A64 ExC Transporter S PDF

Diunggah oleh

Cruzado Vilca AmesquitaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

A64 ExC Transporter S PDF

Diunggah oleh

Cruzado Vilca AmesquitaHak Cipta:

Format Tersedia

A64 ExC Transporter-S

Materials Transporter

Getman materials transport vehicles are versatile underground carriers designed to move materials throughout

a mining operation reliably and efficiently, ensuring loads are delivered where they are needed when they

are needed. Available customized packages maximize the opportunity for utilization throughout underground

operations while increasing efficiency and productivity during loading and unloading scenarios.

Getmans A64 ExC Transporter-S is specially designed to safely and efficiently transport bulk explosives

throughout underground operations, increasing operational safety through purpose-built features such as full

anti-static lining in all loading areas as well as separate enclosed compartments for blasting caps, detonator

cord and other explosives materials.

A64 materials transport vehicles protect worker safety by eliminating the need for improvised solutions when

transporting heavy, dangerous or specialized loads, and integrate into the full A64 product range, allowing for

efficient inventory carrying requirements and minimal maintenance training requirements.

Product Datasheet

Updated March 3, 2016

A64 ExC Transporter-S

Materials Transporter

Technical Specifications

Engine

Tier III approved engine - 4-cylinder

Mercedes Benz OM904LA, 129 kW (173 hp) @ 2200 rpm

Cummins QSB4.5, 127 kW (170 hp) @ 2200 rpm

Liquid-cooled, turbocharged

113 L (30 gal) fuel tank with self-closing cap

Exhaust System

Catalytic exhaust conditioner and silencer

Transmission

Dana Clark 32000 powershift transmission

Three speeds forward and reverse

4-wheel drive

Axles

Heavy-duty Carraro 28.43 planetary drive axle package

Tires

10.0020-16pr mine service tires

Brake System

Fully hydraulic wet disc service brakes on each axle

Spring applied, hydraulic pressure release wet disc secondary

brake

Automatic secondary brake application upon loss of brake

accumulator pressure, transmission pressure or electrical

power

Steering

Orbitrol controlled articulated frame steering

Heavy-duty, self-aligning bearings inside replaceable inserts

Two double-acting steer cylinders with replaceable bushings

in cylinder and frame ears

40 articulation each direction

Hydraulic System

Hot side/cold side engine layout

Hydraulic hoses routed to cold side of engine

Open center hydraulic circuits with gear hydraulic pump

Diagnostic test ports with quick couple fittings for: each axle,

service brake application pressure, and hydraulic pumps

10-micron return filter

151 L (40 gal) hydraulic reservoir

Operator Compartment

Three-point contact for entry and exit

ROPS/FOPS certified compartment (SAE J1040C, CSA B-352,

ISO 3471)

Open canopy

Enclosed cabin with heater and air conditioner

Operator and passenger seating

Mechanical suspension operator seat

Retractable lap seat belts

Instrumentation

Engine and transmission gauges

Engine temperature

Engine oil pressure

Voltmeter

Hour meter

Tachometer

Transmission clutch pressure

Converter temperature

Brake accumulator pressure gauge

Brake accumulator low-pressure warning

Park brake applied warning light

Audio/visual alert for high engine temperature

Audio/visual alert for low engine pressure

Electrical System

24 V, 100 A alternator

Lockable electrical master switch (lockout)

Maintenance-free 12 V batteries

LED lighting package (IP69K rated): two 900 lm front

headlights, two 900 lm rear headlights

Sealed and oil resistant wiring

Fully sealed connectors

Fully sealed electrical boxes

Other General Equipment

Variable audio backup alarm (87-112 dBA)

2.3 kg (5 lb) fire extinguisher

Wheel chocks

Four nozzle Ansul fire suppression system tied to engine

shutdown

Optional Equipment

Wiggins fill system

Lincoln auto-lubrication package

Ansul Checkfire automatic actuation fire suppression system

with linear detection loop

Product Datasheet

Updated March 3, 2016

A64 ExC Transporter-S

Materials Transporter

Deck Arrangement*

Materials Transporting Package

Anti-static storage for up to eighty 25 kg (55 lb) ANFO bags

Blasting cap and detonator storage compartment lined with

plywood and gypsum board to prevent transfer of static

charge, 480 mm/290 mm/760 mm (19 in/11.5 in/30 in)

W/H/D

*Consult Getman for special configurations

Product Datasheet

Updated March 3, 2016

A64 ExC Transporter-S

Materials Transporter

Design Features and Layout

Fluid levels easily

checked using groundlevel sight gauges

Built on the reliable

Getman A64 Chassis

All filters and lubrication

points accessible from

ground level

Blasting cap and detonator

storage compartment with

static-preventing lamination

Anti-static ANFO

bag storage

Product Datasheet

Updated March 3, 2016

A64 ExC Transporter-S

Materials Transporter

Dimensions and Maneuverability

2264

[7-5]

1722

[5-8]

801

[2-8]

18

283 GRND

[11.125] CLRN

11

10.0020 TIRES

3048

[10]

7235

[23-9]

DETONATOR

STORAGE BOX

1956

[6-5]

3172

[10-5]

3539

[11-7]

Machine Length

Wheelbase Length

Ground Clearance

Machine Height

1705

[5-7]

40

7235 mm

285 in

3048 mm

120 in

283 mm

11.125 in

2264 mm

89 in

1000

[3-3]

R5397

[R17-8]

Product Datasheet

Updated

2084March 3, 2016

[6-10]

A64 ExC Transporter-S

Materials Transporter

2264

[7-5]

1722

[5-8]

801

[2-8]

Dimensions

and Maneuverability

18

283 GRND

[11.125] CLRN

11

10.0020 TIRES

3048

[10]

7235

[23-9]

DETONATOR

STORAGE BOX

1956

[6-5]

3539

[11-7]

1705

[5-7]

3172

[10-5]

40

R5397

[R17-8]

1000

[3-3]

2084

[6-10]

2000

[6-7]

R3147

[R10-4]

3172

[10-5]

Machine Width

2084 mm

82 in

Inner Turning Radius

3147 mm

124 in

Outer Turning Radius

5397 mm

212 in

Product Datasheet

Updated March 3, 2016

A64 ExC Transporter-S

Materials Transporter

Engine and Performance

Mercedes Benz OM904 Engine Package

Cummins QSB4.5 Engine Package

Manufacturer

Mercedes

Manufacturer

Cummins

Model

OM904

Model

QSB4.5

Stage

Tier III

Stage

Tier III

Design

4 Cylinders in line, water cooled

Design

4 Cylinders in line, water cooled

Max Power

129 kW (173 hp) @ 2200 rpm

Max Power

127 kW (170 hp) @ 2200 rpm

Exhaust System

Catalytic exhaust conditioner and silencer

Exhaust System

Catalytic exhaust conditioner and silencer

Aspiration

50.0

Aspiration

50.0

Turbocharged

Fuel Consumption

Fuel Consumption

220 g/kW-hr (0.361 lb/hp-hr)

Speed Chart with Estimated GVW: 8,600 kg (19,000 lb)

Dana Clark 32000 Transmission

Standard Heavy-Duty Carraro 28.43 Axles

1020-16pr Mine-Duty tires

10.0

% Incline

30.0

0.0

243 g/kW-hr (0.399 lb/hp-hr)

40.0

1st Gear

2nd Gear

0.0

40.0

30.0

20.0

3rd Gear

Speed Chart with Estimated GVW: 8,600 kg (19,000 lb)

Dana Clark 32000 Transmission

Standard Heavy-Duty Carraro 28.43 Axles

1020-16pr Mine-Duty tires

10.0

50.0

5.0

10.0

15.0

20.0

0.0

25.0

2nd Gear

3rd Gear

0.0

40.0

5.0

10.0

15.0

20.0

25.0

KPH

% Incline

30.0

20.0

10.0

0.0

1st Gear

50.0

KPH

% Incline

% Incline

40.0

20.0

Turbocharged

30.0

20.0

10.0

0.0

5.0

10.0

15.0

20.0

25.0

0.0

0.0

5.0

KPH

10.0

15.0

20.0

25.0

KPH

20%

9%

Maximum Recommended

Longitudinal Tramming Gradient

0%

Maximum Recommended

Transverse Tramming Gradient

0%

Product Datasheet

Updated March 3, 2016

A64 ExC Transporter-S

Materials Transporter

About Getman Corporation

Getman Corporation is a global supplier of mobile equipment

to the mining industry, offering customer-specific solutions to

underground mines in the production and production support

classes of equipment. All Getman equipment is designed with

extensive research and development and is supported by over fifty

years of experience in serving the underground mining industry.

Through our network of distributors we sell and support our

products on six continents, offering exceptional product solutions

and following up with world class aftermarket support. At Getman

Corporation, designing and building trucks for the underground mining industry is what we do. We take pride in being the preferred

supplier of underground production and production support equipment to miners globally by offering customer-specific, value-driven

and long-lasting solutions.

For more information contact your Getman distributor or email us at info@getman.com, or visit our website at www.getman.com.

For parts or service support, email us at parts@getman.com or service@getman.com.

Getman Corporation assembled this datasheet with the intention of passing along the most accurate information possible, however this document shall not be binding in any way and

shall be considered informational only. All values stated herein are theoretical in nature. All orders are accepted based on the terms and conditions set forth in the individual purchase

or sales agreement. Getman reserves the right to make changes to the specification herein at any time and without further notification.

Pictured machines in this document may contain optional and additional equipment.

Getman Corporation

59750 34th Avenue

Bangor, MI 49013 USA

Tel +1 (269) 427-5611

Fax +1 (269) 427-8781

www.getman.com

Product Datasheet

Updated March 3, 2016

Anda mungkin juga menyukai

- VVDED302023 Altistart 48 Modbus ProtocolDokumen61 halamanVVDED302023 Altistart 48 Modbus ProtocoledevaldwilsonBelum ada peringkat

- AUBO I5 USER MANUAL V4.3.1 USA PDFDokumen171 halamanAUBO I5 USER MANUAL V4.3.1 USA PDFMiro Mirach PremrlBelum ada peringkat

- Lista de Componentes ExC3000Dokumen1 halamanLista de Componentes ExC3000pressisoBelum ada peringkat

- Variador BaldorDokumen270 halamanVariador BaldorjoelBelum ada peringkat

- WEG 09 2017 Standard Stock Catalog Pump Motors Us100 Brochure English PDFDokumen46 halamanWEG 09 2017 Standard Stock Catalog Pump Motors Us100 Brochure English PDFmacaco28Belum ada peringkat

- Macsteel VRN - Wear Abrasion Steels - Creusabro 8000Dokumen4 halamanMacsteel VRN - Wear Abrasion Steels - Creusabro 8000jonodo89Belum ada peringkat

- SPR York 4 14 Line Boring Spec SheetDokumen2 halamanSPR York 4 14 Line Boring Spec SheetАлмаз КенжетаевBelum ada peringkat

- Páginas Desdeatlas Copco Xats 400 JD t3Dokumen2 halamanPáginas Desdeatlas Copco Xats 400 JD t3german gualavisi100% (1)

- ASA Hydraulik Catalog PDFDokumen60 halamanASA Hydraulik Catalog PDFMiguel VlntìnBelum ada peringkat

- Algoma SteelDokumen18 halamanAlgoma Steelsahzaidi544Belum ada peringkat

- JFE Everhard PDFDokumen12 halamanJFE Everhard PDFCris Yo CrisBelum ada peringkat

- Idealarc DC-600: Rugged Multi-Process Power For Industrial ManufacturingDokumen4 halamanIdealarc DC-600: Rugged Multi-Process Power For Industrial Manufacturingmkpasha55mpBelum ada peringkat

- Hand ToolsDokumen98 halamanHand ToolsAndry Perdana PutraBelum ada peringkat

- Technical Specification Simba w6 C - 9851 2635 01 - tcm835-1537599Dokumen4 halamanTechnical Specification Simba w6 C - 9851 2635 01 - tcm835-1537599Cecitafex2014Belum ada peringkat

- Sullivan - 15 20 25 30 40Dokumen3 halamanSullivan - 15 20 25 30 40MrMike82Belum ada peringkat

- Notes:: 1) Check Boms For Different Values (See Table 1) and Population OptionsDokumen3 halamanNotes:: 1) Check Boms For Different Values (See Table 1) and Population OptionsMarin Marinescu100% (1)

- Manual de Operaciones FMR20Dokumen84 halamanManual de Operaciones FMR20ericleiva66Belum ada peringkat

- NOVEMBER 2015 Surplus Record Machinery & Equipment DirectoryDokumen748 halamanNOVEMBER 2015 Surplus Record Machinery & Equipment DirectorySurplus RecordBelum ada peringkat

- CF75G - Oil-Injected Screw Compressor Airend: Operating RangeDokumen1 halamanCF75G - Oil-Injected Screw Compressor Airend: Operating Rangeahmad nh100% (1)

- Bomba Graco 210esDokumen10 halamanBomba Graco 210esoscadilioBelum ada peringkat

- Sumitomo HSMDokumen68 halamanSumitomo HSMEdisson Yanqui VivancoBelum ada peringkat

- 3M 6800 Full Face MaskDokumen6 halaman3M 6800 Full Face MaskAlvarioBelum ada peringkat

- Ficha Tecnica Alpha 30Dokumen7 halamanFicha Tecnica Alpha 30jonathan francisco allende escobarBelum ada peringkat

- WAD Cynoprobe PDFDokumen9 halamanWAD Cynoprobe PDFGerehBelum ada peringkat

- Manual SopladorDokumen47 halamanManual SopladorTATIANA MARTINEZBelum ada peringkat

- HSA Catalogue 2012Dokumen470 halamanHSA Catalogue 2012ViniciusBelum ada peringkat

- CPI ProFlow SoftwareDokumen2 halamanCPI ProFlow SoftwareCarlos TorrezBelum ada peringkat

- Quincy QT Series Model QT-5Dokumen18 halamanQuincy QT Series Model QT-5mkaukolaBelum ada peringkat

- Alpha 30 TDS 100037843 - V4Dokumen10 halamanAlpha 30 TDS 100037843 - V4Diego Antonio Barra MuñozBelum ada peringkat

- Pig Trap End Closure1 PDFDokumen24 halamanPig Trap End Closure1 PDFashishBelum ada peringkat

- Manual de Partes Genie Tml4000nDokumen82 halamanManual de Partes Genie Tml4000nRicardo UrielBelum ada peringkat

- Sandvik Du411 Underground Drill Rig: Technical SpecificationDokumen4 halamanSandvik Du411 Underground Drill Rig: Technical SpecificationIng del Pele0% (1)

- Stock List PDFDokumen4 halamanStock List PDFAL Wahid SpareBelum ada peringkat

- 900A ProductGuideDokumen16 halaman900A ProductGuideEdson EscobedoBelum ada peringkat

- Serial NosDokumen39 halamanSerial Nosskoty123Belum ada peringkat

- CB 214D ManualDokumen12 halamanCB 214D ManualZoranBelum ada peringkat

- MTII 11-4129 LT-650 - Parts ManualDokumen330 halamanMTII 11-4129 LT-650 - Parts ManualAdan BenitezBelum ada peringkat

- Brochure XA (H, T, V, X) S 186-600C, XRHS 666C, V900, X1300, XA (T, V) S 100-1200 Cud China 2958 0961 52 EnglishDokumen2 halamanBrochure XA (H, T, V, X) S 186-600C, XRHS 666C, V900, X1300, XA (T, V) S 100-1200 Cud China 2958 0961 52 EnglishMuhammad BintangBelum ada peringkat

- Ez6 SaftronicsDokumen23 halamanEz6 SaftronicsJorge Eduardo Molina ValarezoBelum ada peringkat

- Sb-2500D Specifications: Engine: Fume Extraction SystemDokumen2 halamanSb-2500D Specifications: Engine: Fume Extraction SystemMariano David Pons Merino100% (1)

- 8997 2503 00 Diagrams and Drawings PDFDokumen65 halaman8997 2503 00 Diagrams and Drawings PDFJaime DiazBelum ada peringkat

- Operating Manual: For Electric Motor / Gear MotorDokumen46 halamanOperating Manual: For Electric Motor / Gear MotorPablo Hidalgo Valenzuela100% (1)

- Power Team PQ120 ManualDokumen10 halamanPower Team PQ120 ManualTitanplyBelum ada peringkat

- 38 Alemite Product Catalog PDFDokumen277 halaman38 Alemite Product Catalog PDFthailan100% (1)

- BT7000 PartsDokumen123 halamanBT7000 PartsPilaquinga DiegoBelum ada peringkat

- Donaldson p564669 Breather, TrapDokumen2 halamanDonaldson p564669 Breather, TrapJorge Eduardo González EncisoBelum ada peringkat

- B08 3 A6t PDFDokumen2 halamanB08 3 A6t PDFRakESaN SoundwangS100% (1)

- 020-051 Manual Anfo LoaderDokumen745 halaman020-051 Manual Anfo LoaderPedro Garcia100% (1)

- Ecm660 AtlasDokumen574 halamanEcm660 Atlasedgar cabrera100% (1)

- TroubleshootDokumen85 halamanTroubleshootnova hilangBelum ada peringkat

- ELITE40 Operation Manual 1210Dokumen57 halamanELITE40 Operation Manual 1210Edgar Castañeda100% (1)

- 2629 Eca Scheme Energy Technology ProductsDokumen964 halaman2629 Eca Scheme Energy Technology ProductsYohan JayaBelum ada peringkat

- 0981-0530 I14 201504kyservDokumen118 halaman0981-0530 I14 201504kyservGarth Lilly100% (1)

- Telecrane Radio Remote Control F21 Series & F24 Series ManualDokumen40 halamanTelecrane Radio Remote Control F21 Series & F24 Series Manualelin373Belum ada peringkat

- Rock Drill / PerforadoraDokumen16 halamanRock Drill / PerforadoraSerkanAlBelum ada peringkat

- Cement Tech C-Series Truck MixerDokumen2 halamanCement Tech C-Series Truck MixerW MoralesBelum ada peringkat

- Parker WiperDokumen4 halamanParker WiperZMCONTROLBelum ada peringkat

- Utimec LF 600 Agitator 100018506Dokumen7 halamanUtimec LF 600 Agitator 100018506lucas0% (1)

- A64 PC Datasheet PDFDokumen8 halamanA64 PC Datasheet PDFCruzado Vilca AmesquitaBelum ada peringkat

- A64 HD Pallet Handler Datasheet PDFDokumen8 halamanA64 HD Pallet Handler Datasheet PDFCruzado Vilca AmesquitaBelum ada peringkat

- A64 Service Fuel PDFDokumen8 halamanA64 Service Fuel PDFCruzado Vilca AmesquitaBelum ada peringkat

- A64 Pallet Handler Datasheet PDFDokumen10 halamanA64 Pallet Handler Datasheet PDFCruzado Vilca AmesquitaBelum ada peringkat

- A64 HD A 70 PDFDokumen8 halamanA64 HD A 70 PDFCruzado Vilca AmesquitaBelum ada peringkat

- A64 HD R 60 Datasheet PDFDokumen8 halamanA64 HD R 60 Datasheet PDFCruzado Vilca AmesquitaBelum ada peringkat

- A64 Service Lube Datasheet PDFDokumen8 halamanA64 Service Lube Datasheet PDFCruzado Vilca AmesquitaBelum ada peringkat

- A64 Service Lube S PDFDokumen8 halamanA64 Service Lube S PDFCruzado Vilca AmesquitaBelum ada peringkat

- A64 HD R 50 Datasheet PDFDokumen9 halamanA64 HD R 50 Datasheet PDFCruzado Vilca AmesquitaBelum ada peringkat

- A64 PC Datasheet PDFDokumen8 halamanA64 PC Datasheet PDFCruzado Vilca AmesquitaBelum ada peringkat

- A64 HD Pallet Handler Datasheet PDFDokumen8 halamanA64 HD Pallet Handler Datasheet PDFCruzado Vilca AmesquitaBelum ada peringkat

- A64 Product Catalog: Features - Configurations - SpecificationsDokumen26 halamanA64 Product Catalog: Features - Configurations - SpecificationsCruzado Vilca AmesquitaBelum ada peringkat

- A64 PC Datasheet PDFDokumen8 halamanA64 PC Datasheet PDFCruzado Vilca AmesquitaBelum ada peringkat

- A64 Exc 2-500er: Explosives ChargerDokumen10 halamanA64 Exc 2-500er: Explosives ChargerCruzado Vilca AmesquitaBelum ada peringkat

- A64 ExC 3000 Datasheet PDFDokumen10 halamanA64 ExC 3000 Datasheet PDFCruzado Vilca AmesquitaBelum ada peringkat

- A64 Exc 2-500er: Explosives ChargerDokumen10 halamanA64 Exc 2-500er: Explosives ChargerCruzado Vilca AmesquitaBelum ada peringkat

- A64 Product Catalog: Features - Configurations - SpecificationsDokumen26 halamanA64 Product Catalog: Features - Configurations - SpecificationsCruzado Vilca AmesquitaBelum ada peringkat

- A64 Exc 2-500er: Explosives ChargerDokumen10 halamanA64 Exc 2-500er: Explosives ChargerCruzado Vilca AmesquitaBelum ada peringkat

- A64 Crane Datasheet PDFDokumen9 halamanA64 Crane Datasheet PDFCruzado Vilca AmesquitaBelum ada peringkat

- A64 Crane-S PDFDokumen9 halamanA64 Crane-S PDFCruzado Vilca AmesquitaBelum ada peringkat

- A64 Cable Stringer DatasheetDokumen9 halamanA64 Cable Stringer DatasheetCruzado Vilca AmesquitaBelum ada peringkat

- A64 Exc 2-500er: Explosives ChargerDokumen10 halamanA64 Exc 2-500er: Explosives ChargerCruzado Vilca AmesquitaBelum ada peringkat

- A64 Exc 2-500er: Explosives ChargerDokumen10 halamanA64 Exc 2-500er: Explosives ChargerCruzado Vilca AmesquitaBelum ada peringkat

- A64 Product Catalog: Features - Configurations - SpecificationsDokumen26 halamanA64 Product Catalog: Features - Configurations - SpecificationsCruzado Vilca AmesquitaBelum ada peringkat

- A64 Exc 2-500er: Explosives ChargerDokumen10 halamanA64 Exc 2-500er: Explosives ChargerCruzado Vilca AmesquitaBelum ada peringkat

- A64 Product Catalog: Features - Configurations - SpecificationsDokumen26 halamanA64 Product Catalog: Features - Configurations - SpecificationsCruzado Vilca AmesquitaBelum ada peringkat

- A64 Boom 2 1300 Datasheet PDFDokumen9 halamanA64 Boom 2 1300 Datasheet PDFCruzado Vilca AmesquitaBelum ada peringkat

- A64 Boom 2 1300 Datasheet PDFDokumen9 halamanA64 Boom 2 1300 Datasheet PDFCruzado Vilca AmesquitaBelum ada peringkat

- A64 Boom 2 1300 Datasheet PDFDokumen9 halamanA64 Boom 2 1300 Datasheet PDFCruzado Vilca AmesquitaBelum ada peringkat

- A64 Cable Stringer S DatasheetDokumen9 halamanA64 Cable Stringer S DatasheetCruzado Vilca AmesquitaBelum ada peringkat

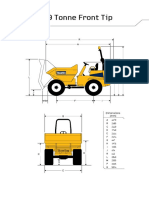

- 9tonne Front Tip UK PDFDokumen2 halaman9tonne Front Tip UK PDFQuelmis De La Cruz Vilca AmesquitaBelum ada peringkat

- Lista de Plată Pe Luna Decembrie 2020 C1 Scara c1Dokumen1 halamanLista de Plată Pe Luna Decembrie 2020 C1 Scara c1mariusdumiteBelum ada peringkat

- Physical Inventory Format VehiclesDokumen4 halamanPhysical Inventory Format VehiclesScribdTranslationsBelum ada peringkat

- SSP 374 Traction Control An Assist SystemsDokumen88 halamanSSP 374 Traction Control An Assist SystemsainginerBelum ada peringkat

- Hyundai Product - PositioningDokumen5 halamanHyundai Product - PositioningAkshit GuptaBelum ada peringkat

- Clutch EatonDokumen1 halamanClutch EatonAion RadamanthysBelum ada peringkat

- 619 SSP G enDokumen28 halaman619 SSP G en2507 Nguyễn Hồ Anh QuânBelum ada peringkat

- Saint Gobain Prise List 01.02.2020Dokumen9 halamanSaint Gobain Prise List 01.02.2020jaya prakash0% (1)

- ZF 5hp 19fla Automatic Transmission Spare Parts CatalogueDokumen6 halamanZF 5hp 19fla Automatic Transmission Spare Parts CataloguexewidyvyBelum ada peringkat

- Battery Trackless Train 24 Persons To Saridi From BettyDokumen4 halamanBattery Trackless Train 24 Persons To Saridi From BettyALINSANI TRAVELBelum ada peringkat

- Pasha Hawaii Guide - Preparing Your Vehicle ShipmentDokumen3 halamanPasha Hawaii Guide - Preparing Your Vehicle ShipmentUmrbek NazarovBelum ada peringkat

- Saudi Arabia - Sales of Selected Toyota Models 2019 StatistaDokumen1 halamanSaudi Arabia - Sales of Selected Toyota Models 2019 Statistahimanshu.bajpaiBelum ada peringkat

- T-REX 1200R Parts Manual CAMPAGNA MOTORSDokumen70 halamanT-REX 1200R Parts Manual CAMPAGNA MOTORScytoxxBelum ada peringkat

- Jatco JF017 Forma de Armado y DesarmadoDokumen18 halamanJatco JF017 Forma de Armado y DesarmadoTransmisiones Vicab100% (3)

- Daftar Spare Part PDFDokumen80 halamanDaftar Spare Part PDFManiso MnsBelum ada peringkat

- Sample Maintenance Sheet: TrailerDokumen2 halamanSample Maintenance Sheet: TrailerTrisBelum ada peringkat

- DuraTrax RC CatalogDokumen15 halamanDuraTrax RC CatalogMindfighterBelum ada peringkat

- Ficha Tecnica Isx 450 PDFDokumen2 halamanFicha Tecnica Isx 450 PDFJulio Gámez0% (1)

- Audi A6 3.0 TDI (230kW) Quattro S Tronic Tehnilised Andmed PDF Formaadis (Inglise Keeles)Dokumen1 halamanAudi A6 3.0 TDI (230kW) Quattro S Tronic Tehnilised Andmed PDF Formaadis (Inglise Keeles)Marusca Sergiu VladBelum ada peringkat

- ISF MainPrint 27012021 0550Dokumen2 halamanISF MainPrint 27012021 0550abdouBelum ada peringkat

- NISSAN RL4F03A/V, RE4F03A, RE4F03B: 4 SPEED FWD (Electronic & Hydraulic Control)Dokumen3 halamanNISSAN RL4F03A/V, RE4F03A, RE4F03B: 4 SPEED FWD (Electronic & Hydraulic Control)Riichard ColmenareesBelum ada peringkat

- Forza - Motorsport.3.official - Game.guide - Xbox360 UnleashedDokumen256 halamanForza - Motorsport.3.official - Game.guide - Xbox360 UnleashedRaj'Jon Marquis GrayBelum ada peringkat

- November 5Dokumen16 halamanNovember 5fijitimescanadaBelum ada peringkat

- Barang2 NHFDokumen53 halamanBarang2 NHFDevi Rista A.Belum ada peringkat

- Volkswagen Accessories PDFDokumen166 halamanVolkswagen Accessories PDFluismcmcBelum ada peringkat

- Introduction and Customer Information: Side View of John Deere Backhoe Loader (Manufactured 2000-)Dokumen725 halamanIntroduction and Customer Information: Side View of John Deere Backhoe Loader (Manufactured 2000-)Rafael GarciaBelum ada peringkat

- HEMM Dumper01Dokumen113 halamanHEMM Dumper01miningnova2100% (2)

- AuctionPricelist 9Dokumen25 halamanAuctionPricelist 9sherwin cuentoBelum ada peringkat

- Bosch Tune Up Parts PDFDokumen9 halamanBosch Tune Up Parts PDFdwebs262Belum ada peringkat

- NGV 2 Electdiag 1-10-02 14-09-03Dokumen58 halamanNGV 2 Electdiag 1-10-02 14-09-03sanachBelum ada peringkat

- Automotive InteriorsDokumen273 halamanAutomotive InteriorsAnnavarapu GopalakrishnaBelum ada peringkat