Calibrating The Discharge Coefficient of Semicircular Crested Weir

Diunggah oleh

شيماء الهاشميDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Calibrating The Discharge Coefficient of Semicircular Crested Weir

Diunggah oleh

شيماء الهاشميHak Cipta:

Format Tersedia

Eng. & Tech. Journal, Vol. 28, No.

24, 2010

Calibrating the Discharge Coefficient of Semicircular

Crested Weir

Thabet M. Abdul-latif * & Mohammed Sharif Abdul-Mohsen*

Received on: 31/5/2010

Accepted on: 4/11/2010

Abstract

This study deals with the evaluation of discharge coefficient of semicircle

crested weir extending across the full width of the channel (suppressed).It is stable

over flow pattern, easy to pass floating debris, and has large coefficient of

discharge. Data obtained from laboratory experiments provide information on

head discharge relationship for three models with different radius of curvature.

Each model has an empirical head- discharge equation. The momentum equation

is applied to derive discharge per unit width. The predicted values of discharge

coefficient for the proposed models based on direct discharge measurement & the

derived discharge equation. The proper application of this study is an equation

show that the discharge coefficient is proportional with upstream head above weir

crest & inversely with the radius of curvature.

Keywords: Curvilinear flow, pressure distribution, discharge coefficient

semicircular.

. ( )

.

.

.

.

.

Introduction

A semicircular broad crested

weir consists of an obstruction in the

form of a raised portion of bed

extending across the full width of the

channel. This raised portion has a

shape of semicircle figure (1). The

basic difference between broad

crested weir and the present model is

the curvature of stream lines. The

effect of curvature is to produce

appreciable acceleration components

or centrifugal forces normal to the

direction of flow [3].Another feature

of this model that it has larger

discharge capacity than the broad

crested weir and sharp crested weirs.

Related applications include three

models of polished wood models

*Building &Construction Engineering Department, University of Technology/ Baghdad

6831

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.28, No.24, 2010

with different radius of curvature. In

the present study the models

calibrated to determine the relation

between the head and rate of

discharge.

Theoretical Background

The two dimensional flow

patterns over cylindrical weirs can

describe by the Equation of motion

in

the

s-and

n-direction

[9].Curvilinear flow resulting in

diversion of pressure distribution

from hydrostatic as the flow occur in

the vertical plane[3] .The pressure

will be less than hydrostatic pressure

in convex flow when centrifugal

force acting upward against the

gravity action[7]. The rate of

departure from hydrostatic pressure

distribution is defined by the local

centrifugal acceleration ( /r). Thus

the change of piezometric head in ndirection is [9]:

The integration of equation (1) from

point (1) to point (2) in the ndirection figure (2a) yields:

Calibrating the Discharge Coefficient of

Semicircular Crested Weir

Critical Depth

In a rectangular horizontal

channel with hydrostatic pressure

distribution, the flow depth at critical

flow condition equals:

(4)

dc is commonly called the critical

flow depth at the crest of semicircular weir, critical flow occurs but

the pressure distribution is not

hydrostatic.

The

stream

line

curvature implies that the pressure

gradient is less than hydrostatic and

velocity distribution is rapidly varied

[1].Critical depth and its position on

weir are governed mainly by

frictional effects and stream line

curvature. Therefore, curvilinear

flow (dc/y1)

while in parallel

flow (dc/y1)

[6]. For all these

reasons, the depth at the crest of

semi-circular weir is expected to

differ from equation (4).

Computation of Pressure

Distribution

equals

the

Where

piezometric head at point (1) and

point

(2)

respectively

and

is the loss of

piezometric head due to curvature of

surface line. A decrease of

piezometric head, which is due to

centrifugal acceleration, necessarily

a corresponding increase of velocity

head, thus:

Knowledge of the variation in

pressure is particularly important in

the design of hydraulic structure,

over which and in which flow is a

curved nature. The induced pressure

forces may cause damage or erosion

to the face of the structure. In the

vertical plane the effect of streamline

curvature is to increase or decrease

the pressure distribution. Flow over a

convex surface the pressure is

6832

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.28, No.24, 2010

Calibrating the Discharge Coefficient of

Semicircular Crested Weir

reduced below hydrostatic [8]. For

curved profiles, the total pressure

distribution can be determined

analytically by numerical method or

graphically by flow net analysis.

The second method is adopted in this

study. Figure (3) show the

application of flow-net analysis on

model (I). The corresponding

variation of pressure distribution

along the weir surface shown in

figure (4). Calculation of pressure

forces acting on the downstream

weir surface that counteract pressure

force acting on upstream weir

surface revel that the ratio between

these

two

resultant

forces

approximately (0.5) and thats mean

the upstream force is twice than the

down stream force for the three types

of models and the pressure force per

unit width acting on weir surface

which is equal and opposite in

direction to force exerted by weir on

block of water is calculated from

equation:

frictional forces on channel bed and

the second is frictional forces on

weir surface. The longitudinal

section of the short length of

horizontal channel shown in the

figure(5) in which the flow is

impeded by semicircular weir

located on channel bed.

Let the force exerted by the

weir on flow be (Pw) as derived in

equation (5).if the momentum

equation is applied to the body of

water between upstream approach

section (1) and downstream section

(2) as shown in the figure (5),the

following equation may be written:

. (6)

Where (q) the discharge per unit

width, y1and y2 are upstream and

downstream

weir

depths.

Experimental data have shown that

on the average,

in that

case the above equation can be

simplified and solved for q as:

(5)

Where y1 is upstream flow depth.

The accuracy of the last assumption

has been checked by flow-net

analysis.

Evaluation of Discharge

The discharge per unit width

of a broad crested weir across a

rectangular channel (q) can be

determined by application of the

momentum principle. Since it deals

only with external forces represented

by

upstream and downstream

hydrostatic and pressure forces

acting on weir surface. The

assumptions to be made are the

frictional forces ( ), ( ) are

negligible, where first symbol is the

(7)

Where

,

( ) is coefficient has the dimension

of (L3), is gravity acceleration, and

( ) is the upstream head above the

weir crest. In practice the observed

discharge differs from equation (7)

because it based on idealized

assumptions such as: hydrostatic

pressure distribution and uniform

velocity distribution in reality these

effects do occur and the must be

6833

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.28, No.24, 2010

accounted for by introduction of a

discharge coefficient (Cd)

Experimental Works

The

experiments

were

performed in a horizontal laboratory

flume with (5m) length, (0.076 m)

width, and (0.15) depth. Both bed

and walls were made of fibber glass

to

ensure

hydraulic

smooth

condition, figure (1). The flume is

supplied with a constant head tank.

The water discharge was measured

by a volume-time method, the flow

depth had been measured using point

gages, and the flow of semi-circle

were investigated in the laboratory

for three models of weir with

different radius of curvature (4, 6, 7)

cm which are placed along (3.85 m)

downstream out let of the tank and

fixed directly on side walls

(suppressed

type).

The

flow

regulating value was adjusted to give

the maximum possible discharge

with the corresponding depth

upstream and downstream of the

weir. The discharge was reduced in

five steps and series of readings for

(q) and (H) were taken for each type

of weirs. All experiments done with

zero slope channel bed. In addition,

photographs were taken during the

experiments and used to visualize the

flow pattern as shown in the figure

(1). Full details of data were reported

in appendix (A).

Experimental Results

The variations of (q) with (H)

for three models were shown in

figures (6), (7), and (8) respectively,

with five readings for each model as

showing in appendix (A). By

plotting (Log q) against (Log H) a

straight line relationship obtained its

equation of association, (q = C*Hm)

the

experimental

relationship

between (q) and (H) are:

Calibrating the Discharge Coefficient of

Semicircular Crested Weir

..

(For

R = 4 cm)..... (8)

(For

R = 6cm)..... (9)

(For

R = 7 cm).. (10)

Experimental data shows that the

practical range of the coefficient to

(

is varied as shown in table

(1).

Effect of Upstream Head on

Discharge Coefficient

The discharge coefficient data

are plotted as function of ratio (H/R).

The graphical representation show

that the discharge coefficient is

proportional to the ratio of (H/R) as

illustrated in figure (9). It appears

that if (R=) the stream lines are

straight and if they are curved there

is a significant flow velocity result is

increasing of discharge coefficient.

Effect of Radius of Curvature on

Discharge Coefficient.

The effect of radius of curvature was

investigated through series of

experiments. The average discharge

coefficients for each model are

plotted versus radius of curvature as

shown in the figure (10) which

reveal that the discharge coefficient

increased as the radius of curvature

decreased.

That is for any element of

stream line having radius of

curvature (r), has a normal

component of acceleration (an)

which is equal to ( 2/r) [9].

Resulting in non uniform velocity

distribution which has maximum

6834

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.28, No.24, 2010

Calibrating the Discharge Coefficient of

Semicircular Crested Weir

value at the inner surface and lower

value at the surface of flow as shown

in the figure (11).Thus the velocity

profile over the crest of circular weir

is significantly differs from the

theoretical log-law profile due to the

strong favorable pressure gradient

[2].

Discussion:

Pressure Distribution

The existence of centrifugal forces in

the upstream and down stream crosssection bounding the considered

zone of acceleration causing

reduction in pressure. This reduction

of pressure is investigated through

the application of flow-net analysis

with positive values of water

pressure measured along the weir

surface.

Under

those

such

circumstance where the over flowing

jet is in contact with the body of weir

and under pressure may not

developed near the weir crest. Note

that the reduction in pressure due to

streamlines curvature increases the

discharge coefficient.

Weir Coefficient

increases with increasing values of

(H) over the range of the calibration

note that the flow over the weir was

independent of downstream water

level. It's apparent at very low values

of (H), the effect of surface tension

and viscosity would influence the

behavior and results in curves shown

in figure (9).

For very high weir( that is R/H

large)the velocity of approach

becomes small so that (EH) but

with lower weir and the same flow

rate the velocity of approach

becomes larger and (E/H) increasing

in magnitude resulting in larger

values of (Cd) for lower weirs. The

actual flow over the weir will be less

than the ideal flow because the

effective flow area is considerably

smaller than (H*L) due to drawdown

from the top and contraction of flow

from the crest below [4].

In the case in which there is bed

curvature, equation will contain

additional term due to bed curvature

[7]. This effect included in equation

(7). Since the flow lie in vertical

curved plane, thus subjected to

normal acceleration in addition to

tangential acceleration and it may

used to conclude that a decrease of

velocity is to be expected with

increase of distance from center of

curvature [9]. Which result in

decreases in discharge coefficient as

radius of curvature increased as

shown in figure (10).

The pressure gradient over the crest

of semicircle broad crested weir

result in increasing discharge

coefficients illustrated in equation

(1).A decrease of piezometric head

due to centrifugal acceleration

necessarily induces a corresponding

increase of velocity head as given in

equation (3).

In the head-discharge equation of

each type of models, there is a weir

coefficient which represents the

combination of the approach velocity

head at measuring station, the

breadth of flow at control section,

and the streamline curvature. Thus

the influences of all these values are

included in weir coefficient (C). The

practical ranges of the coefficient (C)

to (H3/2) are shown in table (1).

Discharge coefficient

The

variation

of

discharge

coefficient (Cd) with respect to head

normalized to radius of curvature

(H/R) show that the discharge

coefficient is greatly effected by the

upstream head over the crest (H) and

the discharge coefficient values

6835

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.28, No.24, 2010

Calibrating the Discharge Coefficient of

Semicircular Crested Weir

Conclusions

The main objective of this study is to

estimate the discharge coefficient for

semicircular crested weir. The

experimental results and theoretical

discharge equation show that the

discharge coefficient increases as the

head upstream the weir crest

increased, the degree of curvature of

over flowing has a significant

influence on (Cd) and the discharge

coefficient

increases

if

the

streamlines curvature increases.

Thus the discharge coefficient is

depends on shape and type of the

measuring structure.

The pressure distribution varies

along the weir surface and there is a

transition from hydrostatic to

hydrodynamic pressure forces as the

flow moves in curvilinear vertical

plane however the determination of

these forces are calculated from

flow-net analysis.

From practical experiments

there are three different value of (C)

related to (H3/2) these values are

depend on the shape of approaching

channel section and to the power of

the head above the crest level. Each

of the empirical stage-discharge

equations (1, 2, 3) of this type have

been derived for that structure only.

References

[1] Chanson, H. and Montes, J.S. "

Over flow Characteristics of

Circular Weir: Effect of inflow

condition . "Journal of irrigation

and drainage energy. ASCE, Vol.

124, No.3, PP.152-162 (ISSNO

733-9437).

[2] Chara. Z, Jun. J.P. "Influence of a

gap on flow around horizontal

cylinder" E-mail: chara@ ih. Cas.

Cz,ih@ih. Cas.cz

[3] Chow, V.T. ,"Open Channel

Hydraulics", McGraw-Hill Book

Co. , 1959.

[4] Daugherty, R.L. Franzini, J.B.

Finnmore, E.J. "Fluid mechanics

with Engineering Application",

McGraw-Hill Book Co. , 1985.

[5] M. Heidarpour , H. Afzalimehr,

E. Khorami, " Application of

Stream Flow Around a Circular

cylinder to Circular-Crested Weir

Flow" Journal of Since and

Technology of Agriculture and

Natural Resources" 2008.

[6] M.L. Williams, J.M. Reddy, V.

Hasfuther , " calibration of long

crested

weir,

Discharge

Coefficient" Technical report ,

University of Wyoming. 2006

[7] Oscar Castro-Orgaz and H.

Chanson "Bernoulli Theorem,

Minimum Specific Energy, and

Water Wave Celerity in Open

Channel Flow" Journal of

Irrigation and Drainage Eng.

ASCE/2009/733.

[8] R.C. Berger and G.F. Carey

"Free surface flow over curved

surfaces part II : computational

model" International Journal for

numerical methods in Fluids.2005

[9] Vennerd, J.K, "Elementary

Fluid Mechanics", John Wiley and

Sons Book Co., 1961.

6836

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.28, No.24, 2010

Calibrating the Discharge Coefficient of

Semicircular Crested Weir

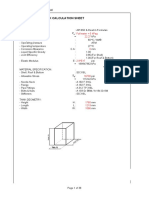

Table (1) coefficient values for models.

Type

of

weir radius (cm)

(C) value

Model I

1.7648

Model II

2.1898

Model III

2.1747

model

Figure (1) Flow pattern over the model. (I)

6837

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.28, No.24, 2010

Calibrating the Discharge Coefficient of

Semicircular Crested Weir

Figure (2) convex flow

Figure (3) Flow-net diagram for model (I).

6838

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.28, No.24, 2010

Calibrating the Discharge Coefficient of

Semicircular Crested Weir

Figure (4) pressure distribution over the weir

Figure (5) Definition sketch for momentum considerations.

6839

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.28, No.24, 2010

Calibrating the Discharge Coefficient of

Semicircular Crested Weir

Figure (6) the relationship between (q) with (H) for model (I)

Figure (7) the relationship between (q) with (H) for model (II)

6840

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.28, No.24, 2010

Calibrating the Discharge Coefficient of

Semicircular Crested Weir

Figure (8) the relationship between (q) with (H) for model (III)

Figure (9) relationship between Cd with H/R

6841

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.28, No.24, 2010

Calibrating the Discharge Coefficient of

Semicircular Crested Weir

Figure (10) average discharge coefficient VS. radius of curvature

Figure (11) velocity distribution on crest of the model

(after M. Heidarpour, 2008)

6842

PDF created with pdfFactory Pro trial version www.pdffactory.com

Eng. & Tech. Journal, Vol.28, No.24, 2010

Calibrating the Discharge Coefficient of

Semicircular Crested Weir

Appendix (A)

Experimental Data

Laboratory measurement for model (I) with (R = 4 cm) (the measured at equal distance of (1 cm) from the center line)

Q

Upstream

C.L

downstream

(l/s)

1.098 7.88 7.88 7.88 7.88 7.88 7.83 7.7

7.63 7.49 7.35 7.1

6.83 6.27 5.6

0.972

7.72 7.7

7.68 7.6

7.55 7.5

7.4

7.21 7.1

6.89 6.54 6.09 5.4

0.78

7.2

7.2

7.2

7.2

7.2

7.2

7.1

7.04 6.9

6.7

0.714

6.9

6.9

6.9

6.9

6.9

6.86 6.8

0.62

6.72 6.72 6.72 6.72 6.72 6.72 6.62 6.46 6.2

4.85 3.94 3.09 2.3

1.8

4.55 3.67 2.67 1.98 1.5

6.35 6.08 5.53 4.86 3.61 3.46 1.68 1.2

6.63 6.46 6.19 5.73 5.25 4.5

6

1.59 1.45 1.4

1.25

1.27 1.2

1.12 1.12

0.92

3.3

2.1

1.36 0.9

0.86

5.64 5.18 4.32 3.3

1.9

0.99 0.84 0.75

Laboratory measurement for model (II) with (R = 6 cm) (the measured at equal distance of (1 cm) from the center line)

Q (l/s)

Upstream

C.L

1.229

9.9

9.88 9.8

9.76 9.7

1.209

9.7

9.7

9.7

9.7

9.53 9.53 9.4 9.24 9.2

1.083

9.5

9.5

9.5

9.5

9.44 9.34 9.3 9.2

0.980

9.35 9.35 9.35 9.35 9.3

0.9337

9.14 9.1

9.64 9.6 9.45 9.34 9.14 8.9

9.2

9.04 8.98 8.9 8.75 8.6

8.63 8.25 7.78 7.2

9.05 8.61 8.43 8

9.06 9.84 8.6

9.1 9.04 8.9

downstream

8.7

8.5

8.35 8

6843

PDF created with pdfFactory Pro trial version www.pdffactory.com

8.3

7.54 6.9

6.5

5.4

4.44 3.15 2.44 1.84 1.54 1.33

5.1

3.9

2.99 2.16 1.5

7.62 6.84 5.95 4.96 3.68 2.7

8.24 7.88 7.4

6.77 5.9

8.1

6.5

7.7

7.2

4.8

3.5

5.64 4.96 3.1

1.9

2.47 1.7

1.3

1.54 1.25

1.2

2.05 1.34 1.08

Eng. & Tech. Journal, Vol.28, No.24, 2010

Calibrating the Discharge Coefficient of

Semicircular Crested Weir

Laboratory measurement for model (III) with (R = 7 cm) (the measured at equal distance of (1 cm) from the center line)

Q (l/s)

1.25

Upstream

10.72

10.6

10.6

10.5

C.L

10.44 10.32 10.2 10

Downstream

9.92 9.5

9.14 8.6

8.1

7.4

6.5

9.51 9.2

8.9

8.45 7.8

7.1

6.26 5.1

8.6

8.2

0.9868 10.26

10.26 10.26 10.17 10.1

10

9.9

9.7

0.8282 9.9

9.9

9.9

9.9

9.9

9.7

9.6

9.44 9.25 9

0.7587 9.67

9.67

9.67

9.67

9.65

9.5

9.4

9.2

0.6622 9.5

9.5

9.5

9.42

9.3

9.25

9.2

9.02 8.92 8.62 8.3

9.08 8.84 8.5

6844

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.75 2.6

7.66 6.91 5.96 4.63 3.1

8.09 7.6

7.9

5.98 4.98 2.98 2.15 1.64 1.32

6.8

5.7

2.9

1.77 1.2

1.1

1.32 1

4.46 2.77 1.75 1.15 0.86 0.75

7.34 6.53 5.54 4.4

2.6

1.5

0.75

Anda mungkin juga menyukai

- Pressure Drop in Laminar and Turbulent Flows in Circular PipeDokumen17 halamanPressure Drop in Laminar and Turbulent Flows in Circular Pipegestapo85Belum ada peringkat

- D-STEAM SIZING FOR VAPORIZING AMMONIADokumen2 halamanD-STEAM SIZING FOR VAPORIZING AMMONIAVinh Do ThanhBelum ada peringkat

- Hydraulic Jump ExperimentDokumen10 halamanHydraulic Jump ExperimentArvin De Lara Sanchez75% (4)

- 01 - 2011 - Hamill, Leslie - Understanding Hydraulics-Palgrave Macmillan PDFDokumen655 halaman01 - 2011 - Hamill, Leslie - Understanding Hydraulics-Palgrave Macmillan PDFDiego Orozco Rodriguez100% (1)

- 12951-Guidelines On Road Drainage-2Dokumen62 halaman12951-Guidelines On Road Drainage-2suaddadBelum ada peringkat

- 12951-Guidelines On Road Drainage-2Dokumen62 halaman12951-Guidelines On Road Drainage-2suaddadBelum ada peringkat

- Transport Phenomena I EssentialsDari EverandTransport Phenomena I EssentialsPenilaian: 2.5 dari 5 bintang2.5/5 (3)

- Pressure Pulsation in Reciprocating Pump - Part 1Dokumen9 halamanPressure Pulsation in Reciprocating Pump - Part 1Jose PradoBelum ada peringkat

- Abb FlowmetersDokumen84 halamanAbb FlowmetersAna QuintanaBelum ada peringkat

- Aspen Properties With ExcelDokumen27 halamanAspen Properties With Excelkukoo06Belum ada peringkat

- Trends: Present in Surge Tank DesignDokumen34 halamanTrends: Present in Surge Tank DesignashishroshanBelum ada peringkat

- Computational Wind Engineering 1: Proceedings of the 1st International Symposium on Computational Wind Engineering (CWE 92) Tokyo, Japan, August 21-23, 1992Dari EverandComputational Wind Engineering 1: Proceedings of the 1st International Symposium on Computational Wind Engineering (CWE 92) Tokyo, Japan, August 21-23, 1992S. MurakamiBelum ada peringkat

- CFD Ball ValveDokumen8 halamanCFD Ball ValveKelvin Octavianus DjohanBelum ada peringkat

- The Mechanics of Water-Wheels - A Guide to the Physics at Work in Water-Wheels with a Horizontal AxisDari EverandThe Mechanics of Water-Wheels - A Guide to the Physics at Work in Water-Wheels with a Horizontal AxisBelum ada peringkat

- Discharge Coefficient for Sharp-Crested Side Weir in Supercritical FlowDokumen8 halamanDischarge Coefficient for Sharp-Crested Side Weir in Supercritical FlowNacera BenslimaneBelum ada peringkat

- Ijciet: International Journal of Civil Engineering and Technology (Ijciet)Dokumen18 halamanIjciet: International Journal of Civil Engineering and Technology (Ijciet)IAEME PublicationBelum ada peringkat

- Fluid Dynamic Loading On Curved Riser PipesDokumen8 halamanFluid Dynamic Loading On Curved Riser PipeskhaphucBelum ada peringkat

- Crane J M Et Al - 2009 - Laminar Jet Discharged Into A Dead End TubeDokumen21 halamanCrane J M Et Al - 2009 - Laminar Jet Discharged Into A Dead End TubejadamiatBelum ada peringkat

- Head-Discharge Relationships For Rectangular Flat-Crested Slit WeirDokumen6 halamanHead-Discharge Relationships For Rectangular Flat-Crested Slit Weirشيماء الهاشميBelum ada peringkat

- An Experimental Study of Flow Over V - Shape Crump Weir CrestDokumen12 halamanAn Experimental Study of Flow Over V - Shape Crump Weir CresthisiBelum ada peringkat

- Flow Over A Broad-Crested Weir in Subcritical Flow Conditions, Physical StudyDokumen6 halamanFlow Over A Broad-Crested Weir in Subcritical Flow Conditions, Physical Studyho_afsharBelum ada peringkat

- Fluid Flow Through CrackDokumen14 halamanFluid Flow Through CrackAnwar PariyarathBelum ada peringkat

- Jet Control of The Draft Tube Vortex Rope in Francis Turbines at Partial DischargeDokumen14 halamanJet Control of The Draft Tube Vortex Rope in Francis Turbines at Partial DischargeFilip NikolicBelum ada peringkat

- Attenuation of Cavity Flow Oscillation Through Leading Edge Flow ControlDokumen25 halamanAttenuation of Cavity Flow Oscillation Through Leading Edge Flow ControlRehan NaseerBelum ada peringkat

- Labyrinth WierDokumen5 halamanLabyrinth Wiershefali1501Belum ada peringkat

- Free End Effects On The Near Wake Flow Structure Behind A Finite Circular CylinderDokumen16 halamanFree End Effects On The Near Wake Flow Structure Behind A Finite Circular CylinderMario Raul FreitasBelum ada peringkat

- Im Paper 25 K KawakitaDokumen10 halamanIm Paper 25 K KawakitaTAPAS SINGHBelum ada peringkat

- Free Flow Below Skew Sluice Gate: Talib MansoorDokumen9 halamanFree Flow Below Skew Sluice Gate: Talib MansoorIJERDBelum ada peringkat

- Steady Vortex Flow in Tangential IntakeDokumen8 halamanSteady Vortex Flow in Tangential IntakeEdgar ChuquipiondoBelum ada peringkat

- Cowl DeflectionDokumen7 halamanCowl DeflectionSrinivasan GunasekaranBelum ada peringkat

- Coherent Turbulence and Entrainment in A Supersonic, Axisymmetric Shear LayerDokumen27 halamanCoherent Turbulence and Entrainment in A Supersonic, Axisymmetric Shear LayerAmbara BernabeuBelum ada peringkat

- Calculation of The Transient Response of Small Orifices PDFDokumen10 halamanCalculation of The Transient Response of Small Orifices PDFsunilghajuBelum ada peringkat

- The Spiral-Channel Viscous Micropump: A.T. Al-Halhouli, M. I. Kilani, A. Al-Salaymeh, and S. BüttgenbachDokumen10 halamanThe Spiral-Channel Viscous Micropump: A.T. Al-Halhouli, M. I. Kilani, A. Al-Salaymeh, and S. BüttgenbachNur AlamBelum ada peringkat

- Ying 2011 A PDFDokumen6 halamanYing 2011 A PDFAngel CerriteñoBelum ada peringkat

- Interaction Between Sootblower Jet and Superheater Platens in Recovery BoilersDokumen4 halamanInteraction Between Sootblower Jet and Superheater Platens in Recovery BoilersAgung Pramu AjiBelum ada peringkat

- Ski Jump Hydraulics of Leak-Floor Flip BucketDokumen10 halamanSki Jump Hydraulics of Leak-Floor Flip BucketPrameela GurungBelum ada peringkat

- Jurnal Sharp Crested Weir (Important)Dokumen11 halamanJurnal Sharp Crested Weir (Important)Dante TjandraBelum ada peringkat

- Surface Roughness Effects On Discharge Coefficient of Broad Crested WeirDokumen7 halamanSurface Roughness Effects On Discharge Coefficient of Broad Crested WeirAnbu KumarBelum ada peringkat

- Pile to Slab Bridge Connections TestingDokumen10 halamanPile to Slab Bridge Connections TestingIsom Bahri BahriBelum ada peringkat

- Across Wind Vibrations of Structures of PDFDokumen25 halamanAcross Wind Vibrations of Structures of PDFAbhijeet OundhakarBelum ada peringkat

- Spillway Pre2Dokumen34 halamanSpillway Pre2Vikram SinghBelum ada peringkat

- Applications of The Momentum Principle - Hydraulic Jump, Surge and Flow Resistance Open ChannelsDokumen44 halamanApplications of The Momentum Principle - Hydraulic Jump, Surge and Flow Resistance Open ChannelsPaula Andrea Espinal100% (1)

- Relaxation Behaviour of Lithium-Borosilicate GlassesDokumen8 halamanRelaxation Behaviour of Lithium-Borosilicate GlassesInnovative Research PublicationsBelum ada peringkat

- Experimental Study of Flow About A Square Cylinder Placed On A WallDokumen4 halamanExperimental Study of Flow About A Square Cylinder Placed On A Wallxikun WBelum ada peringkat

- Wind Tunnel Velocity Profiles Generated by Differentially-Spaced Flat PlatesDokumen10 halamanWind Tunnel Velocity Profiles Generated by Differentially-Spaced Flat PlatesMario AlemanBelum ada peringkat

- Vol1no4-10 BhuiyanFDokumen11 halamanVol1no4-10 BhuiyanFSandra PowersBelum ada peringkat

- Numerical Simulation of Flow Past A Circular Cylinder With Varying Tunnel Height To Cylinder Diameter at Re 40Dokumen7 halamanNumerical Simulation of Flow Past A Circular Cylinder With Varying Tunnel Height To Cylinder Diameter at Re 40International Journal of computational Engineering research (IJCER)Belum ada peringkat

- 2004 Yossef ICHEDokumen9 halaman2004 Yossef ICHEVirgilio MartínezBelum ada peringkat

- Ye 2014Dokumen11 halamanYe 2014Albab HossainBelum ada peringkat

- Bendway Weir Designrio Grande Physical Model PDFDokumen10 halamanBendway Weir Designrio Grande Physical Model PDFVikasMahendrakarBelum ada peringkat

- Yin 2010Dokumen8 halamanYin 2010Pisindu DanushaBelum ada peringkat

- UEME 3112 Free Turbulent Jet May 2015Dokumen5 halamanUEME 3112 Free Turbulent Jet May 2015Adam Leong0% (1)

- Contraction Design - Bell 1988Dokumen37 halamanContraction Design - Bell 1988guto_spriteBelum ada peringkat

- Experimental Study and CFD Simulation of Two-Phase Flow Around Multi-Shape Obstacles in Enlarging ChannelDokumen17 halamanExperimental Study and CFD Simulation of Two-Phase Flow Around Multi-Shape Obstacles in Enlarging ChannelAndrés Sánchez GonzálezBelum ada peringkat

- Numerical modelling of subcritical open channel flowDokumen7 halamanNumerical modelling of subcritical open channel flowchrissbansBelum ada peringkat

- Chap 5 HJDokumen3 halamanChap 5 HJAdron LimBelum ada peringkat

- Surface Vortices and Pressures in Suction Intakes of Vertical Axial-Flow PumpsDokumen22 halamanSurface Vortices and Pressures in Suction Intakes of Vertical Axial-Flow PumpssauroBelum ada peringkat

- Purpose: The Fluid Mechanics of Ureteroscope IrrigationDokumen6 halamanPurpose: The Fluid Mechanics of Ureteroscope IrrigationClaudia PérezBelum ada peringkat

- Studies of Compression Corner Flowfields Using THREE Turbulent ModelsDokumen7 halamanStudies of Compression Corner Flowfields Using THREE Turbulent Modelsarnalt_stalinBelum ada peringkat

- A Comparison of Standard k-ε and Realizable k-ε Turbulence Models in Curved and Confluent ChannelsDokumen27 halamanA Comparison of Standard k-ε and Realizable k-ε Turbulence Models in Curved and Confluent ChannelsStephen Owen HizkiaBelum ada peringkat

- Hydraulic Jumps and Nonuniform Open Channel Flow CourseDokumen27 halamanHydraulic Jumps and Nonuniform Open Channel Flow CourseDianne M. DepositarioBelum ada peringkat

- Efficient Cruise and High-Acceleration Motions of Lunate PlanformsDokumen13 halamanEfficient Cruise and High-Acceleration Motions of Lunate Planformssamik4uBelum ada peringkat

- CHAPTER 4 Bernoulli Equation and Applications FinalDokumen29 halamanCHAPTER 4 Bernoulli Equation and Applications Finalgcytd65e756c56e765r100% (1)

- Hole Cleaning Performance of Light-Weight Drilling Fluids During Horizontal Underbalanced DrillingDokumen6 halamanHole Cleaning Performance of Light-Weight Drilling Fluids During Horizontal Underbalanced Drillingswaala4realBelum ada peringkat

- OrificeDokumen7 halamanOrificePrasillaPrisiBelum ada peringkat

- Fluid Dynamics in Complex Fractured-Porous SystemsDari EverandFluid Dynamics in Complex Fractured-Porous SystemsBoris FaybishenkoBelum ada peringkat

- 1 s2.0 S2090447915002117 MainDokumen8 halaman1 s2.0 S2090447915002117 Mainشيماء الهاشميBelum ada peringkat

- Head-Discharge Relationships For Rectangular Flat-Crested Slit WeirDokumen6 halamanHead-Discharge Relationships For Rectangular Flat-Crested Slit Weirشيماء الهاشميBelum ada peringkat

- 1 s2.0 S2090447914000926 MainDokumen11 halaman1 s2.0 S2090447914000926 Mainشيماء الهاشميBelum ada peringkat

- Effect of Vertical Curvature of Flow at Weir Crest On Discharge CoefficientDokumen14 halamanEffect of Vertical Curvature of Flow at Weir Crest On Discharge CoefficientMadusha TisseraBelum ada peringkat

- Determination of Discharge Coefficient of Rectangular Broad-Crested Side Weir in Trapezoidal Channel by CFDDokumen7 halamanDetermination of Discharge Coefficient of Rectangular Broad-Crested Side Weir in Trapezoidal Channel by CFDشيماء الهاشميBelum ada peringkat

- Water 07 05378 PDFDokumen18 halamanWater 07 05378 PDFشيماء الهاشميBelum ada peringkat

- Numerical Modeling of Sharp-Crested Triangular Plan Form Weirs Using FLUENTDokumen7 halamanNumerical Modeling of Sharp-Crested Triangular Plan Form Weirs Using FLUENTشيماء الهاشميBelum ada peringkat

- Coefficient of Broad-Crested Weirs in Natural ChannelsDokumen14 halamanCoefficient of Broad-Crested Weirs in Natural Channelsشيماء الهاشميBelum ada peringkat

- ADOTHighwayDrainageDesignManual HydraulicsDokumen760 halamanADOTHighwayDrainageDesignManual Hydraulicsmetra2slrBelum ada peringkat

- 01560Dokumen12 halaman01560sebastian zepeda alvarezBelum ada peringkat

- Development of Rectangular Broad-Crested Weirs For Flow Characteristics and Discharge MeasurementDokumen1 halamanDevelopment of Rectangular Broad-Crested Weirs For Flow Characteristics and Discharge Measurementشيماء الهاشميBelum ada peringkat

- Strenght of Mat DR AhmedDokumen184 halamanStrenght of Mat DR AhmedAlaomda Albasrawy100% (1)

- (Journal of Hydrology and Hydromechanics) Discharge Coefficient of A Rectangular Sharp-Edged Broad-Crested WeirDokumen5 halaman(Journal of Hydrology and Hydromechanics) Discharge Coefficient of A Rectangular Sharp-Edged Broad-Crested Weirشيماء الهاشميBelum ada peringkat

- Elmer Tutorials For SVALIDokumen152 halamanElmer Tutorials For SVALIbunjiiBelum ada peringkat

- Vanleeuwen PDFDokumen81 halamanVanleeuwen PDFشيماء الهاشميBelum ada peringkat

- 2007swmapp9 PDFDokumen15 halaman2007swmapp9 PDFشيماء الهاشميBelum ada peringkat

- Broad-Crested Weir Application On 15000-Acre Farm PDFDokumen5 halamanBroad-Crested Weir Application On 15000-Acre Farm PDFشيماء الهاشميBelum ada peringkat

- 2007swmapp9 PDFDokumen15 halaman2007swmapp9 PDFشيماء الهاشميBelum ada peringkat

- 2015 1008963 PDFDokumen12 halaman2015 1008963 PDFشيماء الهاشميBelum ada peringkat

- 14 7 PDFDokumen2 halaman14 7 PDFشيماء الهاشميBelum ada peringkat

- Weirs PDFDokumen20 halamanWeirs PDFشيماء الهاشميBelum ada peringkat

- MScThesis Ren PDFDokumen138 halamanMScThesis Ren PDFشيماء الهاشميBelum ada peringkat

- s42385743 Mphil Finalthesis PDFDokumen112 halamans42385743 Mphil Finalthesis PDFشيماء الهاشميBelum ada peringkat

- 10 1 1 401 9257 PDFDokumen9 halaman10 1 1 401 9257 PDFشيماء الهاشميBelum ada peringkat

- MScThesis Ren PDFDokumen138 halamanMScThesis Ren PDFشيماء الهاشميBelum ada peringkat

- Mat FoundationDokumen28 halamanMat FoundationMuhammad Salman Amir FASTNUBelum ada peringkat

- Master Vdocuments - MX Rectangular Tank CalculationDokumen38 halamanMaster Vdocuments - MX Rectangular Tank CalculationVipul GandhiBelum ada peringkat

- PHY F2 End Term 1Dokumen9 halamanPHY F2 End Term 1Selifa AbutiBelum ada peringkat

- High School Science Part IIDokumen256 halamanHigh School Science Part IIskmrrl0% (1)

- Evaluasi Kestabilan SuspensiDokumen13 halamanEvaluasi Kestabilan SuspensiMarthin Ferryanto RumahorboBelum ada peringkat

- Lessons Learned From Formation Pressure Measurements While DrillingDokumen14 halamanLessons Learned From Formation Pressure Measurements While DrillingjombibiBelum ada peringkat

- Single / Multistage Restriction Orifice AssembliesDokumen3 halamanSingle / Multistage Restriction Orifice Assembliesmohan babuBelum ada peringkat

- Chapter 2: Some Concepts and Definitions: ThermodynamicsDokumen66 halamanChapter 2: Some Concepts and Definitions: ThermodynamicsTanoosh KancharlaBelum ada peringkat

- Foam Chamber: Model - Fca & Fca-SDokumen8 halamanFoam Chamber: Model - Fca & Fca-SkalaiBelum ada peringkat

- Blackmer Autogas HandbookDokumen32 halamanBlackmer Autogas HandbookMuhammad ImranBelum ada peringkat

- PropertiesDokumen11 halamanPropertiesImranKabirBelum ada peringkat

- X Phy Masterkey Formulae 22 - 23Dokumen10 halamanX Phy Masterkey Formulae 22 - 23Mayank SahuBelum ada peringkat

- Modulos Resilient in Granulas Soils PDFDokumen25 halamanModulos Resilient in Granulas Soils PDFLuisRodrigoPerezPintoBelum ada peringkat

- Problems With Pitots: Question-AIRDokumen3 halamanProblems With Pitots: Question-AIRArnold StevenBelum ada peringkat

- Saudi Aramco Test ReportDokumen5 halamanSaudi Aramco Test Reportkarthi51289Belum ada peringkat

- Understanding Pump Curves: Taco Radiant Made Easy Application Guide Technical DocumentsDokumen4 halamanUnderstanding Pump Curves: Taco Radiant Made Easy Application Guide Technical DocumentsmohdnazirBelum ada peringkat

- Est TK EmissDokumen2 halamanEst TK EmissAZDOLMANBelum ada peringkat

- AGR 102 TheoryDokumen140 halamanAGR 102 TheoryKuttyBelum ada peringkat

- Well Test PaperDokumen3 halamanWell Test PaperJoseph Bimo100% (1)

- Molecular Mass Transport: 3.1 Introduction of Mass TransferDokumen34 halamanMolecular Mass Transport: 3.1 Introduction of Mass Transfergaurav sriBelum ada peringkat

- FT JOB 303 Modern Tools For Hopper Design PDFDokumen8 halamanFT JOB 303 Modern Tools For Hopper Design PDFhuyBelum ada peringkat

- TEST CODE: 807Dokumen76 halamanTEST CODE: 807Sandeep PrajapatiBelum ada peringkat

- Exercise Solid FluidDokumen3 halamanExercise Solid FluidChai Chun TanBelum ada peringkat

- PFD 8Dokumen1 halamanPFD 8Miftah MasrurBelum ada peringkat