OTC 7478 Planning For Abandonment: T.W. Bartlett, Amoco (UK) Exploration Co

Diunggah oleh

Muhammad NizamiJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

OTC 7478 Planning For Abandonment: T.W. Bartlett, Amoco (UK) Exploration Co

Diunggah oleh

Muhammad NizamiHak Cipta:

Format Tersedia

OTC 7478

Planning for Abandonment

T.W. Bartlett, Amoco (UK) Exploration Co.

Copyright 1994, Offshore Technology Conference

This paper was presented at the 26th Annual OTC In Houston, Texas, U.S.A., 2-5 May 1994,

This paper was selected for presentation by the OTC Program Committee following review of information contained in an abstract submitted by the author(s). Contents of the pap.er,

as presented, have not been reviewed by the Offshore Technology Conference and are subject to correction by the author(s), The material, as presented, does not necessarily reflect

any position of the Offshore Technology Conference or its officers. Permission 10 copy is restricted to an abstract of not more Ihan 300 words. lIIustratlon~ may not be copied. The abstract

should contain conspicuous acknowledgment of where and by whom the paper Is presented.

ABSTRACT

Commendable words of introduction one might say! but

how does one go about this planning exercise, being

creative and having lateral thinking, receive participation

from other operators within this industry to achieve a:

The objective of this series of papers is to address the

pressing issues surrounding the concept of abandonment

of Northern North Sea offshore production facilities and

structural steel jackets. For many operators there is a

notional idea that when you are finished with an offshore

production facility and structural steel jackets, they

merely sails away over the horizon never to be seen or

heard of again, but the real world dictates otherwise.

" SAFE AND COST EFFECTIVE DiSPOSITION FOR

SUCH A FACILITY"

The Oil and Gas industry until now has been rather slow

and reluctant to respond to the idea that abandonment is

right around the corner. A question that has been so

prevalent in recent days, "WHY PLAN"?

For those that operate today in the Northern North Sea

there is perhaps a uniqueness in character related to the

design, fabrication, installation and operation of these

Northern North Sea offshore production facilities.

Approaching now for many the reality of abandonment,

removal and disposal of these facilities, the oil and gas

industries must now also recognise that unique

methodology requires to be developed for implementation

to overcome this daunting task of abandonment.

Innovative and lateral thinking being employed by those

companies and individuals who have risen to take up the

challenge to achieve the goals and objectives, developing

the ultimate solution to this enormous problem facing the

oil and gas industry today.

"Just hecause I never lead the industry in such

circumstances, does not mean I am not responsihle for

planning them all well"

A deliberate Abandonment Plan is the most essential tool

that must be developed at the outset of the abandonment

project, ensuring that you have defined clearly your goals

and objectives to produce a safe and cost effective

disposition for the offshore production facilities and

structural steel jacket. Planning allows for abandonment

projects to :-

Many common aspects and activities exist for operators to

undertake jointly during the planning, engineering and

the various implementation stages for this ultimate episode

in field life.

Set out the strategy, philosophy, goals and

objectives for the abandonment programme.

Identify the requirements of

the various

legislation that must be adhered too.

Identify the potential

emironmental

issues

"GOING WHERE NO OTHER HAS GONE BEFORE"

References, nomenclature and figures at end of paper.

93

hazards, safety and

to

be

resolved.

PLANNING FOR ABANDONMENT

Identify the cost drivers.

Communicate to your management the magnitude

of the potential problems that must be overcome.

Communicate to the relevant govemment

departments the prospective options under

consideration and the potential consequences.

Planning may be half the effort required to accomplish the

goals and the objectives of the abandonment project, but it

is only a fraction of the ultimate cost. Through careful and

detailed planning exercises an opportunity exists to save

millions of pounds that could be better invested in the

development of new oil and gas fields. One must always

remember that the ultimate cost of engineering, platform

removal and disposal could well exceed the original

investment for the facility. The investment into

abandonment of offshore facilities is not recoverable and

does not pay dividends on capital expenditure to the

shareholders.

Utilising the planning process correctly provides

opportunities to eliminate and engineer out those

technical, safety and environmental problems that if not

dealt with in a timely manner could in effect cause

escalation in costs to the point of, "BREAKING the

BANK" to rectify and recover the situation.

ABANDONMENT

During the planning

process for abandonment

there are limited periods

of time that the process

can stop, but ultimately

the facility must be

abandoned and removed

to some degree.

Planning for first oil or

gas imposes an ultimate

date to meet the

commitment to supply

the market place with

product.

No such date exists when

planning for

abandonment, no market

forces are imposed, no

product to produce

revenue.

Planning for installation

utilising conventional

methods e.g. SSCV's

could mean entering

into contracts that are

expensive due to market

demand.

Abandonment of

platforms does not

necessarily rely on

conventional methods

e.g. SSCV's

Topsides and jackets are

fabricated in various

types of construction

yards depending on the

available facilities.

The yards utilised in

construction are not

necessarily suitable for

receiving large

quantities of modules

from offshore facilities.

Loading out of topsides

and jackets from

constmction yards are

by particular methods in

order that they can be

installed to suit the

platform topsides

arrangement.

Loading out of topside

modules may not be

removed in a similar

manner as modifications

will be necessary to

reinstate the structural

integrity and lifting

capability.

LEGISLATION GOVERNING ABANDONMENT

There are several key legislative documents that must be

considered and taken into account when planning for

abandonment in the UK sector of the North Sea.

There is this misconception that abandonment of offshore

facilities is the reverse of the installation process, nothing

could be further from the truth.

INSTALLATION

During the planning

process for the

development of an

acreage there are

discrete time periods

where the design,

procurement,

construction,

installation,

commissioning and

reservoir exploitation

can be stopped for a

number of reasons.

OTC 7478

THE PETROLEUM ACT 1987

There are several pieces of legislation that refer to

abandonment of offshore platforms on the United

Kingdom Continental Shelf (UKCS), none of which

attempted to clarify UK legal responsibilities until the

Petroleum Act of 1987. The UK govemment's position

prior to this act coming into force was to keep removal

costs to a minimum whilst safeguarding navigation and the

interest of users of the sea, protecting the marine

environment and adhering to the Oslo and London

Dumping Conventions. Prior to this act, the Secretary of

State had such power to carry out the abandonment and

recover all the cost from the operator. This act gave the

Secretary of State the following additional powers :

To give written notice requiring the submission of

abandonment proposals, with the person or

persons given notice liable for the discharge of the

abandonment obligations.

To make such regulations relating to

abandonment, which may include but not be

limited too :-

1.

94

Standards and safety

requirements

dismantling, removal and disposal.

for

OTC 7478

THOMAS WILLIAM BARTLETT

2.

Standards and safety requirements for any

remaining seabed debris resultant from partial

removal.

3.

Provisions for the prevention of pollution.

Due to the rapid advances in technology it became evident

that the existing National and International law including

the 1958 convention would require significant changes. In

1982 a major review was undertaken and the bases of the

conference were:-

4.

Provision for inspection.

Notice should be given of all proposals for the

construction of offshore platforms.

5.

Provide means to ensure any party is capable of

carrying out their obligations, and if not satisfied,

detail necessary action to be implemented.

There must be permanent means of warning of

their presence.

6.

Having the right to carry out such work that it

meets the criteria set out by the Secretary of State

and to recover all cost from the said party.

Abandoned and disused structure shall be

removed to give safety to all navigation with

respect to existing navigation standards.

7.

Provide penalties for the failure to comply with

such notices.

The position, depth and dimension of all partially

removed structures shall be made public

knowledge.

These and other details are covered in additional

references.

CONVENTIONS 1972

These conventions introduced regulations primarily to

govern and protect the marine environment from

pollution. The London Convention prohibits global

dumping of oil and requires a special permit to be granted

for the dumping of scrap metal and bulky material, this

would include such things as platform topsides and

structures. This is perhaps less clear in the Oslo

Convention which covers specifically the North East

Atlantic and the North Sea. Although dumping of waste

from a platform is prohibited, it is not clear if the intent is

to cover the disposal of topsides and' structures by

dumping. The Oslo and London Conventions are

implemented in the UKCS under the Dumping at Sea Act

of 1974, prohibiting the permanent disposal of substances

and articles at sea, except in accordance with these

conventions.

The Secretary can also serve notices to anyone connected

with the operation of offshore platforms, in fact all

operators currently operating such facilities in the UKCS

have been given notice as of January 1988 to submit their

removal plans.

The Petroleum Act does not define the actual removal

standards as the UK government has held in abeyance

such standards until such times that there is an

international agreement. However, the UK government

has stated in 1989 and 1990 that removal standards will

include and take into account. fishing interests,

environmental considerations and the guideline published

by the International Maritime Organisation (IMO).

THE COASTAL PROTECTION ACT 1949

To bring some focus on the whole subject of planning for

abandonment several key questions must be answered :-

This act governs exploration and exploitation in the

UKCS, but it is not specific with regard to platform

abandonment, removal and disposal. Following this, the

Coastal Protection Act required permission from the

Department of Trade and Industry (DTI) to install

offshore structures, provided that there was no obstruction

or danger to navigation. The provisions under this Act

were extended in 1964 under the Continental Shelf Act,

under which permission to remove any object from the

seabed must first be obtained from the DTI.

What time frame am I working in.

How long will it take.

What must I produce.

What issues must I address.

THE GENEVA CONVENTION 1958

Who wants all this information.

Under Article 5.5 it states that an installations either

disused or abandoned must be removed to seabed level,

these regulations were later adopted at the first United

Nations Conference on the Law of the Sea (UNCLOS).

What is for "Information Only" and what is for

"Approval".

When must it be submitted.

UNCLOS 1981

What expertise is available.

95

PLANNING FOR ABANDONMENT

What resources are required.

How much will it cost.

WHAT TIME FRAME

Hopefully by the time we finish these presentations you

will have started the planning process. You can never start

too early in fact abandonment planning should be part of

the process you go through when you plan for the

development of some offshore acreage, if you don't you

could be too late. Time is of the essence, should your

offshore facility be abandoned in the next five years then

you should be started and developing those options you

think are feasible for your facility. If the year 2000 - 2005

is your time frame then you must seriously consider

starting your planning now.

HOW LONG WILL IT TAKE

To set the bench mark, in the UK sector the operator must

submit his abandonment Safety Case at least six months

prior to the planned date for implementation of the

deconstruction programme. Simple engineering norms can

be applied to determine the start date which is probably

3/4 years prior to your submission.

OTC7478

Should a major piece of equipment fail will it be

replaced or will it be the controlling factor in the

decision.

Should you stop producing before reservoir

abandonment commences or should you produce

down to the last well.

What process will be implemented during

reservoir and well abandonment.

What equipment, tubing and conductors will be

recovered in the well abandonment programme.

How will the conductors be recovered and broken

down.

What method will be implemented in process and

utility cleaning.

What methods

deconstruction.

What are the issues associated with each option.

What methods

deconstruction.

are

are

available

for

available

for

topsides

jacket

WHAT MUST I PRODUCE

What are the issues associated with each option.

There are four key documents that must be produced and

submitted to government.

What are the safety issues and criteria.

Long Term Development Plan.

Where and how can topsides and structures be

disposed off.

Cessation of Production (COP) Document.

What are the environmental issues and criteria.

Costed Abandonment Plan (CAP)

Platform Abandonment Safety Case

What are the issues and criteria for the

environmental assessment.

What engineering and validation activities are

required.

What legal aspects must be addressed.

What are the liabilities and how can they be

disposed off.

Tax liabilities e.g. VAT, Import Tax, Corporation

Tax and Capital Gains Tax.

WHAT ISSUES MUST BE ADDRESSED

There are many and varied issues to be addressed by

during the planning for abandonment phase. This has

often been referred to as the Pandora's box, when you

think you have addressed every thing possible, you open

what might be considered the last door, just to find several

more issues. The last issue will be address when you finally

dispose of your liability.

What optimisation can be implemented to defer

abandonment.

When is a facility sub economic.

Should a major piece of equipment that is retired

from service be reclaimed to reduce operational

and maintenance burdens.

WHO WANTS ALL THIS INFORMATION

As abandonment in the UK at present is on a "Case by

Case" submission, no precedence will be set by previous

platform abandonment e.g. "Piper Alpha". Therefore

every operator is faced with going through the same

procedure producing the same amount of information and

re inventing the wheel in many instances for every

96

OTC 7478

THOMAS WILLIAM BARTLETT

platform. In the UKCS the DTI will be the recipient of all

the information generated during the planning phase

simply to demonstrate that every aspect has been

identified, addressed, costed and taken into account prior

to applying for formal "Approval" to abandon the

offshore facility.

3.

WHAT IS FOR "INFORMATION ONLY"

WHAT IS FOR "APPROVAL".

All the information generated during engineering studies,

conceptual and detail design activities which evaluates and

fully costed potential abandonment options must be

reviewed by the DTI. There is a requirement for every

operator to produce and submit for "Approval" a fully

costed abandonment plan prior to the commencement of

the abandonment implementation programme. This fully

costed abandonment will contain all the relevant

information describing the proposed and alteruative

abandonment options addressing all the issues associated

with it.

WHEN MUST IT BE SUBMITTED

As previously identified there are four key documents that

must be developed and submitted to various UK

government departments for acceptance and / or

approval.

1.

The Long Term Development Plan is submitted to

the DTI sometime during the early years of the

field development and exploitation. This plan

describes the strategy to maximise the recovery of

the reserves, highlighting key milestones to be

achieved and potential end of field life date. This

is submitted for review and acceptance by the

DTL

2.

The Cessation of Production (COP) document is

submitted to the DTI some 3 to 4 years prior to

the economic limit being reached. This COP

document will contain but not be limited to the

following information:-

Technical description of the reservoir.

Technical description of process and utility

optimisation.

Production profile through end of field life.

Description of possible uses for the field.

Conceptual abandonment plans.

Order of magnitude cost estimates for the

abandonment.

The Costed Abandonment Plan will be developed

during the last 3 - 4 years of the field life as the

operator plans for the abandonment of the

offshore facility. This must be submitted in a

timely manner to the DTI for "Approval" from

the Secretary of State to allow the deconstruction

programme to commence.

Reservoir and well abandonment programme is submitted

on a "well by well" case 28 days prior to the Health and

Safety Executive (HSE) and the Department of Trade and

Industry (DTI) for approval to abandon the reservoir and

well. A well is only considered suspended if the final cap

has not been installed and the conductors removed.

4.

The Platform Abandonment Safety Case must be

submitted at least six months in advance of the

planned deconstruction date to the HSE for

"Approval".

WHAT EXPERTISE IS AVAILABLE

This topic highlights an area where very little

development work has been undertaken either by the Oil

and Gas industries and those contractors who provide

support. Up until now the general consensus has been its

years away and we will think about when its more

convenient. When one considers the sums of money spent

on training and retraining of personnel in the industry

today to meet the rigorous demands of tomorrow, there is

not a true expert to be found. Its perhaps the old cliche

once again, "WHAT COMES FIRST THE CHICKEN OR

THE EGG", we have no experts because we have never

done it on this scale before.

We have no abandonment expertise because that is not the

industry we are in, oil and gas production is where we

generate our major cash flow therefore our effort is

focused on that aspect. The day has arrived and now is

when planning for the future platform abandonment's

demands that we have a level of expertise to meet the

challenge.

WHAT RESOURCES ARE REQUIRED

Due to the very complex nature abandonment it is evident

that many new skills require to be developed,

incorporating and drawing upon existing skills that could

enhance the planning and management this new business.

If we don't have the proper level of skilled resources then

there is that possibility that the wrong option could be

embarked upon with catastrophic results, with the

industry paying the penalties.

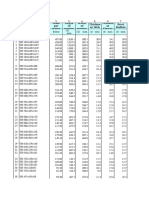

HOW MUCH WILL IT COST

97

Development of cost for the various options that are

available has been a time consuming exercise for there is

no cost data base to draw upon. Opdons have been

PLANNING FOR ABANDONMENT

developed to a level in order that realistic costs could be

projected with some level of confidence. Building up cost

from first principals has indicated that the ultimate cost

could far exceed those cost experienced in the planning

and development of these offshore fields.

OTC 7478

THE PROJECT PLAN

Developing the Project Plan without drawing upon vital

input and experience from the identified areas of expertise

to accomplish the project goals and objectives, then the

whole plan will be severely limited in the ability to

implement and measure actual performance and success.

Several areas of catastrophic failure could be experienced

in determining the schedule for design activities,

procurement of materials, securing essential contractors,

equipment and resources and the control of costs etc. The

Project Plan clearly identifies key milestones, deliverables

and resources highlighting the critical path for the

project. Key drivers are also identified approvals,

consents, abandonment safety case, environmental

assessment and deconstruction work packs and contracts.

"NEVER BEFORE HA VE OPERATORS HAD SO LITTLE

TIME IN WHICH TO DO SO MUCH"

Effective management of time and resources being vital

commodities in the battle for better understanding of the

real issues in order that realistic goals and objectives may

be set and achieved. The oil and gas industry should never

under estimate the true cost in time and resources to

establish the requirements of government legislative

documents and the way they will be interpreted for

implementation.

EXECUTION PLAN

OPPORTUNITY TO DEVELOP

FOR DE-CONSTRUCTION

METHODOLOGY

Development of the Execution Plan is on the critical path

during the early stages of design activities drawing upon

the various areas of expertise such as design contractors,

fabricators, marine contractors and specialised trades etc.

Major limiting factors to be addressed are such things as

essential personnel, logistics, specialised trades, equipment

and even the weather. Considering that the deconstruction

site may be two or three hundred miles from shore in a

hostile offshore environment, making it critical that work

activities are clearly defined with resources, material and

work plan.

Today we approach the subject of abandonment with a

traditional approach, being equivalent to designing a

product without contemplating how it will be produced, or

is there a market for this product. There are great

opportunities available to change the paradigms associated

with the planning, engineering and implementation of an

abandonment programme because of the unique nature of

this new business.

BENEFICIAL OPPORTUNITY MISSED

DECONSTRUCTION METHODS

Considering how great this opportunity really is, why have

so many failed to recognise it and enjoy the benefits.

There are many apparent reasons for this. The industry

takes it for granted that if we build under certain criteria,

then all we need to do is reverse the process. Contractual

issues around the sale of oil and gas are key drives for the

engineering design, procurement, construction and

installation, and in many ways precludes innovative and

effective engineering and true integration with design

engineers, construction and operational personal. Without

developing de-contructability programmes and assigning

of expertise at an early time in the project, the

opportunity is lost to develop the most cost effective,

environmentally acceptable and safe option for the final

disposition of an offshore production facility.

Early design decisions which preclude the use of

technology, construction and deconstruction methods will

create major de-constructability problems. Therefore it is

essential that an open mind approach to the subject of

abandonment be adopted by those engaged in the

development of the various techniques. Innovative and

lateral thinking must be applied to the problems,

establishing the design criteria, selection of methods and

associated equipment. Missing the opportunities to utilise

specialised techniques, equipment and operators which

would bring beneficial cost reduction and savings on

scheduled time.

DISPOSAL

Considering all of the current legislation and how it

relates to the disposal of 60,000 tonnes of structural steel

and process and utility equipment in an acceptable

manner being consistent with Company Policy to produce

a Disposal Plan that is environmentally friendly and safe.

Substantial effort is required in co-ordinating input from

government departments such as the Department of the

Environment, Scottish Office, Department of Fisheries,

Department of Trade and Industry and the Health and

Safety Executive.

RECOGNISING THE PROBLEMS

The oil and gas industry is often like the ostrich with its

head buried in the sand, "If I can't see it, then its not

there". As responsible operators we must change this

approach to doing our business and recognise that there

are many problems associated with the subject of

abandonment, therefore it is incumbent upon the industry

to recognise and resolve these issues cost effectively,

environmentally acceptable and safely.

98

OTC 7478

THOMAS WILLIAM BARTLETT

These issues that have been outlined present the key to the

way forward, giving an opportunity to improve deconstruction programme and the true cost effectiveness of

the project. Highlighting the potential hurdles and

methods to be overcome them enables management and

engineers and contractors to seize the opportunity to

develop innovative and lateral thinking to develop the cost

effective, environmentally acceptable and safe solution for

deconstruction and disposal.

ESSENTIAL

ELEMENTS

PROJECT PLANNING

FOR

SUCCESSFUL

Project planning is the framework that supports the links

between conceptual ideas and the realisation in successful

final execution. What are the basic assumption that make

a successful project happen;

The project goals and objectives must correlate

with those of the Company, the implementation of

the Abandonment Plan which secures a cost

effective, environmentally accepted and safe

project.

To a~hieve these goal the project team must

improve the process of effective project planning.

The planning process requires to have measurable

criteria, so that the processes can be evaluated,

demonstrating that the goals and objectives are

being attained.

root problems can be successfully addressed, then

there is a chance that a "De-constructable"

solution can be achieved.

OVERLOOKED ISSUES

Observing the ground rules is essential if a successful

project is to be realised, therefore the need to prioritise

these in respect to importance, criticality, high risk and

escalation etc. Up until now very little has been considered

on the aspect of timing and the rate of planning for

abandonment.

As an anticipatory decision making methodology and

process, the timing element is central to good planning.

The tool often used to demonstrate the effective planning

exercise is the schedule. The schedule must be detailed

sufficiently to highlight the sequential activities, milestone

dates, deliverables and critical path being updated on a

daily bases. There are of course many other important

time related issues which are overlooked from time to

time.

Realisation that good planning requires dedicated and

experienced personnel for the duration of the

abandonment project cannot be overstated. There are

many issues to be address on the subject of the timing

process of project planning, and it is not the intention of

the discussion in this paper to resolve these.

MANAGEMENT OF DECISIONS

A methodology requires to be developed for

decision making processes to effectively influence

the planning mechanism by organising, who does

what, when and how will it be done.

Don't plan by crises, but rather by proactively

identifying and addressing the issues in a timely

manner, before they happen.

Embarking on the abandonment project planning high on

the priority list of activities is the frequency and the

importance of how, when and who gives approval for

continuance. The outline discussion on abandonment

planning has considered the project goals and objectives,

the opportunities and the timing of decisions etc. would

indicate that there is a major role to be played, that of the

project manager who is there to manage the decision

making process.

Variances in situations demand a flexible

approach to planning, so that adjustments can be

incorporated easily, that expectations and

achievements can be realised. Contextual factors

surrounding abandonment projects, e.g. political,

environmental, safety and even technology have

and influence on the final implementation plan.

The roles and responsibility of the project manager is

critical, primarily there to plan this process, direct and

control it. It has been suggested that in establishing the

abandonment project the prime role of the project

manager is not to co-ordinate or integrate, neither to

make decisions, but rather to manage the decision making

process.

Pragmatism should be one of those guideline that

must be included in the search for the ultimate

abandonment solution by removal of planning

obstacles. There is no lack of abandonment

techniques, but there is a lack in planning

techniques implemented by management. So often

we have to deal with the symptoms of our

working environment, rather than dealing with

the root cause of our problems. If in fact these

The management of the decision making process should

include but not be limited to the following;

99

Development of a strategy for dealing with the

uncertainty, and uncontrollable factors.

Development of methodology and criteria for

evaluation and problem solving.

PLANNING FOR ABANDONMENT

Develop

guidelines

and

procedures

for

information gathering and decimation, decision

making, and project control measures.

Development of the integrated project team, goals

and objectives, roles and responsibilities.

Managing and control of the decision making

process without causing conflict of interest in the

overall project plan.

2.

THE COASTAL PROTECTION ACT 1949

3.

UN CONFERENCE ON THE LAW OF THE

SEA 1958

4.

THE GENEVA CONVENTION 1958

5.

UNCLOS 1981

6.

THE OSLO AND LONDON DUMPING

CONVENTIONS 1972

7.

INTERNATIONAL MARITIME

ORGANISATION 1987

8.

ENERGY SELECT COMMITTEE 1991

9.

OFFSHORE INSTALLATION (SAFETY CODE)

1993

10.

DUMPING AT SEA ACT OF 1974,

11.

EUROPEAN COMMUNITY DIRECTIVES

12.

THE INTERNATIONAL COMMISSION FOR

RADIOLOGICAL PROTECTION (ICRP) 1977

13.

THE IONISING RADIATION REGULATION

(IRR) 1985

14.

THE RADIOACTIVE SUBSTANCE ACT (RSA)

1960

15.

THE INTERNATIONAL ATOMIC ENERGY

AUTHORITY (IAEA)

16.

THE CONTROL OF SUBSTANCES

HAZARDOUS TO HEALTH (COSHH)

REGULATION 1988

(GENERAL ACOP - THIRD EDITION)

17.

THE CONTROL OF CARCINOGENIC

SUBSTANCES (CCS) (CARCINOGENS ACOP THIRD EDITION)

18.

CLASSIFICATION, PACKAGING AND

LABELLING OF DANGEROUS SUBSTANCES

(CPLDS) REGULATION 1984

19.

THE ASBESTOS REGULATION 1969

20.

HEALTH AND SAFETY AT WORK ACT 1974

21.

OFFSHORE SAFETY (OPERATIONAL

SAFETY, HEALTH AND WELFARE)

REGULATION 1976

SUMMARY

In summary, the practise of simple procedures and

techniques to create and develop a systematic awareness to

project management, project planning and decision

making is essential to achieving an approved

abandonment and execution plan. The results that could

be experienced by the oil and gas industries are significant

financial saving that can be invested in the development of

new fields.

OTC 7478

ACKNOWLEDGEMENT

The author wish to thank Amoco (UK) Exploration

Company for their permission to publish this paper and

the co-operation received from Amoco Resource

Development Groups.

BmLIOGRAPHY

Source documents (4) 1986, (45) 1989, (48) 1990

Amoco, Abandonment Feasibility Study Vol. 1-5, 1993

ABBREVIATIONS

UK

UKCS

DTI

HSE

DoE

DoAF

UNCLOS

HLV

SSCV

LAT

SMFL

TCV

VLCC

MOB

DEMOB

LSA

CCTV

United Kingdom

United Kingdom Continental Shelf

Department of Trade and Industry

Health and Safety Executive

Department of the Environment

Department of Agriculture and Fisheries

United Nations Conference on the Law of

the Sea

Heavy Lift Vessel

Semi Submergible Crane Vessel

Lowest Astronomical Tide

Ship Mounted Fork Lift

Travelling Crane Vessel

Very Large Crude Carrier

MObilisation

De-mobilisation

Low Specific Activity

Closed Circuit Television

REFERENCES

1.

THE PETROLEUM ACT 1987

100

Anda mungkin juga menyukai

- Permanent Packer Removal TechniquesDokumen35 halamanPermanent Packer Removal Techniquesmahimoh18Belum ada peringkat

- Standard dimensions and data for steel and stainless steel pipe sizesDokumen7 halamanStandard dimensions and data for steel and stainless steel pipe sizesRSGatesBelum ada peringkat

- A Guide to the Collision Avoidance RulesDari EverandA Guide to the Collision Avoidance RulesPenilaian: 3.5 dari 5 bintang3.5/5 (8)

- SPE-38513-MS The Subsea Well Decommissioning ProjectDokumen9 halamanSPE-38513-MS The Subsea Well Decommissioning ProjectÓscar MedinaBelum ada peringkat

- International Rules On Decommissioning of Offshore InstallationsDokumen10 halamanInternational Rules On Decommissioning of Offshore InstallationsAbdul QaiyumBelum ada peringkat

- Safety of Offshore Structures PDFDokumen46 halamanSafety of Offshore Structures PDFAnonymous IwqK1NlBelum ada peringkat

- The Practice of Reservoir Engineering (Revised Edition)Dari EverandThe Practice of Reservoir Engineering (Revised Edition)Penilaian: 5 dari 5 bintang5/5 (3)

- Offshore StructureDokumen124 halamanOffshore Structureirawantani100% (2)

- UKOOA FPSO Design Guidance NotesDokumen176 halamanUKOOA FPSO Design Guidance Notesnazwan14100% (5)

- Technology For Developing Marginal Offshore OilfieldsDokumen250 halamanTechnology For Developing Marginal Offshore Oilfieldseminent80100% (1)

- Marine and Offshore Pumping and Piping SystemsDari EverandMarine and Offshore Pumping and Piping SystemsPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- (LECTURE) Design of Fixed Offshore StructuresDokumen248 halaman(LECTURE) Design of Fixed Offshore StructuresBreezze Ezzeerb100% (2)

- Offshore Projects and Engineering ManagementDari EverandOffshore Projects and Engineering ManagementPenilaian: 5 dari 5 bintang5/5 (2)

- PDF MC NorskDokumen56 halamanPDF MC NorskIsaac EliasBelum ada peringkat

- Offshore Oil and Gas Overview of (Dti)Dokumen30 halamanOffshore Oil and Gas Overview of (Dti)Gabriel OkuyemiBelum ada peringkat

- 1.01D21A Post perp-TYPE - II B1 (UC152x152X37) Tob2 (UC203X46)Dokumen49 halaman1.01D21A Post perp-TYPE - II B1 (UC152x152X37) Tob2 (UC203X46)balaBelum ada peringkat

- Marine Structural Design CalculationsDari EverandMarine Structural Design CalculationsPenilaian: 4.5 dari 5 bintang4.5/5 (13)

- Report PDFDokumen29 halamanReport PDFmuhammad sholehBelum ada peringkat

- Decomission F Jacket PDFDokumen40 halamanDecomission F Jacket PDFRicardo FigueiredoBelum ada peringkat

- The Economics of Upstream Petroleum ProjectDokumen18 halamanThe Economics of Upstream Petroleum ProjectBenny Lubiantara89% (9)

- The Economics of Upstream Petroleum ProjectsDokumen18 halamanThe Economics of Upstream Petroleum ProjectsRidha ArisBelum ada peringkat

- Offshore Helideck Design GuidelinesDokumen307 halamanOffshore Helideck Design Guidelinestambok100% (1)

- Decommissioning in The North Sea - Demand Vs Capacity - Low-ResDokumen100 halamanDecommissioning in The North Sea - Demand Vs Capacity - Low-ResQasim Ismail100% (1)

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceDari EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceBelum ada peringkat

- Oil and Gas Field Development Lecture NotesDokumen34 halamanOil and Gas Field Development Lecture NotesAlhaj MassoudBelum ada peringkat

- ADIPEC Paper - Extending The Life of An Ageing Offshore FacilityDokumen11 halamanADIPEC Paper - Extending The Life of An Ageing Offshore FacilityPasquale CutriBelum ada peringkat

- Concrete Batch Plant Control Plan PDFDokumen42 halamanConcrete Batch Plant Control Plan PDFkatfy1Belum ada peringkat

- HSE in Well OpsDokumen34 halamanHSE in Well OpsethelchudiBelum ada peringkat

- FPSO Design and Conversion-A Designer ApproachDokumen21 halamanFPSO Design and Conversion-A Designer ApproachDzakyHaidar100% (1)

- Fisher Maritime Fisher Maritime: Management of Shipyard Projects: Insights and Lessons LearnedDokumen32 halamanFisher Maritime Fisher Maritime: Management of Shipyard Projects: Insights and Lessons Learnedgeorgekc77Belum ada peringkat

- 2006 OA On The Execution of A Fast-Track Disconnectable FPSODokumen25 halaman2006 OA On The Execution of A Fast-Track Disconnectable FPSOUthanmalliah NagarajanBelum ada peringkat

- New Technologies for Emission Control in Marine Diesel EnginesDari EverandNew Technologies for Emission Control in Marine Diesel EnginesBelum ada peringkat

- Standard Design of SilosDokumen12 halamanStandard Design of SilosTarun VermaBelum ada peringkat

- Enhanced Heavy Oil Recovery Using Steam InjectionDokumen5 halamanEnhanced Heavy Oil Recovery Using Steam InjectionabdobedirBelum ada peringkat

- FPSODokumen6 halamanFPSONatanael ZangerolamoBelum ada peringkat

- DNV Template Biofouling Management Plan Rev1 Tcm4-524330Dokumen14 halamanDNV Template Biofouling Management Plan Rev1 Tcm4-524330Mary Smith100% (1)

- Design of Floating Offshore Platform Technical ReportDokumen18 halamanDesign of Floating Offshore Platform Technical Reportjeremytoh89Belum ada peringkat

- DNV Template Biofouling Management Plan Rev1 tcm142-524330Dokumen16 halamanDNV Template Biofouling Management Plan Rev1 tcm142-524330Baba Ghanoush100% (1)

- Energies: Technical Definition of The Tetraspar Demonstrator Floating Wind Turbine FoundationDokumen11 halamanEnergies: Technical Definition of The Tetraspar Demonstrator Floating Wind Turbine FoundationMahmoudBelum ada peringkat

- Marine Port Structure GuidanceDokumen12 halamanMarine Port Structure Guidancemulyadi100% (1)

- Green Ports: Inland and Seaside Sustainable Transportation StrategiesDari EverandGreen Ports: Inland and Seaside Sustainable Transportation StrategiesPenilaian: 5 dari 5 bintang5/5 (1)

- Term Paper On Oil Field Development PlanDokumen9 halamanTerm Paper On Oil Field Development Plane9xsjk8h100% (1)

- Whitepaper - Boat Landing Replacement - QatarDokumen13 halamanWhitepaper - Boat Landing Replacement - QatarRavikumar mahadevBelum ada peringkat

- Mek4450 Marine Opertaions Theory PDFDokumen50 halamanMek4450 Marine Opertaions Theory PDFdsrfgBelum ada peringkat

- What The North Sea Can Teach The WorldDokumen9 halamanWhat The North Sea Can Teach The WorldJohn simpsonBelum ada peringkat

- OTC 20489 Azurite Field Development: FDPSO Design and Integration ChallengesDokumen11 halamanOTC 20489 Azurite Field Development: FDPSO Design and Integration ChallengessubramanianBelum ada peringkat

- My National and Comparative Oil and Gas PaperDokumen14 halamanMy National and Comparative Oil and Gas PaperDominic KyaloBelum ada peringkat

- Guide to Onshore Oil and Gas Field DevelopmentDokumen15 halamanGuide to Onshore Oil and Gas Field Developmentghostforever0Belum ada peringkat

- APPEA-Offshore Oil and Gas Decommissioning Decision-Making Guidelines July 2016 AustraliaDokumen19 halamanAPPEA-Offshore Oil and Gas Decommissioning Decision-Making Guidelines July 2016 AustraliaDustin WalkerBelum ada peringkat

- DecommissioningDokumen7 halamanDecommissioningYong Kai MingBelum ada peringkat

- SNAME-ToS-2019-010 (Review of Offshore Mooring System Life Extension - Challenges and Recommendations)Dokumen16 halamanSNAME-ToS-2019-010 (Review of Offshore Mooring System Life Extension - Challenges and Recommendations)ManuelBelum ada peringkat

- Onshore FDP Guidance Aug 2016Dokumen12 halamanOnshore FDP Guidance Aug 2016irene oriarewoBelum ada peringkat

- Abandono de PozosDokumen3 halamanAbandono de PozosRodolfo CabreraBelum ada peringkat

- Dry Dock - MSC Circ1223 (E)Dokumen2 halamanDry Dock - MSC Circ1223 (E)RasmiCoolBelum ada peringkat

- IMO Marine Environmental Protection Committee - March 2010 - tcm155-193338Dokumen4 halamanIMO Marine Environmental Protection Committee - March 2010 - tcm155-193338Nick GounarisBelum ada peringkat

- SPE-177729-MS Improving Mega Project Economics Through The Use of Early ProductionDokumen4 halamanSPE-177729-MS Improving Mega Project Economics Through The Use of Early Productionmohamed_sahnoun_enisBelum ada peringkat

- Commissioning A Process PlantDokumen63 halamanCommissioning A Process PlantGeorge Van BommelBelum ada peringkat

- Designing Floating Offshore PlatformsDokumen18 halamanDesigning Floating Offshore PlatformsAriecandra MahesaBelum ada peringkat

- Petroleum Exploration and Exploitation in NorwayDari EverandPetroleum Exploration and Exploitation in NorwayPenilaian: 5 dari 5 bintang5/5 (1)

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyDari EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyBelum ada peringkat

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationDari EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationBelum ada peringkat

- AgnDokumen1 halamanAgnMuhammad NizamiBelum ada peringkat

- An Overview of Steam Injection Projects in Fractured Carbonate Reservoirs in The Middle EastDokumen10 halamanAn Overview of Steam Injection Projects in Fractured Carbonate Reservoirs in The Middle EastMuhammad NizamiBelum ada peringkat

- 3 ST1311-008Dokumen7 halaman3 ST1311-008Muhammad NizamiBelum ada peringkat

- Silabus MatematikaDokumen14 halamanSilabus MatematikaMuhammad NizamiBelum ada peringkat

- Syllabus of IOAA 2012Dokumen4 halamanSyllabus of IOAA 2012Galih PrimansyahBelum ada peringkat

- Emulsi 2Dokumen56 halamanEmulsi 2Muhammad NizamiBelum ada peringkat

- File KosongDokumen1 halamanFile KosongMuhammad NizamiBelum ada peringkat

- IOAA SyllabusDokumen6 halamanIOAA SyllabusAbdul Rasyid ZakariaBelum ada peringkat

- Factors affecting materials properties: Heat treatment, processing, environmental reactionsDokumen3 halamanFactors affecting materials properties: Heat treatment, processing, environmental reactionsRomari Estrella MirandaBelum ada peringkat

- 7B AnswerDokumen6 halaman7B AnswertarasasankaBelum ada peringkat

- Material 2 2021Dokumen94 halamanMaterial 2 2021Buildings Sub Division No. 1 MultanBelum ada peringkat

- ECOBA Statistic 2004Dokumen1 halamanECOBA Statistic 2004dungnv2733Belum ada peringkat

- HLS Sleeve Anchor Technology ManualDokumen5 halamanHLS Sleeve Anchor Technology ManualHerli SiswoyoBelum ada peringkat

- GC Guy Wire (US) Catalog Sheet FinalDokumen1 halamanGC Guy Wire (US) Catalog Sheet FinalAde 'aiyie' SasmitaBelum ada peringkat

- Air Hoists & TrolleyDokumen12 halamanAir Hoists & TrolleyHimindra ChaaubeBelum ada peringkat

- BOQ Sipil GI 150 KV TarjunDokumen5 halamanBOQ Sipil GI 150 KV TarjunMarketing MptBelum ada peringkat

- Staad Training Day 1Dokumen116 halamanStaad Training Day 1Bee AnquilianoBelum ada peringkat

- Livorsi TTK1150EL TTK1050EL TTK1025EL TTK975EL TTK950EL TTK850EL TTK750EL Trim Tab With Electronic Sensors Installation Manual ENDokumen16 halamanLivorsi TTK1150EL TTK1050EL TTK1025EL TTK975EL TTK950EL TTK850EL TTK750EL Trim Tab With Electronic Sensors Installation Manual ENTerrence JonesBelum ada peringkat

- Tender Process AND DocumentationDokumen35 halamanTender Process AND DocumentationHardik GandhiBelum ada peringkat

- Hvacr: Wholesale CatalogDokumen104 halamanHvacr: Wholesale Catalogsiva8784Belum ada peringkat

- SD SD1Dokumen1 halamanSD SD1Mohammed AldajaBelum ada peringkat

- CPCCCA3025 PresentationDokumen34 halamanCPCCCA3025 PresentationPranay BansalBelum ada peringkat

- Retaining Wall Problems: Lateral Forces, Active Pressure, Passive PressureDokumen9 halamanRetaining Wall Problems: Lateral Forces, Active Pressure, Passive PressureHannah Grace AringoBelum ada peringkat

- IIT Fracture and Fatigue Short CourseDokumen248 halamanIIT Fracture and Fatigue Short CourseSumit BasuBelum ada peringkat

- Copper Bonded Steel Earth RodDokumen9 halamanCopper Bonded Steel Earth Rodemmanuel_nyirendaBelum ada peringkat

- Diversion Head WorksDokumen8 halamanDiversion Head WorksMrinmoy SahaBelum ada peringkat

- Progress Billing No. 21 for Peninsula Garden Midtown Homes - Mahogany TowerDokumen100 halamanProgress Billing No. 21 for Peninsula Garden Midtown Homes - Mahogany TowerJohn Philip GarciaBelum ada peringkat

- 002JTGT B02-01-2008-EnDokumen75 halaman002JTGT B02-01-2008-Enziming liBelum ada peringkat

- Stainless steel penthouse railing detailsDokumen1 halamanStainless steel penthouse railing detailsRenz ChuaBelum ada peringkat

- Instruction Manual For DODGE Para-Flex High Speed and Flywheel CouplingsDokumen2 halamanInstruction Manual For DODGE Para-Flex High Speed and Flywheel CouplingsJonBelum ada peringkat

- Compressive Strength of Concrete - Cube Test Procedure ResultsDokumen5 halamanCompressive Strength of Concrete - Cube Test Procedure ResultsAriyan AriyanBelum ada peringkat

- What Is The Column Kicker - Its Formworks, Application and AdvantagesDokumen2 halamanWhat Is The Column Kicker - Its Formworks, Application and AdvantagesNaveen BansalBelum ada peringkat

- Building Services I: 2. Water Supply 3. Sanitation 4. Rain Water Harvesting 5. Fire ServicesDokumen21 halamanBuilding Services I: 2. Water Supply 3. Sanitation 4. Rain Water Harvesting 5. Fire ServicesBharathVenkatachalamBelum ada peringkat