Structural Steels PDF

Diunggah oleh

vigneshDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Structural Steels PDF

Diunggah oleh

vigneshHak Cipta:

Format Tersedia

Structural

Steels

1 Steel description and applications Our structural steels are also developed to enhance

processability:

laser steels(*) make it possible to cut them with high precision

As a result of joining the

cold forming steels optimize the forming properties in order to

forces of Duferco Clabecq

guarantee an excellent finishing

and Verona Steel into one

unique division, we propose As you sometimes expect more of your steel for outside

one of the largest range of applications, we also propose special solutions:

thickness in structural steels. steels with improved resistance to atmospheric corrosion(*)

combine strength and inner protection against weathering

effects

Our long experience in these

floor plates(*), with their numerous combinations of grades

steels is another advantage, and thickness, are an answer for higher security in long-

as we can meet most of your lasting hard weather and utilization conditions

technical requirements.

Whether you are looking for a widespread mix of thickness, small

For a long time, we have quantities in any grade or when you have special requirements,

proven our know-how in the our plates and bars keep each time the same high quality which

following sectors: makes their reputation.

earthmoving, mining and quarrying machinery

mechanical construction Our sales representatives help you to

structural steelwork find the most appropriate plates to fulfill

oil & gas storage tanks your specific requirements.

wind towers Dont hesitate to contact us.

etc.

2 Standards

Japanese Canada USA USA USA

EN 10025-2 EN 10025-3 EN 10025-5 (*)

JIS 3106 CSA G40-21 ASTM ASTM ASTM

S185 1.0035 A283 Gr. A,B,C,D S275 N 1.0490 S235 JOW 1.8958

Thanks

S235JRto its experience

1.0038 in structural

SM 400 A steel, Duferco

230 G Clabecq can meet S275 NL

construction of earthmoving, miningS235

1.0491 and J2Wquarrying

1.8961 machinery

S235J0

all the 1.0114 in termsSMof400quality

expectations B - even the toughest ones - in S355 N 1.0545 S355 JOW 1.8959 A588

mechanical construction

S235 J2 1.0117 SM 400 C S355 NL 1.0546 A572 Gr. 50 S355 JOWP 1.8945

the following sectors: structural steelwork S355 J2W 1.8965

S275 JR 1.0044 260 W, WT A572 Gr. 42 S420 N 1.8902 A572 Gr. 60

oil & gas storage tanks S355 J2WP 1.8946

S275 JO 1.0143 A36 S420 NL 1.8912

S275 J2 1.0145 A573 Gr. 65 construction

S460 N of wind towers

1.8901 S355 K2W 1.8967

S355 JR 1.0045 SM 490 A 350 W, WT A633 Gr. C,D etc.

S460 NL 1.8903

S355 JO 1.0553 SS 490 B

S355 J2 1.0577 SS 490 C A573 Gr. 70 If you need medium thickness, small quantities in any type or when

S355 K2 1.0596 SS 490 YB you have USA our plates keep each time the

special requirements, USAsame

EN 10025-4 EN 10148-2

S235 JRC 1.0122 ASTM ASTM

S235 JOC 1.0115 high quality which makes their reputation.

S275 M 1.8818 S315 MC 1.0972

S235 J2C 1.0119 S275 ML 1.8819 S355 MC 1.0976 A656 Gr. 50

S275 JRC 1.0128 OurS355

salesM representatives

1.8823 help you to find

S420the

MC most1.0980

appropriate plates

A656 Gr. 60

S275 JOC 1.0140 S355 ML

to fulfill 1.8834 requirements.

your specific A945 S460hesitate

Dont MC 1.0982

to contact them.

S275 J2C 1.0142 S420 M 1.8825 S500 MC 1.0984 A656 Gr. 70

S355 JRC 1.0551 S420 ML 1.8836 A945 S550 MC 1.0986 A656 Gr. 80

S355 JOC 1.0554 S460 M 1.8827 S700MC (*) 1.8974

S355 J2C 1.0579

Plate_B10-02_E

S460 ML 1.8838 (*) see also the specific data sheets

S355 K2C 1.0594 for these products

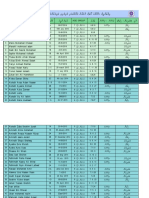

3 Dimensions

Plate_B10-02_E

Hot Rolled Steels Forged Plates Forged Bars

Grades Width/ Delivery Delivery Delivery

Certificates

Thickness Thickness Thickness

length Conditions (2) Conditions (3) Conditions (3)

S 185

S 235 JR max. thickness range:

S 235 JO 3-150

S 235 J2 A as rolled (AR),

S 275 JR (depending on the normalized rolled

norm or on the deli- or normalized (N), as rolled (AR), as rolled (AR), (2.1)

S 275 JO normalized

very condition, it may thermomechanically 151-360 rolled or 361-1000 normalized rolled 2.2/3.1/3.2

Structural S 275 J2 be limited to 25,40mm, controlled rolled (M) or normalized (N)

S 355 JR 120mm or 130 mm) normalized (N)

S 355 JO

S 355 J2 Please contact us

EN 10025-2 for the feasibility!

S 355 K2 B

E 295 4,76-120 normalized rolled 2.2/3.1/3.2

E 335 12-16 or normalized (N)

S 235 JRC

S 235 J2C A

S 275 J2C normalized rolled or

3-30 normalized (N) 2.2/3.1/3.2

S 355 JOC

S 355 J2C B

S 355 K2C

Cold forming S 355 MC 3-20

B

S 420 MC

S 460 MC 5-25,4 thermomechanically

EN 10149-2 S 500 MC controlled rolled (M)

C

S 550 MC 8-16

S 700 MC 10-16

S 275 N

A

S 275 NL

3-120

S 355 N

S 355 NL

EN 10025-3 B normalized rolled or

S 420 N normalized (N) 3.1/3.2

3-70

S 420 NL

S 460 N

3-25,40 C

Weldable S 460 NL

Fine Grain S 275 M

A

S 275 ML 3-63

S 355 M

S 355 ML B thermomechanically

EN 10025-4 3-40

S 420 M controlled rolled (M)

S 420 ML

S 460 M 3-25,4 C

S 460 ML

S 355 JOWP

3-12 B

Steels With S 355 J2WP

Improved S 235 JOW

A as rolled (AR), (2.1)

Atmospheric EN 10025-5 S 235 J2W normalized rolled

2.2/3.1/3.2

Corrosion S 355 JOW 3-80 (1) or normalized (N)

Resistance S 355 J2W B

S 355 K2W

(1) between 64 and 80: max width is 2750mm (2) the plant may not accept certain delivery conditions in order to respect mechanical results (3) no production of J2+AR and JR+N

4 Elementary precautions

As the workability of structural steels differs from the one to the other, before using advanced techniques for cutting,welding, forming, etc...

it is recommended to observe elementary precautions and to strictly Our technical experts are at your disposal for any request or

follow the instructions given in the norms and in the technical guides requirement.

The information given in this data sheet is correct at the time of publishing and is intended to give a general guideline for the purchasing and use of the steels. Values quoted must not be considered as being

guaranteed unless specifically confirmed separately in writing.

Duferco Clabecq S.A. Verona Steel S.p.A. Companies of STEEL INVEST & FINANCE,

Rue de Clabecq 101 - B-1460 ITTRE - Belgium Via Antonio Salieri, 24 - 37050 Vallese di Oppeano (VR) - Italy

NLMK - Duferco joint venture

Tel. : +32 (0)2 391 91 00 - Fax. : +32 (0)2 391 98 90 Tel. : + 39 045 69 97 900 - Fax : + 39 045 69 97 915

clabecq@duferco.be - www.dufercobelgium.com info@veronasteel.eu - www.veronasteel.eu INTEGRATED STEEL SOLUTIONS

Anda mungkin juga menyukai

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantDari EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Reinforced Concrete Buildings: Behavior and DesignDari EverandReinforced Concrete Buildings: Behavior and DesignPenilaian: 5 dari 5 bintang5/5 (1)

- High Strength Steels For Naval ApplicationsDokumen19 halamanHigh Strength Steels For Naval ApplicationsRaju NagendraBelum ada peringkat

- Structural Steels Equivalent ChartDokumen2 halamanStructural Steels Equivalent ChartHamdan PkBelum ada peringkat

- Aming Members Sept 04Dokumen16 halamanAming Members Sept 04Edison BecerraBelum ada peringkat

- Guidance Note Structural Steels No. 3.01: ScopeDokumen6 halamanGuidance Note Structural Steels No. 3.01: ScopeAndronikos SkiadopoulosBelum ada peringkat

- DuplexSellSheet 01 12Dokumen2 halamanDuplexSellSheet 01 12rickthetrickstertrickyBelum ada peringkat

- Bulb Flats BrochureDokumen12 halamanBulb Flats BrochureVivek GuptaBelum ada peringkat

- Fusion Bond Epoxt Coating BrochureDokumen12 halamanFusion Bond Epoxt Coating Brochure4uengineerBelum ada peringkat

- As3679 Material CatalogDokumen5 halamanAs3679 Material CatalogEsapermana RiyanBelum ada peringkat

- Steel, Structural Tubing, Cold Formed, Welded, Carbon, Zinc-Coated (Galvanized) by The Hot-Dip ProcessDokumen3 halamanSteel, Structural Tubing, Cold Formed, Welded, Carbon, Zinc-Coated (Galvanized) by The Hot-Dip ProcessAli Saleh Saad AL-isawiBelum ada peringkat

- Steel Plates With Excellent HAZ Toughness For Offshore StructuresDokumen7 halamanSteel Plates With Excellent HAZ Toughness For Offshore Structures구용찬Belum ada peringkat

- Novocon 1050 SubmittalDokumen5 halamanNovocon 1050 SubmittalBibhawesh PandeyBelum ada peringkat

- Astm F436M 2000Dokumen5 halamanAstm F436M 2000Jesse ChenBelum ada peringkat

- HP Composite Design ExampleDokumen43 halamanHP Composite Design ExampleShervin PeneroBelum ada peringkat

- TB29 - Deckform Sept 02Dokumen2 halamanTB29 - Deckform Sept 02Ravinesh SinghBelum ada peringkat

- Umesh Rajshirke Material Properties and Their Design Value PDFDokumen53 halamanUmesh Rajshirke Material Properties and Their Design Value PDFVarun VermaBelum ada peringkat

- Const PPT (Reinf. Types)Dokumen21 halamanConst PPT (Reinf. Types)Shefali GoswamiBelum ada peringkat

- ENG Structural SteelsDokumen2 halamanENG Structural SteelsOlalla CuiñaBelum ada peringkat

- Case Hardening SteelsDokumen52 halamanCase Hardening SteelsGururaja TantryBelum ada peringkat

- Automotive ComponentsDokumen12 halamanAutomotive ComponentsfightingfalconBelum ada peringkat

- Decking and Roofing BrochureDokumen4 halamanDecking and Roofing BrochurejsbharadwajBelum ada peringkat

- Duplex SSDokumen12 halamanDuplex SSTushar PatilBelum ada peringkat

- Acroni PDFDokumen15 halamanAcroni PDFIgor GrujićBelum ada peringkat

- AFI Data Sheet Pre Engineered Metal Building Insulation PEBI No PixDokumen3 halamanAFI Data Sheet Pre Engineered Metal Building Insulation PEBI No PixWafaa abd elhamedBelum ada peringkat

- Why Use Duplex StainlessDokumen2 halamanWhy Use Duplex StainlessPaolo VisentinBelum ada peringkat

- FRP Product PDFDokumen4 halamanFRP Product PDFGowrisankarBelum ada peringkat

- Design: Where Continuous Operation Is Required, Speeds May Be Limited To 107Mpm and Pressure Maximum To 240 KpaDokumen30 halamanDesign: Where Continuous Operation Is Required, Speeds May Be Limited To 107Mpm and Pressure Maximum To 240 KpaglobalindosparepartsBelum ada peringkat

- MES Die Castings Design and Specification Guide: Delivery Engineered SolutionsDokumen12 halamanMES Die Castings Design and Specification Guide: Delivery Engineered SolutionsRafał Lesiczka100% (1)

- A Rehabilitation of RCC - PSC BridgesDokumen77 halamanA Rehabilitation of RCC - PSC BridgesOneTech ManBelum ada peringkat

- 28 - Hofmann - Trackpads Brochure - A4Dokumen4 halaman28 - Hofmann - Trackpads Brochure - A4Jorge Villalobos100% (1)

- Brochure Hot-FormedStructuralHollowSectionsDokumen5 halamanBrochure Hot-FormedStructuralHollowSectionsAugusto.FilhoBelum ada peringkat

- Zinc Alloy Thermo-Diffusion Coatings (TDC) On Steel Fasteners, Hardware, and Other ProductsDokumen5 halamanZinc Alloy Thermo-Diffusion Coatings (TDC) On Steel Fasteners, Hardware, and Other ProductsSofia Yuli100% (1)

- Catalogo Afã Motores CaterpillarDokumen166 halamanCatalogo Afã Motores CaterpillarAlexis SanchezBelum ada peringkat

- ASTM A325-Tightening Bolts StructureDokumen6 halamanASTM A325-Tightening Bolts StructureMarta Driantono0% (1)

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDokumen2 halamanDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelBo WangBelum ada peringkat

- The Blue Book - Structural Steel TablesDokumen51 halamanThe Blue Book - Structural Steel Tablesdavideristix100% (2)

- Astm 1011 - 0Dokumen8 halamanAstm 1011 - 0Tomás jesus De Paz LópezBelum ada peringkat

- Steel in Stadium EgineeringDokumen4 halamanSteel in Stadium EgineeringFrans HeidelooBelum ada peringkat

- MBIE - Grade 500E Reinforcing Steel - Good PracticeDokumen8 halamanMBIE - Grade 500E Reinforcing Steel - Good PracticeNelson ChinBelum ada peringkat

- LT0780 4 Extrait Catalogue ERICO AnglaisDokumen11 halamanLT0780 4 Extrait Catalogue ERICO AnglaisMattelecBelum ada peringkat

- 3.6.5 Bi-Metal Kwik-Flex Self-Drilling Screws (Pg. 168-170) - 2Dokumen4 halaman3.6.5 Bi-Metal Kwik-Flex Self-Drilling Screws (Pg. 168-170) - 2LauraMilenaHernándezTorresBelum ada peringkat

- Bimetallic FastenersDokumen8 halamanBimetallic FastenersMark Cristian Delas AlasBelum ada peringkat

- Astm C955-09Dokumen4 halamanAstm C955-09rodrigoBelum ada peringkat

- Trench Sheeting BrochureDokumen8 halamanTrench Sheeting BrochurehameedBelum ada peringkat

- C955 09Dokumen4 halamanC955 09guillermoBelum ada peringkat

- Deformed and Plain Stainless Steel Wire and Welded Wire For Concrete ReinforcementDokumen9 halamanDeformed and Plain Stainless Steel Wire and Welded Wire For Concrete ReinforcementAcácio AlvesBelum ada peringkat

- Reinforcing Steel BarsDokumen17 halamanReinforcing Steel BarsRonald BilogBelum ada peringkat

- PlanchasDiamantadas RuukkiDokumen3 halamanPlanchasDiamantadas RuukkiFelipeBelum ada peringkat

- AKG Bearings - SRBDokumen2 halamanAKG Bearings - SRBWahyu HadiBelum ada peringkat

- Structural Steel For BridgesDokumen6 halamanStructural Steel For BridgesFRANZ RICHARD SARDINAS MALLCOBelum ada peringkat

- Cold Rolled SteelpdfDokumen16 halamanCold Rolled Steelpdfimrahim07Belum ada peringkat

- Astm A 1011M PDFDokumen8 halamanAstm A 1011M PDFJuan CarlosBelum ada peringkat

- 101 (2006)Dokumen2 halaman101 (2006)Eng-Mahmoud AtiaBelum ada peringkat

- VN Rapid Response Final Rev12 23 PDFDokumen40 halamanVN Rapid Response Final Rev12 23 PDFSube OhBelum ada peringkat

- Astm A123 2013 PDFDokumen8 halamanAstm A123 2013 PDFjoao carlos protz100% (2)

- ASTM F 436 Standard Specification For Hardened Steel WashersDokumen6 halamanASTM F 436 Standard Specification For Hardened Steel WashersILSEN N. DAETBelum ada peringkat

- Hand Book For Steel Structure Quality Control on SiteDari EverandHand Book For Steel Structure Quality Control on SiteBelum ada peringkat

- The Essentials of Material Science and Technology for EngineersDari EverandThe Essentials of Material Science and Technology for EngineersPenilaian: 5 dari 5 bintang5/5 (1)

- Itp ErectionDokumen6 halamanItp ErectionvigneshBelum ada peringkat

- Itp ErectionDokumen6 halamanItp ErectionvigneshBelum ada peringkat

- Astm A 234 GR WPB Pipe FittingsDokumen2 halamanAstm A 234 GR WPB Pipe FittingsvigneshBelum ada peringkat

- Itp ErectionDokumen6 halamanItp ErectionvigneshBelum ada peringkat

- ITP Is The Minimum Requirement of The Activities For Quality Control and Inspection of The FieldDokumen3 halamanITP Is The Minimum Requirement of The Activities For Quality Control and Inspection of The FieldvigneshBelum ada peringkat

- 9 77 Pages Mutiple Questions For CSWIP Question Answers Solved Past Papers Cswip 3.1Dokumen77 halaman9 77 Pages Mutiple Questions For CSWIP Question Answers Solved Past Papers Cswip 3.1Umah SangarBelum ada peringkat

- Installation Method Statement of HDPE Piping PDFDokumen5 halamanInstallation Method Statement of HDPE Piping PDFvignesh75% (4)

- 5S Audit Form (Draft) 12-10-09 Rev4 NLDokumen4 halaman5S Audit Form (Draft) 12-10-09 Rev4 NLvigneshBelum ada peringkat

- I. Ust F Ii. C S P: EAK Esting HecklistDokumen7 halamanI. Ust F Ii. C S P: EAK Esting HecklistvigneshBelum ada peringkat

- Prem Qa & QCDokumen4 halamanPrem Qa & QCvigneshBelum ada peringkat

- 5S Audit Form (Draft) 12-10-09 Rev4 NLDokumen4 halaman5S Audit Form (Draft) 12-10-09 Rev4 NLvigneshBelum ada peringkat

- Orbital Projects & Services LLC: Rofessional EsumeDokumen2 halamanOrbital Projects & Services LLC: Rofessional EsumevigneshBelum ada peringkat

- Orbital Projects & Services LLC: Rofessional EsumeDokumen2 halamanOrbital Projects & Services LLC: Rofessional EsumevigneshBelum ada peringkat

- High Density Polyethylene Smooth Liner: Product Data Property Test Method ValuesDokumen1 halamanHigh Density Polyethylene Smooth Liner: Product Data Property Test Method ValuesvigneshBelum ada peringkat

- Kingston Paints Pty - LTD: Material Safety Data SheetDokumen4 halamanKingston Paints Pty - LTD: Material Safety Data SheetvigneshBelum ada peringkat

- Material Grade Comparison Chart PDFDokumen1 halamanMaterial Grade Comparison Chart PDFHelen Kate Saccuan100% (1)

- Reduce CO2 With Higher Grade Steel.: For Further Information Contact Paul Airey (Peers) - Tel 01204 558500Dokumen1 halamanReduce CO2 With Higher Grade Steel.: For Further Information Contact Paul Airey (Peers) - Tel 01204 558500vigneshBelum ada peringkat

- Kavacha - WHD20 Isolator.Dokumen1 halamanKavacha - WHD20 Isolator.vigneshBelum ada peringkat

- Wma Site Office and Welfare Facility Facilities: ElectricalDokumen3 halamanWma Site Office and Welfare Facility Facilities: ElectricalvigneshBelum ada peringkat

- Gulf Crown EP 2 Lithium Grease-Gulf OilDokumen4 halamanGulf Crown EP 2 Lithium Grease-Gulf OilvigneshBelum ada peringkat

- CMAT Score CardDokumen1 halamanCMAT Score CardRaksha RudraBelum ada peringkat

- "Working Capital Management": Master of CommerceDokumen4 halaman"Working Capital Management": Master of Commercekunal bankheleBelum ada peringkat

- Times Leader 03-16-2013Dokumen61 halamanTimes Leader 03-16-2013The Times LeaderBelum ada peringkat

- Political Conditions in ArabiaDokumen11 halamanPolitical Conditions in ArabiaAsad Malik100% (2)

- An Introduction To The Catholic Charismatic RenewalDokumen5 halamanAn Introduction To The Catholic Charismatic RenewalNoah0% (1)

- ThesisDokumen44 halamanThesisjagritiBelum ada peringkat

- Letter To Singaravelu by M N Roy 1925Dokumen1 halamanLetter To Singaravelu by M N Roy 1925Avinash BhaleBelum ada peringkat

- C1 Level ExamDokumen2 halamanC1 Level ExamEZ English WorkshopBelum ada peringkat

- Cuthites: Cuthites in Jewish LiteratureDokumen2 halamanCuthites: Cuthites in Jewish LiteratureErdincBelum ada peringkat

- Jurnal AJISDokumen16 halamanJurnal AJISElsa AugusttenBelum ada peringkat

- Gujarat Technological UniversityDokumen5 halamanGujarat Technological Universityvenkat naiduBelum ada peringkat

- Student Guidelines The School PoliciesDokumen5 halamanStudent Guidelines The School PoliciesMaritessBelum ada peringkat

- Script PDFDokumen1 halamanScript PDFWahid KhanBelum ada peringkat

- EvaluationDokumen4 halamanEvaluationArjay Gabriel DudoBelum ada peringkat

- Thesis RecruitmentDokumen62 halamanThesis Recruitmentmkarora122Belum ada peringkat

- Facts:: Topic: Serious Misconduct and Wilfull DisobedienceDokumen3 halamanFacts:: Topic: Serious Misconduct and Wilfull DisobedienceRochelle Othin Odsinada MarquesesBelum ada peringkat

- Developing A Business Plan For Your Vet PracticeDokumen7 halamanDeveloping A Business Plan For Your Vet PracticeMujtaba AusafBelum ada peringkat

- HumanitiesprojDokumen7 halamanHumanitiesprojapi-216896471Belum ada peringkat

- The Approach of Nigerian Courts To InterDokumen19 halamanThe Approach of Nigerian Courts To InterMak YabuBelum ada peringkat

- Consolidated Terminals Inc V Artex G R No L 25748 PDFDokumen1 halamanConsolidated Terminals Inc V Artex G R No L 25748 PDFCandelaria QuezonBelum ada peringkat

- Shop Decjuba White DressDokumen1 halamanShop Decjuba White DresslovelyBelum ada peringkat

- Definition of Social PharmacyDokumen7 halamanDefinition of Social PharmacyShraddha PharmacyBelum ada peringkat

- Organization and ManagementDokumen65 halamanOrganization and ManagementIvan Kirby EncarnacionBelum ada peringkat

- Open Quruan 2023 ListDokumen6 halamanOpen Quruan 2023 ListMohamed LaamirBelum ada peringkat

- CHAPTER 1 - 3 Q Flashcards - QuizletDokumen17 halamanCHAPTER 1 - 3 Q Flashcards - Quizletrochacold100% (1)

- Types of Business LettersDokumen11 halamanTypes of Business LettersernewstBelum ada peringkat

- Shipping - Documents - Lpg01Dokumen30 halamanShipping - Documents - Lpg01Romandon RomandonBelum ada peringkat

- Relative Clauses: A. I Didn't Know You Only Had OnecousinDokumen3 halamanRelative Clauses: A. I Didn't Know You Only Had OnecousinShanti AyudianaBelum ada peringkat

- Chapter 1 Introduction To Quranic Studies PDFDokumen19 halamanChapter 1 Introduction To Quranic Studies PDFtaha zafar100% (3)