Determination of California Bearing Ratio of Laboratory Compacted Soils

Diunggah oleh

MazharYasinDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Determination of California Bearing Ratio of Laboratory Compacted Soils

Diunggah oleh

MazharYasinHak Cipta:

Format Tersedia

Geotechnical and Foundation Engineering December 7, 2016

EXPERIMENT # 9

DETERMINATION OF CALIFORNIA BEARING RATIO OF

LABORATORY COMPACTED SOILS

9.1 OBJECTIVE

To determine the California bearing ratio on laboratory compacted soils by

conducting a load penetration test in the laboratory.

The California bearing ratio test is penetration test meant for the evaluation of

sub-grade strength of roads and pavements.

This test method provides for the determination of the CBR of a material at

optimum water content or a range of water content from a specified compaction

test and a specified dry unit weight.

9.2 APPARATUS

Loading Machine

The loading machine shall be equipped with a movable head or base that

travels at a uniform (not pulsating) rate of 0.05 in. (1.27 mm)/min for use in

forcing the penetration piston into the specimen.

Mold

The mold shall be a rigid metal cylinder with an inside diameter of 6 in

(152.4mm) and a height of 7 in (177.8 mm).

Spacer Disk

A circular metal spacer disc having a minimum outside diameter of 5 in.

(150.8 mm) but no greater than will allow the spacer disc to easily slip into the

mold. The spacer disc shall be 2.416 in. (61.37mm) in height.

Drying Oven

Capable of maintaining a uniform temperature of (1105C)

Mixing Tools

Miscellaneous tools such as mixing pan, spoon, trowel, spatula etc.

The University of Lahore 63

Geotechnical and Foundation Engineering December 7, 2016

9.3 SIGNIFICANCE AND USE

The California bearing ratio test is penetration test meant for the evaluation of

sub-grade strength of roads and pavements.

The results obtained by these tests are used with the empirical curves to

determine the thickness of pavement and its component layers. This is the most

widely used method for the design of flexible pavement.

9.4 RELATED THEORY

The design of flexible pavement is divided into three parts:

i. Determination the compaction characteristics of soil (AASHTO T-180 and

ASTM D1557)

ii. Determination of the CBR of the soil (AASHTO T193-93 and ASTM D1883)

iii. Determination of the thickness of pavement on the bases of CBR

There are two methods to design the flexible pavement

i. On the bases of GI (Group Index)

ii. On the bases of CBR value

9.4.1 GROUP INDEX

Group index is used in the AASHTO soil classification system. Group index of the soil

is calculated as

= 0.01( 15)( 10)

Where:

GI= Group Index

F=Percentage passing #200 Sieve

PI=Plasticity Index

Greater will be the group index lower will be the quality of sub grade material.

9.4.2 CALIFORNIA BEARING RATIO (C.B.R)

CBR is the ratio of Load (Corrected) required to cause the specific penetration of the

plunger to the standard load of the same penetration of the plunger. It is expressed as

Percentage (%).

California Bearing Ratio (CBR) test was developed by the California Division of

Highway as a method of classifying and evaluating soil-sub grade and base course

materials for flexible pavements. CBR test, an empirical test, has been used to

The University of Lahore 64

Geotechnical and Foundation Engineering December 7, 2016

determine the material properties for pavement design. Empirical tests measure the

strength of the material and are not a true representation of the resilient modulus.

It is a penetration test wherein a standard piston, is used to penetrate the soil at a

standard rate.

This test method is used to evaluate the potential strength of subgrade, subbase and

base course material including recycled material for use in road and air field pavement.

The CBR value obtains in this test in an integral part of several flexible pavement

design method.

The following table gives the standard loads adopted for different penetrations for the

standard material with a C.B.R. value of 100%

Penetration of plunger (mm) Standard load (kg)

2.5 1370

5.0 2055

7.5 2630

10.0 3180

12.5 3600

( )

= 0

Standard load for 0.1in penetration =3000 lb

Standard load for 0.2in penetration =4500 lb

9.4.3 METHOD OF CBR TEST:

There are two method of CBR test

1- Point CBR (1 sample, 56 blows & compacted in 5 layers)

3-Point CBR (3 sample @ 10,30,65 blows in 5 layers)

9.5 PROCEDURE

Place the mould with base plate containing the sample, with the top face of the

sample exposed, centrally on the lower platen of the testing machine.

Fir into place the cylindrical plunger and force-measuring devise assembly with

the face of the plunger resting on the surface of the sample.

The University of Lahore 65

Geotechnical and Foundation Engineering December 7, 2016

Secure the penetration dial gauge in position. Record its initial zero reading, or

reset it to read zero.

Start the test so that the plunger penetrates the sample and at the same instant

start the timer.

Record readings of the force gauge at intervals of penetration of 0.5mm, to a

total penetration not exceeding 13 mm.

After completing the penetration test or tests, determine the moisture content

of the test sample

Test results are plotted in the form of a load-penetration diagram by drawing a

curve through the experimental points. Usually the curve will be convex

upwards but sometimes the initial part of the curve is concave upwards and,

over this section, a correction becomes necessary. The correction consists of

drawing a tangent to the curve at its steepest slope and producing it back to cut

the penetration axis. This point is regarded as the origin of the penetration scale

for the corrected curve.

Penetrations of 2.5mm and 5mm are used for calculating the CBR value. From

the test curve, with corrected penetration scale if appropriate, read off the forces

corresponding to 2.5mm and 5mm penetration. Express these as a percentage

of the standard forces at these penetrations. Take the higher percentage as the

CBR value.

9.6 OBSERVATIONS & CALCULATIONS

Diameter of mould = 6 inch

Height of mould = 7 inch

O.M.C (form Modified Proctors compaction test) =13 %

Dry density (form Modified Proctors compaction test) = 19.7 kN/m3

Proving Ring Constant = 2.43 lb/div

L.C of deformation dial gauge = 0.01 mm

Volume of mould

6

= 7

4

= 197.92

= 0.00324

The University of Lahore 66

Geotechnical and Foundation Engineering December 7, 2016

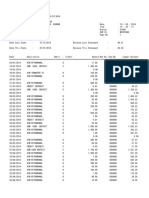

10 Blows 30 Blows 65 Blows

Penetration Load Load Load

Dial Gauge Penetration Gauge Load Gauge Load Gauge Load

Readings Reading Reading Reading

mm lb lb

0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

50.00 0.50 1.00 2.43 10.00 24.30 6.00 14.58

100.00 1.00 14.00 34.02 40.00 97.20 11.00 26.73

150.00 1.50 27.00 65.61 65.00 157.95 28.00 68.04

200.00 2.00 38.00 92.34 100.00 243.00 46.00 111.78

250.00 2.50 49.00 119.07 130.00 315.90 63.00 153.09

300.00 3.00 57.00 138.51 150.00 364.50 83.00 201.69

350.00 3.50 65.00 157.95 175.00 425.25 105.00 255.15

400.00 4.00 78.00 189.54 200.00 486.00 126.00 306.18

450.00 4.50 90.00 218.70 222.00 539.46 145.00 352.35

500.00 5.00 103.00 250.29 240.00 583.20 167.00 405.81

550.00 5.50 110.00 267.30 260.00 631.80 190.00 461.70

600.00 6.00 119.00 289.17 278.00 675.54 222.00 539.46

650.00 6.50 124.00 301.32 294.00 714.42 244.00 592.92

700.00 7.00 134.00 325.62 311.00 755.73 258.00 626.94

750.00 7.50 142.00 345.06 328.00 797.04 270.00 656.10

800.00 8.00 143.00 347.49 340.00 826.20 280.00 680.40

850.00 8.50 151.00 366.93 348.00 845.64 291.00 707.13

900.00 9.00 156.00 379.08 357.00 867.51 299.00 726.57

950.00 9.50 163.00 396.09 362.00 879.66 302.00 733.86

1000.00 10.00 169.00 410.67 362.00 879.66 304.00 738.72

1050.00 10.50 172.00 417.96 360.00 874.80 308.00 748.44

1100.00 11.00 178.00 432.54 345.00 838.35 311.00 755.73

1150.00 11.50 183.00 444.69 335.00 814.05 317.00 770.31

1200.00 12.00 187.00 454.41 330.00 801.90 319.00 775.17

1250.00 12.50 191.00 464.13 325.00 789.75 312.00 758.16

1300.00 13.00 192.00 466.56 324.00 787.32 311.00 755.73

The University of Lahore 67

Geotechnical and Foundation Engineering December 7, 2016

9.6.1 GRAPH BETWEEN LOAD VS PENETRATION

Load Vs Penetration Graph

1000.0

900.0

800.0

700.0

Load (lb.)

600.0

500.0

400.0

300.0

200.0

30 Blows 65 Blows 10 Blows

100.0

0.0

0.0 2.0 4.0 6.0 8.0 10.0 12.0 14.0

2.5 mm 5 mm Penetration (mm)

9.6.2 CBR VALUE FOR 10 BLOWS

Load at 0.1in (2.5mm) penetration = 138.51 lb.

CBR at 0.1in (2.5mm) penetration

Load at 0.1 inch penetration

100

0.1 hpenetration

138.51

= 100

3000

=5%

Load at 0.2-in (5mm) penetration = 267.30 lb.

CBR at 0.2-in (5mm) penetration

Load at 0.2 inch penetration

100

0.2 h penetration

267.30

= 100

4500

=6%

So

CBR value (10 blows) = 6 %

Dry Density

W 1 = Weight of empty mould = 5.908 kg = 0.058 kN

W 2= Weight of wet soil + mould =11.842 kg = 0.1162 kN

=

The University of Lahore 68

Geotechnical and Foundation Engineering December 7, 2016

0.1162 0.058

=

0.00324

= 17.967 /

=

1+

17.967

=

1 + 0.13

= 15.9 /

9.6.3 CBR VALUE FOR 30 BLOWS

Load at 0.1in (2.5mm) penetration = 364.50 lb.

CBR at 0.1in (2.5mm) penetration

Load at 0.1 inch penetration

100

0.1 h penetration

364.50

= 100

3000

= 12 %

Load at 0.2-in (5mm) penetration = 631.80 lb.

CBR at 0.2-in (5mm) penetration

Load at 0.2 inch penetration

100

0.2 h penetration

631.80

= 100

4500

= 14 %

So

CBR value (30 blows) = 14 %

Dry Density

W 1 = Weight of empty mould = 6.16 kg = 0.0604 kN

W 2= Weight of wet soil + mould =12.726 kg = 0.1248 kN

=

0.1248 0.0604

=

0.00324

= 19.880 /

=

1+

The University of Lahore 69

Geotechnical and Foundation Engineering December 7, 2016

19.880

=

1 + 0.13

= 17.593 /

9.6.4 CBR VALUE FOR 65 BLOWS

Load at 0.1in (2.5mm) penetration = 201.69 lb.

CBR at 0.1in (2.5mm) penetration

Load at 0.1 inch penetration

100

0.1 h penetration

201.69

= 100

3000

=7%

Load at 0.2-in (5mm) penetration = 461.70 lb.

CBR at 0.2-in (5mm) penetration

Load at 0.2 inch penetration

100

0.2 h penetration

461.70

= 100

4500

= 10 %

So

CBR value (65 blows) = 10 %

Dry Density

W 1 = Weight of empty mould = 6.046 kg = 0.00593 kN

W 2= Weight of wet soil + mould =12.95 kg = 0.1270 kN

=

0.1270 0.0593

=

0.00324

= 20.904 /

=

1+

20.904

=

1 + 0.13

= 18.499 /

The University of Lahore 70

Geotechnical and Foundation Engineering December 7, 2016

9.6.5 Table of Dry Density and CBR value

No of blows Dry Density ( / ) CBR value (%)

10 Blows 15.900 6

30 Blows 17.593 14

65 Blows 18.499 10

9.6.6 GRAPH BETWEEN DRY DENSITY VS CBR VALUE

Dry density vs CBR value

16.000

14.000

12.000

10.000

8.000

6.000

4.000

85 % of Optimum Density

2.000

0.000

15.500 16.000 16.500 17.000 17.500 18.000 18.500 19.000

9.6.7 CBR VALUE OF 85% OF OPTIMUM DRY DENSITY

CBR Value at 85 % of Optimum dry density = 0.8519.7

= 16.745 kN/m3

CBR value = 11 %

The University of Lahore 71

Geotechnical and Foundation Engineering December 7, 2016

9.7 REFERENCE

ASTM D1883

Standard Test Method for CBR (California Bearing Ratio) of Laboratory-Compact Soils

9.8 COMMENTS

CBR test is an empirical test method and cannot be related accurately with any

fundamental or physical property of the soil or pavement material tested.

Generally, the CBR value at 2.5 mm penetration is higher and this value is adopted as

the CBR value of the soil sample. However, if higher CBR value is obtained at 5.0 mm

penetration, the CBR test is to be repeated to verify the result. If CBR value at 5.0 mm

penetration is higher in the repeat test also, this higher value is adopted as the CBR

value of the soil sample.

CBR test may be conducted in the laboratory either on remoulded or undisturbed soil

specimens. CBR test can also be conducted in the field.

The initial concavity in the curve indicates that during the initial application of load, the

plunger penetrated at a more rapid rate and later further penetration values are

consistent with respect to the load applied.

In our case concavity starts at 0.5 mm so we take the readings start from 0.5mm to

3mm and 5.5mm for CBR value. CBR value at 85% of optimum dry density is 11%

The University of Lahore 72

Anda mungkin juga menyukai

- Pressuremeter Testing: Methods and InterpretationDari EverandPressuremeter Testing: Methods and InterpretationPenilaian: 5 dari 5 bintang5/5 (2)

- CBR TestDokumen9 halamanCBR TestHans IzairiBelum ada peringkat

- CBR TestDokumen9 halamanCBR TestHelmi ZakiuddinBelum ada peringkat

- CBR TestDokumen7 halamanCBR TestNanaBelum ada peringkat

- Report Highway 5Dokumen6 halamanReport Highway 5Leo AmiraBelum ada peringkat

- Transportation Engineering - I Sessional COURSE NO: 3502Dokumen20 halamanTransportation Engineering - I Sessional COURSE NO: 3502Mohammad ParvejBelum ada peringkat

- CE-452 CBR TestDokumen15 halamanCE-452 CBR TestNandon RoyBelum ada peringkat

- Experiment No. 1 California Bearing RatioDokumen33 halamanExperiment No. 1 California Bearing Ratioluther joyda alafrizBelum ada peringkat

- Highway Engineering Laboratory: Tests NameDokumen6 halamanHighway Engineering Laboratory: Tests NameRana Abdelbaset BostanjiBelum ada peringkat

- LECT-16-Subgrade EvaluationDokumen83 halamanLECT-16-Subgrade EvaluationSujitkumar BeheraBelum ada peringkat

- S11200147 Geoffrey Vuinakelo CBR TEST LAB1Dokumen6 halamanS11200147 Geoffrey Vuinakelo CBR TEST LAB1AISEA HBelum ada peringkat

- California Bearing RatioDokumen6 halamanCalifornia Bearing RatiocruzserBelum ada peringkat

- Geotechnical Engineering Lab: Anup KumarDokumen7 halamanGeotechnical Engineering Lab: Anup Kumar008 Anup KumarBelum ada peringkat

- (Type The Document Title) : Title - California Bearing RatioDokumen7 halaman(Type The Document Title) : Title - California Bearing RatioDebasish Dev BarmaBelum ada peringkat

- CBR ProcedureDokumen5 halamanCBR ProcedureRohitBelum ada peringkat

- California Bearing Ratio Test: 1. ObjectiveDokumen3 halamanCalifornia Bearing Ratio Test: 1. ObjectiveVickyBelum ada peringkat

- California Bearing Ratio Test: 1. ObjectiveDokumen3 halamanCalifornia Bearing Ratio Test: 1. ObjectivePanchadcharam PushparubanBelum ada peringkat

- California Bearing Ratio Test: 1. ObjectiveDokumen3 halamanCalifornia Bearing Ratio Test: 1. ObjectivesiddharthBelum ada peringkat

- Transport Lab EXP 3.8Dokumen6 halamanTransport Lab EXP 3.8Mohd SaufiBelum ada peringkat

- CBR Practicum Report - Basic Soil MechanicsDokumen18 halamanCBR Practicum Report - Basic Soil MechanicsShiela Ariesta EfendiBelum ada peringkat

- Practical No. 9 (CBR)Dokumen5 halamanPractical No. 9 (CBR)slawek780303Belum ada peringkat

- Civil - Highway Lab Manual - 2018Dokumen17 halamanCivil - Highway Lab Manual - 2018Altamash NadimallaBelum ada peringkat

- CBR Test ReportDokumen8 halamanCBR Test ReportRubaneswary SridharanBelum ada peringkat

- Exp09 - California Bearing Ratio (CBR) and Stripping TestDokumen6 halamanExp09 - California Bearing Ratio (CBR) and Stripping TestAli M. ChehadehBelum ada peringkat

- Test 3 CBRDokumen13 halamanTest 3 CBRhasaneen alameedyBelum ada peringkat

- Civil and Environmental Engineering DepartmentDokumen12 halamanCivil and Environmental Engineering DepartmentMuhd SyahidBelum ada peringkat

- Highway Lab Manual 2021Dokumen119 halamanHighway Lab Manual 2021ISMAILA AMOTOTOBelum ada peringkat

- California Bearing Ratio Test (CBR Test) (IS: 2720 PART-16) : Test Load Standar D LoadDokumen8 halamanCalifornia Bearing Ratio Test (CBR Test) (IS: 2720 PART-16) : Test Load Standar D LoadBad BadBelum ada peringkat

- CBR Lab ReportDokumen11 halamanCBR Lab ReportFazrul Amin50% (2)

- Method Obtaining Sam Determination: A Simple For Undisturbed Soil Pies For CBRDokumen8 halamanMethod Obtaining Sam Determination: A Simple For Undisturbed Soil Pies For CBRMimicry TarnBelum ada peringkat

- Geotechnical Engineering Lab ReportDokumen34 halamanGeotechnical Engineering Lab Reportfaisal hussin100% (1)

- CBR Intro - Procedures EchcbraDokumen2 halamanCBR Intro - Procedures EchcbraNur SyahiraBelum ada peringkat

- CBR TestDokumen8 halamanCBR TestSyafiq Latif100% (2)

- Submitted To:-Submitted To: - Submitted By: - Submitted By:-: Experiment Number: - 05Dokumen17 halamanSubmitted To:-Submitted To: - Submitted By: - Submitted By:-: Experiment Number: - 05SOURAE MRIDHABelum ada peringkat

- CBR Test ReportDokumen13 halamanCBR Test ReportRubaneswary SridharanBelum ada peringkat

- California Bearing RatioDokumen8 halamanCalifornia Bearing RatioairpavsetBelum ada peringkat

- Lab ReportDokumen65 halamanLab ReportWilliam Liew75% (8)

- TE - Experiment - 6 FinalDokumen7 halamanTE - Experiment - 6 FinalthaqiffxussBelum ada peringkat

- Matias, Eiron Audrey P. - Time Setting of Portland CementDokumen19 halamanMatias, Eiron Audrey P. - Time Setting of Portland CementMiNT MatiasBelum ada peringkat

- CBRDokumen8 halamanCBRbinod gurungBelum ada peringkat

- CBR Lab ReportDokumen14 halamanCBR Lab ReportAmira Azwa Jamion100% (2)

- Laboratory Tests at Geotechnical Lab (Jadavpur University) During PG 1st Semester (August 2014Dokumen8 halamanLaboratory Tests at Geotechnical Lab (Jadavpur University) During PG 1st Semester (August 2014ranajit janaBelum ada peringkat

- Lab 11 - CBR TestDokumen9 halamanLab 11 - CBR Testnabil mahadzirBelum ada peringkat

- Report Politeknik Concrete Sieve Analysis of Coarse AggregatesDokumen10 halamanReport Politeknik Concrete Sieve Analysis of Coarse AggregatesMuhammad MuazzamBelum ada peringkat

- CBR TestDokumen7 halamanCBR Testjayantgupta28110Belum ada peringkat

- S11198623 - Adi Natalia Nacola - Lab FourDokumen10 halamanS11198623 - Adi Natalia Nacola - Lab FourNatalia NacolaBelum ada peringkat

- Khwopa College of Engineering: Tribhuvan UniversityDokumen9 halamanKhwopa College of Engineering: Tribhuvan UniversitySudip ShresthaBelum ada peringkat

- CBR ExperimentDokumen9 halamanCBR ExperimentAniket JainBelum ada peringkat

- Lab ReportDokumen65 halamanLab ReportShah RulBelum ada peringkat

- California Bearing Ratio TestDokumen7 halamanCalifornia Bearing Ratio TestBhaskara Rao KatragaddaBelum ada peringkat

- LAB 5 - CBR Test OEL 1Dokumen6 halamanLAB 5 - CBR Test OEL 1ZULFAQAR BIN MOHAMMAD NIZAMBelum ada peringkat

- California Bearing Ratio PrintDokumen5 halamanCalifornia Bearing Ratio PrintvethamoortyBelum ada peringkat

- Aggregate Lab-Report (Repaired)Dokumen66 halamanAggregate Lab-Report (Repaired)h100% (1)

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryDari EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryBelum ada peringkat

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsDari EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsPenilaian: 5 dari 5 bintang5/5 (1)

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsDari EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechBelum ada peringkat

- Scale Models in Engineering: Fundamentals and ApplicationsDari EverandScale Models in Engineering: Fundamentals and ApplicationsBelum ada peringkat

- Lecture 1 & 2: Construction ProjectsDokumen19 halamanLecture 1 & 2: Construction ProjectsMazharYasinBelum ada peringkat

- SBR LatexDokumen2 halamanSBR LatexMazharYasinBelum ada peringkat

- Construction and Building MaterialsDokumen9 halamanConstruction and Building MaterialsMazharYasinBelum ada peringkat

- Hot Weather ConcretingDokumen6 halamanHot Weather ConcretingMazharYasinBelum ada peringkat

- Drawing Lecture-1Dokumen28 halamanDrawing Lecture-1MazharYasinBelum ada peringkat

- Uol HRD EdifDokumen1 halamanUol HRD EdifMazharYasinBelum ada peringkat

- CementDokumen12 halamanCementMazharYasinBelum ada peringkat

- Table: Assembled Joint Masses Joint Masssource U1 U2 U3 R1 R2 R3 CenterxDokumen80 halamanTable: Assembled Joint Masses Joint Masssource U1 U2 U3 R1 R2 R3 CenterxMazharYasinBelum ada peringkat

- Brick BondsDokumen4 halamanBrick BondsMazharYasinBelum ada peringkat

- Experiment No. 10: To Determine The Effect of Rate of Loading On The Compressive Strength of P.C.C Cube and CylinderDokumen3 halamanExperiment No. 10: To Determine The Effect of Rate of Loading On The Compressive Strength of P.C.C Cube and CylinderMazharYasinBelum ada peringkat

- Structurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceDokumen1 halamanStructurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceMazharYasinBelum ada peringkat

- Structurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceDokumen1 halamanStructurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceMazharYasinBelum ada peringkat

- SDOF Damped Forced Vibration - NewmarkDokumen5 halamanSDOF Damped Forced Vibration - NewmarkMazharYasinBelum ada peringkat

- GRE+GAT WORD LIST (Edited)Dokumen442 halamanGRE+GAT WORD LIST (Edited)MazharYasinBelum ada peringkat

- SP ColumnDokumen2 halamanSP ColumnMazharYasinBelum ada peringkat

- Durga Padma Sai SatishDokumen1 halamanDurga Padma Sai SatishBhaskar Siva KumarBelum ada peringkat

- Dr. Najeebuddin Ahmed: 969 Canterbury Road, Lakemba, Sydney, NSW, Australia, 2195Dokumen2 halamanDr. Najeebuddin Ahmed: 969 Canterbury Road, Lakemba, Sydney, NSW, Australia, 2195Najeebuddin AhmedBelum ada peringkat

- Capsule Research ProposalDokumen4 halamanCapsule Research ProposalAilyn Ursal80% (5)

- Sworn Statement of Assets, Liabilities and Net WorthDokumen3 halamanSworn Statement of Assets, Liabilities and Net WorthShelby AntonioBelum ada peringkat

- A Comparison of Pharmaceutical Promotional Tactics Between HK & ChinaDokumen10 halamanA Comparison of Pharmaceutical Promotional Tactics Between HK & ChinaAlfred LeungBelum ada peringkat

- Belimo Fire & Smoke Damper ActuatorsDokumen16 halamanBelimo Fire & Smoke Damper ActuatorsSrikanth TagoreBelum ada peringkat

- Bank Statement SampleDokumen6 halamanBank Statement SampleRovern Keith Oro CuencaBelum ada peringkat

- tdr100 - DeviceDokumen4 halamantdr100 - DeviceSrđan PavićBelum ada peringkat

- Drill String DesignDokumen118 halamanDrill String DesignMohamed Ahmed AlyBelum ada peringkat

- Gravity Based Foundations For Offshore Wind FarmsDokumen121 halamanGravity Based Foundations For Offshore Wind FarmsBent1988Belum ada peringkat

- Lec # 26 NustDokumen18 halamanLec # 26 NustFor CheggBelum ada peringkat

- Braga - 2016 - On Standing's A Precariat Charter - Confronting The Precaritisation of Labour in Brazil and PortugalDokumen12 halamanBraga - 2016 - On Standing's A Precariat Charter - Confronting The Precaritisation of Labour in Brazil and PortugalLiam MurciaBelum ada peringkat

- Huawei Core Roadmap TRM10 Dec 14 2011 FinalDokumen70 halamanHuawei Core Roadmap TRM10 Dec 14 2011 Finalfirasibraheem100% (1)

- Mounting BearingDokumen4 halamanMounting Bearingoka100% (1)

- Certification and LettersDokumen6 halamanCertification and LettersReimar FerrarenBelum ada peringkat

- Leeka Kheifets PrincipleDokumen6 halamanLeeka Kheifets PrincipleAlexandreau del FierroBelum ada peringkat

- Communication On The Telephone InfoDokumen30 halamanCommunication On The Telephone Infomelese100% (1)

- EE1000 DC Networks Problem SetDokumen7 halamanEE1000 DC Networks Problem SetAmit DipankarBelum ada peringkat

- An Over View of Andhra Pradesh Water Sector Improvement Project (APWSIP)Dokumen18 halamanAn Over View of Andhra Pradesh Water Sector Improvement Project (APWSIP)gurumurthy38Belum ada peringkat

- A Survey On Multicarrier Communications Prototype PDFDokumen28 halamanA Survey On Multicarrier Communications Prototype PDFDrAbdallah NasserBelum ada peringkat

- Paul Milgran - A Taxonomy of Mixed Reality Visual DisplaysDokumen11 halamanPaul Milgran - A Taxonomy of Mixed Reality Visual DisplaysPresencaVirtual100% (1)

- In Partial Fulfillment of The Requirements For The Award of The Degree ofDokumen66 halamanIn Partial Fulfillment of The Requirements For The Award of The Degree ofcicil josyBelum ada peringkat

- Manuscript - Batallantes &Lalong-Isip (2021) Research (Chapter 1 To Chapter 3)Dokumen46 halamanManuscript - Batallantes &Lalong-Isip (2021) Research (Chapter 1 To Chapter 3)Franzis Jayke BatallantesBelum ada peringkat

- UCAT SJT Cheat SheetDokumen3 halamanUCAT SJT Cheat Sheetmatthewgao78Belum ada peringkat

- Between:-Mr. Pedro Jose de Vasconcelos, of Address 14 CrombieDokumen2 halamanBetween:-Mr. Pedro Jose de Vasconcelos, of Address 14 Crombiednd offiBelum ada peringkat

- DR-2100P Manual EspDokumen86 halamanDR-2100P Manual EspGustavo HolikBelum ada peringkat

- Jetweigh BrochureDokumen7 halamanJetweigh BrochureYudi ErwantaBelum ada peringkat

- Home Guaranty Corp. v. Manlapaz - PunzalanDokumen3 halamanHome Guaranty Corp. v. Manlapaz - PunzalanPrincess Aliyah Punzalan100% (1)

- Algorithm - WikipediaDokumen34 halamanAlgorithm - WikipediaGilbertBelum ada peringkat

- Is.14785.2000 - Coast Down Test PDFDokumen12 halamanIs.14785.2000 - Coast Down Test PDFVenkata NarayanaBelum ada peringkat