37 Material Storage

Diunggah oleh

Khuda BukshDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

37 Material Storage

Diunggah oleh

Khuda BukshHak Cipta:

Format Tersedia

Assessors Name:

Assessors signature:

Sajimon KK

Ref No: Rev 02 RA 2009 - Depa

Method

Statement

by When?

Cross reference to

SSOW/method

statement: (Highlight

one below)

Activity/

Operation

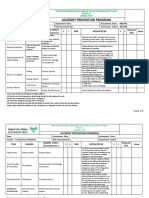

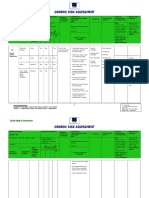

37

Significant

hazard

Fire and

Explosion

HIGH

M/S 001

YES

NO

Persons at risk

E

YES

YES

Oth

ers

YES

Control measures

required:

Prior to

commencement

of the activity

MATERIAL

STORAGE

RISK RATING MATRIX

Likelihood: 5 very likely 4 likely 3 fairly likely 2 unlikely 1 very unlikely

Severity: 5 catastrophic 4 major 3 moderate 2 minor 1 insignificant

Action by

SSOW/Method statement

Ref No:

Page No:

Risk

severity

(before

controls

are in

place)

Location of

task/operation being

assessed:

Site

Carry-out Risk

assessments for any

material storage

activities which

creates potential

hazards.

Adequate and

suitable training and

education shall be

given to operatives

involved in handling

and storing of

hazardous and

flammable materials,

Emergency

evacuation

procedure, Basic first

aid and Basic fire

fighting.

Task Carried

out by?

Date of

assessment:

15 January 09

Review date:

Ongoing

N.B.

Other on site

control measures

may be required

due to weather

conditions/other

reasons at time

of

task/operation:

Work must not

start until the

risks have

been assessed:

Residual risk:

The risk left

after all control

measures have

been put in

place see

risk matrix at

footer:

Project

Manager

Construction

Manager

Site Manager

Project

Engineer

HSE Manager

Provide good

housekeeping to

ensure that storage

area is free from

accumulated

materials that cause

tripping, fires or

explosions; or that

may contribute to the

harboring of rats and

other pest.

E = employees

C = contractors/subcontractors

P = Public

QMS Rev 02 RA 2009

Sajimon KK January 09

Assessors Name:

Assessors signature:

Sajimon KK

Ref No: Rev 02 RA 2009 - Depa

Cross reference to

SSOW/method

statement: (Highlight

one below)

Page No:

Activity/

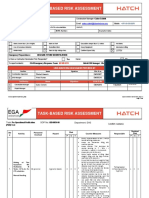

Operation

Significant

hazard

Reactivity

Risk

severity

(before

controls

are in

place)

HIGH

YES

NO

Persons at risk

E

YES

YES

Method

Statement

by When?

Location of

task/operation being

assessed:

Site

SSOW/Method statement

Ref No:

M/S 001

Oth

ers

Control measures

required:

Accidental

Medium

HIGH

YES

YES

Ensure that all

passageways shall be

remained CLEAR of

obstructions and

tripping hazards.

Passageways and

aisles shall be

appropriately marked

permanently.

Storage of material

shall not create any

hazard; bags,

containers, bundle,

etc shall be stacked,

blocked, interlocked

and limited in height

(2 meter high max.)

so that they are

stable and secure

against sliding or

collapse. Paint walls

or post with stripes

to indicate maximum

stacking heights for

quick reference.

NO SMOKING POLICY

shall be strictly

followed in the

material storage

area.

YES

YES

Task Carried

out by?

Date of

assessment:

15 January 09

Review date:

Ongoing

N.B.

Other on site

control measures

may be required

due to weather

conditions/other

reasons at time

of

task/operation:

Work must not

start until the

risks have

been assessed:

Residual risk:

The risk left

after all control

measures have

been put in

place see

risk matrix at

footer:

YES

MATERIAL

STORAGE

Musculoskel

etal Disorder

Action by

YES

RISK RATING MATRIX

Likelihood: 5 very likely 4 likely 3 fairly likely 2 unlikely 1 very unlikely

Severity: 5 catastrophic 4 major 3 moderate 2 minor 1 insignificant

E = employees

C = contractors/subcontractors

P = Public

QMS Rev 02 RA 2009

Sajimon KK January 09

Assessors Name:

Assessors signature:

Sajimon KK

Ref No: Rev 02 RA 2009 - Depa

Cross reference to

SSOW/method

statement: (Highlight

one below)

Page No:

Activity/

Operation

Significant

hazard

Spill

Risk

severity

(before

controls

are in

place)

YES

NO

Persons at risk

E

Method

Statement

by When?

Location of

task/operation being

assessed:

Site

SSOW/Method statement

Ref No:

M/S 001

Oth

ers

E

S

Control measures

required:

NO HOT WORKS

ACTIVITY shall be

performed inside and

near the material

storage area. PERMIT

to WORK shall be

secured and

approved by project

manager prior to

commence hot work

activity.

In adhering to fire

safety precautions,

All flammable and

combustible

materials shall be

stored according to

their fire

characteristics.

Adequate signage

shall be

conspicuously posted

inside and outside

the storage area.

Adequate numbers of

Fire point and Exit

routes shall be

permanently marked,

signed and free from

any obstructions.

Flammable liquids

MATERIAL

STORAGE

RISK RATING MATRIX

Likelihood: 5 very likely 4 likely 3 fairly likely 2 unlikely 1 very unlikely

Severity: 5 catastrophic 4 major 3 moderate 2 minor 1 insignificant

Action by

Task Carried

out by?

Date of

assessment:

15 January 09

Review date:

Ongoing

N.B.

Other on site

control measures

may be required

due to weather

conditions/other

reasons at time

of

task/operation:

Work must not

start until the

risks have

been assessed:

Residual risk:

The risk left

after all control

measures have

been put in

place see

risk matrix at

footer:

Medium

E = employees

C = contractors/subcontractors

P = Public

QMS Rev 02 RA 2009

Sajimon KK January 09

Assessors Name:

Assessors signature:

Sajimon KK

Ref No: Rev 02 RA 2009 - Depa

Cross reference to

SSOW/method

statement: (Highlight

one below)

Page No:

Activity/

Operation

Significant

hazard

Risk

severity

(before

controls

are in

place)

YES

NO

Persons at risk

E

Method

Statement

by When?

Location of

task/operation being

assessed:

Site

SSOW/Method statement

Ref No:

M/S 001

Oth

ers

Control measures

required:

Task Carried

out by?

Date of

assessment:

15 January 09

Review date:

Ongoing

N.B.

Other on site

control measures

may be required

due to weather

conditions/other

reasons at time

of

task/operation:

Work must not

start until the

risks have

been assessed:

Residual risk:

The risk left

after all control

measures have

been put in

place see

risk matrix at

footer:

must be separated

from other materials

by a fire wall.

MATERIAL

STORAGE

RISK RATING MATRIX

Likelihood: 5 very likely 4 likely 3 fairly likely 2 unlikely 1 very unlikely

Severity: 5 catastrophic 4 major 3 moderate 2 minor 1 insignificant

Action by

All hazardous

materials shall be

adequately LABELLED

and Material Safety

Data Sheet (MSDS)

for all hazardous

materials shall be

readily available and

communicated to all

users.

Physical separation

should be provided

for reactive

chemicals.

Suitable type of

Personal protective

equipment should be

used and workers

must be trained in

their proper use and

maintenance.

Provision for

Emergency Rescue

Low

E = employees

C = contractors/subcontractors

P = Public

QMS Rev 02 RA 2009

Sajimon KK January 09

Assessors Name:

Assessors signature:

Sajimon KK

Ref No: Rev 02 RA 2009 - Depa

Cross reference to

SSOW/method

statement: (Highlight

one below)

Page No:

Activity/

Operation

Significant

hazard

Risk

severity

(before

controls

are in

place)

YES

NO

Persons at risk

E

Method

Statement

by When?

Location of

task/operation being

assessed:

Site

SSOW/Method statement

Ref No:

M/S 001

Oth

ers

Control measures

required:

Action by

Task Carried

out by?

Date of

assessment:

15 January 09

Review date:

Ongoing

N.B.

Other on site

control measures

may be required

due to weather

conditions/other

reasons at time

of

task/operation:

Work must not

start until the

risks have

been assessed:

Residual risk:

The risk left

after all control

measures have

been put in

place see

risk matrix at

footer:

Plan shall be in place.

All operatives shall

understand what to

do in case of any

incidents happened.

Arrangement of

Welfare facilities

should be provided in

case of any accident.

At least one first aid

kit shall be readily

available at the

material storage

area.

Maintain adequate

clearance between

materials and wall,

partition ( no closer

than 18 inches ).

MATERIAL

STORAGE

RISK RATING MATRIX

Likelihood: 5 very likely 4 likely 3 fairly likely 2 unlikely 1 very unlikely

Severity: 5 catastrophic 4 major 3 moderate 2 minor 1 insignificant

E = employees

C = contractors/subcontractors

P = Public

QMS Rev 02 RA 2009

Sajimon KK January 09

Anda mungkin juga menyukai

- COSHH Risk AssessmentDokumen6 halamanCOSHH Risk AssessmentKyle RobertsonBelum ada peringkat

- SWMS 1 Loading, Unloading & ShiftingDokumen8 halamanSWMS 1 Loading, Unloading & ShiftingJ.j.JijoBelum ada peringkat

- Ra Lightning Protection SystemDokumen16 halamanRa Lightning Protection SystemamalBelum ada peringkat

- Task Risk Assessment For (Compressed Air Line Tie-In)Dokumen11 halamanTask Risk Assessment For (Compressed Air Line Tie-In)Venkadesh Periathambi100% (2)

- JHEA Loading and Offloading FENCEDokumen13 halamanJHEA Loading and Offloading FENCEStansilous Tatenda NyagomoBelum ada peringkat

- Workplace Inspection ChecklistDokumen119 halamanWorkplace Inspection ChecklistFarid SedekyBelum ada peringkat

- Risk Assessment of Installation of Chilled Water PipesDokumen20 halamanRisk Assessment of Installation of Chilled Water PipesVlad KaroBelum ada peringkat

- Risk Assessment For Drainage uPVC PipesDokumen1 halamanRisk Assessment For Drainage uPVC PipesZameer Basha Navzath AliBelum ada peringkat

- Using Hand Drill (WS)Dokumen2 halamanUsing Hand Drill (WS)John KalvinBelum ada peringkat

- Split Unit InstallationDokumen33 halamanSplit Unit Installationsree100% (1)

- Safe Working Procedure For Loading and UnloadingDokumen3 halamanSafe Working Procedure For Loading and Unloadingsizwe100% (1)

- Ra For Fire Protection Piping Installation WorksDokumen7 halamanRa For Fire Protection Piping Installation WorksprinceBelum ada peringkat

- Safe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)Dokumen6 halamanSafe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)tamoor sarwarBelum ada peringkat

- Skillbuild Risk Assessment: Competition Organising Partner: Citb /skillbuild Competition Skills: BricklayingDokumen6 halamanSkillbuild Risk Assessment: Competition Organising Partner: Citb /skillbuild Competition Skills: BricklayinguknandiBelum ada peringkat

- Fire Risk Assessment FormDokumen19 halamanFire Risk Assessment FormGopinath SekarBelum ada peringkat

- 20-RAS-Transformer InstallationDokumen2 halaman20-RAS-Transformer InstallationWalid MarhabaBelum ada peringkat

- Safety - Permit To Dig: PART A: To Be Completed For ALL Operations Involving Breaking GroundDokumen4 halamanSafety - Permit To Dig: PART A: To Be Completed For ALL Operations Involving Breaking GroundParashuram PatilBelum ada peringkat

- Demobilization Risk Assessment and Method StatementDokumen25 halamanDemobilization Risk Assessment and Method StatementVishu KumarBelum ada peringkat

- Hse - The Selection and Management of Mobile Elevating Work PlatformsDokumen6 halamanHse - The Selection and Management of Mobile Elevating Work PlatformsrewmarineBelum ada peringkat

- Hazards Associated With Plant and Equipment (Including Non-Powered Plant and Hand Tools)Dokumen7 halamanHazards Associated With Plant and Equipment (Including Non-Powered Plant and Hand Tools)وأكثرهم كارهونBelum ada peringkat

- Rmdjv-pj74-Hiradc-subc 03 (Hoisting & Rigging)Dokumen1 halamanRmdjv-pj74-Hiradc-subc 03 (Hoisting & Rigging)myn maliQueBelum ada peringkat

- Autoclaves - Generic Assessment - L Use of AutoclavesDokumen1 halamanAutoclaves - Generic Assessment - L Use of AutoclavesaKureishiBelum ada peringkat

- Form Inspection Premob - Quarterly (1) - 2Dokumen26 halamanForm Inspection Premob - Quarterly (1) - 2Ryan RhamdhaniBelum ada peringkat

- Risk Assessment For Pov TestingDokumen9 halamanRisk Assessment For Pov TestingvinodhyperBelum ada peringkat

- Excavation Working in Trenches Swms 10281-6Dokumen17 halamanExcavation Working in Trenches Swms 10281-6JamesBelum ada peringkat

- RA013-C Panel Electrical Work-8766Dokumen4 halamanRA013-C Panel Electrical Work-8766anisaanBelum ada peringkat

- Crane Hoist Sling Safety ProgramDokumen14 halamanCrane Hoist Sling Safety Programomar sadiqBelum ada peringkat

- Fire & Safety ChecklistDokumen30 halamanFire & Safety ChecklistjashnBelum ada peringkat

- SWMS Mobilisation of Blocks For MLT TEST RKDokumen14 halamanSWMS Mobilisation of Blocks For MLT TEST RKrakeshkhanna78100% (1)

- 2.8 HSE Training MatrixDokumen2 halaman2.8 HSE Training MatrixMuhammad HassaanBelum ada peringkat

- Risk Assessment - Hot Water BoilersDokumen4 halamanRisk Assessment - Hot Water BoilersUgonnaBelum ada peringkat

- WMS Infineon Project Tower ( Lifting Activities)Dokumen14 halamanWMS Infineon Project Tower ( Lifting Activities)tanaBelum ada peringkat

- JSO Cable Drum (02 Sept.'07)Dokumen2 halamanJSO Cable Drum (02 Sept.'07)Francis Enriquez TanBelum ada peringkat

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDokumen2 halamanProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (1)

- Job Safety Analysis FormDokumen2 halamanJob Safety Analysis FormHSE S4Belum ada peringkat

- Work PermitDokumen1 halamanWork PermitJeffersonDeGuiaBelum ada peringkat

- SWMS Bored PilingDokumen17 halamanSWMS Bored PilingnaraBelum ada peringkat

- Construction Assessment Checklist: Green TagDokumen2 halamanConstruction Assessment Checklist: Green TagRyan GillespieBelum ada peringkat

- Larsen & Toubro Limited Buildings and Factories Independent CompanyDokumen5 halamanLarsen & Toubro Limited Buildings and Factories Independent CompanyabbasBelum ada peringkat

- COVID-19 Risk Assesment For NCCCLDokumen3 halamanCOVID-19 Risk Assesment For NCCCLmohit100% (2)

- New Monthly SHE ReportsDokumen21 halamanNew Monthly SHE ReportsGIRI BISWAS100% (1)

- Hazardous Energy Control ProcedureDokumen20 halamanHazardous Energy Control ProcedureRam Kumar BarathanBelum ada peringkat

- RA Templates ElectricalDokumen17 halamanRA Templates ElectricalAbid MujtabaBelum ada peringkat

- RAMS For Installation of Fire Fighting SystemDokumen24 halamanRAMS For Installation of Fire Fighting SystemAnandu AshokanBelum ada peringkat

- Hazard Identification and Risk Assessment & Risk RatingDokumen12 halamanHazard Identification and Risk Assessment & Risk RatingMuhammad Syauqi ShaidanBelum ada peringkat

- Weekly Tower Light Check ListDokumen1 halamanWeekly Tower Light Check ListpjosesmBelum ada peringkat

- Hazard Identification and Risk AssessmentDokumen7 halamanHazard Identification and Risk AssessmentRahulBelum ada peringkat

- JSA GC-5 Mobile ScaffoldingDokumen6 halamanJSA GC-5 Mobile Scaffoldinggrande100% (2)

- First Aid Cases RecordDokumen1 halamanFirst Aid Cases RecordFrancis Enriquez TanBelum ada peringkat

- HSMC Employee Induction Procedure (Offices)Dokumen3 halamanHSMC Employee Induction Procedure (Offices)Anonymous 4e7GNjzGWBelum ada peringkat

- Job Safety Analysis: Potential Risk FactorsDokumen1 halamanJob Safety Analysis: Potential Risk FactorsFrancis VinojBelum ada peringkat

- F04 Site Safety HandbookDokumen40 halamanF04 Site Safety Handbooksalman ahmed0% (1)

- Safety Award ApplicationDokumen7 halamanSafety Award ApplicationJason Smith100% (1)

- NEBOSH International General Certificate Week 2 Element 5: Electrical SafetyDokumen32 halamanNEBOSH International General Certificate Week 2 Element 5: Electrical SafetyJaballa AliBelum ada peringkat

- Safety Signs On Construction SiteDokumen1 halamanSafety Signs On Construction SiteBëBå Wossen AssefaBelum ada peringkat

- RA Every ActvityDokumen38 halamanRA Every ActvityvijayBelum ada peringkat

- Electrical Work at Wellsite HARCDokumen2 halamanElectrical Work at Wellsite HARCErni Tri LestariBelum ada peringkat

- Work at Height Safety Question & AnswersDokumen34 halamanWork at Height Safety Question & AnswersKhuda BukshBelum ada peringkat

- Work at Heigh at Night SafetyDokumen49 halamanWork at Heigh at Night SafetyKhuda BukshBelum ada peringkat

- Toxic Gas Fact SheetDokumen15 halamanToxic Gas Fact SheetKhuda BukshBelum ada peringkat

- Monthly HSE Performance ReportDokumen17 halamanMonthly HSE Performance ReportKhuda BukshBelum ada peringkat

- HSE Docs 186 HSE Checklists Hseprof ComDokumen57 halamanHSE Docs 186 HSE Checklists Hseprof ComMansoor BabbarBelum ada peringkat

- Materials Handling, Storage, Use, and DisposalDokumen54 halamanMaterials Handling, Storage, Use, and DisposalKhuda BukshBelum ada peringkat

- Safety GuideDokumen53 halamanSafety GuideKhuda BukshBelum ada peringkat

- HSE PLAN by HTTPSDokumen52 halamanHSE PLAN by HTTPSKhuda BukshBelum ada peringkat

- HSE (Trainor Et Al) - 2006 - HSE Report No 426 ACUTEXDokumen106 halamanHSE (Trainor Et Al) - 2006 - HSE Report No 426 ACUTEXKhuda Buksh100% (1)

- 1691582034614Dokumen16 halaman1691582034614Joseph NBelum ada peringkat

- Stamp: Copy No. HolderDokumen266 halamanStamp: Copy No. HolderMd EnaamAzharBelum ada peringkat

- Short Note For Safety OfficerDokumen24 halamanShort Note For Safety OfficerKhuda BukshBelum ada peringkat

- Permit To Work ProcedureDokumen42 halamanPermit To Work ProcedureKhuda Buksh100% (1)

- 500 Technical Questions Safety&Fire-1Dokumen26 halaman500 Technical Questions Safety&Fire-1Saad GhouriBelum ada peringkat

- Checklist For Heavy Equipment - 1Dokumen15 halamanChecklist For Heavy Equipment - 1Katita ChascaBelum ada peringkat

- HSE Procedure For Planning & AuditingDokumen4 halamanHSE Procedure For Planning & AuditingKhuda Buksh100% (1)

- HSE-BMS-010 Permit To WorkDokumen24 halamanHSE-BMS-010 Permit To WorkKhuda BukshBelum ada peringkat

- NFPAP Member Registration Form - WordDokumen1 halamanNFPAP Member Registration Form - WordKhuda BukshBelum ada peringkat

- HSE Procedure For Garbage DisposalDokumen4 halamanHSE Procedure For Garbage DisposalKhuda BukshBelum ada peringkat

- 02 Abrasive WheelsDokumen2 halaman02 Abrasive WheelsKhuda BukshBelum ada peringkat

- ISO 45001 Gap Analysis ChecklistDokumen7 halamanISO 45001 Gap Analysis ChecklistKhuda Buksh75% (12)

- HSE Drilling and Well Control ProcedureDokumen5 halamanHSE Drilling and Well Control ProcedureKhuda Buksh100% (2)

- 3S Technical Proposal OHSAS ISO Implementation PDFDokumen38 halaman3S Technical Proposal OHSAS ISO Implementation PDFKhuda BukshBelum ada peringkat

- Ppe Stop and ThinkDokumen3 halamanPpe Stop and ThinkKhuda BukshBelum ada peringkat

- Quality PlanDokumen21 halamanQuality PlanTAHER AMMAR88% (8)

- 06 Power Tools OperationDokumen2 halaman06 Power Tools OperationKhuda BukshBelum ada peringkat

- Weekly Safety InspDokumen4 halamanWeekly Safety InspKhuda BukshBelum ada peringkat

- Emergency ProceduresDokumen23 halamanEmergency ProceduresKhuda BukshBelum ada peringkat

- 03 Wood CuttingDokumen1 halaman03 Wood CuttingKhuda BukshBelum ada peringkat

- CV Zafar Ul Haq KhokharDokumen1 halamanCV Zafar Ul Haq KhokharKhuda BukshBelum ada peringkat

- Hibon - SN Ingersoll Rand BlowerDokumen7 halamanHibon - SN Ingersoll Rand BlowermarquezsiemBelum ada peringkat

- 05 Astm Grain Size MeasurementsDokumen27 halaman05 Astm Grain Size MeasurementsnareshBelum ada peringkat

- Gulika in Vedic AstrologyDokumen8 halamanGulika in Vedic AstrologyCatchdgreen100% (1)

- Obs and Gynae PassmedDokumen7 halamanObs and Gynae PassmedrahulBelum ada peringkat

- 9500 MPR Wireless TransmissionDokumen46 halaman9500 MPR Wireless TransmissionMahdi AhmadiBelum ada peringkat

- A Guide To Maintenance Metrics-ProgramDokumen5 halamanA Guide To Maintenance Metrics-ProgramLy QuanBelum ada peringkat

- Buk Uuuuuu UuuuuuuDokumen92 halamanBuk Uuuuuu UuuuuuuJanaliyaBelum ada peringkat

- Fate NumeneraDokumen24 halamanFate Numeneraimaginaari100% (1)

- Looking For Cochlear Dead Regions A Clinical Experience With TEN TestDokumen9 halamanLooking For Cochlear Dead Regions A Clinical Experience With TEN TestVinay S NBelum ada peringkat

- Super GisDokumen535 halamanSuper GisNegrescu MariusBelum ada peringkat

- Today! 2 Activity Book AKDokumen10 halamanToday! 2 Activity Book AKMark Arenz Corixmir80% (5)

- CN 235 Aircraft DefinitionDokumen22 halamanCN 235 Aircraft DefinitionMoch Dedy100% (4)

- Fact Sheeton Canola OilDokumen15 halamanFact Sheeton Canola OilMonika ThadeaBelum ada peringkat

- PX 150 UsaDokumen138 halamanPX 150 UsaramiroBelum ada peringkat

- 1Dokumen3 halaman1Pradeep PunterBelum ada peringkat

- 10 To 11-ClassDokumen111 halaman10 To 11-ClassVikaas SagerBelum ada peringkat

- Brochure Smart Grid Foundation CourseDokumen6 halamanBrochure Smart Grid Foundation CourseKULDEEP MEENABelum ada peringkat

- Masterseal 530: Surface Applied Capillary Waterproofing For Concrete and MortarDokumen2 halamanMasterseal 530: Surface Applied Capillary Waterproofing For Concrete and MortarHoang An ViBelum ada peringkat

- CEPF640/CEBF640 CEFF640: N-Channel Enhancement Mode Field Effect Transistor FeaturesDokumen4 halamanCEPF640/CEBF640 CEFF640: N-Channel Enhancement Mode Field Effect Transistor FeaturesAngel FaneitezBelum ada peringkat

- Sperm Cell: Specialised CellsDokumen2 halamanSperm Cell: Specialised CellsRhynnieBelum ada peringkat

- An Automated Energy Meter Reading System Using GSM TechnologyDokumen8 halamanAn Automated Energy Meter Reading System Using GSM TechnologyBarBelum ada peringkat

- ASI Hammer Injection Block ManualDokumen16 halamanASI Hammer Injection Block ManualGerardo Manuel FloresBelum ada peringkat

- Aviation MagazinesDokumen46 halamanAviation Magazinesyogaga100% (1)

- Lenskart Solutions PVT LTD Company ProfileDokumen13 halamanLenskart Solutions PVT LTD Company ProfileAnujaBelum ada peringkat

- CatalogDokumen52 halamanCatalogtalabiraBelum ada peringkat

- Interactions of Microplastic Debris Throughout The Marine Ecosystem Final Tracked-Galloway, TS Cole, M Lewis, CDokumen22 halamanInteractions of Microplastic Debris Throughout The Marine Ecosystem Final Tracked-Galloway, TS Cole, M Lewis, CTrydawBelum ada peringkat

- Artikel Penelitian Annisa Humairah IbrahimDokumen15 halamanArtikel Penelitian Annisa Humairah Ibrahimisma nurhandayaniBelum ada peringkat

- Taiwan API Manufacturer ListDokumen4 halamanTaiwan API Manufacturer Listkalyani dynamicsBelum ada peringkat

- The Foods of Italy BookDokumen92 halamanThe Foods of Italy BookmanupopBelum ada peringkat

- ABS Rules For Cable SizingDokumen2 halamanABS Rules For Cable SizingMohammed JassimBelum ada peringkat