report For SAEJudian Anthony100% (1)

- Downloads Papers N5d6b504fab15dDokumen9 halamanDownloads Papers N5d6b504fab15dNithin SunnyBelum ada peringkat

- 272 Concept Class Mansoura University DR Rev 2Dokumen8 halaman272 Concept Class Mansoura University DR Rev 2Gazzara WorldBelum ada peringkat

- Project Report On ATV Prototype BAJA SAE INDIADokumen60 halamanProject Report On ATV Prototype BAJA SAE INDIAsanket50% (6)

- TST Paper Belt Angle GIL FinalDokumen22 halamanTST Paper Belt Angle GIL FinalGibin GilBelum ada peringkat

- 2009 67 Ilardo PDFDokumen11 halaman2009 67 Ilardo PDFChaitanya KulkarniBelum ada peringkat

- Structural Analysis of Double-Wishbone Suspension SystemDokumen7 halamanStructural Analysis of Double-Wishbone Suspension SystemIJRASETPublicationsBelum ada peringkat

- JART10-2012 Design of A Composite Drive Shaft and Its Coupling For Automotive ApplicationDokumen9 halamanJART10-2012 Design of A Composite Drive Shaft and Its Coupling For Automotive ApplicationcubanninjaBelum ada peringkat

- Design & Fabrication of Rear Outboard Wheel Assembly For An ATVDokumen5 halamanDesign & Fabrication of Rear Outboard Wheel Assembly For An ATVumeshBelum ada peringkat

- Composite Leaf Spring 1 PDFDokumen4 halamanComposite Leaf Spring 1 PDFVijay AnandBelum ada peringkat

- FEA of A CrankshaftDokumen7 halamanFEA of A CrankshaftLakshman ReddyBelum ada peringkat

- Design Analysis Fabrication and Testing of Composite Leaf Seminar ReportDokumen26 halamanDesign Analysis Fabrication and Testing of Composite Leaf Seminar Reportyash1239100% (1)

- Performance Analysis of Two Mono Leaf Spring Used For Maruti 800 VehicleDokumen3 halamanPerformance Analysis of Two Mono Leaf Spring Used For Maruti 800 VehicleVinoth KumarBelum ada peringkat

- Design of Formula SAE Suspension ComponentsDokumen13 halamanDesign of Formula SAE Suspension ComponentsYasser Rohom0% (1)

- Sinter Diffusion Bonded Idler Sprocket of Automotive EngineDokumen10 halamanSinter Diffusion Bonded Idler Sprocket of Automotive Engineمحمد تانزيم ابراهيمBelum ada peringkat

- Detailed Tire Modeling For Crash Applications: J D Reid, D A Boesch and R W BielenbergDokumen11 halamanDetailed Tire Modeling For Crash Applications: J D Reid, D A Boesch and R W BielenbergjaydeepnaruleBelum ada peringkat

- Sae Technical 2008-36-0253 Paper Series: Design and Optimization of A Space Frame ChassisDokumen11 halamanSae Technical 2008-36-0253 Paper Series: Design and Optimization of A Space Frame ChassisCharlie TejBelum ada peringkat

- Trang 81 115Dokumen35 halamanTrang 81 115Diệp Vĩ KhangBelum ada peringkat

- Ev Design Report 2018Dokumen6 halamanEv Design Report 2018Williams PoeBelum ada peringkat

- Figure 7.1 - Fearon's Final Gripper DesignDokumen8 halamanFigure 7.1 - Fearon's Final Gripper Designpatricks01_22Belum ada peringkat

- Parameters Optimization of Motorcycle FrameDokumen16 halamanParameters Optimization of Motorcycle FrameVani AdigaBelum ada peringkat

- Analisis PDFDokumen5 halamanAnalisis PDFLuis Alberto Garrido MendozaBelum ada peringkat

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallDari EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallPenilaian: 4 dari 5 bintang4/5 (8)

- The Modern Chassis: A Practical Manual of Automotive Chassis and Suspension DesignDari EverandThe Modern Chassis: A Practical Manual of Automotive Chassis and Suspension DesignPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesDari EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesBelum ada peringkat

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreDari EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MorePenilaian: 4.5 dari 5 bintang4.5/5 (11)

- 1-s2.0-S2214785322074636-mainDokumen7 halaman1-s2.0-S2214785322074636-mainjeroldscdBelum ada peringkat

- Introduction About Digital PrototypingDokumen24 halamanIntroduction About Digital PrototypingjeroldscdBelum ada peringkat

- IC Engine IES GATE IAS 20 Years Question and AnswersDokumen77 halamanIC Engine IES GATE IAS 20 Years Question and AnswersSaajal Sharma96% (26)

- Guest IntroDokumen2 halamanGuest IntrojeroldscdBelum ada peringkat

- MechanicalDokumen26 halamanMechanicalkannanviknesh086319Belum ada peringkat

- Getting Started: Overview and LogisticsDokumen7 halamanGetting Started: Overview and LogisticsjeroldscdBelum ada peringkat

- Shortcut SearchDokumen1 halamanShortcut SearchjeroldscdBelum ada peringkat

- Computer Aided Process PlanningDokumen25 halamanComputer Aided Process PlanningMayur RautBelum ada peringkat

- B.E. Mech PDFDokumen113 halamanB.E. Mech PDFarulmuruguBelum ada peringkat

- History of Strength of Materials - TimoshenkoDokumen231 halamanHistory of Strength of Materials - TimoshenkoHélio Gomes FilhoBelum ada peringkat

- InflationDokumen30 halamanInflationsumit134Belum ada peringkat

- Material Science Conventional Question and AnswerDokumen14 halamanMaterial Science Conventional Question and AnswerChitransh Agarwal100% (3)

- Development of SolidsDokumen2 halamanDevelopment of SolidsjeroldscdBelum ada peringkat

- GST Chapter Wise RateDokumen213 halamanGST Chapter Wise RateMoneycontrol News92% (280)

- 05 Introduction To AutoCADDokumen56 halaman05 Introduction To AutoCADjeroldscdBelum ada peringkat

- Instructions Installing The SoftwareDokumen1 halamanInstructions Installing The SoftwarejeroldscdBelum ada peringkat

- Intro to AutoCAD: Commands, Editing, Drawing 2D/3D ShapesDokumen20 halamanIntro to AutoCAD: Commands, Editing, Drawing 2D/3D ShapesjeroldscdBelum ada peringkat

- Orthographic Projection - WWW - Helenhudspith.com-Slash-Resources-Slash-Graphics-Slash-John - H-Slash-Orthographic PDFDokumen26 halamanOrthographic Projection - WWW - Helenhudspith.com-Slash-Resources-Slash-Graphics-Slash-John - H-Slash-Orthographic PDFjeroldscdBelum ada peringkat

- AutoCAD Tutor SolidModelDokumen19 halamanAutoCAD Tutor SolidModelHansrajKumawatBelum ada peringkat

- AutoCAD For BeginnersDokumen82 halamanAutoCAD For Beginnersdalaalstreet09Belum ada peringkat

- New Text DocumentDokumen1 halamanNew Text DocumentjeroldscdBelum ada peringkat

- AutoCAD For BeginnersDokumen82 halamanAutoCAD For Beginnersdalaalstreet09Belum ada peringkat

- Trigonometric Formula Sheet: Definition of The Trig FunctionsDokumen10 halamanTrigonometric Formula Sheet: Definition of The Trig Functionsmonelmetal100% (1)

- Problems in I UnitDokumen6 halamanProblems in I UnitjeroldscdBelum ada peringkat

- RectangeDokumen2 halamanRectangejeroldscdBelum ada peringkat

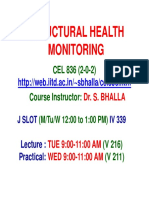

- Cel 836Dokumen11 halamanCel 836jeroldscdBelum ada peringkat

- CE6461 - Fluid Mechanics and Machinery Laboratory PDFDokumen65 halamanCE6461 - Fluid Mechanics and Machinery Laboratory PDFjeroldscdBelum ada peringkat

- Turbo and Related Codes: Theory and Design ofDokumen12 halamanTurbo and Related Codes: Theory and Design ofjeroldscdBelum ada peringkat

- QEEE-Sep2013 Presentation To TEQIP CollegesDokumen11 halamanQEEE-Sep2013 Presentation To TEQIP CollegesraviitlabBelum ada peringkat

- LinksDokumen1 halamanLinksjeroldscdBelum ada peringkat

- Brand Preference Study of Hero MotorsDokumen19 halamanBrand Preference Study of Hero Motorsrkpreethi100% (1)

- Drilling Rig Brochure DandoDokumen16 halamanDrilling Rig Brochure DandoGogot Pantja ParijogoBelum ada peringkat

- Clutches Brakes CtenDokumen156 halamanClutches Brakes CtenRiz WanBelum ada peringkat

- Locsin II v. MekeniDokumen4 halamanLocsin II v. MekeniejpBelum ada peringkat

- Lecture 02 ItM Ford Vs Sloan Case MN302Class3Dokumen4 halamanLecture 02 ItM Ford Vs Sloan Case MN302Class3Sayonee Choudhury100% (1)

- Raisoni Industrial Hinjewadi Mechanical CopaniesDokumen5 halamanRaisoni Industrial Hinjewadi Mechanical CopaniesGp MishraBelum ada peringkat

- Rammer In15Dokumen16 halamanRammer In15ANTONIO LUGOCAL100% (1)

- Organization StructureDokumen67 halamanOrganization StructureDivya AgarwalBelum ada peringkat

- Timing Belt Mazda Millenia S 2002Dokumen5 halamanTiming Belt Mazda Millenia S 2002Carlos MendozaBelum ada peringkat

- Man EpbDokumen4 halamanMan EpbDimaBelum ada peringkat

- Oil ChangeDokumen10 halamanOil ChangeAzeem SarwarBelum ada peringkat

- The Valley's Nickel Volume 1 Issue 23Dokumen20 halamanThe Valley's Nickel Volume 1 Issue 23The Valley's NickelBelum ada peringkat

- Media Planning For Toyota PriusDokumen44 halamanMedia Planning For Toyota PriusNicole Faiella100% (1)

- BAJA SAE-India Rulebook 2022Dokumen155 halamanBAJA SAE-India Rulebook 2022SakthiBelum ada peringkat

- Project On (Tata Motors)Dokumen61 halamanProject On (Tata Motors)SATYABRAT MAHALIK100% (1)

- Appraisal of Multilevel Car Parking Facility at KG Road-Cbd Area, Bengaluru CityDokumen16 halamanAppraisal of Multilevel Car Parking Facility at KG Road-Cbd Area, Bengaluru CityesatjournalsBelum ada peringkat

- Feniex Pegasus Apollo Interior Light BarDokumen16 halamanFeniex Pegasus Apollo Interior Light Bardonald_wilson4741Belum ada peringkat

- Torin 2-Ton Hydraulic Trolley Jack ManualDokumen6 halamanTorin 2-Ton Hydraulic Trolley Jack ManualWIRAKOCHABelum ada peringkat

- Lecture 3 CasesDokumen3 halamanLecture 3 CasesSrabon AhmedBelum ada peringkat

- Clay Brick Making Machine Mew CB 3000Dokumen5 halamanClay Brick Making Machine Mew CB 3000Aakansh NigamBelum ada peringkat

- OTR Load InflationDokumen77 halamanOTR Load InflationAchmad AnwarBelum ada peringkat

- Nissan Service and Maintenance Guide 2011Dokumen5 halamanNissan Service and Maintenance Guide 2011claude100% (50)

- Samuk ForkliftDokumen14 halamanSamuk ForkliftFajrin M. NatsirBelum ada peringkat

- Bpme 6093 Modenas Combine LastDokumen12 halamanBpme 6093 Modenas Combine LastjibamcomotBelum ada peringkat

- Report - Electric VehiclesDokumen32 halamanReport - Electric VehiclesTechSci Research100% (2)

- Slip Ring PresentationDokumen12 halamanSlip Ring PresentationMynampati Sai SrinivasBelum ada peringkat

- 2013 March UpdateDokumen16 halaman2013 March UpdateAnonymous 9eadjPSJNgBelum ada peringkat

- Mindex Resources Development vs. Ephraim Morillo DigestDokumen1 halamanMindex Resources Development vs. Ephraim Morillo DigestlawBelum ada peringkat

- Companies DirectoryDokumen137 halamanCompanies DirectorySiddhartha Govil75% (4)

- BuriDokumen73 halamanBuriFaizan NazirBelum ada peringkat