HSC01 SM10 MEC07 00002: Duty Specification

Diunggah oleh

warmaster81Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

HSC01 SM10 MEC07 00002: Duty Specification

Diunggah oleh

warmaster81Hak Cipta:

Format Tersedia

1 c_juhkan 14.10.2015 jarhar 15.10.2015 jushyv 15.10.

2015 Approved for further engineering

0 c_juhkan 10.09.2015 jarhar 10.09.2015 pettik 10.09.2015 First Issue

Name Date Name Date Name Date Revision Text

Rev

Prepared Checked Released

Status: Original Size:

APPROVED FOR FURTHER ENGINEERING A4

Customer: Project Phase: Site No.:

Sardich MC IMPLEMENTATION 01

Project Name: Customer Document ID:

Sardich Kazandol SX-EW Plant

Replaced by: Replaces:

Document Title:

DUTY SPECIFICATION

HYDROMETALLURGICAL COPPER PROCESSING PLANT

TANK FARM

Electrolyte Filter

SM10-HQ-001...002

Equipment No: Item No:

Project ID: Plant Code: Plant Unit Code: Document Type: Running No: Revision: Sheet of Sheets:

113718 HSC01 SM10 MEC07 00002 1 1 (5)

The contents of this document are the sole property of Outotec Oyj. Any rights not expressly granted herein are reserved. Outotec Document ID:

Reproduction, transfer or distribution of part or all of the contents in any form without the prior written permission of Outotec is

prohibited. OU100018130

\Project\113718\HSC01\SM10\M\EC07\Basic Engineering\113718_HSC01_SM10_MEC07_00002_OU100018130_R1.docx

Sardich Kazandol SX-EW Plant

DUTY SPECIFICATION

HYDROMETALLURGICAL COPPER

PROCESSING PLANT

Table of Contents

1 SCOPE ............................................................................................................................... 4

1.1 Subject ....................................................................................................................... 4

1.2 Battery limits............................................................................................................... 4

2 OPERATION CONDITIONS ............................................................................................... 4

3 CODES AND STANDARDS................................................................................................ 5

4 DESIGN DATA ................................................................................................................... 5

5 MATERIAL .......................................................................................................................... 5

6 SERVICES REQUIRED ...................................................................................................... 5

Project ID: Plant Code: Plant Unit Code: Document Type: Running No: Revision: Sheet of Sheets:

113718 HSC01 SM10 MEC07 00002 1 2 (5)

The contents of this document are the sole property of Outotec Oyj. Any rights not expressly granted herein are reserved. Outotec Document ID:

Reproduction, transfer or distribution of part or all of the contents in any form without the prior written permission of Outotec is

prohibited. OU100018130

\Project\113718\HSC01\SM10\M\EC07\Basic Engineering\113718_HSC01_SM10_MEC07_00002_OU100018130_R1.docx

Sardich Kazandol SX-EW Plant

DUTY SPECIFICATION

HYDROMETALLURGICAL COPPER

PROCESSING PLANT

INTRODUCTION

Purpose of this specification is to specify parameters in certain aspects, which shall

be included to the Manufacturers fabrication routines and Inspection and Testing

Plan but are not necessarily determined in other specifications or Machine Directive

(2006/42/EC) or design standards.

The equipment specified in this document shall be used in SX-EW Plant located in

Kazandol, Macedonia.

Following nominations on parties apply:

Client Sardich MC, Macedonia

Vendor Outotec (Finland) Oy

Manufacturer Fabricator of items as specified in EU-regulations

accordance with EN standards

Subvendor Provider to Manufacturer

Project ID: Plant Code: Plant Unit Code: Document Type: Running No: Revision: Sheet of Sheets:

113718 HSC01 SM10 MEC07 00002 1 3 (5)

The contents of this document are the sole property of Outotec Oyj. Any rights not expressly granted herein are reserved. Outotec Document ID:

Reproduction, transfer or distribution of part or all of the contents in any form without the prior written permission of Outotec is

prohibited. OU100018130

\Project\113718\HSC01\SM10\M\EC07\Basic Engineering\113718_HSC01_SM10_MEC07_00002_OU100018130_R1.docx

Sardich Kazandol SX-EW Plant

DUTY SPECIFICATION

HYDROMETALLURGICAL COPPER

PROCESSING PLANT

1 SCOPE

1.1 Subject

From rich electrolyte after settler electrolyte is pumped through dual media (DM)

electrolyte filters to electrolyte circulation tank. Solids and organic entrainments are

removed from the rich electrolyte solution in the electrolyte filters. The filters are

backwashed typically once or twice per day using lean electrolyte from electrolyte

circulation tank.

Electrolyte filter equipment consist of following items

Item Qty Description

SM10-HQ-001002 2 Electrolyte Filters

Total number of items: 3

This specification covers the minimum requirements for design of electrolyte filter.

1.2 Battery limits

Between base plates and supporting legs of the filters and integrated

equipment.

Package supply between flanges in bolted joint at the feed piping before

equipment and discharge piping after equipment.

Package supply between flanges in bolted joints at the wash water feed and

discharge pipe lines.

2 OPERATION CONDITIONS

Process equipment are located inside and minimum ambient temperature is 15 oC

Project ID: Plant Code: Plant Unit Code: Document Type: Running No: Revision: Sheet of Sheets:

113718 HSC01 SM10 MEC07 00002 1 4 (5)

The contents of this document are the sole property of Outotec Oyj. Any rights not expressly granted herein are reserved. Outotec Document ID:

Reproduction, transfer or distribution of part or all of the contents in any form without the prior written permission of Outotec is

prohibited. OU100018130

\Project\113718\HSC01\SM10\M\EC07\Basic Engineering\113718_HSC01_SM10_MEC07_00002_OU100018130_R1.docx

Sardich Kazandol SX-EW Plant

DUTY SPECIFICATION

HYDROMETALLURGICAL COPPER

PROCESSING PLANT

3 CODES AND STANDARDS

Following standards have to be taken in account:

European Union Machine Directive 98/37/EC

Pressure Equipment directive 97/23/EC

ATEX directive 94/9/EC

On site inspection for the assembly and installation by Outotec representative is

mandatory and included in the delivery scope.

4 DESIGN DATA

Electrolyte flow, design 39 m3/h

Copper concentration 50 g/l

Iron concentration <1,5 g/l

H2SO4 concentration 160 g/l

Feed organic concentration <50 mg/l

Organic concentration target <2 mg/l

Filter media Anthracite, garnet

5 MATERIAL

Metal parts in contact with slurry, material AISI 316L or equal. Blower material:

Ductile Iron

6 SERVICES REQUIRED

Electrolyte feed flow rate 37,8 m3/h

Back wash flow rate 50,3 m3/h

Air scour flow rate 170 m3/h

Instrument air for process valves

Pressure 6-10 bar (over pressure)

Air temperature 5 C - 80 C

Project ID: Plant Code: Plant Unit Code: Document Type: Running No: Revision: Sheet of Sheets:

113718 HSC01 SM10 MEC07 00002 1 5 (5)

The contents of this document are the sole property of Outotec Oyj. Any rights not expressly granted herein are reserved. Outotec Document ID:

Reproduction, transfer or distribution of part or all of the contents in any form without the prior written permission of Outotec is

prohibited. OU100018130

\Project\113718\HSC01\SM10\M\EC07\Basic Engineering\113718_HSC01_SM10_MEC07_00002_OU100018130_R1.docx

Anda mungkin juga menyukai

- SP0904-M00600-Q18-0041 Sub 01 Status B - 240222 - 182612Dokumen6 halamanSP0904-M00600-Q18-0041 Sub 01 Status B - 240222 - 182612Amine ait talebBelum ada peringkat

- CT Framework Release Notes 2.3.2.0Dokumen12 halamanCT Framework Release Notes 2.3.2.0HEMANT RAMJIBelum ada peringkat

- Technical Spec EVC Pump - R0Dokumen18 halamanTechnical Spec EVC Pump - R0AyahKenzieBelum ada peringkat

- Exhibit a - Scope of Work (Meji Ggcp v3)Dokumen85 halamanExhibit a - Scope of Work (Meji Ggcp v3)Eteure ReubenBelum ada peringkat

- JAW - 00-K - 11a - 040 - PP - 144 - Commissioning ITP - MV System Essential Boards - 00BDA10 - Rev.0Dokumen21 halamanJAW - 00-K - 11a - 040 - PP - 144 - Commissioning ITP - MV System Essential Boards - 00BDA10 - Rev.0MedrouaBelum ada peringkat

- Earthworks Technical SpecificationDokumen48 halamanEarthworks Technical SpecificationFeng XueBelum ada peringkat

- Technical Specification of DG-1Dokumen33 halamanTechnical Specification of DG-1Shariq AkhtarBelum ada peringkat

- Technical Specification FOR Pull Out Test Procedure: Jordan Risha 50 MW PV ProjectDokumen16 halamanTechnical Specification FOR Pull Out Test Procedure: Jordan Risha 50 MW PV Projectrames100% (1)

- 00 BL - Eip Tre 001Dokumen41 halaman00 BL - Eip Tre 001Jessica RodriguezBelum ada peringkat

- 12.PDE-CMG-G000-EC-00003 - 000 - 02 - ES Welding of Storage TanksDokumen12 halaman12.PDE-CMG-G000-EC-00003 - 000 - 02 - ES Welding of Storage TanksIonut FloricaBelum ada peringkat

- SK PHARMA-12022023151112Dokumen21 halamanSK PHARMA-12022023151112remarkhb.maintenanceBelum ada peringkat

- Technical Specification For TankDokumen19 halamanTechnical Specification For Tankhelard68100% (1)

- Fabrication Procedure for Hasbah Offshore Gas Facilities Tie-In PlatformDokumen50 halamanFabrication Procedure for Hasbah Offshore Gas Facilities Tie-In PlatformBashir AlamBelum ada peringkat

- Sc13003-p5003-q03-0003 - Itp Sea Water Intake SystemDokumen17 halamanSc13003-p5003-q03-0003 - Itp Sea Water Intake SystemDwi Mulyanti DwimulyantishopBelum ada peringkat

- Ma'Aden Engineering Manual: Piping MaterialsDokumen21 halamanMa'Aden Engineering Manual: Piping Materialssameer ejaazBelum ada peringkat

- NMDC Travel Safety India 001Dokumen31 halamanNMDC Travel Safety India 001Santiago MaldonadoBelum ada peringkat

- Technical Specification For Motor Operated ValvesDokumen6 halamanTechnical Specification For Motor Operated ValvesĐặng Trung AnhBelum ada peringkat

- VD 1233 330 Dig 001 1Dokumen12 halamanVD 1233 330 Dig 001 1Reza AranBelum ada peringkat

- C1944526-01-WGS-EL00-ITP-0202 - 03 - Treated Water Filter - Material Test Certificate For Filter VesselDokumen61 halamanC1944526-01-WGS-EL00-ITP-0202 - 03 - Treated Water Filter - Material Test Certificate For Filter VesselNishit KhuntBelum ada peringkat

- Functional Specifications FOR Test Separation Module: Onshore Engg Services, N Delhi Document No.: OESG/ARP/TSP/M002 REVDokumen18 halamanFunctional Specifications FOR Test Separation Module: Onshore Engg Services, N Delhi Document No.: OESG/ARP/TSP/M002 REVAnonymous O0lyGOShYGBelum ada peringkat

- Movspec 01451069Dokumen11 halamanMovspec 01451069Steve BauangBelum ada peringkat

- Upgrading Fine Filters at CC Water Injection PlantDokumen83 halamanUpgrading Fine Filters at CC Water Injection PlantNAMOBelum ada peringkat

- PaintingDokumen22 halamanPaintingAmit Kumar MilanBelum ada peringkat

- Incluir Dossier de Calidad y Como Se Entregaran Los DocumentosDokumen11 halamanIncluir Dossier de Calidad y Como Se Entregaran Los DocumentosXavier AFBelum ada peringkat

- 26071-100-V2a-H701-04002 - R02 - Datasheet For MFDDokumen54 halaman26071-100-V2a-H701-04002 - R02 - Datasheet For MFDogyriskyBelum ada peringkat

- 056 Rev00 Barcode & Data MatrixDokumen10 halaman056 Rev00 Barcode & Data MatrixWILSIMAR SILVABelum ada peringkat

- Hvac RFP 2Dokumen12 halamanHvac RFP 2ahmedBelum ada peringkat

- STOD-GEN-AED-0000-ME-SPE-0005 - Functional Specification For Chemical InjectionDokumen20 halamanSTOD-GEN-AED-0000-ME-SPE-0005 - Functional Specification For Chemical InjectionAHMED AMIRABelum ada peringkat

- Ram Study ReportDokumen140 halamanRam Study ReportEmad Elgebesy0% (1)

- 8188-MD-FEA-RFQ-001 Rev-0Dokumen24 halaman8188-MD-FEA-RFQ-001 Rev-0sridharBelum ada peringkat

- 02013-RFQ-036-REV00 Chemical Storage Building DesignDokumen7 halaman02013-RFQ-036-REV00 Chemical Storage Building DesignOusmane DiengBelum ada peringkat

- Hdpe FieldDokumen44 halamanHdpe Fieldwesqui100% (1)

- CM Work Order: Latest Used WorkorderDokumen2 halamanCM Work Order: Latest Used WorkorderMohammed ArifBelum ada peringkat

- Sonatrach: Owner'S Doc. No. 0422-85-X06-706 Job Code JGC Doc. No. Rev. 0-2204-00-0000 S-A002-1520-004 1Dokumen22 halamanSonatrach: Owner'S Doc. No. 0422-85-X06-706 Job Code JGC Doc. No. Rev. 0-2204-00-0000 S-A002-1520-004 1rifi.ftechconsultingBelum ada peringkat

- IQ For Strip Packing Machine SE - 140Dokumen15 halamanIQ For Strip Packing Machine SE - 140Fernanda GarantiaBelum ada peringkat

- Structural Design Basis - Rev ADokumen28 halamanStructural Design Basis - Rev Ayogaraj sBelum ada peringkat

- P246101-E-BE-00-000-EL-RFQ-005 (Request For Quotation of Diesel Generator) - RevDokumen26 halamanP246101-E-BE-00-000-EL-RFQ-005 (Request For Quotation of Diesel Generator) - Revhafid CJSPBelum ada peringkat

- VD 1233 330 DPH 001 0Dokumen11 halamanVD 1233 330 DPH 001 0Reza AranBelum ada peringkat

- Company ProfileDokumen8 halamanCompany Profileengjam3Belum ada peringkat

- Design BasisDokumen30 halamanDesign BasisRahulBelum ada peringkat

- 9085780-Qa-Ced-0001 00 (Id 325596)Dokumen5 halaman9085780-Qa-Ced-0001 00 (Id 325596)Mikhael RodriguesBelum ada peringkat

- Document No.: Ion Small Oil Series 3Ph ManualDokumen26 halamanDocument No.: Ion Small Oil Series 3Ph ManualErol DAĞBelum ada peringkat

- 5 - Relatório de Teste de Conformidade A IEC 62109 Bureau Veritas - Inversor SolarEdge SE20.1KDokumen131 halaman5 - Relatório de Teste de Conformidade A IEC 62109 Bureau Veritas - Inversor SolarEdge SE20.1KCesar Biasi de MouraBelum ada peringkat

- B2 Tower & Gallery en 0Dokumen75 halamanB2 Tower & Gallery en 0miguelBelum ada peringkat

- STOD-GEN-AED-0000-ME-SPE-0012 - Functional Specification For AGP Booster PumpsDokumen14 halamanSTOD-GEN-AED-0000-ME-SPE-0012 - Functional Specification For AGP Booster PumpsAHMED AMIRABelum ada peringkat

- Iqwq SJ Qpqac 0e 0003 C40M075 - 3Dokumen21 halamanIqwq SJ Qpqac 0e 0003 C40M075 - 3محمدباقر جميل عبد الشهيدBelum ada peringkat

- CE-MI-TEST V3PM012-Change Code of Functional LocationDokumen8 halamanCE-MI-TEST V3PM012-Change Code of Functional LocationNeeraj GuptaBelum ada peringkat

- C2254-GSC-UZF Technical Specification Rev. 1Dokumen20 halamanC2254-GSC-UZF Technical Specification Rev. 1Amit DofeBelum ada peringkat

- K2S-CWS230907-GEN-BA6070-00007 - A01 - Work Method Statement For The Installation of 8mva TransfomerDokumen16 halamanK2S-CWS230907-GEN-BA6070-00007 - A01 - Work Method Statement For The Installation of 8mva TransfomerAzeta Robert100% (1)

- WHP02-SMO1-ASYYY-16-392001-0001-A0-Hvac &elect Comments PG 17, 4,12,13,...Dokumen30 halamanWHP02-SMO1-ASYYY-16-392001-0001-A0-Hvac &elect Comments PG 17, 4,12,13,...Hibri HalimBelum ada peringkat

- Block 5 Al Shaheen Field Development: GLF-WHP02-EPCI4Dokumen30 halamanBlock 5 Al Shaheen Field Development: GLF-WHP02-EPCI4Hibri HalimBelum ada peringkat

- Job Specification For CMSDokumen12 halamanJob Specification For CMSTauqueerAhmadBelum ada peringkat

- DQ - CRAB For Lyo LoadingDokumen30 halamanDQ - CRAB For Lyo Loadingdhanu_lagwankarBelum ada peringkat

- EDO-MNL-COE-COR-INT-XXX-016-622-801-Rev-A-ION-2430-OFC OIL COOLED AUTOMATIC TRANSFORMERDokumen26 halamanEDO-MNL-COE-COR-INT-XXX-016-622-801-Rev-A-ION-2430-OFC OIL COOLED AUTOMATIC TRANSFORMERErol DAĞBelum ada peringkat

- GF 202 Loop Check Analogue Input Rev02 - CGC01Dokumen244 halamanGF 202 Loop Check Analogue Input Rev02 - CGC01Gürkan SaltıkBelum ada peringkat

- HDPE Piping SpecificationDokumen28 halamanHDPE Piping SpecificationYakubu100% (1)

- RFCC PDFDokumen324 halamanRFCC PDFMohamed AdelBelum ada peringkat

- E0864 000 CT 007 Method Statement Construction of Concrete Piles Rev0Dokumen11 halamanE0864 000 CT 007 Method Statement Construction of Concrete Piles Rev0ali mohammedBelum ada peringkat

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionDari EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- KNX System: ManualDokumen48 halamanKNX System: Manualwarmaster81Belum ada peringkat

- Grundfosliterature 1531Dokumen18 halamanGrundfosliterature 1531warmaster81Belum ada peringkat

- Room Thermostats: Basic DocumentationDokumen38 halamanRoom Thermostats: Basic Documentationwarmaster81Belum ada peringkat

- Ramna ZemjaDokumen2 halamanRamna Zemjawarmaster81Belum ada peringkat

- VLT AutomationDrive FC 300 90-0 KW - Design Guide - MG34S202 25Dokumen1 halamanVLT AutomationDrive FC 300 90-0 KW - Design Guide - MG34S202 25warmaster81Belum ada peringkat

- Filtrate nozzle sizes and standardsDokumen1 halamanFiltrate nozzle sizes and standardswarmaster81Belum ada peringkat

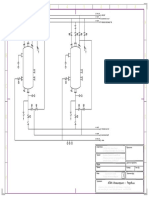

- Ednopolna Shema 12-09-2016 Layout1Dokumen1 halamanEdnopolna Shema 12-09-2016 Layout1warmaster81Belum ada peringkat

- Filter A4 H PDFDokumen1 halamanFilter A4 H PDFwarmaster81Belum ada peringkat

- HSC01 SM10 MEC07 00002: Duty SpecificationDokumen5 halamanHSC01 SM10 MEC07 00002: Duty Specificationwarmaster81Belum ada peringkat

- Nozasti Osiguraci GGDokumen6 halamanNozasti Osiguraci GGwarmaster81Belum ada peringkat

- Cake Slice Box Base TemplateDokumen1 halamanCake Slice Box Base Templatewarmaster81Belum ada peringkat

- Ednopolna Shema 09-06-2017 Layout1Dokumen1 halamanEdnopolna Shema 09-06-2017 Layout1warmaster81Belum ada peringkat

- TNN Layout1Dokumen1 halamanTNN Layout1warmaster81Belum ada peringkat

- GrundfosliteratureDokumen86 halamanGrundfosliteraturewarmaster81Belum ada peringkat

- Controlling and Monitoring Directly From A Cell Phone: CCM 164 Examples of UseDokumen1 halamanControlling and Monitoring Directly From A Cell Phone: CCM 164 Examples of Usewarmaster81Belum ada peringkat

- Crtez Filter A4 HDokumen1 halamanCrtez Filter A4 Hwarmaster81Belum ada peringkat

- Prisma G: Low Voltage CatalogueDokumen200 halamanPrisma G: Low Voltage Cataloguewarmaster81Belum ada peringkat

- Grundfosliterature 3367013 PDFDokumen1 halamanGrundfosliterature 3367013 PDFwarmaster81Belum ada peringkat

- IK Impact Test Schedule: Table 1: Relation Between IK Code and Impact EnergyDokumen1 halamanIK Impact Test Schedule: Table 1: Relation Between IK Code and Impact Energywarmaster81Belum ada peringkat

- 451 59a PDFDokumen44 halaman451 59a PDFwarmaster81Belum ada peringkat

- Filter A4 HDokumen1 halamanFilter A4 Hwarmaster81Belum ada peringkat

- LR9F5371 thermal overload relay product data sheetDokumen2 halamanLR9F5371 thermal overload relay product data sheetwarmaster81Belum ada peringkat

- Abb PLC Phtc02u en WebDokumen181 halamanAbb PLC Phtc02u en Webwarmaster81Belum ada peringkat

- Atv61 Programming Manual en 1760649 08 PDFDokumen265 halamanAtv61 Programming Manual en 1760649 08 PDFConrado AlvarezBelum ada peringkat

- Guide To Low Voltage Circuit Breaker Standards - 2015Dokumen36 halamanGuide To Low Voltage Circuit Breaker Standards - 2015k1gabitzu9789100% (2)

- IK Protection Code ChartDokumen2 halamanIK Protection Code Chartwarmaster81Belum ada peringkat

- C120N Circuit Breakers (Curves B, C, D)Dokumen4 halamanC120N Circuit Breakers (Curves B, C, D)warmaster81Belum ada peringkat

- EX215028 Busbar CatalogueDokumen164 halamanEX215028 Busbar Cataloguewarmaster81Belum ada peringkat

- Grundfosliterature 5768738Dokumen36 halamanGrundfosliterature 5768738warmaster81Belum ada peringkat

- Basic Mechanical and HVAC SystemsDokumen29 halamanBasic Mechanical and HVAC Systemsวรศิษฐ์ อ๋องBelum ada peringkat

- North Territory Occupation ListDokumen7 halamanNorth Territory Occupation ListHariza Jaya MuhammadBelum ada peringkat

- Aeronautical Engineers Board Exam Room Assignments - November 2013Dokumen11 halamanAeronautical Engineers Board Exam Room Assignments - November 2013ScoopBoyBelum ada peringkat

- Design Documentation GuidelinesDokumen7 halamanDesign Documentation Guidelinesmelsime001Belum ada peringkat

- Sem 7 SyallDokumen29 halamanSem 7 SyallAman SainiBelum ada peringkat

- BC0049 Software EngeneringDokumen25 halamanBC0049 Software EngeneringRaj ChowdhuryBelum ada peringkat

- Civil Engineering ProjectDokumen87 halamanCivil Engineering ProjectNeeraj Porwal100% (6)

- Comparison Between Dynamic and Static Pile Load TestingDokumen11 halamanComparison Between Dynamic and Static Pile Load TestingMOST PASONBelum ada peringkat

- EIT Adv Dip Mechanical Engineering TechnologyDokumen33 halamanEIT Adv Dip Mechanical Engineering TechnologyAnsar Ali100% (1)

- Mech Brochure PDFDokumen16 halamanMech Brochure PDFarvi_vinBelum ada peringkat

- ASME Review Guide for Quality Control SystemsDokumen12 halamanASME Review Guide for Quality Control SystemsSathish KumarBelum ada peringkat

- Tugas 1Dokumen2 halamanTugas 1Laisa HusrainiBelum ada peringkat

- Annex G Agcc Iso 9001 CertificationDokumen1 halamanAnnex G Agcc Iso 9001 CertificationasifaliabidBelum ada peringkat

- Pipe Specification A106 Specification A106 NPS 1/8 - 48 ANSI Schedules To 160Dokumen1 halamanPipe Specification A106 Specification A106 NPS 1/8 - 48 ANSI Schedules To 160Denise Koh Chin HuiBelum ada peringkat

- Graphical and Mechanical Computation - Alignment Charts, LipkaDokumen126 halamanGraphical and Mechanical Computation - Alignment Charts, Lipkaboo10626850Belum ada peringkat

- Additions, AlterationsDokumen4 halamanAdditions, AlterationsTan ChingBelum ada peringkat

- Strength of Materials IiDokumen48 halamanStrength of Materials IiARUNRAJH.V.GBelum ada peringkat

- CV Format ExmpleDokumen4 halamanCV Format ExmpleZameer PathanBelum ada peringkat

- Functional Safety and IEC 61508 A Basic Guide PDFDokumen9 halamanFunctional Safety and IEC 61508 A Basic Guide PDFfitasmounirBelum ada peringkat

- M 195-06 Lightweight Aggregates PDFDokumen6 halamanM 195-06 Lightweight Aggregates PDFWalticoZegarraHerreraBelum ada peringkat

- Basic Engineering Circuit Analysis 10thDokumen185 halamanBasic Engineering Circuit Analysis 10thGustavoBelum ada peringkat

- Optimization of Prototype Projects of Aeronautical Engineering Students of Philippine State College of AeronauticsDokumen119 halamanOptimization of Prototype Projects of Aeronautical Engineering Students of Philippine State College of AeronauticsDerik RoqueBelum ada peringkat

- Exam Program Nov 2022 (Civil Engg)Dokumen4 halamanExam Program Nov 2022 (Civil Engg)PRC BaguioBelum ada peringkat

- Software Engineering MethodologyDokumen38 halamanSoftware Engineering MethodologyRifky Fahrul ArifinBelum ada peringkat

- Draft 5 Jul CoursewiseDokumen177 halamanDraft 5 Jul Coursewisesharvani genatikattiBelum ada peringkat

- Mechanisation and Automation Evolution of Automation Goals and Applications of AutomationDokumen7 halamanMechanisation and Automation Evolution of Automation Goals and Applications of AutomationRifat RashidBelum ada peringkat

- Q4 Structural EngineerDokumen4 halamanQ4 Structural Engineerpaul machariaBelum ada peringkat

- Work Immersion Portfolio PH Pogi IdokqueenDokumen25 halamanWork Immersion Portfolio PH Pogi IdokqueenCarl Jeric Urbina100% (1)

- Factors Influencing Procurement SystemsDokumen10 halamanFactors Influencing Procurement SystemsYudish Deerpaul100% (8)

- 2018 SeismicwindforcesDokumen622 halaman2018 SeismicwindforcesTerry TriestBelum ada peringkat