3W High Power LED PDF

Diunggah oleh

tittyjohnJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

3W High Power LED PDF

Diunggah oleh

tittyjohnHak Cipta:

Format Tersedia

3W High Power LED

Features

Highest flux per LED family in the world

Very long operating life (up to 100k hours)

Available in Red, Yellow, Green, Blue, White

Lambertian radiation pattern

More energy efficient than incandescent and most halogen lamps

Low voltage DC operated

Cool beam, safe to the touch

Fully dimmable

No UV

Superior ESD protection

lower Rth

3W Blue LED

RoHS compliant Lead-free

Instant light (less than 100ns )

Applications

Portable (flashlight, bicycle)

Reading lights (car, bus, aircraft)

Orientation

Mini-accent

Decorative

Fiber optic alternative

Appliance

Sign and channel letter

Architectural detail

Cove lighting

Automotive exterior (Stop-Tail-Turn,CHMSL,Mirror side repeat)

3W White LED & Aluminum PCB

Edge lit signs (Exit, point of sale)

Catalog

1. Red 3W High Power LED ...........................................................................................................................................2

2. Yellow 3W High Power LED.......................................................................................................................................4

3. Green 3W High Power LED .......................................................................................................................................7

4. Blue 3W High Power LED ..........................................................................................................................................9

5. White 3W High Power LED ......................................................................................................................................12

Package Dimensions (unit:mm) .................................................................................................................................14

3W High Power LED

1. Red 3W High Power LED

Chip

PART NO

Material

Emitted Color

GaAllnP

Red

LED-P3-D-Red

Lens Color

WATER CLEAR

Absolute Maximum Ratings (Ta = 25)

Items

Symbol

Absolute Maximum Rating

Unit

Forward Current

IF

0.7

Peak Forward Current*

IFP

0.8

Reverse Voltage

VR

Power Dissipation

PD

Electrostatic discharge

ESD

2000

Operation Temperature

TOPR

-40~+80

Storage Temperature

TSTG

-40~+100

Lead Soldering Temperature*

TSOL

Max. 260 for 3sec Max.

*IFP ConditionsPulse Width10msec duty1/10

* Our MCPCB is usual use for installation and connection during application, but the ability of heat dissipation

is not enough. If lighted, our high power stars will need better another type heat dissipation equipment. So we

recommend the working time is not over 5 -10 seconds without any heat dissipation equipment.

*Reflow, wave peak and soak stannum soldering etc. is not suitable for this products.

*Suggest to solder it by professional high power LED soldering machine.

*Can use in variable temperature searing iron with soldering condition :260 degree less than 3 seconds.

Typical Electrical & Optical Characteristics ( Ta = 25)

Items

Symbol

Condition

Min.

Forward Voltage

VF

IF=0.7A

2.0

Reverse Current

IR

VR=5V

50% Power Angle

21/2

IF=0.7A

Luminous Intensity

IF=0.7A

Recommend Forward Current

IF

Wave Length

Typ.

Max.

Unit

2.8

50

uA

110

140

deg

50

80

lm

0.7

IF=0.7A

620

A

630

nm

Notes:1.Tolerance of measurement of forward voltage 0.1V.

2.Tolerance of measurement of peak Wavelength 2.0nm.

3.Tolerance of measurement of luminous intensity 15%.

Wayjun Technology Co.,Ltd

-2-

www.wayjun.com

3W High Power LED

Typical Electrical/Optical Characteristics Curves (Ta=25 Unless Otherwise Noted)

Wayjun Technology Co.,Ltd

-3-

www.wayjun.com

3W High Power LED

Radiation Pattern

2. Yellow 3W High Power LED

PART NO

Chip

Material

Emitted Color

GaAllnP

Yellow

LED-P3-D-Yellow

Lens Color

WATER CLEAR

Absolute Maximum Ratings (Ta = 25)

Items

Symbol

Absolute Maximum Rating

Unit

Forward Current

IF

0.7

Peak Forward Current*

IFP

0.8

Reverse Voltage

VR

Power Dissipation

PD

Electrostatic discharge

ESD

2000

Operation Temperature

TOPR

-40~+80

Storage Temperature

TSTG

-40~+100

Lead Soldering Temperature*

TSOL

Max. 260 for 3sec Max.

*IFP ConditionsPulse Width10msec duty1/10

* Our MCPCB is usual use for installation and connection during application, but the ability of heat dissipation

is not enough. If lighted, our high power stars will need better another type heat dissipation equipment. So we

recommend the working time is not over 5 -10 seconds without any heat dissipation equipment.

*Reflow, wave peak and soak stannum soldering etc. is not suitable for this products.

*Suggest to solder it by professional high power LED soldering machine.

*Can use in variable temperature searing iron with soldering condition :260 degree less than 3 seconds.

Wayjun Technology Co.,Ltd

-4-

www.wayjun.com

3W High Power LED

Typical Electrical & Optical Characteristics ( Ta = 25)

Items

Symbol

Condition

Min.

Forward Voltage

VF

IF=0.7A

2.0

Reverse Current

IR

VR=5V

50% Power Angle

21/2

IF=0.7A

Luminous Intensity

IF=0.7A

Recommend Forward Current

IF

Wave Length

Typ.

Max.

Unit

2.8

50

uA

110

140

deg

50

80

lm

0.7

IF=0.7A

580

A

595

nm

Notes:1.Tolerance of measurement of forward voltage 0.1V.

2.Tolerance of measurement of peak Wavelength 2.0nm.

3.Tolerance of measurement of luminous intensity 15%.

Typical Electrical/Optical Characteristics Curves (Ta=25 Unless Otherwise Noted)

Wayjun Technology Co.,Ltd

-5-

www.wayjun.com

3W High Power LED

Radiation Pattern

Wayjun Technology Co.,Ltd

-6-

www.wayjun.com

3W High Power LED

3. Green 3W High Power LED

Chip

PART NO

Material

LED-P3-D-Green

Lens Color

Emitted Color

InGaN

Green

WATER CLEAR

Absolute Maximum Ratings (Ta = 25)

Items

Symbol

Absolute Maximum Rating

Unit

Forward Current

IF

0.7

Peak Forward Current*

IFP

0.8

Reverse Voltage

VR

Power Dissipation

PD

Electrostatic discharge

ESD

2000

Operation Temperature

TOPR

-40~+80

Storage Temperature

TSTG

-40~+100

Lead Soldering Temperature*

TSOL

Max. 260 for 3sec Max.

*IFP ConditionsPulse Width10msec duty1/10

* Our MCPCB is usual use for installation and connection during application, but the ability of heat dissipation

is not enough. If lighted, our high power stars will need better another type heat dissipation equipment. So we

recommend the working time is not over 5 -10 seconds without any heat dissipation equipment.

*Reflow, wave peak and soak stannum soldering etc. is not suitable for this products.

*Suggest to solder it by professional high power LED soldering machine.

*Can use in variable temperature searing iron with soldering condition :260 degree less than 3 seconds.

Typical Electrical & Optical Characteristics ( Ta = 25)

Items

Symbol

Condition

Min.

Forward Voltage

VF

IF=0.7A

3.0

Reverse Current

IR

VR=5V

50% Power Angle

21/2

IF=0.7A

Luminous Intensity

IF=0.7A

Recommend Forward Current

IF

Wave Length

Typ.

Max.

Unit

3.8

50

uA

110

140

deg

120

160

lm

0.7

IF=0.7A

520

A

530

nm

Notes:1.Tolerance of measurement of forward voltage 0.1V.

2.Tolerance of measurement of peak Wavelength 2.0nm.

3.Tolerance of measurement of luminous intensity 15%.

Wayjun Technology Co.,Ltd

-7-

www.wayjun.com

3W High Power LED

Typical Electrical/Optical Characteristics Curves (Ta=25 Unless Otherwise Noted)

Wayjun Technology Co.,Ltd

-8-

www.wayjun.com

3W High Power LED

Radiation Pattern

4. Blue 3W High Power LED

PART NO

Chip

Material

Emitted Color

InGan

Blue

LED-P3-D-Blue

Lens Color

WATER CLEAR

Absolute Maximum Ratings (Ta = 25)

Items

Symbol

Absolute Maximum Rating

Unit

Forward Current

IF

0.7

Peak Forward Current*

IFP

0.8

Reverse Voltage

VR

Power Dissipation

PD

Electrostatic discharge

ESD

2000

Operation Temperature

TOPR

-40~+80

Storage Temperature

TSTG

-40~+100

Lead Soldering Temperature*

TSOL

Max. 260 for 3sec Max.

*IFP ConditionsPulse Width10msec duty1/10

* Our MCPCB is usual use for installation and connection during application, but the ability of heat dissipation

is not enough. If lighted, our high power stars will need better another type heat dissipation equipment. So we

recommend the working time is not over 5 -10 seconds without any heat dissipation equipment.

*Reflow, wave peak and soakstannum soldering etc. is not suitable for this products.

*Suggest to solder it by professional high power LED soldering machine.

*Can use in variable temperature searing iron with soldering condition :260 degree less than 3 seconds.

Wayjun Technology Co.,Ltd

-9-

www.wayjun.com

3W High Power LED

Typical Electrical & Optical Characteristics ( Ta = 25)

Items

Symbol

Condition

Min.

Forward Voltage

VF

IF=0.7A

3.0

Reverse Current

IR

VR=5V

50% Power Angle

21/2

IF=0.7A

Luminous Intensity

IF=0.7A

Recommend Forward Current

IF

Wave Length

Typ.

Max.

Unit

3.8

50

uA

110

140

deg

20

50

lm

0.7

IF=0.7A

460

A

470

nm

Notes:1.Tolerance of measurement of forward voltage 0.1V.

2.Tolerance of measurement of peak Wavelength 2.0nm.

3.Tolerance of measurement of luminous intensity 15%.

Typical Electrical/Optical Characteristics Curves (Ta=25 Unless Otherwise Noted)

Wayjun Technology Co.,Ltd

- 10 -

www.wayjun.com

3W High Power LED

Radiation Pattern

Wayjun Technology Co.,Ltd

- 11 -

www.wayjun.com

3W High Power LED

5. White 3W High Power LED

Chip

PART NO

Material

Emitted Color

InGaN

White

LED-P3-D-White

Lens Color

WATER CLEAR

Absolute Maximum Ratings (Ta = 25)

Items

Symbol

Absolute Maximum Rating

Unit

Forward Current

IF

0.7

Peak Forward Current*

IFP

0.8

Reverse Voltage

VR

Power Dissipation

PD

Electrostatic discharge

ESD

4500

Operation Temperature

TOPR

-40~+80

Storage Temperature

TSTG

-40~+100

Lead Soldering Temperature*

TSOL

Max. 260 for 3sec Max.

*IFP ConditionsPulse Width10msec duty1/10

* Our MCPCB is usual use for installation and connection during application, but the ability of heat dissipation

is not enough. If lighted, our high power stars will need better another type heat dissipation equipment. So we

recommend the working time is not over 5 -10 seconds without any heat dissipation equipment.

*Reflow, wave peak and soakstannum soldering etc. is not suitable for this products.

*Suggest to solder it by professional high power LED soldering machine.

*Can use in variable temperature searing iron with soldering condition :260 degree less than 3 seconds.

Typical Electrical & Optical Characteristics ( Ta = 25)

Items

Symbol

Condition

Min.

Forward Voltage

VF

IF=0.7A

3.2

Reverse Current

IR

VR=5V

50% Power Angle

21/2

IF=0.7A

Luminous Intensity

IF=0.7A

Recommend Forward Current

IF

Chromaticity

Tc

Max.

Unit

4.0

50

uA

110

140

deg

160

180

lm

0.7

IF=0.7A

White Color Region

6000

A

6500

--

Chromaticity Coordinates

Thermal Resistance,Junction to Case

Typ.

X=-RJP

IF=0.35A

Y=-10

/W

Notes:1.Tolerance of measurement of forward voltage 0.1V.

2.Tolerance of measurement of peak Wavelength 2.0nm.

3.Tolerance of measurement of luminous intensity 15%.

Wayjun Technology Co.,Ltd

- 12 -

www.wayjun.com

3W High Power LED

Typical Electrical/Optical Characteristics Curves (Ta=25 Unless Otherwise Noted)

Wayjun Technology Co.,Ltd

- 13 -

www.wayjun.com

3W High Power LED

Radiation Pattern

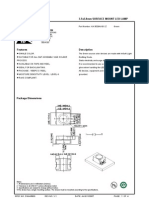

Package Dimensions (unit:mm)

Notes:

All dimensions in mm tolerance is 0.2mm unless otherwise noted.

Wayjun Technology Co.,Ltd

- 14 -

www.wayjun.com

3W High Power LED

Box Dimensions

3W High Power LED

3W High Power LED & Aluminum PCB

50 pcs. Per Box

25 pcs. Per Box

Dimensions: 13.9mm * 15.0mm

Dimensions:13.9mm * 17.8mm

Note the use of high-power LED

Product Protection

LED is the electrostatic sensitive devices, so the product storage, transportation, application process, paying

particular attention to static electricity, electromagnetic waves, and together with the necessary anti-static measures

Safety Precautions

Harmful substances such devices include GaAs, GaAs dust and fumes are toxic, this product can not be broken,

cutting or grinding, not with chemicals to dissolve.

Design and Application

1. in the ratings to be used within the operating LED current limit function of the resistor. How much resistance will

have to refer to the specific product specifications required to calculate the rated current plus that.

2. LED to be used in parallel mode, each LED channel by adding resistors are required, must not be led directly to

multiple parallel.

3. circuits shall be designed to note: When the LED goes out to prohibit reverse voltage.

4. circuitry required to design note: the lights, turn off the lights when you prevent the instantaneous voltage.

Wayjun Technology Co.,Ltd

- 15 -

www.wayjun.com

3W High Power LED

5. solder direction (electrode direction) to be orthogonal with the direction of PCB.

6. high temperature will reduce its performance and reliability, please stay away from heat sources.

Cleaning

1. avoid the use of non-designated chemical solvents to clean the LED.

For example: trichloroethene, chlorosilanes, acetone, difluoro esters.

2. If necessary cleaning carried out at room temperature, and not more than 1 minute.

3. When using any cleaning a chemical solvent to be especially careful, because some chemical solvents will

damage the gel surface.

4. recommend the use of isopropyl alcohol or pure water (not tap water) for cleaning.

5. If using pure water, then immediately after cleaning dehumidifying, forced drying.

Save

1. before unpacking, LED should be stored in 30 / 90% RH or less environment. After opening the package, LED

should be placed in 30 / 70% RH or below the environment

2. effective use for 1 year, after opening in 168H (7 days) of the exhausted.

3. If the use of desiccant fade or expired, the need to dry and roast: 60 6 / 24H.

4.LED James Gray lens easily, you need to do a good job related to dust control measures

Pick and place

Grasping LED can only touch on the body frame, tweezers, a tool can not put pressure on the lens, not to stamp.

stab or push the lens.

Heat treatment

When the LED current drive is too large the Tj (junction temperature) will exceed its limit, which can cause serious

shorten the life of LED, the heat treatment measures to effectively reduce the thermal resistance applications. More

common practice is to install the LED package device PCB board in the metal matrix. 1W LED products require heat

the metal substrate surface area of at least 30 C (3W products recommended above 80 C ), and its thermal

conductivity is higher than 2.0W/mK.LED and thermal conductivity of metal substrate by a better combination of

thermal plastic, thermal requirements Coefficient is higher than 1.0W/mK. thickness of less than 100um.

Warranty

All products manufactured by WAYJUN TECHNOLOGY are under warranty regarding defective materials for a

period of two years from the date of delivery to the original purchaser.

Copyright

Copyright 2009, by ShenZhen Wayjun Technology Co.,Ltd. All rights are reserved. ShenZhen Wayjun Technology

Co.,Ltd reserves the right to make improvements to the products described in this manual at any time without notice.

Trademark

The names used for identification only may be registered trademarks of their respective companies.

Edition: V1.3

Date: March 2011

Wayjun Technology Co.,Ltd

- 16 -

www.wayjun.com

Anda mungkin juga menyukai

- Esu Testing (Iec 60601-2-2)Dokumen41 halamanEsu Testing (Iec 60601-2-2)Marcele FonsecaBelum ada peringkat

- Theory and Applications (Chapters 1 Thru 9) Selector Guide.Dokumen498 halamanTheory and Applications (Chapters 1 Thru 9) Selector Guide.spyeagle100% (1)

- 1W High Power LEDDokumen16 halaman1W High Power LEDCalvin BurtBelum ada peringkat

- 3W High Power LEDDokumen14 halaman3W High Power LEDdattariderBelum ada peringkat

- 3W High Power LEDDokumen14 halaman3W High Power LEDkobayashi_ariefBelum ada peringkat

- 100W White LEDDokumen6 halaman100W White LEDLoknathBhartiBelum ada peringkat

- HK-S3 3W-W: FeaturesDokumen4 halamanHK-S3 3W-W: FeaturesMario PortillaBelum ada peringkat

- HP5W PDFDokumen4 halamanHP5W PDFSergio AriasgagoBelum ada peringkat

- Luckylight: 0.56" Triple Digit Numeric Displays Technical Data SheetDokumen6 halamanLuckylight: 0.56" Triple Digit Numeric Displays Technical Data SheetSergiu BadalutaBelum ada peringkat

- Led RGB Super Bright SMD1206Dokumen4 halamanLed RGB Super Bright SMD1206Mamduh Dliyaul JawwadBelum ada peringkat

- Hebei I.T. (Shanghai) Co., Ltd. Part No.: S12LY9C: FeaturesDokumen2 halamanHebei I.T. (Shanghai) Co., Ltd. Part No.: S12LY9C: FeaturesAlbert GTBelum ada peringkat

- 1W High Power LED PDFDokumen14 halaman1W High Power LED PDFdyaza_1Belum ada peringkat

- 1608 SMD Led, 0603 SMD LedDokumen12 halaman1608 SMD Led, 0603 SMD Ledrafael012Belum ada peringkat

- Luckylight: White Backlight Displays Technical Data SheetDokumen6 halamanLuckylight: White Backlight Displays Technical Data SheetanzuresinkBelum ada peringkat

- DS-0035 3W PM2L-3LLx-SD v1.6Dokumen13 halamanDS-0035 3W PM2L-3LLx-SD v1.6Pavan KumarBelum ada peringkat

- Ossv 53 e 1 ADokumen1 halamanOssv 53 e 1 Axor_45Belum ada peringkat

- Everlight Electronics Co.,Ltd.: 5.0mm Round Type LED Lamps Part No.: FeaturesDokumen4 halamanEverlight Electronics Co.,Ltd.: 5.0mm Round Type LED Lamps Part No.: FeaturesDhuck DhBelum ada peringkat

- Xpower: Preliminary Spec Part Number: Aad1-9090Qb10Zc-SDokumen4 halamanXpower: Preliminary Spec Part Number: Aad1-9090Qb10Zc-SJuan David OrtizBelum ada peringkat

- BrightPhoton - VCSEL - LD0940-B130-0014CC-1035 Spec V.01Dokumen4 halamanBrightPhoton - VCSEL - LD0940-B130-0014CC-1035 Spec V.01黄孙峰Belum ada peringkat

- Uvtop260 FW To39 LEDDokumen5 halamanUvtop260 FW To39 LEDslowmosquitoBelum ada peringkat

- LSP-DXXX Specification SheetDokumen3 halamanLSP-DXXX Specification Sheetanil kawanBelum ada peringkat

- To56 10g DFB Laser Diode 1330nm Data Sheet 602003Dokumen3 halamanTo56 10g DFB Laser Diode 1330nm Data Sheet 602003GLsun MallBelum ada peringkat

- Technical Data Sheet 0.56" Triple Digit SMD Displays: ELST-511SYGWA/S530-E2/S290Dokumen8 halamanTechnical Data Sheet 0.56" Triple Digit SMD Displays: ELST-511SYGWA/S530-E2/S290StuxnetBelum ada peringkat

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.39" Single Digit DisplaysDokumen5 halamanEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.39" Single Digit DisplaysLuis Angel PBelum ada peringkat

- Uvled 385 nv3bDokumen5 halamanUvled 385 nv3b林益祥Belum ada peringkat

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.56" Dual Digit DisplaysDokumen5 halamanEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.56" Dual Digit DisplaysStuxnetBelum ada peringkat

- Display - ELD-511SURWB-S530-A3Dokumen5 halamanDisplay - ELD-511SURWB-S530-A3guibsgvBelum ada peringkat

- D+led-Ld5rDokumen6 halamanD+led-Ld5rJulia EchazarretaBelum ada peringkat

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 1.9mm Round Subminiature "Yoke" Lead LEDDokumen9 halamanEverlight Electronics Co.,Ltd.: Technical Data Sheet 1.9mm Round Subminiature "Yoke" Lead LEDStuxnetBelum ada peringkat

- Data Sheet For 8mm Super Bright White LED Dip Type 1/2watt High Power LED SeriesDokumen2 halamanData Sheet For 8mm Super Bright White LED Dip Type 1/2watt High Power LED SeriesEtbn SnoaBelum ada peringkat

- Technical Data Sheet 0.56" Quadruple Digit SMD Displays: ELSF-512SYGWA/S530-E2/S290Dokumen8 halamanTechnical Data Sheet 0.56" Quadruple Digit SMD Displays: ELSF-512SYGWA/S530-E2/S290StuxnetBelum ada peringkat

- T-1 3/4 (5Mm) Full Color Led Lamp: AttentionDokumen9 halamanT-1 3/4 (5Mm) Full Color Led Lamp: AttentionAdindanvrynBelum ada peringkat

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.4" Dual Digit DisplaysDokumen5 halamanEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.4" Dual Digit DisplaysStuxnetBelum ada peringkat

- Ast Sp06 1200t1xyh1 Abcdefg Ul A0Dokumen3 halamanAst Sp06 1200t1xyh1 Abcdefg Ul A0aarti04072000Belum ada peringkat

- To56 10g DFB Laser Diode 1310nm Data Sheet 602002Dokumen3 halamanTo56 10g DFB Laser Diode 1310nm Data Sheet 602002GLsun MallBelum ada peringkat

- 5mm RGB Led Common CathodeDokumen3 halaman5mm RGB Led Common CathodeThushaniDeSilvaBelum ada peringkat

- C-WDM DFB-LD To-Can: OD-YK60002B May 16, 2006Dokumen4 halamanC-WDM DFB-LD To-Can: OD-YK60002B May 16, 2006BrunoSimardBelum ada peringkat

- Property of Lite-On Only FeaturesDokumen11 halamanProperty of Lite-On Only FeaturesBLUEE009Belum ada peringkat

- Technical Data Sheet 0.51" Single Digit SMD Displays: ELSS-505SYGWA/S530-E2Dokumen8 halamanTechnical Data Sheet 0.51" Single Digit SMD Displays: ELSS-505SYGWA/S530-E2StuxnetBelum ada peringkat

- Data Sheet: HLMP-HD61, HLMP-HM61 and HLMP-HB61Dokumen12 halamanData Sheet: HLMP-HD61, HLMP-HM61 and HLMP-HB61Web BrowserBelum ada peringkat

- 3w Trueopto RGB LedDokumen13 halaman3w Trueopto RGB LedAntonis KanourasBelum ada peringkat

- HP60MUVA, Sterilization LEDDokumen8 halamanHP60MUVA, Sterilization LEDbar catalinBelum ada peringkat

- Lapara Cultivo 90WDokumen3 halamanLapara Cultivo 90Whongoloco12Belum ada peringkat

- AST SP06 1000T1XYH1 Abcdefg UL A0Dokumen3 halamanAST SP06 1000T1XYH1 Abcdefg UL A0aarti04072000Belum ada peringkat

- Preliminary Spec: 10Mm (0.4inch) Dual Digit Numeric DisplayDokumen4 halamanPreliminary Spec: 10Mm (0.4inch) Dual Digit Numeric DisplaycepimasterodroBelum ada peringkat

- LSD400XXDokumen9 halamanLSD400XXDavid_MacielBelum ada peringkat

- Product Specification: Model No.:JL-504OC5ABDokumen4 halamanProduct Specification: Model No.:JL-504OC5ABgpagliardiniBelum ada peringkat

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.8" Single Digit DisplaysDokumen6 halamanEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.8" Single Digit DisplaysStuxnetBelum ada peringkat

- Led 5mm yDokumen6 halamanLed 5mm yMarcos PainenahuelBelum ada peringkat

- LS SF67 (8) 1usd24Dokumen7 halamanLS SF67 (8) 1usd24Nexor PocztaBelum ada peringkat

- Specifications For Approval: 395nm UV Led PKGDokumen18 halamanSpecifications For Approval: 395nm UV Led PKGStiven AndrewBelum ada peringkat

- AST SP06 1200T1XYA1 Abcdefg UL A0Dokumen3 halamanAST SP06 1200T1XYA1 Abcdefg UL A0aarti04072000Belum ada peringkat

- Product Specification: PDC284-CAMR21-BWDokumen6 halamanProduct Specification: PDC284-CAMR21-BWapi-62031994Belum ada peringkat

- Data Sheet: HLMP-RL20, HLMP-SL20Dokumen9 halamanData Sheet: HLMP-RL20, HLMP-SL20Anonymous pMVR77x1Belum ada peringkat

- Preliminary Spec: 3.5X2.8Mm Surface Mount Led LampDokumen4 halamanPreliminary Spec: 3.5X2.8Mm Surface Mount Led LampBab AbaBelum ada peringkat

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.56" Dual Digit DisplaysDokumen5 halamanEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.56" Dual Digit Displaysciubaca1Belum ada peringkat

- Uv LedDokumen1 halamanUv LedArup KuntiBelum ada peringkat

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.39" Single Digit DisplaysDokumen5 halamanEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.39" Single Digit DisplaysStuxnetBelum ada peringkat

- AST SP06 750T1XYH1 Abcdefg UL A0Dokumen3 halamanAST SP06 750T1XYH1 Abcdefg UL A0aarti04072000Belum ada peringkat

- Datasheet PDFDokumen5 halamanDatasheet PDFreybimBelum ada peringkat

- Elt512surwa - S53 PDFDokumen5 halamanElt512surwa - S53 PDFilian ivanovBelum ada peringkat

- Running 12 LEDDokumen1 halamanRunning 12 LEDtittyjohnBelum ada peringkat

- House Rent Receipt Format 252Dokumen1 halamanHouse Rent Receipt Format 252kansjee100% (4)

- Technical SpecificationsDokumen4 halamanTechnical SpecificationstittyjohnBelum ada peringkat

- LOgDokumen1 halamanLOgtittyjohnBelum ada peringkat

- 3G Huawei RAN Resource Monitoring and Management LibreDokumen53 halaman3G Huawei RAN Resource Monitoring and Management LibreVikas KhantwalBelum ada peringkat

- RCC EventDokumen1 halamanRCC EventtittyjohnBelum ada peringkat

- VassiliouDokumen73 halamanVassilioutittyjohnBelum ada peringkat

- UNIX VI EditorDokumen17 halamanUNIX VI Editorleopard_friend100% (2)

- HSPA+ R7, R8, R9 and R10: July 2011Dokumen45 halamanHSPA+ R7, R8, R9 and R10: July 2011tittyjohnBelum ada peringkat

- Internet Reg BackupDokumen21 halamanInternet Reg BackuptittyjohnBelum ada peringkat

- 3GPP Lte RLCDokumen40 halaman3GPP Lte RLCrainydays2010Belum ada peringkat

- Chocolate CakeDokumen2 halamanChocolate CaketittyjohnBelum ada peringkat

- Rail-to-Rail, High Output Current Amplifier: Features Pin ConfigurationDokumen17 halamanRail-to-Rail, High Output Current Amplifier: Features Pin ConfigurationBernat Feixas ZaplanaBelum ada peringkat

- Vacuum GaugesDokumen2 halamanVacuum Gauges123vidyaBelum ada peringkat

- SoC or System On Chip Seminar ReportDokumen28 halamanSoC or System On Chip Seminar ReportVivek PandeyBelum ada peringkat

- Ohms LawDokumen5 halamanOhms LawCesar BlBelum ada peringkat

- " Trade: " Electrician ": Draft Syllabus FORDokumen6 halaman" Trade: " Electrician ": Draft Syllabus FORprasadum2321Belum ada peringkat

- Fully Reused VLSI Architecture of FM0 / Manchester Encoding Using SOLS Technique For DSRC Applications Chapter-1Dokumen60 halamanFully Reused VLSI Architecture of FM0 / Manchester Encoding Using SOLS Technique For DSRC Applications Chapter-1snehaBelum ada peringkat

- Data Bulletin Ground-Fault Systems For Circuit Breakers Equipped With Micrologic™ Electronic Trip UnitsDokumen4 halamanData Bulletin Ground-Fault Systems For Circuit Breakers Equipped With Micrologic™ Electronic Trip UnitsKarthik MandyaBelum ada peringkat

- JVC ManualDokumen107 halamanJVC ManualAlphaBelum ada peringkat

- Structure of Power SystemDokumen60 halamanStructure of Power SystemDamodharan ChandranBelum ada peringkat

- Erection Testing and CommissioningDokumen30 halamanErection Testing and CommissioningEngr Muhammad Abu BakrBelum ada peringkat

- Siem Spareparts MasterDrDokumen8 halamanSiem Spareparts MasterDrMuhdiBelum ada peringkat

- EPHY105L LabManualDokumen49 halamanEPHY105L LabManualaryanBelum ada peringkat

- BFR91Dokumen5 halamanBFR91norgenBelum ada peringkat

- Sheet Peak Detector Lf398Dokumen11 halamanSheet Peak Detector Lf398Bryan CarmonaBelum ada peringkat

- Tentative: Triac Drivers Programmable Controllers AC-Output Modules Solid-State RelaysDokumen6 halamanTentative: Triac Drivers Programmable Controllers AC-Output Modules Solid-State RelaysGabriel GriecoBelum ada peringkat

- X-Ray Diffraction Techniques For Thin FilmsDokumen15 halamanX-Ray Diffraction Techniques For Thin FilmsBenjamin BlairBelum ada peringkat

- IRF630Dokumen10 halamanIRF630Jose M PeresBelum ada peringkat

- 1.characteristics of MOSFETDokumen8 halaman1.characteristics of MOSFETabcdefgBelum ada peringkat

- Speed FanDokumen26 halamanSpeed FanGeorgios PuliarekosBelum ada peringkat

- RESISTANCEDokumen9 halamanRESISTANCERohit SahuBelum ada peringkat

- Understanding Basic Electrical TheoryDokumen9 halamanUnderstanding Basic Electrical TheoryRyan Pranada VillalonBelum ada peringkat

- Lesson Plan: Unit 1Dokumen6 halamanLesson Plan: Unit 1saravanaeee2004Belum ada peringkat

- Isc 2SC3355: Isc Silicon NPN RF TransistorDokumen6 halamanIsc 2SC3355: Isc Silicon NPN RF TransistorAicky IkrackBelum ada peringkat

- A Seminar Topic: Plastic ElectronicsDokumen26 halamanA Seminar Topic: Plastic ElectronicsSavi sharma75% (4)

- DC Motor Control Using 8085Dokumen48 halamanDC Motor Control Using 8085Bhavya Wadhwa100% (3)

- ME 224 Project: Lie Detector: June 6, 2003Dokumen17 halamanME 224 Project: Lie Detector: June 6, 2003ajayikayodeBelum ada peringkat

- Panasonic TH-32F410X Chassis KM36 PDFDokumen66 halamanPanasonic TH-32F410X Chassis KM36 PDFDeveloper AwladBelum ada peringkat

- Basics of Thin Film TechnologyDokumen28 halamanBasics of Thin Film TechnologyVivek Bela100% (1)