Specifications For Flooring Work

Diunggah oleh

ErMelvinDiasJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Specifications For Flooring Work

Diunggah oleh

ErMelvinDiasHak Cipta:

Format Tersedia

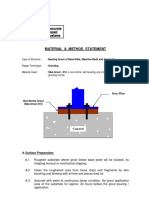

HINDUSTAN PETROLEUM CORPORATION LIMITED

GURU GOBIND SINGH REFINERY

PRODUCTS EVACUATION PROJECT

(GGSRPEP)

SPECIFICATIONS FOR FLOORING WORK

0435-JH0902-00-AR-SPC-0002

C

B

Issued for Tender

Issued for Client Review

RAR

UDB

AK

RAR

UDB

AK

06/06/09

29/05/09

Issued for SDC

REV

DESCRIPTION

RAR

UDB

AK

26/05/09

PREP

CHECKED

WORLEYPARSONS

APPROVAL

DATE

HPCL

APPROVAL

DATE

SPECIFICATIONS FOR FLOORING WORK

1.0

SCOPE

This specification covers the requirement of providing labour, material, construction

aids, workmanship etc. for providing and fixing flooring, skirting and dado work on

floors and walls.

2.0

APPLICABLE CODES

Note: - Wherever reference is made to IS Codes, on any page of this Technical

Specification (including annexures), applicable year of publication of IS Code is as

stated below.

Following specifications will be considered as part of this specification:

IS 383-1999

: Coarse and fine aggregate from natural sources for concrete.

IS 1237-1980

: Cement concrete flooring tiles.

IS 1443-1972

IS 2114 -1984

: Code of practice for laying and finishing of cement concrete

flooring tiles.

: Code of practice for laying in-situ terrazzo floor finish

IS 2571-1970

: Code of practice for laying insitu cement concrete flooring.

IS 2386-1963

(Part 1 - Part 8)

IS 3461-1980

: Methods of test for aggregates for concrete.

: Specification for PVC asbestos floor tiles.

IS 3462-1986

: Specification for unbacked flexible PVC flooring.

IS 4441

IS 4631-1986

: Code of practice for use of silicate type Chemical resistant

mortars.

: Code of practice for use of resin type chemical resistant

mortar.

: Specification for ceramic unglazed vitreous acid-resistant

Tiles.

: Code of practice for laying epoxy resin floor toppings.

IS 4832

: Specification for Chemical Resistant Mortars.

Part-1: 1969

: Part-1 Silicated type.

Part-2: 1969

: Part-2 Resin type.

Part-3: 1968

: Part-3 Sulphur type

IS 4971

: Recommendations for selection of Industrial floor finishes.

IS 5318-1969

: Code of practice for laying of flexible PVC sheet and tile

flooring.

: Code of practice for laying in-situ granolithic concrete flooring

topping.

: Ceramic tiles -definitions, classifications, characteristics and

marking

: Ceramic Tiles Methods of test

IS 4443

IS 4457-1982

IS 5491-1969

IS 13712 -1993

IS 13630 : (Part

0435-JH0902-00-AR-SPC-0002

Page 2 of 14

SPECIFICATIONS FOR FLOORING WORK

1 to 13)-1993

IS 13753 -1993

IS 13754 -1993

IS 13755 -1993

IS 13756 -1993

3.0

: Dust-pressed ceramic tiles with water absorption of E 10%

(group B III)

: Dust-pressed ceramic tiles with water absorption of 6% E

10% (group B IIb)

: Dust-pressed ceramic tiles with water absorption of 3% E 6%

(group B IIa)

: Dust-pressed ceramic tiles with water absorption of E 3%

(group B I)

PRIORITY OF REQUIREMENTS

In case of any variation and discrepancy in condition between the special conditions,

this specification and codes, order of priority shall be as under:-

4.0

(1)

Special conditions

(2)

This specification

(3)

Codes

TYPES OF FLOORING

Various types of flooring and linings materials / systems are used for floor finishing

over base floor, rigid / flexible viz. concrete, metal, stone, wood, etc., for different types

of applications viz. Industrial, Non-industrial.

Although plain concrete Base floor as laid conforming to IS 2571 would be satisfactory

for many purposes, Various types of floor hardening / topping / coating / lining are

applied to improve physical, mechanical, and chemical properties of the base floor to

desired extent.

5.0

INDUSTRIAL FLOORING

Generally in Industrial Flooring the purpose of flooring, is one or more combination of

following requirements

(a) For heavy duty floors, this is subject to heavy loads, severe abrasion and

impact

(b) For dust free and clean environment

(c) For chemical and corrosion resistance

Further classification based on material / system used is stated in the subsequent

paragraphs.

6.0

METALLIC FLOORING

For all Industrial plant floors subject to heavy loading, plants requiring dust proof and

wear resistant floors, use of Metallic floor replaces the brittle, dusty granular properties

of a plain cement floor with toughness, ductility and wear resistant properties of the

Metallic surfaces.

0435-JH0902-00-AR-SPC-0002

Page 3 of 14

SPECIFICATIONS FOR FLOORING WORK

6.1

Artificial Patent Stone (APS) Flooring

Artificial Patent Stone (APS) Flooring shall be laid in overall thickness of 40mm over

sub base and shall conform to IS: 5491 in workmanship.

Base layer shall be 25mm thick in M15 grade concrete and wearing layer shall be

15mm thick in 1:3 (1 cement: 3 course sand by volume)

Base layer shall be laid over sub base in alternate panels in desired shape and

pattern. Each panel shall not exceed 1.5m in width. Panel shall be bound by 3x30 PVC

strip panel dividers, fixed in position with their top at proper level maintaining the

required levels, slopes, linearity, etc. as required. Before laying the base course, neat

cement slurry @ 2.75 kg of cement per sq. meter of area shall be applied by brush

over the prepared sub base. The border of the panel shall have metered joints at the

corner of the room and intermediate joints shall be in straight line with panel joints.

Cement concrete shall be placed in position and beaten with trowel and finished

smooth. Beating shall cease as soon as surface is found covered with cream of mortar.

Necessary slope shall be provided.

Wearing layer shall be laid within 15 minutes of laying base layer. The cement and

aggregates for the top layer shall be mixed dry. After mixing, sufficient quantity of

washed sand and water shall be added to make the mix plastic but not flowing. The top

and bottom layer shall firmly grip together. The base course shall be free of excessive

moisture before starting the floor finishing. Use of dry cement, cement sand mixture

sprinkled on the surface to stiffen the concrete or absorb excessive moisture shall not

be permitted.

While the concrete is still green, cement @ 2.75 kg per Sq.M of floor area shall be

mixed with water to form thick slurry and spread over the surface. It shall be pressed

twice by means of iron floats, once when the slurry is applied and second time when

the cement starts setting. The junction of floor with wall plaster, cladding, skirting shall

be rounded off uniformly up to a radius of 25mm unless otherwise mentioned.

Each finished portion of floor, on completion shall be kept wet with ponding for a

minimum period of 7 days

Skirting shall be 18 mm thick laid with cement mortar (1 cement: 3 coarse sand by

volume. The surface on which the skirting is to be applied shall be prepared and

skirting shall be laid. The junction between flooring and wall shall be rounded off to a

radius of 25mm if not otherwise mentioned. While the mortar is still green, cement @

2.75Kg per square meter shall be mixed with water to form thick slurry and applied

over the mortar. It shall be pressed twice by means of iron floats, once when the slurry

is applied and second time when the cement starts setting. The skirting shall be cured

for 7 days.

6.2

APS Flooring with Ironite Topping (Heavy Duty Flooring)

Heavy Duty Flooring shall be laid in overall thickness of 50mm over sub base and shall

conform to IS: 5491 in workmanship.

0435-JH0902-00-AR-SPC-0002

Page 4 of 14

SPECIFICATIONS FOR FLOORING WORK

Base layer shall be 35mm thick in cement concrete (1 cement: 1.5 coarse sand: 3.5

stone aggregates of 10mm to 6mm size by volume). Base layer shall be laid over sub

base in alternate panels in desired shape and pattern. Each panel shall not exceed

1.5m in width. Panel shall be bound by 3x30 PVC strip panel dividers, fixed in position

with their top at proper level maintaining the required levels, slopes, linearity, etc. as

required. Before laying the base course, neat cement slurry @ 2.75 kg of cement per

sq. meter of area shall be applied by brush over the prepared sub base. The border of

the panel shall have metered joints at the corner of the room and intermediate joints

shall be in straight line with panel joints. Cement concrete shall be placed in position

and beaten with trowel and finished smooth. Beating shall cease as soon as surface is

found covered with cream of mortar. Necessary slope shall be provided.

Wearing Top layer/ finishing layer shall be of cement, hardener and stone aggregate

mix of 15mm thickness laid over the base course. Unless otherwise mentioned, one

part of approved quality hardener and four parts of cement by weight shall be mixed

dry. This dry mixture shall be mixed with stone grit of 6mm and down size in the ratio

of 1 hardener and cement mixture: 2 stone grit by volume. Just enough water shall

then be added to the mix. The mixture so obtained shall then be laid on the base

course within 2 to 4 hours of latter's laying. It shall be firmly pressed into bottom

concrete so as to have a good bond with it. After the starting of initial setting, the

surface shall be finished smooth and true with steel floats.

Each finished portion of floor, on completion shall be kept wet with ponding for a

minimum period of 7 days.

6.3

Readymade Brands

Various brands of metallic floor toppings are available from various manufacturers viz.

Euco Plate and Diamond Plate from STP Ltd., Chapdur from Sica Qualcrete Ltd.

7.0

NON-METALLIC FLOORING

Epoxy resins on account of their qualities of adhesion and chemically resistant are

used for non-metallic floor topping.

For industrial plant where floors requiring dust reduction and oil resistance, NonMetallic flooring is recommended. Various brands of Epoxy floor hardeners are

available for floor hardening while later is still Green. Topping, Coating or Lining shall

be applied as per the extent of requirements specified by Engineer-In-Charge.

Types and Applications of Epoxy Resin / Non - metallic flooring are stated below.

7.1

Trowel Type

This is usually heavily filled with sand or other suitable aggregate and the compound is

applied by trowel. Such compounds are often referred to as mortars or screeds.

Application of 5 mm to 6mm thick screed for monolithic, dust free, abrassion resistant,

anti skid chemical resistant flooring is recommended to obtain satisfactory

performance.

0435-JH0902-00-AR-SPC-0002

Page 5 of 14

SPECIFICATIONS FOR FLOORING WORK

7.2

Flow Type

This is usually a solventless compound containing filler and pigment and the mixture

when poured directly on to the surface will flow and level itself often with little

assistance to form a smooth continuous coating. Applications of 150 to 300 micron

thick coating for abrassion resistant and dust free flooring, and 1.5 mm to 2 mm thick

self levelling floor topping for factory floors is recommended.

7.3

Terrazzo Floors

The Portland cement in the conventional terrazzo floors is replaced by epoxy resin

binder. Such flooring formulations serve the dual purpose of providing a good

appearance and chemical resistance. Minimum thickness recommended is 10 mm.

7.4

Non-skid Floors

This type of floor may be prepared by sprinkling a suitable grit on an epoxy floor

topping when the later is still in a tacky state.

7.5

Materials

7.5.1 Epoxy Resin Blend

This shall be based on a liquid epoxy resin (which is usually a condensation product of

Bisphenol) with or without constituents such as plasticizers, diluents and special

pigments as may be necessary.

7.5.2

Hardener Blend

This shall contain a chemical, usually an amine, and amine - adduct or polyamide

which will react with the epoxy resin at ambient temperatures to give a cured

thermoset resin product. Hardeners based on amines and amine-adducts exhibit

higher chemical resistance than polyamides but polyamide hardeners must be used

where floors are exposed to frequent impact stress and fluctuations in temperature

7.5.3

Aggregates

Selected dry aggregates, such as quartz sand or calcined bauxite grit with graded

particle size as recommended by the resin manufacturer shall be supplied as a

separate component.

7.5.4

Coal Tar

Coal tar extenders are used to lower the cost and increase the flexibility of epoxy resin

formulations. Besides, coal tar blending increases the resistance of water although the

mechanical and chemical resistance properties are lowered.

0435-JH0902-00-AR-SPC-0002

Page 6 of 14

SPECIFICATIONS FOR FLOORING WORK

Note: The resin, hardener and aggregate shall be mixed in the proportion as specified

by the Engineer-In-Charge or Manufacturers Specification and used as

specified in this standard.

7.6

Surface Preparation

To ensure proper adhesion of the Epoxy resin mix, surface shall be cleaned, free from

grease and oil, dry and rough.

All laitance shall be removed from concrete surface washing the floor with dilute

Hydrochloric Acid. Sand blasting or hacking may be adopted for roughening the

surface.

All cracks and broken areas on an existing concrete base shall be sealed / filled with

fresh concrete before application of Epoxy resin topping.

Grease and oil shall be removed by washing the surface with solvents such as

Acetone or a suitable detergent.

7.7

Laying

7.7.1 Mixing of Epoxy resin blend

The constituents required for a particular epoxy resin topping shall be mixed just

before use, in correct proportion specified by the Manufacturer. The order of addition of

the components shall be resin, hardener and aggregate (in dry condition) and duration

of mixing shall be adequate to ensure through mixing.

7.7.2 Application

Application of blended epoxy resin topping shall be done uniformly over the prepared

area to give the required thickness. The floor area may be divided in sections to get

uniform thickness.

7.8

Manufacturers

For non-metallic flooring, chemical products from various manufacturers are available

viz. FOSROC, SICA QUALCRETE MC-BAUCHEMIE, STP. LTD., CHEMBOND etc.

Note: Engineer-In-charge shall approve Product and Manufacturer prior to its use in

the works

7.9

Other Types of Industrial Flooring

7.9.1

Acid Resistant Tiles / Bricks

Acid Resistant Tiles are used in flooring and lining to prevent corrosion of surface by

acids and other chemicals as well as to resist abrassion on floors. These tiles are

made up of materials like clay, feldspar, quartz, and talc and vitrified at high

temperatures in ceramic kilns and kept unglazed to prevent slipperiness when laid on

floor.

Chemical resistant mortars as per IS 4832 are used for laying these tiles. Laying and

finishing procedure similar to the other glazed ceramic tiles described elsewhere.

0435-JH0902-00-AR-SPC-0002

Page 7 of 14

SPECIFICATIONS FOR FLOORING WORK

7.9.2

FRP Grating / Plate Flooring

Fiber glass Reinforced polyester (FRP) Grating / Plate Flooring are available in

standard size panels and are suitable for industrial flooring viz. Platform Staircase,

Ramps, Catwalk, and Trench covers etc.

7.9.3

Manufacturers

1. CHEMGRATE CORP. of USA FRP Products under Brand names CHEMGRATE,

CHEMPLATE, and CHEMTREAD etc.

2. INTERNATIONAL GRATING INC of USA FRP Products under Brand names

KORDEK GRATING / PLATE etc.

8.0

NON INDUSTRIAL FLOORING

These are used for non-industrial purpose viz. commercial and residential flooring

where light duty, dust free, clean environment and decorative purposes are governing

criteria for choosing type of floor finishes. These are described below:

8.1

Plain Cement concrete / Mosaic / Terrazzo Flooring

8.1.1 In Situ Work

Methods commonly adopted for laying In-Situ Terrazzo Finish Surface shall be as per

IS 2114.

8.1.2

Tiling Work

Terrazzo/Mosaic tiles shall be of approved colour and size and shall be 25 mm thick

unless otherwise specified.

a)

Tolerance

Tolerance on length or breadth shall be plus or minus one millimeter and on

thickness plus 3 mm.

b)

Wearing layer

Minimum wearing layer shall not be less than 5 mm for tiles. Color and texture

of the wearing layer shall be uniform throughout its thickness.

c)

Resistance to wear

When tested as per IS 1237, the thickness of wearing shall not be more than

3.5 mm for tiles.

The CONTRACTOR shall submit to the Engineer-In-Charge, samples of the

tiles proposed to be used for the work and shall obtain his approval before

placing the order.

0435-JH0902-00-AR-SPC-0002

Page 8 of 14

SPECIFICATIONS FOR FLOORING WORK

The colour and quality of tiles used in work shall be similar to the sample

approved. If after polishing it is revealed that the quality is not the same as per

the sample, the work shall be rejected and shall be redone as instructed at the

CONTRACTOR's cost.

For odd shaped size, the tiles shall be cut to the required size without

damaging the tiles.

d)

Laying of tiles

Surface Preparation:

The base courses either P.C.C. or R.C.C. slab shall be brushed with a stiff

bristle broom removing all laitance. The brooming shall expose some of the

aggregates and roughen the surface adequately to provide a mechanical bond

for the topping. The base shall be cleared of any deposition i.e. grease, oil,

paint etc. on its surface which will interfere with the bond and thoroughly

cleaned of loose particles and dust with water by scrubbing with stiff brush.

Foreign substance not removed by scrubbing shall be chipped off. After the

base is chipped clean, it shall be saturated with water overnight. If specified,

proprietary brand adhesive solution of approved make shall be applied as per

manufacturer's specification to the old concrete surface so as to ensure proper

bond between old concrete surface and new in-situ topping.

Bedding:

Levels of prepared surface to be checked and verified before starting any

bedding work. Mortar pads shall be provided at suitable intervals to establish

the level and slope for the tiling work. Minimum 20mm thick under bed of 1:6

cement mortars spread uniform on the prepared concrete floor base and

compacted to proper grade.

The method of laying the tiles shall be in accordance with IS 1443. Before the

tiles are laid these shall be soaked in water for about 15 minutes and then

allowed to dry out for the same time. Just prior to laying the tiles, cement slurry

of the consistency of a thick paint at the rate of 4 kg per square meter shall be

spread over a small area of mortar bed at a time and then the tiles shall be set

on it in the desired pattern. Each tile shall be gently tapped with wooden mallet

till it is properly bedded. As each tile is placed, its surface level shall be

checked and any unevenness shall be corrected by rectifying the mortar bed.

The tiles shall be laid with the side edges absolutely touching each other so

that the joints shall be as fine and imperceptible as possible. After the entire

floor of each room is completed, slurry of the same coloured cement as the

colour of the tiles shall be spread over the surface and rubbed in so as to seal

even the thinnest joints between the tiles and then make the surface

impervious. Nobody shall be allowed to walk over the flooring during the first 24

hours. As soon as the cement slurry in the joints has hardened, the surface

shall be kept continually wet for at least 7 days.

14 days after laying the tiles, the surface shall be ground smooth with an

approved type of grinding machine, with carborundum stones of 48 to 60 grit.

The floor shall be kept wet during the grinding process. Materials ground off

shall be removed by squeezing and flushing with water.

Any air holes, pits or other blemishes observed in the surface shall then be

filled with paste made of 1:2 cement and marble powder and water. After the

0435-JH0902-00-AR-SPC-0002

Page 9 of 14

SPECIFICATIONS FOR FLOORING WORK

patch filler has hardened the floor shall be cured for another 7 days. The

surface shall then receive the second and the final grinding with successive

grades of carborundum stones of 120 and 220 to 350 grit respectively until a

uniformly smooth and even surface is obtained. Finally it shall be thoroughly

washed with soap water and mopped clean to the satisfaction of the EngineerIn-Charge.

e)

Skirting

The skirting shall be of the same materials as that of the floor tiles and shall be

of the exact size specified. It shall be fixed to the wall with cement mortar 1:4

bedding. Grinding and polishing shall be carried out by hand using

carborundum of appropriate quality.

f)

Applications

For Non plant building floorings.

g)

Manufacturers

Various Manufacturers are available. viz. NITCO, KAJARIA , SPARTECH etc.

Note: Sample and Manufacturers shall be approved by Engineer-In-charge prior to its

use in the work.

8.2

Stone / Marble / Granite Flooring

Shahabad, Kota, Cuddapah, Stones are readily available in rough or smooth

surfaces in tile or slab forms and are generally used for non-industrial and light

industrial flooring purposes where rigid, non porous floor finish is required.

Where decorative and easier to clean, longer lasting floor finish is required,

marble and Granite may be used. Tiles or slabs of marble and granite may be

fixed by cement mortar or chemical adhesive to the base floor.

8.2.1

APPLICATION

Stone flooring shall be laid in minimum 40mm overall thickness over sub base.

For steps, joints in floor shall be permitted only when width / length is more

than 0.6 / 2 meter. Thickness of the stone slabs shall be 25mm for floor and

tread & 18mm for dado / skirting. Skirting shall normally be 125mm high unless

specified otherwise.

PREPARATION OF BASE

The base courses either P.C.C. or R.C.C. slab shall be brushed with a stiff

bristle broom removing all laitance. The brooming shall expose some of the

aggregates and roughen the surface adequately to provide a mechanical bond

for the topping. The base shall be cleared of any deposition i.e. grease, oil,

paint etc. on its surface which will interfere with the bond and thoroughly

0435-JH0902-00-AR-SPC-0002

Page 10 of 14

SPECIFICATIONS FOR FLOORING WORK

cleaned of loose particles and dust with water by scrubbing with stiff brush.

Foreign substance not removed by scrubbing shall be chipped off. After the

base is chipped clean, it shall be saturated with water overnight. If specified,

proprietary brand adhesive solution of approved make shall be applied as per

manufacturer's specification to the old concrete surface so as to ensure proper

bond between old concrete surface and new in-situ topping.

LAYING

The mortar shall be 15mm thick in 1:6 (1Cement: 6 Coarse sand by volume) for flooring

and 12mm thick in 1:3 (1 cement: 3 coarse sand by volume) for skirting. The mortar shall

be laid for fixing one slab at a time. The slab shall be washed clean before laying. After

laying once over cement mortar bedding, the slab shall be pressed, tapped gently to bring it

in level, then lift & laid aside. Top surface of mortar then shall be corrected by adding fresh

mortar at hollows & depressions. The mortar shall then be allowed to harden & cement

slurry of honey likes consistency @ 4.4 Kg of cement per Sq. M. shall be spread over

mortar. The slab edges shall be buttered with white cement (with necessary pigment) grout

to match the shade of slabs. The slabs shall then be gently placed in position & tapped with

wooden mallets till it is properly bedded in level.

The slabs in flooring shall continue for not less than 10mm under the plaster / skirting.

GRINDING & POLISHING

Grinding (with machine except for skirting & small areas) shall be commenced when the

joints are properly set. First grinding shall be done with carborundum stones of 48 to 60

grade grit filled in machine. Water shall be properly used during grinding.

When the floor has been uniformly rubbed, it shall be cleaned with water baring all pin

holes. It shall then be covered with a thin coat of cement mixed with pigments to match with

colour of the stone. This grout shall be kept moist for a weak. Thereafter the second

grinding shall be started with Carborundum stone of 120grit. Grinding & curing shall follow

again.

Final grinding shall be with Carborundum of grade 220 to 350 grit using water in

abundance. The floor shall be washed clean with water, oxalic acid powder shall then be

dusted at 35 gms / Sq. M on surface rubbed with machine fitted Hessian bobs or rubbed

hard with woolen rags. The floor shall then be washed clean & dried with a soft cloth or

linen.

If any stone slab is disturbed or damaged, it shall be refitted or replaced & properly jointed

& polished.

8.3

Ceramic Tile Flooring

0435-JH0902-00-AR-SPC-0002

Page 11 of 14

SPECIFICATIONS FOR FLOORING WORK

Ceramic tiles shall be of approved make, size and shade and shall conform to IS 13756. No

cracked, chipped or wrapped tiles shall be used in the works. Surface of the tile can be

smooth, profiled, wavy, decorated, glossy, matt, etc.

8.3.1 Surface Preparation

All masonry faces shall be cleaned thoroughly by removing dirt, loose mortar, efflorescence

etc. The concrete surfaces shall be brushed to remove all laitance and roughened to

provide a bond for the bedding.

8.3.2

Fixing tiles

The masonry and concrete faces shall be given a coat of cement plaster 12 mm thick

(in proportion 1:4). The surface of the plaster shall be scarified with wire brush for

getting a good bond between the tiles and the bedding.

The tiles shall be soaked in clean water for about half an hour before using. After

soaking, tiles shall be removed from water and stacked on clean surface. The back of

the tile shall be buttered with 1:2 plastic cement mortar to a thickness slightly in excess

of the finished thickness required and the tile pressed to the wall and tapped back in

position. Alternatively a rich fatty mortar shall be applied on the bedding and the tile

pressed into it, care being taken to ensure that the keys of the tiles are buttered up

with mortar.

It shall be ensured that the back of the tile is solid over the whole area. Joints shall be

uniform, even, straight and as thin as possible in any case not more than 3.0 mm.

Surfaces of tiles having been fixed, the joints shall be cleaned of gray cement and

refilled with cement paste of the same shade as that of the tiles. The tiled surface shall

be left wet for a period of 7 days.

Glazed rounded corner convex or concave shall be provided where specified and no

extra cost will be paid for the same.

After the completion of the work the surface shall be cleaned of all stains etc.

Alternatively tiles may be fixed with Tile Adhesive chemicals of which, various

proprietary brands are available. In such case soaking of tile with water before using

shall not be done. Manufacturers specification shall be used for Tile adhesive fixing.

8.3.3

Applications

Generally used for walls and floors of toilets and kitchens etc., where constant risk of

spoiling interior finish due to water, is there. Also it can be used elsewhere for decorative

surface and clean environment.

8.3.4

Manufacturers

Ceramic Tiles shall be of approved manufacturers such as HR JOHNSON, HINDUSTAN

SANITARYWARE, NITKO, KAJARIA or equivalent.

0435-JH0902-00-AR-SPC-0002

Page 12 of 14

SPECIFICATIONS FOR FLOORING WORK

Note: Sample and Manufacturers shall be approved by Engineer-In-charge prior to its

use in the work.

8.4

PVC Flooring

PVC Flooring provides dust-free, noise absorbing, resilient, non-porous, decorative surface.

The two types of PVC Flooring are as follows:

(a) Flexible PVC Flooring

(b) Rigid PVC Flooring

Flexible PVC Flooring is available in sheet form is suitable for lighter traffic.

Flexible PVC flooring are not suitable for areas exposed to continuous sun light

and rain. Flexible PVC Flooring is liable to be damaged by burning cigarette

stumps. Thickness of sheet shall be 2mm unless specified otherwise.

Rigid PVC flooring is available in standard tile sizes such as 300 mm x 300 mm

and comparatively more suitable for heavy traffic and rigid floors. Thickness of tile

shall be 2mm unless specified otherwise.

The size, type and shade of the tiles shall be as specified and/or as directed by the

Engineer-In-Charge and conforming to IS 3461/ IS 3462. PVC Flooring shall be

anti-static type.

8.4.1

Adhesive

The adhesive shall be of the type and make recommended by the manufacturer of

P. V. C. tiles. Preparation and laying shall be done as per IS 5318.

8.4.2

Surface Preparation

For concrete base floor, surface shall be scraped free of all foreign material and swept

clean. Surface shall be kept wet for 24 hours by sprinkling water and then screed topping

(1:3 cement mortar) of 3 mm thickness shall be provided over the concrete to get required

even and levelled surface. Before laying is undertaken, it shall be ensured that the

prepared surface is even and perfectly dry.

8.4.3

Laying

The adhesive shall be spread evenly on the base and on the back of the tiles as prescribed

by the manufacturer. Time shall be allowed, for the solvent in the adhesive to evaporate.

The tiles shall then be pressed firmly into contact with the surface and smoothed down with

a suitable tool. Weights shall be used to avoid tendency of curling. Immediately after, the

tiles shall be rolled with 5 kg wooden roller to get the tiles bonded down properly. The tiles

shall be laid with butt joints throughout and the joints shall be very fine. After laying, any

adhesive sticking to the surface of the tiles shall be removed immediately and shall not be

allowed to harden. After a week of laying the surface shall be cleaned with mild soap and

wet cloth.

8.4.4 Manufacturers

0435-JH0902-00-AR-SPC-0002

Page 13 of 14

SPECIFICATIONS FOR FLOORING WORK

1.

PVC flexible flooring sheets under brand name Wonder Floors by Premier Vinyl

Flooring, Armstrong or equivalent.

2.

PVC flooring Tiles under brand name Marblex by Bhor Industries, Armstrong or

equivalent.

0435-JH0902-00-AR-SPC-0002

Page 14 of 14

Anda mungkin juga menyukai

- Backfill SpecificationDokumen5 halamanBackfill SpecificationRrsBelum ada peringkat

- 33 05 13 Manholes and Structures 10Dokumen4 halaman33 05 13 Manholes and Structures 10salamBelum ada peringkat

- Concrete Pre Pour Planning For Civil ProjectsDokumen6 halamanConcrete Pre Pour Planning For Civil ProjectshemantrulzBelum ada peringkat

- BOQ WaterproofingDokumen6 halamanBOQ WaterproofingShashi Bhushan SinghBelum ada peringkat

- MasterSeal 550Dokumen38 halamanMasterSeal 550Ahmad ElghazolyBelum ada peringkat

- Concrete Terms and Industry TerminologyDokumen12 halamanConcrete Terms and Industry TerminologyNguyen Dang Hanh100% (8)

- 25.MOS Template - Installation of HDPE LiningDokumen14 halaman25.MOS Template - Installation of HDPE LiningAnantha PadmanabhanBelum ada peringkat

- Ms For Rubbed ConcreteDokumen6 halamanMs For Rubbed Concreteᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Belum ada peringkat

- QC PlanDokumen51 halamanQC PlanAllan KhatasioBelum ada peringkat

- Effect of Restraint, Volume Change, and Reinforcement On Cracking of Mass ConcreteDokumen26 halamanEffect of Restraint, Volume Change, and Reinforcement On Cracking of Mass ConcreteDIDIER ANGEL LOPEZ RINCONBelum ada peringkat

- Specifications For Painting WorksDokumen2 halamanSpecifications For Painting WorksvinodBelum ada peringkat

- Joints To Avoid CracksDokumen8 halamanJoints To Avoid Cracksprakashcg123Belum ada peringkat

- Qcs 2010 Part 14 Protective Treatments For ConcreteDokumen19 halamanQcs 2010 Part 14 Protective Treatments For ConcreteRotsapNayrb100% (1)

- Quality Issues in ConstructionDokumen25 halamanQuality Issues in ConstructionMohamedBelum ada peringkat

- Non Conformance Report: Refer Attached PhotographsDokumen8 halamanNon Conformance Report: Refer Attached PhotographsJitender Tanwar100% (1)

- Quality Control of Ready Mixed Concrete Can Be Divided Into Three Convenient Areas LikeDokumen11 halamanQuality Control of Ready Mixed Concrete Can Be Divided Into Three Convenient Areas Likeee iabBelum ada peringkat

- 16 - Specification of Work - Part 22Dokumen161 halaman16 - Specification of Work - Part 22Yadunath RavikumarBelum ada peringkat

- Methodology For Convreting WorksDokumen7 halamanMethodology For Convreting WorksLokesh SaranBelum ada peringkat

- MAR - Blockwork Accessories PDFDokumen144 halamanMAR - Blockwork Accessories PDFMariam MousaBelum ada peringkat

- Sika Crack Injection Method Statement PDFDokumen16 halamanSika Crack Injection Method Statement PDFDP PRANBelum ada peringkat

- Specifications - Two Storey BuildingDokumen17 halamanSpecifications - Two Storey BuildingRoque III JaguioBelum ada peringkat

- Marriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Dokumen9 halamanMarriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Imho TepBelum ada peringkat

- Renovation, Alteration and Addition WordDokumen22 halamanRenovation, Alteration and Addition Word笨豬Belum ada peringkat

- Concrete RepairDokumen112 halamanConcrete RepairAymanZakariaBelum ada peringkat

- Waterproofing Specs (Separate)Dokumen10 halamanWaterproofing Specs (Separate)santhosh kumar t mBelum ada peringkat

- Application of WaterproofingDokumen26 halamanApplication of WaterproofingEm PeeBelum ada peringkat

- Hollow Core Slab PDFDokumen4 halamanHollow Core Slab PDFStraus WaseemBelum ada peringkat

- Crack Detection On Concrete Surfaces UsingDokumen6 halamanCrack Detection On Concrete Surfaces UsingWorld of Computer Science and Information Technology JournalBelum ada peringkat

- Checklist For Concrete WorkdDokumen12 halamanChecklist For Concrete WorkdJawad NaderiBelum ada peringkat

- Glass Fibre Reinforced Gypsum Panel SystemDokumen45 halamanGlass Fibre Reinforced Gypsum Panel Systemumesh100% (4)

- ConcreteDokumen169 halamanConcretesabareesan09Belum ada peringkat

- Polyurea Hot Spray Steel Surfaces Method StatementDokumen9 halamanPolyurea Hot Spray Steel Surfaces Method StatementGvsr SunnyBelum ada peringkat

- Questions For Factory VisitDokumen1 halamanQuestions For Factory VisitJahid HasnainBelum ada peringkat

- Ch5 Masonry ConstructionDokumen23 halamanCh5 Masonry ConstructiongulzamanBelum ada peringkat

- Material & Method Statement: Concrete Repair SystemsDokumen3 halamanMaterial & Method Statement: Concrete Repair SystemsJuris DixonBelum ada peringkat

- Checklist For Terrace WaterproofingDokumen2 halamanChecklist For Terrace WaterproofingSantosh YadavBelum ada peringkat

- MSDGC Contractor QC Plan TemplateDokumen61 halamanMSDGC Contractor QC Plan TemplatedijitBelum ada peringkat

- Home Interior Exterior - Civil Inspector Interview Question and AnswerDokumen5 halamanHome Interior Exterior - Civil Inspector Interview Question and AnswerZeeshanAliBelum ada peringkat

- Concrete Quality Control Plan PDFDokumen20 halamanConcrete Quality Control Plan PDFNazee 122333Belum ada peringkat

- Guidelines For Concrete WorksDokumen6 halamanGuidelines For Concrete WorksFaysal MadiBelum ada peringkat

- 1 MS - Pouring of ConcreteDokumen8 halaman1 MS - Pouring of ConcreteFauzi MastamBelum ada peringkat

- Checklist For Site WorksDokumen54 halamanChecklist For Site WorkskhajaimadBelum ada peringkat

- Specifying Concrete For Durability Cif Dec 05Dokumen9 halamanSpecifying Concrete For Durability Cif Dec 05Veio MacieiraBelum ada peringkat

- ACI 304.6R-91 Guide For The Use of Volumetric-MeasuringDokumen14 halamanACI 304.6R-91 Guide For The Use of Volumetric-MeasuringMihai BanateanuBelum ada peringkat

- Cracks in Concrete StructuresDokumen9 halamanCracks in Concrete StructuresHayman SA100% (1)

- Slab On GradeDokumen2 halamanSlab On GradeVistash Buhary100% (1)

- Method Statement PlasterDokumen3 halamanMethod Statement PlasterArif SyazmiBelum ada peringkat

- SPEC Concrete - 07100 ConcreteDokumen124 halamanSPEC Concrete - 07100 ConcreteroldskiBelum ada peringkat

- Cracking Concrete SurfacesDokumen2 halamanCracking Concrete SurfacesCivilEngClubBelum ada peringkat

- Concrete Crack and Partial-Depth Spall RepairDokumen78 halamanConcrete Crack and Partial-Depth Spall RepairRafeeq WazirBelum ada peringkat

- Epoxy Method 2Dokumen11 halamanEpoxy Method 2Mohamed BadrBelum ada peringkat

- Method Statement For Structural Excavation and BackfillDokumen14 halamanMethod Statement For Structural Excavation and Backfillwajid ZiaBelum ada peringkat

- QCS Section 8 Part 7 (GRP)Dokumen5 halamanQCS Section 8 Part 7 (GRP)glen cristian rivera100% (2)

- Sikafloor® Technical Services: Surface Preparation GuideDokumen12 halamanSikafloor® Technical Services: Surface Preparation GuideMIGUEL ANGEL ACON ROBLEDABelum ada peringkat

- BOQ - GVK Bio Campus Additional Work-Package-IADokumen49 halamanBOQ - GVK Bio Campus Additional Work-Package-IAdeepthikuppuswamyBelum ada peringkat

- Comparative of BOQ - Finishing ItemDokumen202 halamanComparative of BOQ - Finishing Itemanjanepal100% (1)

- Bo QDokumen12 halamanBo QSatheesh SankarapillaiBelum ada peringkat

- Field Operator RoomDokumen4 halamanField Operator RoomKANWARBelum ada peringkat

- Sample BOQ-1Dokumen6 halamanSample BOQ-1Anonymous Of0C4dBelum ada peringkat

- Subject-Construction of Non-Plant Buildings and Allied Facilities at Jodhpur LPG Bottling Plant, RajasthanDokumen24 halamanSubject-Construction of Non-Plant Buildings and Allied Facilities at Jodhpur LPG Bottling Plant, RajasthanSandeep MauryaBelum ada peringkat

- Architectural SymbolsDokumen34 halamanArchitectural SymbolsNiallburke100% (4)

- Bar Chart PDFDokumen1 halamanBar Chart PDFErMelvinDiasBelum ada peringkat

- T Model PDFDokumen1 halamanT Model PDFErMelvinDiasBelum ada peringkat

- 35x45 Model PDFDokumen1 halaman35x45 Model PDFErMelvinDiasBelum ada peringkat

- PresentationDokumen8 halamanPresentationErMelvinDiasBelum ada peringkat

- Carpentry Details (Living & Staricase) : Proposed Residence For Mr. Bhandarakar at Sagar, ShimogaDokumen1 halamanCarpentry Details (Living & Staricase) : Proposed Residence For Mr. Bhandarakar at Sagar, ShimogaErMelvinDiasBelum ada peringkat

- T-Model FF PDFDokumen1 halamanT-Model FF PDFErMelvinDiasBelum ada peringkat

- 36 Final Plan ModelDokumen1 halaman36 Final Plan ModelErMelvinDiasBelum ada peringkat

- Bar Chart PDFDokumen1 halamanBar Chart PDFErMelvinDiasBelum ada peringkat

- 07 Nov 2015 124358050LDK45POTprefeasibilityreportDokumen81 halaman07 Nov 2015 124358050LDK45POTprefeasibilityreportErMelvinDias100% (1)

- Practical Plumbing HandbookDokumen56 halamanPractical Plumbing HandbookcruzserBelum ada peringkat

- Apr2014 Zip 10606379 TD BOQ160Dokumen4 halamanApr2014 Zip 10606379 TD BOQ160ErMelvinDiasBelum ada peringkat

- Cement CoefficientsDokumen2 halamanCement CoefficientsAmit Agarwal95% (57)

- 35x45 ModelDokumen1 halaman35x45 ModelErMelvinDiasBelum ada peringkat

- 123 LL 45Dokumen1 halaman123 LL 45ErMelvinDiasBelum ada peringkat

- 1.13 Tender Section ADokumen12 halaman1.13 Tender Section AErMelvinDiasBelum ada peringkat

- ValuationDokumen2 halamanValuationErMelvinDiasBelum ada peringkat

- Practical Plumbing HandbookDokumen56 halamanPractical Plumbing HandbookcruzserBelum ada peringkat

- Plans Layout3Dokumen1 halamanPlans Layout3ErMelvinDiasBelum ada peringkat

- Estimating and Valuation.Dokumen133 halamanEstimating and Valuation.shrikant83% (6)

- 07 Nov 2015 124358050LDK45POTprefeasibilityreportDokumen81 halaman07 Nov 2015 124358050LDK45POTprefeasibilityreportErMelvinDias100% (1)

- 1455j jh4jh56Dokumen1 halaman1455j jh4jh56ErMelvinDiasBelum ada peringkat

- Building Handover GuideDokumen34 halamanBuilding Handover GuideAnbu Tamil100% (1)

- 1455j jh4jh56Dokumen1 halaman1455j jh4jh56ErMelvinDiasBelum ada peringkat

- West Facing - Plan 2Dokumen1 halamanWest Facing - Plan 2ErMelvinDiasBelum ada peringkat

- T-Model FFDokumen1 halamanT-Model FFErMelvinDiasBelum ada peringkat

- Data Book For Civil Engineers 1Dokumen36 halamanData Book For Civil Engineers 1ErMelvinDias100% (1)

- 02conversion TableDokumen3 halaman02conversion TableravirainbowBelum ada peringkat

- T ModelDokumen1 halamanT ModelErMelvinDiasBelum ada peringkat

- Cocoa Nursery Manual Feb 2013Dokumen51 halamanCocoa Nursery Manual Feb 2013jeffreyBelum ada peringkat

- Master Handover Rev 4-2013Dokumen8 halamanMaster Handover Rev 4-2013MeysamGholizadehBelum ada peringkat

- OSA Winter 2011 NewsletterDokumen18 halamanOSA Winter 2011 NewsletterNABSWOSABelum ada peringkat

- 4 Strength and Durability of Concrete With LC3Dokumen41 halaman4 Strength and Durability of Concrete With LC3Mirza BasitBelum ada peringkat

- Gazettes 1686290048232Dokumen2 halamanGazettes 1686290048232allumuraliBelum ada peringkat

- Chapter 8 Sensation and PerceptionDokumen66 halamanChapter 8 Sensation and Perceptionapi-726122866Belum ada peringkat

- 1st English Lesson 6-7 - CompressedDokumen21 halaman1st English Lesson 6-7 - Compressedharonac588Belum ada peringkat

- Ceramic Fiber 23Dokumen28 halamanCeramic Fiber 23Kowsik RajendranBelum ada peringkat

- Industrial Diesel Generator Set - 50 HZ: General Specifications KOHLER Premium QualityDokumen7 halamanIndustrial Diesel Generator Set - 50 HZ: General Specifications KOHLER Premium QualityABCD123655Belum ada peringkat

- Flexible Learnin G: Group 3 Bsed-Math 2Dokumen48 halamanFlexible Learnin G: Group 3 Bsed-Math 2Niña Gel Gomez AparecioBelum ada peringkat

- California Department of Corrections EmailDokumen3 halamanCalifornia Department of Corrections EmailHeidi McCaffertyBelum ada peringkat

- AASHTO Digital Publications: Instructions Located HereDokumen2 halamanAASHTO Digital Publications: Instructions Located HereMinn LwinBelum ada peringkat

- Kevin Coleman's Sentencing MemoDokumen26 halamanKevin Coleman's Sentencing MemoThe Valley IndyBelum ada peringkat

- M 17Dokumen5 halamanM 17amhm2000100% (1)

- TZ150-03 Service Manual - ChopperDokumen42 halamanTZ150-03 Service Manual - ChopperMax Dean Araújo FernandesBelum ada peringkat

- 1109 KW 1,487 HP: Gross HorsepowerDokumen12 halaman1109 KW 1,487 HP: Gross HorsepowerDedek SukmaBelum ada peringkat

- 1-1FlowCharts For HaccpDokumen3 halaman1-1FlowCharts For HaccpPeter George0% (1)

- Effect of Different Immediate Dentin Sealing Techniques On The Microtensile Bond Strength PDFDokumen6 halamanEffect of Different Immediate Dentin Sealing Techniques On The Microtensile Bond Strength PDFclaudiaBelum ada peringkat

- Personal Loan For JoiningDokumen3 halamanPersonal Loan For JoiningAzim SengalBelum ada peringkat

- 2.10 A Substrate Is Decomposed in The Presence of An Enzyme According To The Michaelis-MentenDokumen2 halaman2.10 A Substrate Is Decomposed in The Presence of An Enzyme According To The Michaelis-MentenEureca ParraBelum ada peringkat

- Experiment-3: Study of Microstructure and Hardness Profile of Mild Steel Bar During Hot Rolling (Interrupted) 1. AIMDokumen5 halamanExperiment-3: Study of Microstructure and Hardness Profile of Mild Steel Bar During Hot Rolling (Interrupted) 1. AIMSudhakar LavuriBelum ada peringkat

- Ra Radtech Cdo July2018Dokumen4 halamanRa Radtech Cdo July2018Angelo MercedeBelum ada peringkat

- Itopride HCL Pynetic 50mg TabDokumen2 halamanItopride HCL Pynetic 50mg TabAusaf AhmadBelum ada peringkat

- 4a-Ancient Indian Engineering BotanyDokumen44 halaman4a-Ancient Indian Engineering BotanyAshok NeneBelum ada peringkat

- 2 Day ALS Programme 24 Candidates IO ARS (March 2016) PDFDokumen2 halaman2 Day ALS Programme 24 Candidates IO ARS (March 2016) PDFCojocariu Emanuel50% (2)

- O/W: Mayne To Reward The Willing: Mayne Pharma Group (MYX)Dokumen8 halamanO/W: Mayne To Reward The Willing: Mayne Pharma Group (MYX)Muhammad ImranBelum ada peringkat

- Assessment of Reading Comprehension 2Dokumen8 halamanAssessment of Reading Comprehension 2Kutu DemangBelum ada peringkat

- SWT Nedelka Cartagena enDokumen2 halamanSWT Nedelka Cartagena enChristian Lazo FerreyraBelum ada peringkat

- The Learner The Learner : 1 QuarterDokumen4 halamanThe Learner The Learner : 1 QuarterRode Jane SumambanBelum ada peringkat

- Lean Six Sigma Green BeltDokumen7 halamanLean Six Sigma Green Beltmulpuru sai snehaBelum ada peringkat

- Marine Structural Design CalculationsDari EverandMarine Structural Design CalculationsPenilaian: 4.5 dari 5 bintang4.5/5 (13)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresDari EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresPenilaian: 1 dari 5 bintang1/5 (2)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDari EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsBelum ada peringkat

- Pocket Guide to Flanges, Fittings, and Piping DataDari EverandPocket Guide to Flanges, Fittings, and Piping DataPenilaian: 3.5 dari 5 bintang3.5/5 (22)

- Advanced Modelling Techniques in Structural DesignDari EverandAdvanced Modelling Techniques in Structural DesignPenilaian: 5 dari 5 bintang5/5 (3)

- To Engineer Is Human: The Role of Failure in Successful DesignDari EverandTo Engineer Is Human: The Role of Failure in Successful DesignPenilaian: 4 dari 5 bintang4/5 (138)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsDari EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsBelum ada peringkat

- Structural Cross Sections: Analysis and DesignDari EverandStructural Cross Sections: Analysis and DesignPenilaian: 4.5 dari 5 bintang4.5/5 (19)

- Bridge Design: Concepts and AnalysisDari EverandBridge Design: Concepts and AnalysisPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Pile Design and Construction Rules of ThumbDari EverandPile Design and Construction Rules of ThumbPenilaian: 4.5 dari 5 bintang4.5/5 (15)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingDari EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingBelum ada peringkat

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesDari EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraPenilaian: 4.5 dari 5 bintang4.5/5 (4)

- Tensegrity: Structural Systems for the FutureDari EverandTensegrity: Structural Systems for the FuturePenilaian: 1 dari 5 bintang1/5 (1)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsDari EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsPenilaian: 4 dari 5 bintang4/5 (16)

- Design and Construction of Soil Anchor PlatesDari EverandDesign and Construction of Soil Anchor PlatesPenilaian: 5 dari 5 bintang5/5 (1)

- Engineering for Kids: Building and Construction Fun | Children's Engineering BooksDari EverandEngineering for Kids: Building and Construction Fun | Children's Engineering BooksPenilaian: 3 dari 5 bintang3/5 (2)