Krebs Mill Max Centrifugal Slurry Pump We BX

Diunggah oleh

PhaniJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Krebs Mill Max Centrifugal Slurry Pump We BX

Diunggah oleh

PhaniHak Cipta:

Format Tersedia

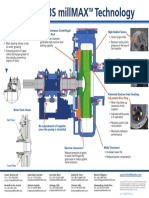

KREBS millMAXTM Pumps

The ORIGINAL suction side sealing pump

millMAX pumps technology

millMAX solves this

kind of problem

Competitors suction liner and

impeller - 550 hours

The millMAX Pump has a unique

patented design developed exclusively

for mill discharge duties and adapted

for other severe abrasive slurries.

The same wet end components can

be offered as a conversion kit to

existing pumps, without the need to

disturb the foundation or existing

bearing frame assembly.

The Heart of the Design

The patented on-line suction side

wear clearance adjustment permits

the initial clearances to be maintained

throughout the life of the pump. This

extends the life of the impeller and

suction wear faces to near, or equal

that of, the casing for a one time

maintenance rebuild.

The millMAX Pump features a

patented on-line wear clearance

adjustment, which minimizes the cost

per ton pumped compared to

conventional hard metal and rubber

lined slurry pumps through:

The reduction of solids grinding

between the impeller and suction side

reduces power consumption and

wear. The millMAX Hybrid Suction

Sealing System maintains constant

flow and pressure, without increasing

speed or the danger of motor

overload.

Increased wear life

Even wear life of all wet end parts

Less down time

Lower power consumption

Increased mill throughput

More consistent cyclone

separation

Improved gland seal performance

Low-cost no risk wet end

replacement

Krebs millMAX Pumps treat the cause

of pump wear and loss of efficiency,

whereas competitive pumps treat the

symptoms through materials or

predictive uneven wear rates.

millMAX after 1500 hours of wear

millMAX Hybrid Suction

Sealing System

We use the latest simulation

software technology for design

and performance testing of our

millMAXTM pumps.

Tight clearances

between the backliner

and impeller ensures

that shaft sealing

system works well.

Tight clearances at

the wear ring prevents

suction-side recirculation.

Wide clearances at

expelling vanes

prevents large solids

from being crushed.

millMAX pumps

In most established millMAX

installations, wear life of parts has

been even and in the majority, overall

wear life has generally improved by

50% to 100%. This increase in wear

life is achieved together with a

reduction in power, generally in the

10% to 20% or lower range.

The reduction in power can then be

taken as a cost savings, or through

additional pumping capacity with the

same installed motor.

With the millMAX Hybrid Suction

Sealing System, the front clearance is

adjusted while the pump is running,

and takes only five minutes to

perform. This clearance is adjusted

normally six to eight times throughout

the life of the wet end parts.

Wet End Conversions

The Krebs millMAX Pump is a new

design, hard metal pump and wet end

conversion kit, designed exclusively

for mill discharge and other abrasive

slurries. The Krebs millMAX Pump

adapts to a variety of power frames

without disturbing the foundation or

bearing frame assemblies.

The millMAX design can be applied

to an existing pump through a wet

end conversion kit, including impeller,

casing, backliner, and gland seal.

10x8 - US - Coal

The millMAX conversion kit is

supplied with an adapter ring, seals,

and all hardware to adapt to a variety

of power frames. This achieves the

same results as a complete pump

on a maintenance budget.

16x14 - Zambia - Copper

20x18-43 - Australia - Gold

24 x 20 - Chile - Copper

14x12 - US - Iron Ore

Technical - Specifications

The Krebs millMAX pump

design includes the following:

Casing - designed for minimum slurry

turbulence and even wear. Includes

integral wear ring, carrier, and adjustment

screws for on-line adjustment and

elimination of suction side recirculation.

millMAX Power Frame

Heavy duty cast pedestal

External bearing assembly

adjustment

Wide bearing centers

Heavy duty shaft and bearings.

Double clamp

High Performance Centrifugal

Dry Gland Seal

Large expeller diameter

generates high suction level

sealing capacity

Zero leakage while operating

Wear Ring - adjustable wear ring

assembly to permit closing of suction side

impeller clearance during operation.

Impeller - designed for high slurry

efficiency and hydraulic performance.

Machined surface at the eye for wear ring

adjustment and high expelling vanes.

Suction Liner - with integral wear

ring (14x12 and larger). Matching full

impeller diameter and profile for close

operating clearance.

Wear Parts - designed hydraulically to

wear evenly. Constructed of high chrome

at 650/720 Brinell hardness.

Reverse Taper Roller Bearings

Increases effective load span to

improve life

Main bearing failure is due to

under greasing

Pumping action of taper rollers

discharges grease to the outside,

preventing ingress of slurry

Power Frame - heavy duty cast iron

pedestal with external bearing assembly

adjustment mechanism. Drilled for

overhead motor mounting assembly.

Water Flush Gland

Flanges - loose intake and discharge

flanges drilled to suit various pipe

requirements.

FULL FLOW

Maximum expected flow rate into a

water flush seal at 10 psig (68.9 kPa)

above pump discharge pressure

Power

Frame

Full

Flow

(gpm)

Full

Flow

(m3/h)

Low

Flow

(gpm)

Low

Flow

(m3/h)

Bearing Assembly - heavy duty shaft

MMAA

8.0

1.8

1.0

0.2

and indirect fitted taper roller bearings

rated at 100,000 hrs B-10 life minimum.

MMA

15.0

3.4

2.0

0.5

MMB

20.0

4.5

3.0

0.7

MMC

25.0

5.7

4.0

0.9

LOW FLOW

MMD

30.0

6.8

5.0

1.1

MME

55.0

12.5

N/A

N/A

MMF

85.0

19.3

N/A

N/A

High Radial Vanes

Clears large solids

Prevents solids from being

crushed

Reduces casing slurry

pressure at the eye of the

impeller

External Wear

Adjustment Screw

Four screws for

on-line wear

clearance

adjustment

Adjusted while the

pump is operating

Adjusted six to

eight times during

the life of the wet

end of the pump

Adjustable

Wear Ring

Wear ring takes

up clearance at

the impeller

Adjusted during

operation

Reduces suction

side recirculation

Maintains

hydraulic

performance

Wide Clearance

Dramatic reduction in

crushing of solids

Increased wear life

Reduced power

consumption

Narrow Clearance

Reduces pressure at gland to assist

centrifugal dry gland seal or reduce

gland water pressure.

driMAX Mechanical Seal

Operates in extreme abrasive

environment

Clearance adjustment can be

made without moving seal

millMAX engineering dimensions

Standard millMAX discharge positions

Top 45 degree

Top vertical

Top horizontal

Bottom 45 degree

Bottom horizontal

Pump Model

Size

Frame

F1

G1

MM080AA4

3X2

MMAA

794

403

138

185

185

200

31

150

110

314

370

42

115

MM100AA4

4X3

MMAA

870

514

185

234

262

200

35

188

148

314

370

42

115

MM100A4

4X3

MMA

974

514

185

234

262

230

188

148

375

431

65

150

MM150A4

6X4

MMA

1020

629

229

285

326

230

55

219

190

375

431

65

150

MM150B4

6X4

MMB

1244

629

229

285

326

300

15

219

190

475

548

80

215

MM200B4

8X6

MMB

1342

998

419

436

480

300

169

290

277

475

548

80

215

MM200C4

8X6

MMC

1491

998

419

436

480

400

69

290

277

666

766

100

227

MM250B4

10X8

MMB

1394

1032

419

442

480

300

168

325

290

475

548

80

215

MM250C4

10X8

MMC

1540

1032

419

442

480

400

68

325

290

666

766

100

227

MM300C4

12X10

MMC

1574

1235

462

570

610

400

198

342

348

666

766

100

227

MM300D4

12X10

MMD

1933

1235

462

570

610

500

98

342

348

863

963

150

349

MM350C4

14X12

MMC

1757

1513

559

687

750

400

314

402

178

666

766

100

263

MM350D4

14X12

MMD

2034

1513

559

687

750

500

214

402

178

863

963

150

349

MM400C4

16X14

MMC

1835

1737

666

804

893

400

426

441

229

666

766

100

263

MM400D4

16X14

MMD

2112

1737

666

804

893

500

326

441

229

863

963

150

349

MM450D4

18x16

MMD

2176

1933

708

908

950

500

452

486

200

863

963

150

349

MM450E4

18X16

MME

2330

1933

708

908

950

850

102

486

200

1022

1111

150

321

MM500D4

20X18

MMD

2224

2032

703

1011

1054

500

515

506

245

863

963

150

349

MM500E4

20X18

MME

2380

2032

703

1011

1054

850

165

506

245

1022

1111

150

321

MM600E5

24X20

MME

2446

2208

791

1030

1226

850

218

565

236

1022

1111

150

321

MM600F5

24X20

MMF

2880

2208

791

1030

1226

1092

24

565

236

1422

1549

190

286

MM700F5

28X26

MMF

3017

2748

1060

1253

1300

1092

235

648

304

1422

1549

190

286

Bare shaft pump

Drive arrangements

Reverse overhead

Key

Hole Dia.

Weight

Pump Model

8X12X100

30

293

235

210

19

182

MM080AA4

8X12X100

30

293

235

247

19

301

MM100AA4

11X18X100

40

323

265

278

22

369

MM100A4

11X18X100

40

323

265

279

22

526

MM150A4

14X22X150

50

410

335

339

29

689

MM150B4

14X22X150

50

410

335

370

29

1496

MM200B4

16X28X180

75

555

455

370

35

1897

MM200C4

14X22X150

50

410

335

384

29

1550

MM250B4

16X28X180

75

555

455

384

35

1952

MM250C4

16X28X180

75

555

455

413

35

2727

MM300C4

36X20X280

78

693

593

487

41

3535

MM300D4

16X28X180

75

555

455

493

35

4396

MM350C4

36X20X280

78

693

593

514

41

5114

MM350D4

16X28X180

75

555

455

532

35

4999

MM400C4

36X20X280

78

693

593

567

41

5754

MM400D4

36X20X280

78

693

593

589

41

8655

MM450D4

36X20X280

38

1048

700

515

32

9314

MM450E4

36X20X280

78

693

593

619

41

10032

MM500D4

36X20X280

38

1048

700

545

32

10732

MM500E4

36X20X280

38

1048

700

555

32

12587

MM600E5

45X25X254

38

1451

1218

534

38

15919

MM600F5

45X25X254

38

1451

1218

583

38

21803

MM700F5

Inline with gearbox

Direct drive

Side by side

www.flsmidthkrebs.com

The FLSmidth Krebs millMAX slurry pump replaced the Warman AHF froth

pump for a customer. The customer reported our millMAX centrifugal slurry

pump more than tripled the life of the wet end slurry pump. We have replaced Warman pumps in many industries all over the world increasing wear

life and efficiency and reducing power consumption.

Our millMAX pumps are used in mining and industrial applications such

as mill discharge and primary cyclone feeds, froth pumps and more. Our

pumps are high quality and our field service technicians are exceptional.

Our pumps are designed for pumping water, mild slurry all the way up to

abrasive slurry applications.

World-class Service

The Krebs customer service philosophy is to consistently exceed the expectations of our customers when it comes to providing

technical support, processing orders and maintaining parts availability. Starting with the sales process, and extending

throughout the life of the supplied process solution, we strive to provide an unmatched, world-class customer experience.

Tucson, Arizona USA

Tel: +1 520 744 8200

E-mail: krebs@flsmidth.com

Neusiedl am See, Austria

Tel. +43 2167 3345

krebseurope@flsmidth.com

Beijing P.R. China

Tel: +86-10 8468 9100

krebschina@flsmidth.com

Queensland, Australia

Tel: +61 7 5519 5700

krebsaustralia@flsmidth.com

Sao Paulo, Brasil

Tel: +55-15-3416-7400

krebsbrasil@flsmidth.com

Chennai, India

Tel: +91 44 4748 1000

krebsindia@flsmidth.com

Western Australia

Tel: +61 8 6258 4800

krebsaustralia@flsmidth.com

Santiago, Chile

Tel: +56 2 2463 8350

krebschile@flsmidth.com

Manila, Philippines

Tel: +63-2-687-9251

Krebs-Philippines@flsmidth.com

Johannesburg, South Africa

Tel. +27 (0)10 210 4750

krebsafrica@flsmidth.com

www.flsmidthkrebs.com

Copyright 2014 FLSmidth A/S. ALL RIGHTS RESERVED. FLSmidth is a (registered) trademark of FLSmidth A/S. This brochure makes no offers, representations or

warranties (express or implied), and information and data contained in this brochure are for general reference only and may change at any time.

#10-001 Rev 12/17/2015 ljr-us

KREBS millMAXTM Pumps

Anda mungkin juga menyukai

- XL1100 BrochureDokumen8 halamanXL1100 BrochureCristian Avila ContrerasBelum ada peringkat

- DATA SHEET MP1000 CrusherDokumen6 halamanDATA SHEET MP1000 CrusherRichard Vica CalvoBelum ada peringkat

- Mill MAX8 PG EmailversionDokumen5 halamanMill MAX8 PG EmailversionPrimitivo GonzálezBelum ada peringkat

- Slurrymax Camur Pompasi 3 PDFDokumen8 halamanSlurrymax Camur Pompasi 3 PDFTecnologia Fabricación MetalmecanicaBelum ada peringkat

- Excel Tramp Release System Upgrade For HP700 and HP800 Cone CrushersDokumen2 halamanExcel Tramp Release System Upgrade For HP700 and HP800 Cone CrushersCarlos Andres Maldonado ArdilesBelum ada peringkat

- Krebs Products For The Coal IndustryDokumen20 halamanKrebs Products For The Coal IndustryABelum ada peringkat

- 10-400FLSmidthKrebs SlurryMAX Brochure EmailDokumen8 halaman10-400FLSmidthKrebs SlurryMAX Brochure EmailpacodmxBelum ada peringkat

- Slurrymax Pump: Split Casing Design For Multiple ApplicationsDokumen8 halamanSlurrymax Pump: Split Casing Design For Multiple Applicationssergio.manuel ovandoBelum ada peringkat

- B.5 MillMAX 3x2-14x12 IOM (July 2015)Dokumen67 halamanB.5 MillMAX 3x2-14x12 IOM (July 2015)Alief FadilBelum ada peringkat

- QMS - General BrochureDokumen6 halamanQMS - General BrochureArpit VermaBelum ada peringkat

- Warman VerticalDokumen4 halamanWarman VerticalCristobal JM CreativBelum ada peringkat

- KREBS slurryMAX Pump BrochureDokumen12 halamanKREBS slurryMAX Pump Brochuredavidgaro12Belum ada peringkat

- 00 Mill MAXSlurry Pump July 2016 CutawayDokumen1 halaman00 Mill MAXSlurry Pump July 2016 CutawayPatricio Acuña100% (1)

- Hofmann - South American Operations Brochure - 190902Dokumen8 halamanHofmann - South American Operations Brochure - 190902Jorge VillalobosBelum ada peringkat

- Leaflet One Piece Jaws 4482 10 21 en Cns LRDokumen2 halamanLeaflet One Piece Jaws 4482 10 21 en Cns LRkhk84jfxchBelum ada peringkat

- MANUAL1 - Copia - 4Dokumen50 halamanMANUAL1 - Copia - 4Jose NoriegaBelum ada peringkat

- 11 - Transport Cross-Beam For Roll UnitsDokumen43 halaman11 - Transport Cross-Beam For Roll UnitsCHRISTIAN ROJAS VALENZUELABelum ada peringkat

- Pans PDFDokumen8 halamanPans PDFJorge Prado DiazBelum ada peringkat

- HE Crushing Solutions Engineeing and MN OverviewDokumen48 halamanHE Crushing Solutions Engineeing and MN OverviewJorge VillalobosBelum ada peringkat

- Jaw CrusherDokumen4 halamanJaw CrusherRebekah HaleBelum ada peringkat

- Paginas TELsmithHP3Dokumen5 halamanPaginas TELsmithHP3Dennis AlexanderBelum ada peringkat

- VibratingEquipmentBrochure PDFDokumen10 halamanVibratingEquipmentBrochure PDFมนต์ชัย บุญธนลาภBelum ada peringkat

- Giw Corporate Brochure DataDokumen7 halamanGiw Corporate Brochure DataALAAN89Belum ada peringkat

- Shineking Cone Crusher Manual BookDokumen32 halamanShineking Cone Crusher Manual BookRiki D. PrastyoBelum ada peringkat

- Washing and Classifying Brochure EnglishDokumen24 halamanWashing and Classifying Brochure EnglishMohammed Alshami GeologistBelum ada peringkat

- Peru Peru: Value For Customs Purposes OnlyDokumen1 halamanPeru Peru: Value For Customs Purposes Onlyharrisonaqp0% (1)

- Crushing and Screening Handbook Edition7 23022023 2Dokumen109 halamanCrushing and Screening Handbook Edition7 23022023 2Gilberto Garnica MurilloBelum ada peringkat

- HPGR Revolution in PlatinumDokumen8 halamanHPGR Revolution in PlatinumtauficsBelum ada peringkat

- Jaw Crusher Broch 2Dokumen12 halamanJaw Crusher Broch 2Nanjappa K NuchumaniandaBelum ada peringkat

- 7.2 Crusher Erection and Maintenance Data - FlsmidthDokumen3 halaman7.2 Crusher Erection and Maintenance Data - FlsmidthWILSON JUAN DE DIOS QUISPE YUPANQUIBelum ada peringkat

- MANUAL DE CONO SYMONS DESDE EMCC - Archivo PDFDokumen27 halamanMANUAL DE CONO SYMONS DESDE EMCC - Archivo PDFGuillermo BalarinniBelum ada peringkat

- 3-8-21 FLSmidth FailureReport - Erdenet 12x10 MillMAX SAG Mill Discharge Rev 1Dokumen10 halaman3-8-21 FLSmidth FailureReport - Erdenet 12x10 MillMAX SAG Mill Discharge Rev 1Cristian CanazaBelum ada peringkat

- Sandvik CA Series Folder 8sid A4 LowDokumen8 halamanSandvik CA Series Folder 8sid A4 LowRelining MineralsBelum ada peringkat

- 005056B6021E1ED4AEFF0B99E4B424D3Dokumen8 halaman005056B6021E1ED4AEFF0B99E4B424D3Cristhian Niño MartinezBelum ada peringkat

- Kubria Cone Crushers: Cutting-Edge Technology in Hard Rock CrushingDokumen5 halamanKubria Cone Crushers: Cutting-Edge Technology in Hard Rock CrushingtonyBelum ada peringkat

- EXCEL High Performance Parts For HP-Cone-Crushers - MetsoDokumen7 halamanEXCEL High Performance Parts For HP-Cone-Crushers - MetsoabcBelum ada peringkat

- Trio TC51 Series Cone Crusher.Dokumen2 halamanTrio TC51 Series Cone Crusher.Enso E Rosales FBelum ada peringkat

- 15 - Load - Construction - Type - Resultado Cabeceras (Area 3000)Dokumen66 halaman15 - Load - Construction - Type - Resultado Cabeceras (Area 3000)Juan Jose San Martin AlfaroBelum ada peringkat

- Vsi 2Dokumen9 halamanVsi 2Vivek AgrawalBelum ada peringkat

- JW Series Jaw Crushers: Terex Minerals Processing SystemsDokumen16 halamanJW Series Jaw Crushers: Terex Minerals Processing SystemsKarin Anderson100% (1)

- HP Liners (Compatibility Mode)Dokumen18 halamanHP Liners (Compatibility Mode)Jeir leao Valencia100% (1)

- Installation, Operation and Maintenance of Airflex Model VC Grinding Mill ClutchesDokumen33 halamanInstallation, Operation and Maintenance of Airflex Model VC Grinding Mill Clutchesdennis_schoonhovenBelum ada peringkat

- Deepak Project On Jaw CrusherDokumen96 halamanDeepak Project On Jaw CrusherAnil Kumar KnBelum ada peringkat

- Mineralizaciones de Cu de Tipo SkarnDokumen10 halamanMineralizaciones de Cu de Tipo SkarnJorge Rios RBelum ada peringkat

- Rocksledger: Primary Jaw CrushersDokumen2 halamanRocksledger: Primary Jaw CrushersMechanical department100% (2)

- FLSmidth TS GyratoryCrusher Brochure Email2015 PDFDokumen8 halamanFLSmidth TS GyratoryCrusher Brochure Email2015 PDFAlex JonatanBelum ada peringkat

- Wmd0976 Trio Tc66 Series Cone Crusher Spec SheetDokumen2 halamanWmd0976 Trio Tc66 Series Cone Crusher Spec SheetYang Wan100% (1)

- Automation and Optimization of Primary Gyratory CrusherDokumen55 halamanAutomation and Optimization of Primary Gyratory Crusherthe requiem LastBelum ada peringkat

- Peças CH430Dokumen9 halamanPeças CH430Adriano MessiasBelum ada peringkat

- Screen BrochureDokumen7 halamanScreen Brochurelrodriguez_892566Belum ada peringkat

- PitmanDokumen7 halamanPitmanjlfyBelum ada peringkat

- Enduron High Pressure Grinding Rolls HPGR Product BrochureDokumen27 halamanEnduron High Pressure Grinding Rolls HPGR Product BrochurerecaiBelum ada peringkat

- MultitecDokumen96 halamanMultitecarietilang100% (1)

- Improper Crusher Feeding: Jaw CrushersDokumen1 halamanImproper Crusher Feeding: Jaw CrushersbfygBelum ada peringkat

- Kreiselbrecher enDokumen7 halamanKreiselbrecher enDiegoAlvarezHuguezBelum ada peringkat

- 10 001 Krebs millMAX Centrifugal Slurry Pumps 2017 PDFDokumen8 halaman10 001 Krebs millMAX Centrifugal Slurry Pumps 2017 PDFNicolas BaquedanoBelum ada peringkat

- 01 Chemical ProcessDokumen333 halaman01 Chemical ProcessDavid ValladaresBelum ada peringkat

- KREBS millMAX-e Slurry Pump BrochureDokumen8 halamanKREBS millMAX-e Slurry Pump BrochureneshaBelum ada peringkat

- Goulds PUMPSDokumen10 halamanGoulds PUMPSMoustafa ElsadanyBelum ada peringkat

- Krebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsDokumen4 halamanKrebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsPhaniBelum ada peringkat

- Krebs Hydrocyclones For Wet Flue Gas Desulfurization ScrubbersDokumen2 halamanKrebs Hydrocyclones For Wet Flue Gas Desulfurization ScrubbersPhaniBelum ada peringkat

- Modeling So Formation Processes in Coal-Fired Boilers: January 2007, Vol. 25Dokumen2 halamanModeling So Formation Processes in Coal-Fired Boilers: January 2007, Vol. 25PhaniBelum ada peringkat

- Krebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsDokumen4 halamanKrebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsPhaniBelum ada peringkat

- ASME B16.34 - 1996 - ValvesDokumen119 halamanASME B16.34 - 1996 - Valvesnadburg100% (1)

- Best Practice Guide Impulse Lines For Differential-Pressure FlowmetersDokumen22 halamanBest Practice Guide Impulse Lines For Differential-Pressure FlowmetersamietkolteBelum ada peringkat

- SuperCritical Boilers in ChinaDokumen57 halamanSuperCritical Boilers in ChinaTushar ChatterjeeBelum ada peringkat

- Correlations For The Grindability of The Ball MillDokumen14 halamanCorrelations For The Grindability of The Ball MillAshwani Prabha BhardwajBelum ada peringkat

- Readers Digest Best JokesDokumen16 halamanReaders Digest Best JokesEskay95% (58)

- PLANT Commissioning PDFDokumen35 halamanPLANT Commissioning PDFhenybamBelum ada peringkat

- MANUALDokumen106 halamanMANUALPhaniBelum ada peringkat

- Why Do Projects FailDokumen4 halamanWhy Do Projects FailPhani100% (1)

- Importance of Project Management On Resource Utilization and Delivery of Quality Deliverables in Various Organized StructuresDokumen17 halamanImportance of Project Management On Resource Utilization and Delivery of Quality Deliverables in Various Organized StructuresPhaniBelum ada peringkat

- Ethics, Fraud and Internal Control - MCQDokumen1 halamanEthics, Fraud and Internal Control - MCQHads LunaBelum ada peringkat

- Identifying Text Structure 1 PDFDokumen3 halamanIdentifying Text Structure 1 PDFUsaid BukhariBelum ada peringkat

- The Science of Cop Watching Volume 008Dokumen433 halamanThe Science of Cop Watching Volume 008fuckoffanddie23579Belum ada peringkat

- Exhaution of Administrative Remedies and The Doctrine of Primary JurisdictionDokumen3 halamanExhaution of Administrative Remedies and The Doctrine of Primary JurisdictionSebastian BorcesBelum ada peringkat

- Final Exam - B2.3 - 002Dokumen3 halamanFinal Exam - B2.3 - 002Dung KimBelum ada peringkat

- 016 Magtajas v. Pryce Properties - 234 SCRA 255Dokumen13 halaman016 Magtajas v. Pryce Properties - 234 SCRA 255JBelum ada peringkat

- TERGITOLTM TMN-100X 90% Surfactant PDFDokumen4 halamanTERGITOLTM TMN-100X 90% Surfactant PDFOnesany TecnologiasBelum ada peringkat

- Visa Travel Insurance Vti 606441Dokumen7 halamanVisa Travel Insurance Vti 606441ASRA CG BZBelum ada peringkat

- Pay SlipDokumen1 halamanPay SlipNaval PandeyBelum ada peringkat

- SCHENCK Vs USADokumen3 halamanSCHENCK Vs USADanny QuioyoBelum ada peringkat

- Inc 2Dokumen19 halamanInc 2MathiBelum ada peringkat

- Chapter 5Dokumen27 halamanChapter 5Devansh GoelBelum ada peringkat

- (CPR) Padilla Vs CA, GR No 121917, 12 March 1997 Case DigestDokumen3 halaman(CPR) Padilla Vs CA, GR No 121917, 12 March 1997 Case Digestarceo.ezekiel0Belum ada peringkat

- Article 19.1 DSU CommentaryDokumen17 halamanArticle 19.1 DSU CommentaryAkshat KothariBelum ada peringkat

- CivproDokumen60 halamanCivprodeuce scriBelum ada peringkat

- Rutgers Fall 2023 INTL Timeline 2.23Dokumen2 halamanRutgers Fall 2023 INTL Timeline 2.23velusunilBelum ada peringkat

- Intolerance and Cultures of Reception in Imtiaz Dharker Ist DraftDokumen13 halamanIntolerance and Cultures of Reception in Imtiaz Dharker Ist Draftveera malleswariBelum ada peringkat

- Ramiro, Lorren - Money MarketsDokumen4 halamanRamiro, Lorren - Money Marketslorren ramiroBelum ada peringkat

- Belgica vs. Ochoa, G.R. No. 208566Dokumen52 halamanBelgica vs. Ochoa, G.R. No. 208566Daryl CruzBelum ada peringkat

- Quota Merit List (Cholistan Area) For DVM (Morning) PDFDokumen1 halamanQuota Merit List (Cholistan Area) For DVM (Morning) PDFadeelBelum ada peringkat

- Prakas On Accreditation of Professional Accounting Firm Providing... EnglishDokumen12 halamanPrakas On Accreditation of Professional Accounting Firm Providing... EnglishChou ChantraBelum ada peringkat

- Legal Basis of International RelationsDokumen22 halamanLegal Basis of International RelationsCyra ArquezBelum ada peringkat

- MD Sirajul Haque Vs The State and OrsDokumen7 halamanMD Sirajul Haque Vs The State and OrsA.B.M. Imdadul Haque KhanBelum ada peringkat

- Adarsh Comp ConsDokumen7 halamanAdarsh Comp ConsAmanBelum ada peringkat

- Corporate Advisory Service Integra GroupDokumen24 halamanCorporate Advisory Service Integra GroupJimmy InterfaxBelum ada peringkat

- Aristotle PDFDokumen6 halamanAristotle PDFAnonymous p5jZCn100% (1)

- TWG-Findings-ABS-CBN Franchise PDFDokumen40 halamanTWG-Findings-ABS-CBN Franchise PDFMa Zola EstelaBelum ada peringkat

- Isu Assessment Form 04152024Dokumen1 halamanIsu Assessment Form 04152024yun48814Belum ada peringkat

- DPRM Form RSD 03 A Revised 2017Dokumen2 halamanDPRM Form RSD 03 A Revised 2017NARUTO100% (2)

- Republic vs. DayotDokumen17 halamanRepublic vs. DayotPanday L. MasonBelum ada peringkat