Std12 Voc GM Em12

Diunggah oleh

Sathisha MkJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Std12 Voc GM Em12

Diunggah oleh

Sathisha MkHak Cipta:

Format Tersedia

EML2322L Time Estimation for Part Manufacturing

#VALUE!

Student Experience Level

MANUFACTURING PROCESS

BEGINNER

INTERMEDIATE

[min]

[min]

mark & cut 1/2" x 2" rectangular bar stock on bandsaw

load part and endmill into mill

face first pair of sides (1/2" x 4") [A]

face second pair of sides (2" x 4") [B]

mill part to final (4") length [C]

machine 2" x 2" x 1/4" step into part [D]

find X, Y zeros using edgefinder

drill and tap (4) 10-24 threaded holes, 0.25" deep [E]

drill and countersink (4) #10 clearance holes, 0.5" deep [F]

drill and ream precision 5/16" hole, 0.5" deep [G]

turn part 90-deg and reload into vise

find X, Y zeros using edgefinder

drill and tap (1) 10-24 threaded hole, 0.75" deep [H]

12

8

10

15

20

30

10

40

25

20

3

10

15

7

5

7

12

15

20

8

35

20

12

2

8

12

time to debur part between steps

time to clean machine when finished

15

10

10

8

243

4.1

181

3.0

ESTIMATED MANUFACTURING TIME:

[min]

[hr]

NOTE 1: times are estimates based on experience; BEGINNER times are how long each

task should take the first time a TA explains it during the assigned parts manufacturing in

the first half of the semester; INTERMEDIATE times are how long it would take a competent

student who paid attention and attended office hours to repeat a similar task; ask a TA if

you have questions about any of the time estimates.

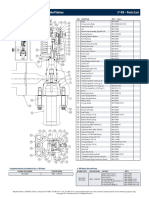

NOTE 2: refer to the image(s) shown below for clarification of the tasks / features detailed

in the table above; when detailing manufacturing time estimates for your individual

concepts, include a sketch of each part; however sketches can be hand drawn or copied

from your DR1 submission; they do not need to be fancy or CAD generated, only detailed

enough to show key part features.

NOTE 3: there are 7 different sheets (pages) in this workbook which are

accessed by selecting the various tabs at the bottom of the page.

EML2322L Time Estimation for Part Manufacturing

#VALUE!

Student Experience Level

MANUFACTURING PROCESS

BEGINNER

[min]

INTERMEDIATE

[min]

mark & cut 2" dia. bar stock on bandsaw

load part and cutting tool into lathe

face first end of part [A]

turn main shoulder on part [B]

cut chamfers on front (2) edges of part [C]

mark & cutoff part to ~1.6" on bandsaw [D]

reload part into lathe and face second end of part [E]

drill and ream precision 5/16" center hole, 1.5" deep [F]

load part and drill chuck into mill

find X, Y zeros using edgefinder

drill and tap (3) 10-24 threaded holes, 0.5" deep [G]

turn part 90-deg and reload into vise

find X, Y zeros using edgefinder

drill and tap (2) 10-24 threaded hole, 0.5" deep [H]

12

8

5

35

5

12

7

25

8

10

30

3

10

20

7

5

3

20

3

7

5

15

6

8

25

2

8

15

misc. time to debur part between steps

time to clean machines when finished

5

20

4

16

215

3.6

149

2.5

ESTIMATED MANUFACTURING TIME:

[min]

[hr]

NOTE 1: times are estimates based on experience; BEGINNER times are how long each

task should take the first time a TA explains it during the assigned parts manufacturing

in the first half of the semester; INTERMEDIATE times are how long it would take a

competent student who paid attention and attended office hours to repeat a similar task;

ask a TA if you have questions about any of the time estimates.

NOTE 2: refer to the image(s) shown below for clarification of the tasks / features

detailed in the table above; when detailing manufacturing time estimates for your

individual concepts, include a sketch of each part; however sketches can be hand drawn

or copied from your DR1 submission; they do not need to be fancy or CAD generated,

only detailed enough to show key part features.

EML2322L Time Estimation for Part Manufacturing

#VALUE!

Student Experience Level

MANUFACTURING PROCESS

BEGINNER

[min]

INTERMEDIATE

[min]

mark & cut 3/16" x 2.5" bar stock on bandsaw

load part(s) into milling machine vise

find X, Y zeros using edgefinder

drill (3) clearance holes for motor mounting, thru [A]

drill (1) clearance hole for motor shaft clearance, thru [B]

drill (2) clearance holes for bracket mounting, thru [C]

10

5

10

20

15

8

3

8

15

10

time to debur part between steps

time to clean machine when finished

5

7

3

5

72

1.2

52

0.9

ESTIMATED MANUFACTURING TIME:

[min]

[hr]

NOTE 1: times are estimates based on experience; BEGINNER times are how long each

task should take the first time a TA explains it during the assigned parts manufacturing in

the first half of the semester; INTERMEDIATE times are how long it would take a

competent student who paid attention and attended office hours to repeat a similar task;

ask a TA if you have questions about any of the time estimates.

NOTE 2: refer to the image(s) shown below for clarification of the tasks / features

detailed in the table above; when detailing manufacturing time estimates for your

individual concepts, include a sketch of each part; however sketches can be hand drawn

or copied from your DR1 submission; they do not need to be fancy or CAD generated,

only detailed enough to show key part features.

EML2322L Time Estimation for Part Manufacturing

#VALUE!

Student Experience Level

MANUFACTURING PROCESS

BEGINNER

[min]

INTERMEDIATE

[min]

mark & cut 2" dia. bar stock on bandsaw

load part and cutting tool into lathe

face first end of part [A]

turn main shoulder on part [B]

cut chamfers on front (2) edges of part [C]

mark & cutoff part to ~1.6" on bandsaw [D]

reload part into lathe and face second end of part [E]

drill and ream precision center hole, 1.5" deep [F]

bore 3/4" dia center hole, 0.9" deep [G]

rotate part 180-deg and reclamp in lathe chuck

drill 10mm dia center hole, 0.4" deep [H]

load part and drill chuck into mill

find X, Y zeros using edgefinder

drill and tap (3) 10-24 threaded holes, 0.5" deep [I]

12

8

5

35

5

12

7

25

12

3

8

8

10

30

7

5

3

20

3

7

5

15

10

1

5

6

8

25

misc. time to debur part between steps

time to clean machines when finished

5

20

4

16

205

3.4

140

2.3

ESTIMATED MANUFACTURING TIME:

[min]

[hr]

NOTE 1: times are estimates based on experience; BEGINNER times are how long each

task should take the first time a TA explains it during the assigned parts manufacturing

in the first half of the semester; INTERMEDIATE times are how long it would take a

competent student who paid attention and attended office hours to repeat a similar task;

ask a TA if you have questions about any of the time estimates.

NOTE 2: refer to the image(s) shown below for clarification of the tasks / features

detailed in the table above; when detailing manufacturing time estimates for your

individual concepts, include a sketch of each part; however sketches can be hand drawn

or copied from your DR1 submission; they do not need to be fancy or CAD generated,

only detailed enough to show key part features.

EML2322L Time Estimation for Part Manufacturing

#VALUE!

Relative Part Complexity

MANUFACTURING PROCESS

SIMPLE

[min]

MORE COMPLEX

[min]

select to material blank from which to make part

layout cut and fold lines using full scale paper template

cut part to overall size using foot shear or bandsaw [A]

center punch hole locations using a hammer and punch

if possible, punch holes using sheetmetal punch press [B]

bend sides or tabs of part using sheetmetal brake(s) [C]

weld corners of part for additional strength or stiffness, or

weld part to another to create a larger assembly [D]

5

10

7

3

7

5

10

20

12

5

12

20

15

25

time to debur part between steps

time to dispose of material scraps when finished

5

3

7

4

60

1.0

115

1.9

ESTIMATED MANUFACTURING TIME:

[min]

[hr]

NOTE 1: times are estimates based on experience; SIMPLE times are how long basic task

should take on simple parts like the one shown below; MORE COMPLEX times are how

long it would take a competent student who attended office hours to make a more complex

part requiring similar features; ask a TA if you have questions about any of the time

estimates.

NOTE 2: refer to the image(s) shown below for clarification of the tasks / features detailed

in the table above; when detailing manufacturing time estimates for your individual

concepts, include a sketch of each part; however sketches can be hand drawn or copied

from your DR1 submission; they do not need to be fancy or CAD generated, only detailed

enough to show key part features.

EML2322L Time Estimation for Part Manufacturing

#VALUE!

Student Experience Level

MANUFACTURING / ASSEMBLY PROCESS

BEGINNER

[min]

INTERMEDIATE

[min]

mark & cut aluminum bar stock on bandsaw

mark & cut 80/20 aluminum extrusion on bandsaw

retrieve pre-cut pieces of 80/20 off shelf

10

7

3

5

5

3

load part into milling machine

load tool (endmill, drill chuck, etc.) into milling machine

face sides (1/2" x 4")

face sides (2" x 4")

mill part to final length

machine 2" x 2" x 1/4" step into part

find X, Y zeros using edgefinder

drill (1) #10 clearance hole, 0.25" deep

drill (4) #10 clearance holes, 0.25" deep

drill and tap (1) 10-24 threaded hole, 0.25" deep

drill and tap (4) 10-24 threaded holes, 0.25" deep

drill and ream precision 5/16" hole, 0.5" deep

3

3

10

15

20

30

10

10

25

15

40

20

1

1

7

12

15

20

8

7

15

10

35

12

load part and cutting tool into lathe

face one end of part

turn main shoulder on part

cut chamfers on front (2) edges of part

drill and ream precision 5/16" center hole, 1.5" deep

8

5

35

5

25

5

3

20

3

15

select the material blank from which to make part

layout cut and fold lines using full scale paper template

cut part to overall size using foot shear or bandsaw

center punch hole locations using a hammer and punch

if possible, punch holes using sheetmetal punch press

bend sides or tabs of part using sheetmetal brake(s)

weld corners of part for additional strength or stiffness, or

weld part to another to create a larger assembly

10

20

12

5

12

20

5

10

7

3

7

5

25

15

attach motor to motor mount

attach motor mount to robot frame

attach wheel hub to motor

attach wheel to wheel hub

attach caster wheel to robot frame

attach and wire control box for first time

10

5

10

10

10

20

5

5

7

7

7

20

etcetera

EML2322L Time Estimation for Part Manufacturing

#VALUE!

Est. Time

[min]

Quantity

[-]

5

7.5

6

2

30

15

0.5

0.3

manufacture motor mount (like course example)

72

144

2.4

manufacture wheel hub (like course example)

modify wheel hub made earlier in the semester

205

20

1

1

205

20

3.4

0.3

attach motor to motor mount [A]

attach motor mount to robot frame [B]

attach wheel hub to motor [C]

attach wheel to wheel hub [D]

attach caster wheel to robot frame [E]

attach and wire control box for first time

7.5

5

8.5

8.5

10

20

2

2

2

2

1

1

15

10

17

17

10

20

0.3

0.2

0.3

0.3

0.2

0.3

503

8.4

MANUFACTURING / ASSEMBLY PROCESS

DESIGN 1

retrieve pre-cut pieces of 80/20 off shelf

mark & cut remaining 80/20 on bandsaw

TOTAL:

Subtotal

[min]

[hr]

DESIGN 2

etcetera

NOTE 1: times are estimates based on experience; ask a TA if you have questions.

NOTE 2: refer to the image(s) shown below for clarification of the various tasks detailed in

the table above; when detailing assembly time estimates for your individual concepts,

include sketch copies from your DR1 submission, or present additonal sketches if the

orignals do not clearly show all components.

Anda mungkin juga menyukai

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- General Machinist HandbookDokumen320 halamanGeneral Machinist HandbookHakuna Matata100% (7)

- Am Am VM VM V V LW: ME488/588 Machining Costs Homework Problem Cylinder PlateDokumen1 halamanAm Am VM VM V V LW: ME488/588 Machining Costs Homework Problem Cylinder PlatepchakkrapaniBelum ada peringkat

- Casting Catalog2 OptDokumen39 halamanCasting Catalog2 OptSathisha MkBelum ada peringkat

- CASTING Design GuideDokumen54 halamanCASTING Design GuideXin Yu75% (4)

- ReceiptDokumen24 halamanReceiptmbasgroupBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- What Is Button RiflingDokumen2 halamanWhat Is Button RiflingGyörgy MurvaiBelum ada peringkat

- Motorized Mechanical Can CrusherDokumen4 halamanMotorized Mechanical Can CrusherANAND KRISHNANBelum ada peringkat

- Chisel NewDokumen4 halamanChisel NewCornelius BillyBelum ada peringkat

- Bore LightDokumen14 halamanBore LightwlamillerBelum ada peringkat

- Manual Valvula 3'' Titan RXDokumen2 halamanManual Valvula 3'' Titan RXrolandBelum ada peringkat

- Kitchen Lay OutDokumen14 halamanKitchen Lay OutLei Azhly HortezBelum ada peringkat

- Hardinge HLV-H Maintenance ManualDokumen186 halamanHardinge HLV-H Maintenance ManualOogway MasterBelum ada peringkat

- Cost Estimation For Mass Production Using Jigs and FixtureDokumen9 halamanCost Estimation For Mass Production Using Jigs and FixturePraveen KumarBelum ada peringkat

- 03 Micro MeterDokumen16 halaman03 Micro MeterHarsh SaharanBelum ada peringkat

- Jig Saw PuzzleDokumen1 halamanJig Saw Puzzleapi-363029217Belum ada peringkat

- Training-Activity-Matrix-NewDokumen3 halamanTraining-Activity-Matrix-NewLyka ollerasBelum ada peringkat

- Amot 8071A Thermocontroller PDFDokumen14 halamanAmot 8071A Thermocontroller PDFИван ПарлапановBelum ada peringkat

- Steyr S40-A1Dokumen63 halamanSteyr S40-A1AUGieDogie1Belum ada peringkat

- NEOPRSP001FM006 - Rev. 00 - Pages 02 - Startup Checklist For SWRO TrainsDokumen2 halamanNEOPRSP001FM006 - Rev. 00 - Pages 02 - Startup Checklist For SWRO Trainsalialharbi021Belum ada peringkat

- Exercise 6Dokumen8 halamanExercise 6Gwyneth Marie DayaganBelum ada peringkat

- SK Form 1: Gripper With HolderDokumen16 halamanSK Form 1: Gripper With HolderVladimirAgeevBelum ada peringkat

- Refrigeration Cycle ComponentsDokumen23 halamanRefrigeration Cycle ComponentskamkarapnaBelum ada peringkat

- Brochure Reamers Type KDokumen2 halamanBrochure Reamers Type KPatrizio MassaroBelum ada peringkat

- Fuze Recognization Guide in WorldDokumen336 halamanFuze Recognization Guide in WorldOlegVal100% (7)

- 100 ITEMS Answer Sheet PDFDokumen1 halaman100 ITEMS Answer Sheet PDFAlice StarBelum ada peringkat

- High Pressure Logic Valves: Mechanical and PilotDokumen6 halamanHigh Pressure Logic Valves: Mechanical and PilotMohamed MusaBelum ada peringkat

- Group 7 RCV Lever: 1. Removal and InstallDokumen15 halamanGroup 7 RCV Lever: 1. Removal and InstallRafał DworakBelum ada peringkat

- Dremel Quick Start BookDokumen49 halamanDremel Quick Start BookPetar Kožul100% (4)

- Sistema de Freno 931Dokumen2 halamanSistema de Freno 931kathy fernandezBelum ada peringkat

- S 60 H - InstallationDokumen4 halamanS 60 H - InstallationshawnespinozaBelum ada peringkat

- Juk LK-1952 1953 1954Dokumen46 halamanJuk LK-1952 1953 1954RHoskaBelum ada peringkat

- Equipment Supplies 1Dokumen77 halamanEquipment Supplies 1alltheloveintheworldBelum ada peringkat

- Method Statement For Fresh Air Handling UnitsDokumen5 halamanMethod Statement For Fresh Air Handling UnitsHuỳnh Đức ThiệnBelum ada peringkat

- Genuis CatalogDokumen469 halamanGenuis Catalogjepoymcsrt2296Belum ada peringkat

- BCSD Ordering HandbookDokumen12 halamanBCSD Ordering Handbookgabrielsilva2042Belum ada peringkat