A2LA-2014REV

Diunggah oleh

Asif RazaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

A2LA-2014REV

Diunggah oleh

Asif RazaHak Cipta:

Format Tersedia

A2LA has accredited

ALL-PRO LABORATORY

Arlington, TX

for technical competence in the field of

Mechanical Testing

This laboratory is accredited in accordance with the recognized International Standard ISO/IEC 17025:2005 General Requirements for

the Competence of Testing and Calibration Laboratories. This accreditation demonstrates technical competence for a defined scope and the

operation of a laboratory quality management system (refer to joint ISO-ILAC-IAF Communiqu dated 8 January 2009).

Presented this 10th day of October 2012.

_______________________

President & CEO

For the Accreditation Council

Certificate Number 1159.01

Valid to October 31, 2014

For the tests to which this accreditation applies, please refer to the laboratorys Mechanical Scope of Accreditation.

SCOPE OF ACCREDITATION TO ISO/IEC 17025:2005

ALL-PRO LABORATORY

1915 Peyco Drive North

Arlington, TX 76001

Mr. Roderick L. Williams Sr. Phone: 817 467 5700

MECHANICAL

Valid To: October 31, 2014

Certificate Number: 1159.01

In recognition of the successful completion of the A2LA evaluation process, accreditation is granted to this

laboratory to perform the following fastener and metals tests:

Test

Standard

Sampling

ASME B18.18.1, B18.18.2M, B18.18.3M;

ASTM F1470 or per product specification

Hardness

Rockwell (B & C)

Brinell (HBW)

Rockwell Superficial (15N & 30N)

Tensile Testing

Wedge and Axial Tensile

Machined Pieces

Proof Load, Internally Threaded Fasteners

Proof Load, Externally Threaded Fasteners

ASTM E18; F606, F606M; SAE J429

ASTM E10

ASTM E18

ASTM F606, F606M; NASM 1312-8; ISO 898-1;

SAE J429

ASTM A370, E8/E8M, F606, F606M; SAE J429

ASTM A370, F606, F606M; SAE J995

ASTM A370, F606, F606M; SAE J429

Torque Testing

Torque-Tension

Wrenching Torque

Locking Torque

Breakaway Torque

IFI 100, 107

NASM 25027

NASM 25027

NASM 25027

Plating Thickness

ASTM B499

Rotational Capacity

ASTM A325; TXDOT Tex-452-A, AASHTO (A325)

(A2LA Cert. No. 1159.01) Revised 03/25/2013

Page 1 of 2

I.

Dimensional Testing1

Parameter

Range

Standards

(Up to 1) in

(1 to 2) in

(Up to 6) in

(Up to 8) in

(Up to 12) in

0.0003 in

0.0010 in

0.0013 in

0.0010 in

0.0020 in

Micrometers

Micrometers

Calipers

Calipers

Calipers

MIL-STD-120

Straightness

(Up to 12) in

N/A

Straightness gage

ANSI B1.2.1

Threads

Pitch Diameter

(Up to 2) in

0.0002 in

Pitch micrometers

#0 to 1 in

(80 to 8 threads) per inch

N/A

Ring gages

(Go/No Go)

ASME B1.2, B1.3M

(Systems 21 & 22);

MIL-STD-120

#4 to 1.0 in

(40 to 8 threads) per inch

Technique

Linear (1D)

Functional

Diameter

CMC2 ()

N/A

Thread plug gage

(Go/No Go)

This laboratory does not offer dimensional testing services. These tests are not equivalent to that of a

calibration.

Calibration and Measurement Capability (CMC) is the smallest uncertainty of measurement that a

laboratory can achieve within its scope of accreditation when performing more or less routine

measurements of nearly ideal measurement standards or nearly ideal measuring equipment. Calibration

and Measurement Capabilities represent expanded uncertainties expressed at approximately the 95 % level

of confidence, usually using a coverage factor of k = 2. The actual measurement uncertainty of a specific

measurement performed by the laboratory may be greater than the CMC due to the behavior of the

customers device and to influences from the circumstances of the specific measurement.

(A2LA Cert. No. 1159.01) Revised 03/25/2013

Page 2 of 2

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- HdfcLogs 20 June 23Dokumen10 halamanHdfcLogs 20 June 23Asif RazaBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Bolting Galvanised SteelDokumen10 halamanBolting Galvanised SteelAsif RazaBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Escape Plan PDFDokumen2 halamanEscape Plan PDFAsif RazaBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Bolting Galvanised SteelDokumen10 halamanBolting Galvanised SteelAsif RazaBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- En 14399-4Dokumen24 halamanEn 14399-4Asif RazaBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Mechanical Properties of Metric FastenersDokumen2 halamanMechanical Properties of Metric FastenersAsif RazaBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- 02 Bolt Screw Bs 3692 Gr. 8.8Dokumen1 halaman02 Bolt Screw Bs 3692 Gr. 8.8Asif Raza0% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Filing FilesDokumen56 halamanFiling FilesAsif RazaBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Mechanical Properties of Metric FastenersDokumen2 halamanMechanical Properties of Metric FastenersAsif RazaBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- ASTM E18-05 AP Note Rockwell Hardness and Rockwell Superficical HardnessDokumen4 halamanASTM E18-05 AP Note Rockwell Hardness and Rockwell Superficical HardnessAsif RazaBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

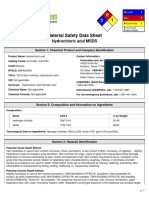

- HCLDokumen7 halamanHCLAsif RazaBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Bottom Nut's Tack Welding On Straigth Anchor Bolt 141106Dokumen2 halamanBottom Nut's Tack Welding On Straigth Anchor Bolt 141106Asif RazaBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Department:-Galvanising Date:-23/11/14: Item No. Cat No / Size Project Pieces Unit WT Total WTDokumen7 halamanDepartment:-Galvanising Date:-23/11/14: Item No. Cat No / Size Project Pieces Unit WT Total WTAsif RazaBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- GGGB6023 Tugasan Tutorial 3 - P69060 Mior SyazrilDokumen5 halamanGGGB6023 Tugasan Tutorial 3 - P69060 Mior SyazrilAmizan AbdullahBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Band Gaps and Electronics Structure of PerovskitesDokumen12 halamanBand Gaps and Electronics Structure of PerovskitesThanh Long TaBelum ada peringkat

- Kraken Intelligence's Taproot Primer - An Upgrade For The AgesDokumen37 halamanKraken Intelligence's Taproot Primer - An Upgrade For The AgesT. CC ElficBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- United States: (12) Patent Application Publication (10) Pub. No.: US 2004/0132474 A1Dokumen17 halamanUnited States: (12) Patent Application Publication (10) Pub. No.: US 2004/0132474 A1BukBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Kou2003 PDFDokumen6 halamanKou2003 PDFGe EffgenBelum ada peringkat

- Deductive ReasoningDokumen2 halamanDeductive ReasoningMariel C. BombitaBelum ada peringkat

- LSM330DLDokumen54 halamanLSM330DLalexanderBelum ada peringkat

- 4-6 Practice: The Quadratic Formula and The DiscriminantDokumen1 halaman4-6 Practice: The Quadratic Formula and The Discriminantasdfasdfasdfasdfasdf0% (1)

- PRACTICAL RESEARCH 2 - Q1 - W1 - Mod1Dokumen13 halamanPRACTICAL RESEARCH 2 - Q1 - W1 - Mod1Ma Fe Evangelista Galia77% (48)

- IP03 Loops-4slides PDFDokumen10 halamanIP03 Loops-4slides PDFRamesh GBelum ada peringkat

- Digital Control SystemDokumen34 halamanDigital Control SystemLaxman Koirala100% (3)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Dual Axis Solar Activity Tracker For Solar Panels: Department of Engineering, Sciences and Humanities (DESH)Dokumen5 halamanDual Axis Solar Activity Tracker For Solar Panels: Department of Engineering, Sciences and Humanities (DESH)sujay patilBelum ada peringkat

- Acn CSDokumen4 halamanAcn CSLeo100% (1)

- HyperMILL Readme enDokumen20 halamanHyperMILL Readme enjimBelum ada peringkat

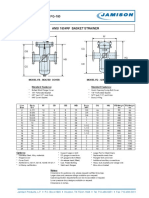

- FB-150 FQ-150 Basket StrainerDokumen1 halamanFB-150 FQ-150 Basket Strainerklich77Belum ada peringkat

- Access Workshop 01Dokumen8 halamanAccess Workshop 01movogonBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- EWAD-CF EEDEN15-435 Data Books EnglishDokumen42 halamanEWAD-CF EEDEN15-435 Data Books EnglishrpufitaBelum ada peringkat

- Test A: Two-Dimensional Motion and VectorsDokumen9 halamanTest A: Two-Dimensional Motion and VectorsAref DahabrahBelum ada peringkat

- Haaland EquationDokumen1 halamanHaaland EquationAmir AzmiBelum ada peringkat

- Register Transfer LanguageDokumen11 halamanRegister Transfer LanguageShiva IdokBelum ada peringkat

- Question For Practice Oracle (11g) With AnswersDokumen32 halamanQuestion For Practice Oracle (11g) With AnswersAnonymous J8V2pZZ100% (4)

- Chapter 3 Ni ChupaghettiDokumen2 halamanChapter 3 Ni ChupaghettiRodemar RosarioBelum ada peringkat

- Fire InvestigationDokumen126 halamanFire InvestigationAbcede IloiloBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Infinix NOTE 5 Stylus Quick Guide: Together We Can!Dokumen16 halamanInfinix NOTE 5 Stylus Quick Guide: Together We Can!LescribeurBelum ada peringkat

- Evaluating Capital ProjectsDokumen254 halamanEvaluating Capital Projectsariff_sodriBelum ada peringkat

- (John F. Moulder) PHI Handbook of XRay Photoelectron SpectrosDokumen192 halaman(John F. Moulder) PHI Handbook of XRay Photoelectron SpectrosCamilo CorredorBelum ada peringkat

- Handwritten English Alphabet RecognitionDokumen8 halamanHandwritten English Alphabet RecognitionIJRASETPublicationsBelum ada peringkat

- Sensor Gaurd Installation and Maintenance ManualDokumen57 halamanSensor Gaurd Installation and Maintenance ManualCapacitacion TodocatBelum ada peringkat

- Configuring Routing by Using Routing and Remote AccessDokumen31 halamanConfiguring Routing by Using Routing and Remote AccessLacus ClyneBelum ada peringkat

- Post Hoc Test in ANOVADokumen17 halamanPost Hoc Test in ANOVAJelly Jean PayeBelum ada peringkat