ELK-04 C 145 2GHV008915 0315en

Diunggah oleh

muraliJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

ELK-04 C 145 2GHV008915 0315en

Diunggah oleh

muraliHak Cipta:

Format Tersedia

Product brochure

Gas-insulated switchgear ELK-04 C, 145 kV

Modular and reliable

ABB and 50 years of GIS innovation

ABB is a leader in power and automation technologies that enable utility and indus-

try customers to improve their performance while lowering environmental impact.

The ABB Group of companies operates in around 100 countries and employs about

145,000 people.

ABB offers a wide range of high-voltage products up to 1200 kV that help enhance

the reliability, efficiency and quality of power in transmission and distribution grids,

power plants and industries while enhancing eco-efficiency. The wide product range

is complemented by a comprehensive service offering.

ABB is the global leader in high-voltage GIS (gas-insulated switchgear) technology

with more than 25,000 bays installed around the world. In 2009, ABB commis-

sioned a GIS rated to handle more than one million volts (1200 kV), with a transmis-

sion capability of 6900 megawatts, reaching new heights in terms of global voltage

levels.

We pioneered high-voltage GIS in the mid-1960s and with the introduction of the

new 145 kV we complete the innovative switchgear portfolio comprising a uniform

design and operation philosophy. We continue to drive technology and innovation

within the full range of advanced GIS for voltages from 52 kV to 1200 kV.

2 GIS ELK-04 C, 145 kV | ABB

Table of contents

ABB and 50 years of GIS innovation 2

The ELK-04 C, 145 kV 4

Applications 4

Benefits 4

Modular, compact design 4

Simple and reliable 4

Convenient operation and serviceability 4

Low environmental impact 4

Advanced features for smart grid enabled GIS substations 4

Technology 5

GIS from ABB 5

ABBs high-voltage circuit-breaker 6

The circuit-breaker 6

The circuit-breaker operating mechanism 7

ABBs disconnectors and earthing switches 8

The disconnector 8

The earthing switch 9

ABBs voltage and current transformers 10

The voltage transformer 10

The current transformer 11

ABBs terminals and connecting elements 12

The connecting elements 12

Surge arresters 12

The terminal connections 13

Transformer connections 13

Cable terminations 13

SF6-air bushings 13

ABBs local control cubicle 14

The local control cubicle (LCC) 14

Advanced features for smart substations 14

ABBs commitment to total quality control 16

Enhancing eco-efficiency over the life cycle 17

The life cycle phases 17

Manufacturing phase 17

Use phase 17

End of life phase 17

Technical data 18

ABB | GIS ELK-04 C, 145 kV 3

The ELK-04 C, 145 kV

Reliability without the complexity

ABB holds a distinguished record of innovations in GIS technology and our latest

ELK-04 series for 145 kV is designed to reduce complexity and life cycle costs.

Applications In a power system, switchgear is used to control, protect and isolate electrical

equipment thereby enhancing the reliability of electrical supply. With GIS technol-

ogy, key components including contacts and conductors are protected with insulat-

ing gas making this a preferred solution where space is a constraint such as in

mega cities or in harsh environmental conditions.

Benefits

Modular, compact design Small, lean three-phase enclosure with single-phase insulators results in a small

footprint and excellent accessibility. A small number of modules and a set of stan-

dardized connection elements allow an optimal realization of different GIS layouts.

ELK-04 C uses a horizontal circuit-breaker and vertical current transformers.

Consequently, the bay requires always the same footprint regardless of the current

transformer configuration. Planning is simplified and the civil works can commence

earlier.

Simple and reliable ELK-04 C reduces complexity by a number of distinct features: conductors and

switches of the three phases are arranged in line and use less complex and fewer

parts. A simple and robust mechanical linkage replaces electrical wiring to drives in

the bay. The drives for disconnector and earthing switches are located at the front

panel and have identical user interface for manual operation and mechanical inter-

locking. Current transformers are located outside the gas compartments without the

need for a gas-tight feed to the secondary terminals.

Convenient operation and The integrated local control cubicle as well as the drive cubicle is located at the

serviceability front of the switchgear. Easy access is granted for manual operation of all equip-

ment.

Gas density information can be displayed on the integrated local control cubicle us-

ing combined density sensors/monitors. All instrument transformers are wired to the

integrated local control cubicle.

A service catwalk between the integrated local control cubicle and the bay gives

convenient access to viewports and gas filling points.

4 GIS ELK-04 C, 145 kV | ABB

The ELK-04 C is designed to enhance eco-efficiency. Optimized, lean enclosures Low environmental impact

and single phase insulators reduce weight and the use of SF6 insulating gas up to

60 percent compared to its predecessor resulting in an outstanding environmental

performance.

To ensure an interoperable and future-proof substation, the ELK-04 C, 145 kV has Advanced features for

been designed to incorporate the core values of the IEC 61850 standard. The stan- smart grid enabled GIS

dard defines strict rules for realizing interoperability between functions and devices substations

used for protection, monitoring, control and automation in substations.

Technology

GIS from ABB are built on 50 years of pioneering research and development and GIS from ABB

experience delivering over 25,000 switchgear bays in over 100 countries. Our

switchgears are crafted using standardized and modular components that enable

the construction of common layouts and bus schemes.

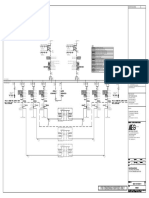

ELK-04 C, 145 kV modules

Circuit-breakers

Disconnectors & earthing switches

Voltage & current transformers

Connecting elements

Control & protection

ABB | GIS ELK-04 C, 145 kV 5

ABBs high-voltage circuit-breaker

Reliable, well proven technology

The circuit-breaker The horizontal circuit-breaker module provides optimal performance and low main-

tenance. ELK-04 C circuit-breakers are equipped with Auto-pufferTM interrupters,

i.e. self-blast interrupters with one unit per pole. They require minimum maintenance

and only a low amount of operational energy. The optimized and compact layout

minimizes the volume of SF6 insulating gas by 70 percent compared to its prede-

cessor. The circuit-breaker fits to all layouts and is used in other ABB GIS applica-

tions as well as for live tank and dead tank circuit-breakers.

Circuit-breaker drive cubicle

Circuit-breaker with operating mechanism

6 GIS ELK-04 C, 145 kV | ABB

To open or close the circuit-breaker, a spring operating mechanism is used. The The circuit-breaker operat-

closing latch generates the energy required to close the circuit-breaker and will ing mechanism

charge the opening latch. The mechanical energy required for opening is therefore

always stored in the opening latch, when the circuit-breaker is closed. Immediately

after the closing a motor automatically reloads the closing latch again. After the

closing latch is charged, the circuit-breaker is always ready to perform an opening

operation or a complete auto-reclosing (O 0.3 s CO).

The entire drive is outside the SF6-gas compartment. The torsion springs produce

less vibration than conventional compression springs and the robust loading mo-

tor ensures that the closing latch is charged in less than 15 seconds. The closing

spring can be charged by means of a hand crank if the auxiliary power supply or

control circuit fails.

2 1 3 6 1 2 5

OFF ON

5

ON

OFF

Legend

1 Opening latch

2 Closing latch

3 Cam support

4 Main operating lever

B 5 Motor

6 Charging gear wheel

A Opening spring

B 4 C A

B Damping device

Mechanical drive with torsion spring C Closing spring

ABB | GIS ELK-04 C, 145 kV 7

ABBs disconnectors and earthing switches

Convenient operation and serviceability

The disconnector The disconnectors provide a safe insulating gap to isolate sections with different

potential, for example busbar disconnectors, which isolate the circuit-breaker from

the busbar.

The operating mechanism of the disconnector and earthing switch is mounted in

the drive cubicle at the front of the bay and contains all the components needed for

operation and is wired to the integrated local control cubicle next to it. Position indi-

cators and hand-crank access are features conveniently located in the drive cabinet

and are easy accessible.

Disconnector and earthing switch

drive cubicle

Disconnector

Busbar disconnector

8 GIS ELK-04 C, 145 kV | ABB

Earthing switches connect isolated sections of the switchgear to the earth potential The earthing switch

during maintenance and assembly work.

Feeder terminals are often equipped with fast-acting (or make-proof) earthing

switches. These devices are able to earth induced currents on overhead lines, dis-

charge capacitances such as cables, and provide safety when the opposite end of

a line is not properly de-energized. The fast-acting earthing switch includes a spring

operated mechanism, which is either charged by a motor or by a hand crank.

Similar to disconnectors, the operating mechanism of the maintenance earthing

switch is located in the drive cubicle at the front of the bay. Hand-crank access,

position indicators and mechanical interlocking, are features conveniently located in

the drive cubicle and are easy accessible from the operators corridor. The operat-

ing mechanism of the fast-acting earthing switch is located at the equipment itself

and controlled via the control cubicle.

Maintenance earthing switch

Fast-acting earthing switch

ABB | GIS ELK-04 C, 145 kV 9

ABBs voltage and current transformers

Highly reliable metering, control and protection functions

The voltage transformer Our maintenance-free voltage and current transformers provide highly reliable me-

tering, control and protection functions. Used for system protection, our powerful

transformers offer years of trouble-free service even for heavy-duty applications.

The three-pole inductive voltage transformers are connected to the switchgear with

a standardized connecting flange and a partition insulator. The primary winding is

coiled on top of the core and the secondary windings.

Voltage transformer

10 GIS ELK-04 C, 145 kV | ABB

The single-pole inductive current transformers are attached to the same housing The current transformer

where the maintenance earthing switch is located. They are located outside the gas

compartment eliminating the need for a gas-tight feed to the secondary terminals.

The current transformer can be placed on the feeder side and on the busbar side

and may contain multiple cores for metering and protection. Current transformer

parameters such as burden, ratio and accuracy class are set to meet specific proj-

ect requirements. Multi-ratio transformers provide different ratios selectable by taps.

Current transformer

ABB | GIS ELK-04 C, 145 kV 11

ABBs terminals and connecting elements

Maximum flexibility

The connecting elements We have versatile terminal and connecting elements that enable the switchgear to

be customized to fit your project requirements. We offer connecting elements in var-

ious shapes and sizes including phase rotation modules, different angular modules

and straight sections.

The busbar module of ELK-04 C covers a universal expansion joint to absorb heat

expansion and vibrations during operation. During site installation, the expansion

element ensures that neighboring bays can be connected easily.

Surge arresters Surge arresters are fully-enclosed metal components that limit switching and light-

ning over voltages. For stable and reliable operations, the ELK-04 C is equipped

with gapless gas-insulated metal-oxide surge arresters. Ratings and discharge

classes are tailored to your project specific requirements.

Busduct with pressure relief device

L-element T-element X-element

12 GIS ELK-04 C, 145 kV | ABB

We offer a complete range of connecting elements for peripherals, such as SF6-air The terminal connections

bushings, enclosures for cable terminations and direct transformer connections.

Our standardized transformer connections link power transformers directly to the Transformer connections

switchgear via SF6 insulated bus ducts. Vibrations, thermal expansion of the trans-

former and switchgear, as well as movements resulting from the settling of founda-

tions, are compensated by bellows and expansion joints. A removable high-voltage

conductor link isolates the transformer for testing.

Our supply can include cable connections of the plug-in type with dry-type or fluid- Cable terminations

filled terminations. The interfaces are conform to IEC standards. A removable link

disconnects and isolates the GIS from the cable during high-voltage test for conve-

nience and ease of operations.

Our lightweight SF 6-air bushings are available in two variants in the standard ver- SF6-air bushings

sion, with composite insulators and silicon sheds or with classical porcelain insula-

tors. Creepage distance, length, and shape depend on the project-specific environ-

mental requirements. We provide SF6-air bushings that are maintenance-free with

self-cleaning silicon sheds.

Cable connection SF6-air bushing

ABB | GIS ELK-04 C, 145 kV 13

ABBs local control cubicle

Reduced commissioning and installation time

The local control cubicle The local control cubicle (LCC) includes all required functions for the control and

(LCC) supervision of the GIS bay. The LCC is usually integrated with the bay and located

on top of the drive cubicle. As an integral part of the ELK-04 C, the LCC is wired,

factory-tested and shipped together with the bay as one transport unit. This reduc-

es installation and commissioning time to a minimum and eliminates errors during

site installation. Connections from the LCCs prepared terminal blocks to dedicated

protection cubicles, control systems, power supply and inter-bay wiring are the only

installation work done on site.

Our LCCs can either be of the Smart Grid Enabled type or the conventional type

with Mimic, position indicators and the associated control switches. Our advanced

Relion family of protection and control-IEDs as well as the conventional Mimic

solution ensures the safe and economical operation of the switchgear.

Advanced features for Our broad range of control and protection systems includes IEC 61850 compli-

smart substations ant products that provide open, future-proof and flexible system architecture. Our

advanced local control cubicles enable monitoring and remote diagnostic functions

ensuring high availability and fast access to precise information from anywhere in

the system, speeding up responses and reducing outage time. Depending on the

project requirements, we can also deliver standalone LCCs with all customary con-

trol and protection devices.

Conventional integrated LCC with mimic Smart Grid Enabled LCC with control, monitoring

and protection

14 GIS ELK-04 C, 145 kV | ABB

The switchgear can be equipped with a Modular Switchgear Monitoring device

(MSM). This add-on monitors SF 6 density, calculates and supervises leakage rates

and gas level limits. It fits all kinds of switchgear layouts. The MSM operates inde-

pendently of control and protection devices. The system status can be conveniently

accessed and displayed at any time through a range of displays, e.g. an LCD dis-

play in the local control cubicle, via IEC 61850-8-1 over SCADA or remotely through

a web browser.

MSM: LC display in the local con-

trol cubicle

Ethernet switch Monitoring PC

Station wide communication IEC 61850

Relion 650 and MSM GIS ELK-04 C, 145 kV

Digital monitoring, measurement, control, protection and communication based on IEC 61850

ABB | GIS ELK-04 C, 145 kV 15

ABBs commitment to total quality control

Highest product quality

Our products are type The ELK-04 C is factory assembled and fully tested as one bay with the local con-

tested according to trol cubicle in a manufacturing facility using an advanced flow production system

different standards that adheres to ABB internal quality and manufacturing excellence procedures. All

IEC bays are produced and tested in controlled conditions under the strict supervision

ANSI/IEEE of ABBs engineers and GIS experts.

ABB believes that innovation is a key to ABBs competitive advantage and it has

consistently invested in research and development to become a market leader. The

ELK-04 C is based on pioneering GIS technology since the 1960s and installation in

around 100 countries. It complies with or exceeds the latest international standards

(IEC/ANSI) and has been type tested in independent laboratories.

We are committed to giving you products of the highest quality that is why we strive

to produce only products that comply with or exceed the latest international stan-

dards (IEC/ANSI). In addition, our products have been type tested in independent

laboratories. Our certified design and manufacturing processes guarantee the high-

est quality of our products.

Our GIS bays are fully assembled and tested in the factory with standardized,

automated and reliable procedures. After routine testing, shipping units are packed

in accordance with the freight carriers requirements, the duration of transportation,

the dispatch route and site storage requirements.

Pre-tested, wired and SF6 pre-filled bays reduce the on-site installation work and

gas handling significantly. Bays are coupled using standard tools. Site testing ac-

cording to IEC/ANSI standards and ABB quality assurance procedures include leak-

age checks on flanges, instrument transformer, control and monitoring functions,

resistance measurements and a high-voltage test. Site installation can be carried

out by ABB or by personnel from your own company under the guidance of a certi-

fied ABB supervisor. ABB offers training courses for every aspect of GIS installation,

operation and maintenance.

ABBs metal-enclosed gas-insulated switchgear requires minimal maintenance in

service. Under normal operational conditions, more than 50 years smooth opera-

tion is assured with periodic visual checks. ABB Service provides competent 24/7

worldwide support in case of failures.

16 GIS ELK-04 C, 145 kV | ABB

Enhancing eco-efficiency over the life cycle

Low environmental impact

For ABB, sustainability is about balancing economic success, environmental stew-

ardship and social progress to benefit all our stakeholders.

Sustainability considerations cover how we design and manufacture products, what

we offer customers, how we engage suppliers, how we assess risks and opportuni-

ties, and how we behave in the communities where we operate and towards one

another, while striving to ensure the health, safety and security of our employees,

contractors and others affected by our activities. In line with our business practices,

we publish environmental product declarations for each product we manufacture.

The life cycle of the ELK-04 C is separated into three phases: manufacture, use and The life cycle phases

disposal. The manufacture scenario includes materials used, transport of compo-

nents and SF6 gas leakage rates. The usage scenario includes transport of products

to customers as well as SF6 gas leakage rates and energy losses assuming a 50-

year life time. The disposal phase refers to SF6 gas leakage rates and the energy for

making recycled metals reusable.

Continuous improvement in product design resulted in a more compact housing that Manufacturing phase

uses less aluminum and other metals

Low thermal losses due to innovative designs and material choices

Full bay shipment due to compact design reduces the environmental impact of

transportation

ABBs factory is ISO 14001 certified for environment best practices and we also

conduct regular environment audits at our suppliers facilities

Online monitoring for preventive maintenance Use phase

The low operating energies used by ABBs modern interrupters combined with the

efficient mechanical spring drives result in lower auxiliary power supply consumption

Type tested for 0.1 percent SF6 gas leakage rate per year

Minimized SF6 gas leakage rates due to well proven sealing system

Use of material which is easy to recycle or dispose End of life phase

Improved maintenance processes that avoid the accidental release of gases and oil

Improved recycling and disposal through clear declarations adjusted to different

global boundary conditions

ABB | GIS ELK-04 C, 145 kV 17

Technical data

ELK-04 C, 145 kV

2500

2250

4800

800

ELK-04 C, 145 kV double busbar bay

Circuit-breakers

Disconnectors and earthing switches

Voltage and current transformers

Connecting elements

Control & protection

Note: Dimensions in mm

18 GIS ELK-04 C, 145 kV | ABB

ELK-04 C, 145 kV Product ID 2GHV010550M0001

Rated voltage kV 145

Rated short-duration power-frequency withstand voltage kV 275

Rated short-duration power-frequency withstand voltage across isolating distance kV 315

Rated lightning impulse withstand voltage kV 650

Rated lightning impulse withstand voltage across isolating distance kV 750

Rated frequency Hz 50/60

Rated normal current A 3150

Rated short-time withstand current kA 40

Rated duration of short-circuit s 3

Rated peak withstand current kA 108

Installation Indoor/outdoor

Rated filling pressure / minimum functional pressure (abs. at 20 C) MPa 0.68/0.60

Circuit-breaker

Rated short-circuit breaking current, 50/60 Hz kA 40

Rated short-circuit making current, peak value kA 108

First pole-to-clear factor 1.3/1.5

Drive type spring

Rated opening time ms 26 ... 35

Rated closing time ms 45 ... 55

Reclosing time ms < 300

Rated operating sequence O-0.3s-CO-3min-CO

Number of mechanical operations class M2

Rated capacitive switching currents class C2

Disconnector and earthing switch

Capacitive current switching capability mA 500

Rated bus-transfer current / rated bus-transfer voltage A/V 1600/30

Fast-acting earthing switch

Rated short-circuit making current kA 108

Rated induced voltage (electromagnetic coupling) kV 6

Rated induced current (electromagnetic coupling) A 100

Rated induced voltage (electrostatic coupling) kV 6

Rated induced current (electrostatic coupling) A 5

Classification for electrical endurance class E1

ABB | GIS ELK-04 C, 145 kV 19

Contact us

ABB AG Note

Copyright ABB. 2GV008915 En / 03.15

We reserve the right to make technical changes or

High Voltage Products modify the contents of this document without prior

Brown-Boveri-Strasse 30 notice. With regard to purchase orders, the agreed

particulars shall prevail. ABB Ltd does not accept any

63457 Hanau-Grossauheim / Germany responsibility whatsoever for potential errors or possible

Phone: +49 6181 5090 lack of information in this document.

We reserve all rights in this document and in the

www.abb.com/highvoltage

subject matter and illustrations contained therein. Any

reproduction, disclosure to third parties or utilization of

its content in whole or parts is forbidden without prior

written consent of ABB Ltd.

Copyright 2015 ABB

All rights reserved

Anda mungkin juga menyukai

- Product Catalogue of ELK-04Dokumen28 halamanProduct Catalogue of ELK-04Aaron MokBelum ada peringkat

- Elk-04 170 Bro 1HC0130351 Ab enDokumen16 halamanElk-04 170 Bro 1HC0130351 Ab enDave ChaudhuryBelum ada peringkat

- MIGRATE D1.1 Final TenneTDokumen137 halamanMIGRATE D1.1 Final TenneTgkoutBelum ada peringkat

- Elk-3 420 1HC0029799 Aj21 enDokumen20 halamanElk-3 420 1HC0029799 Aj21 enaalbaki1Belum ada peringkat

- ELK-3 - 420 - 1HC0029799AGEn 420kV GISDokumen0 halamanELK-3 - 420 - 1HC0029799AGEn 420kV GISMohammed NazeeruddinBelum ada peringkat

- Clearances Advice For PowerDokumen4 halamanClearances Advice For PowerkashifusmanBelum ada peringkat

- E01 & E02+wr1Dokumen134 halamanE01 & E02+wr1faqihu rizkyBelum ada peringkat

- IEE GIL Ref 0306 PDFDokumen5 halamanIEE GIL Ref 0306 PDFJie ChuBelum ada peringkat

- Gis Accessories Installation and Testing (00000002)Dokumen25 halamanGis Accessories Installation and Testing (00000002)Insan AzizBelum ada peringkat

- Determination of The Capitalization Values For No Load Losses and Load LossesDokumen12 halamanDetermination of The Capitalization Values For No Load Losses and Load LossesSaman GamageBelum ada peringkat

- Gis-01 XianDokumen9 halamanGis-01 XianVictor MaciasBelum ada peringkat

- 8BK30 Catalog PDFDokumen22 halaman8BK30 Catalog PDFRafael SilvaBelum ada peringkat

- Daelim Catalog For TransformersDokumen20 halamanDaelim Catalog For TransformersJuan Carlos BasilioBelum ada peringkat

- Current Transformers For GIS SWG Type ELK - 1VLM000628 Rev.3, en 2017.08.28Dokumen12 halamanCurrent Transformers For GIS SWG Type ELK - 1VLM000628 Rev.3, en 2017.08.28Binode sarkarBelum ada peringkat

- 1HYB800001-042A-OM Manual (1-Pole) PDFDokumen193 halaman1HYB800001-042A-OM Manual (1-Pole) PDFFredy MedranoBelum ada peringkat

- Capacitor Bank Spec.Dokumen2 halamanCapacitor Bank Spec.Ratana KemBelum ada peringkat

- 5c595ddd4a55f - Application For Electricity Supply and Agreement Form Final 2019Dokumen8 halaman5c595ddd4a55f - Application For Electricity Supply and Agreement Form Final 2019ابراهيم السعيديBelum ada peringkat

- GIS (E A4) 218hyundaiDokumen24 halamanGIS (E A4) 218hyundaivishalrediffBelum ada peringkat

- Jakarta MP Grid Code Adjusment - DPX - LGC - AlvinDokumen22 halamanJakarta MP Grid Code Adjusment - DPX - LGC - AlvinMellaBelum ada peringkat

- SVC Abb Case StudyDokumen2 halamanSVC Abb Case StudybhsujanBelum ada peringkat

- 7 PDFDokumen258 halaman7 PDFRobbyo Ardiles PBelum ada peringkat

- 220 KV GISDokumen16 halaman220 KV GISAashwinAndeBelum ada peringkat

- PSS Sincal - Reliability in Grid Industry WebinarDokumen31 halamanPSS Sincal - Reliability in Grid Industry Webinarathrun zalaBelum ada peringkat

- 8 GIS Substation Design and Execution Apr 08 09 PDFDokumen119 halaman8 GIS Substation Design and Execution Apr 08 09 PDFRidoAldilaBelum ada peringkat

- What Is New in ABB Relion 670 and 650Dokumen39 halamanWhat Is New in ABB Relion 670 and 650Anonymous lwkZY9Belum ada peringkat

- 00-Different SIEMENS GIS TypesDokumen44 halaman00-Different SIEMENS GIS TypesPélagie DAH SERETENONBelum ada peringkat

- BOQ-HT Sub-Stn. at Market Complex at Baruipur (22 7 11)Dokumen6 halamanBOQ-HT Sub-Stn. at Market Complex at Baruipur (22 7 11)Ramesh AnanthanarayananBelum ada peringkat

- Experience of Specifying and Using Reactors in A Transmission NetworkDokumen8 halamanExperience of Specifying and Using Reactors in A Transmission Networkmrjack1Belum ada peringkat

- Gis PDFDokumen28 halamanGis PDFgloby_pnbBelum ada peringkat

- Canada Power Sf6Dokumen22 halamanCanada Power Sf6alfonso.parkerBelum ada peringkat

- 04 400 KV 50 63 80 125 MVAr Shunt Reactor NGR SA R2 Jul 08Dokumen66 halaman04 400 KV 50 63 80 125 MVAr Shunt Reactor NGR SA R2 Jul 08anjes1Belum ada peringkat

- Reduced Series ReactorDokumen10 halamanReduced Series ReactorclicknagpalBelum ada peringkat

- Buku 3 Executive Summary RUPTL 2015 2024EDokumen52 halamanBuku 3 Executive Summary RUPTL 2015 2024EmuhammadfaridzBelum ada peringkat

- Gas Insulated Transmission Lines (Siemens) PDFDokumen12 halamanGas Insulated Transmission Lines (Siemens) PDFArianna IsabelleBelum ada peringkat

- As 1028-1992 Power Reactors and Earthing TransformersDokumen8 halamanAs 1028-1992 Power Reactors and Earthing TransformersSAI Global - APACBelum ada peringkat

- One Corner of The Delta TertiryDokumen6 halamanOne Corner of The Delta TertiryaocalayBelum ada peringkat

- Draw No - MEG-2113-KYE-CS-301 - 275kV Single Line DiagramDokumen1 halamanDraw No - MEG-2113-KYE-CS-301 - 275kV Single Line DiagramMohamad HishamBelum ada peringkat

- Annexure-17 Fault Ride Through Functions - LVRT HVRT & ZVRT - DelCEN 2500 HV PDFDokumen2 halamanAnnexure-17 Fault Ride Through Functions - LVRT HVRT & ZVRT - DelCEN 2500 HV PDFSAEL SOLARBelum ada peringkat

- Electrical Primary Design of 35 KVDokumen66 halamanElectrical Primary Design of 35 KVsamiaBelum ada peringkat

- PEKIK AD - Power Quality P2BDokumen50 halamanPEKIK AD - Power Quality P2BPinandhito Adi100% (1)

- LTB E CB BrochureDokumen6 halamanLTB E CB BrochureMidhun VargheseBelum ada peringkat

- 765 KV Gis-1Dokumen6 halaman765 KV Gis-1gdkansaraBelum ada peringkat

- Nissin - Gt14 Nissin - Gt14: BUS 150 KV (2000A) Bus A Bus BDokumen1 halamanNissin - Gt14 Nissin - Gt14: BUS 150 KV (2000A) Bus A Bus BirfanBelum ada peringkat

- T60 741x AE1Dokumen694 halamanT60 741x AE1kumarinelBelum ada peringkat

- Kabeldon Cable Accessories 1-420 KV English 2011-05-17 REV 2Dokumen132 halamanKabeldon Cable Accessories 1-420 KV English 2011-05-17 REV 2Jesus VaraBelum ada peringkat

- Shunt Reactors ABBDokumen17 halamanShunt Reactors ABBTaher El NoamanBelum ada peringkat

- VCB Siemens BrochureDokumen32 halamanVCB Siemens BrochureSaurav BhattaraiBelum ada peringkat

- Post & Disc Insulator and Hardware FittingsDokumen15 halamanPost & Disc Insulator and Hardware FittingsVelu SamyBelum ada peringkat

- KTH IEC 61850 For Substation Automation 2013-04-12Dokumen105 halamanKTH IEC 61850 For Substation Automation 2013-04-12Chad WoodBelum ada peringkat

- Section 2 Hvgis Technical Data Sheets: ABB - Technical Schedule 23488 - DUQM + 23489 - MahoutDokumen20 halamanSection 2 Hvgis Technical Data Sheets: ABB - Technical Schedule 23488 - DUQM + 23489 - MahoutjigyeshBelum ada peringkat

- Bundle Spacer: Engineering DepartmentDokumen4 halamanBundle Spacer: Engineering DepartmentpvenkyBelum ada peringkat

- Gas-Insulated Switchgear: Type 8DN8 Up To 170 KV, 63 Ka, 4000 ADokumen33 halamanGas-Insulated Switchgear: Type 8DN8 Up To 170 KV, 63 Ka, 4000 APélagie DAH SERETENONBelum ada peringkat

- Who Needs An EMT Model For Doing Stability Studies 2022Dokumen21 halamanWho Needs An EMT Model For Doing Stability Studies 2022maran sBelum ada peringkat

- Sastec2 - Technical Offer - 220kv Gis JSPL - Angul - Rev CDokumen18 halamanSastec2 - Technical Offer - 220kv Gis JSPL - Angul - Rev CRakesh Kumar Singh (Phase 1B)Belum ada peringkat

- Power-system protection A Complete GuideDari EverandPower-system protection A Complete GuidePenilaian: 1 dari 5 bintang1/5 (1)

- Knowledge is "Real Power": Introduction to Power QualityDari EverandKnowledge is "Real Power": Introduction to Power QualityBelum ada peringkat

- 3D Photovoltaic Devices Complete Self-Assessment GuideDari Everand3D Photovoltaic Devices Complete Self-Assessment GuideBelum ada peringkat

- RVT TNDokumen2 halamanRVT TNGaganprit SinghBelum ada peringkat

- Job Specfication EEDokumen23 halamanJob Specfication EEmuraliBelum ada peringkat

- Approved List of VendorsDokumen35 halamanApproved List of VendorschandruhbkkBelum ada peringkat

- Site & Utility DataDokumen3 halamanSite & Utility DatamuraliBelum ada peringkat

- CPCB DG Set Noise Emission NormsDokumen6 halamanCPCB DG Set Noise Emission NormsRSBelum ada peringkat

- Design BasisDokumen43 halamanDesign Basismurali0% (1)

- EN-Tubular Gel - Valve Regulated Lead Acid Batteries - HBL PDFDokumen16 halamanEN-Tubular Gel - Valve Regulated Lead Acid Batteries - HBL PDFmuraliBelum ada peringkat

- 415V GeneratorsDokumen9 halaman415V GeneratorsmuraliBelum ada peringkat

- 4.VFD Spec. Rev.1Dokumen35 halaman4.VFD Spec. Rev.1wado11100% (1)

- MV Fuse ScneiderDokumen44 halamanMV Fuse ScneidermuraliBelum ada peringkat

- DG 180 - 225 kVADokumen4 halamanDG 180 - 225 kVAmuraliBelum ada peringkat

- Load ShedDokumen41 halamanLoad ShedTayyab SaeedBelum ada peringkat

- Reactive Energy CompensationDokumen38 halamanReactive Energy Compensationcyo3fffBelum ada peringkat

- SFU FRRRN-SDF PDFDokumen21 halamanSFU FRRRN-SDF PDFmuraliBelum ada peringkat

- CMC 356 Technical Data ENU PDFDokumen3 halamanCMC 356 Technical Data ENU PDFhridayranjanBelum ada peringkat

- 1059Dokumen19 halaman1059muraliBelum ada peringkat

- Load Shedding Utility Industrial Power System Reliability PDFDokumen41 halamanLoad Shedding Utility Industrial Power System Reliability PDFmuraliBelum ada peringkat

- ALSTOM Relay CatalogueDokumen20 halamanALSTOM Relay CatalogueINZAMAM MUSHTAQBelum ada peringkat

- Relay Coordination GuidelinesDokumen16 halamanRelay Coordination GuidelinesNitesh Ostwal91% (11)

- 1MRK505031-BEN B en General Differential Protection RED 521 1.0Dokumen20 halaman1MRK505031-BEN B en General Differential Protection RED 521 1.0muraliBelum ada peringkat

- Universal Motor Controller: Custom Application EditorDokumen78 halamanUniversal Motor Controller: Custom Application EditormuraliBelum ada peringkat

- ECO Technology 1HC0114819AA enDokumen2 halamanECO Technology 1HC0114819AA enmuraliBelum ada peringkat

- Reactive Energy CompensationDokumen38 halamanReactive Energy Compensationcyo3fffBelum ada peringkat

- 1MRK506115-UEN en Application Manual REL 505-C1 2.3 PDFDokumen236 halaman1MRK506115-UEN en Application Manual REL 505-C1 2.3 PDFmuraliBelum ada peringkat

- Distance Protection ApplicationDokumen12 halamanDistance Protection Applicationluiscamposch50% (2)

- FN SDFDokumen21 halamanFN SDFArun KumarBelum ada peringkat

- Fuse Catalog 2007enDokumen28 halamanFuse Catalog 2007enjacksonsuarezBelum ada peringkat

- Protection Relay - ANSI Standards - EEPDokumen10 halamanProtection Relay - ANSI Standards - EEPmuraliBelum ada peringkat

- DM Umc100Dokumen71 halamanDM Umc100Laucian NaskapiBelum ada peringkat

- Soc BookDokumen19 halamanSoc BookmuraliBelum ada peringkat

- .:: Astrill Error ::. &NBSP Connection To WWW - Scribd.com:80 Failed (Socket Error # 11002 )Dokumen67 halaman.:: Astrill Error ::. &NBSP Connection To WWW - Scribd.com:80 Failed (Socket Error # 11002 )Hamed GeramiBelum ada peringkat

- Switchgear Orom Heat Load CalculationsDokumen24 halamanSwitchgear Orom Heat Load Calculationspsn_kylmBelum ada peringkat

- S-AAA-GEN-SQA (Safety & Quality) (Rev.0-2015)Dokumen22 halamanS-AAA-GEN-SQA (Safety & Quality) (Rev.0-2015)Clark HonradoBelum ada peringkat

- Scame - Ro ZP00910 GB 3Dokumen76 halamanScame - Ro ZP00910 GB 3Ster RncBelum ada peringkat

- CIGRE Brochure 528 Transformer SpecificationsDokumen70 halamanCIGRE Brochure 528 Transformer SpecificationsMiguel VogtBelum ada peringkat

- Iom Ing Unigear (CCM) Zs1 AbbDokumen106 halamanIom Ing Unigear (CCM) Zs1 AbbHernan Olave OlguinBelum ada peringkat

- ABB VD4 Vakuumski SN PrekidacDokumen100 halamanABB VD4 Vakuumski SN Prekidacjerrash4598Belum ada peringkat

- Substation DesignDokumen764 halamanSubstation DesignNahidi100% (4)

- Cop V2 Isbn 923 9291 06 8 PDFDokumen202 halamanCop V2 Isbn 923 9291 06 8 PDFKhairul Naim AH100% (2)

- DS311 (B)Dokumen310 halamanDS311 (B)Miguel Romo100% (4)

- Online Partial Discharge Testing For 110Dokumen7 halamanOnline Partial Discharge Testing For 110sunilBelum ada peringkat

- Mes Profile 2022Dokumen26 halamanMes Profile 2022رعد الكعودBelum ada peringkat

- REX640 ApplicationsDokumen47 halamanREX640 ApplicationsgoalexBelum ada peringkat

- Automatic Transfer Switch Trans-ATS - D - Manual - EN V03Dokumen54 halamanAutomatic Transfer Switch Trans-ATS - D - Manual - EN V03POTÊNCIA ATIVA GERADORESBelum ada peringkat

- 7155 - 2 Standard For Conveyor BeltDokumen6 halaman7155 - 2 Standard For Conveyor BeltcrankvspistonBelum ada peringkat

- Electrical ProtectionsDokumen183 halamanElectrical ProtectionsTito AriyantoBelum ada peringkat

- SP0407Dokumen12 halamanSP0407isukuruBelum ada peringkat

- Dewpoint Measurement in SF6 Gas-Insulated SwitchgearDokumen2 halamanDewpoint Measurement in SF6 Gas-Insulated SwitchgearvladaukiBelum ada peringkat

- Documentation and Reference Design Guide For Major SubstationsDokumen37 halamanDocumentation and Reference Design Guide For Major SubstationssvcdesignBelum ada peringkat

- Help SIMARIS Project 3.1 enDokumen61 halamanHelp SIMARIS Project 3.1 enVictor VignolaBelum ada peringkat

- M4-Approved Vendor ListDokumen20 halamanM4-Approved Vendor Listisan.structural TjsvgalavanBelum ada peringkat

- Grid AIS L3 FKG2M 0140 2016 07 EN Lo PDFDokumen2 halamanGrid AIS L3 FKG2M 0140 2016 07 EN Lo PDFboby100% (1)

- Grid Code MSDG 200 KW To 2 MW - V3-2 - Updated 23 Oct 2019Dokumen82 halamanGrid Code MSDG 200 KW To 2 MW - V3-2 - Updated 23 Oct 2019Yashveer TakooryBelum ada peringkat

- Automatic Power Factor Correction Equipment /capacitor Banks For Low Voltage Distribution NetworksDokumen13 halamanAutomatic Power Factor Correction Equipment /capacitor Banks For Low Voltage Distribution NetworksBrajan's B.Belum ada peringkat

- ABB Catalogue SafeRing 36Dokumen68 halamanABB Catalogue SafeRing 36JOGmzBelum ada peringkat

- 1TGC902030B0201 MNS System GuideDokumen34 halaman1TGC902030B0201 MNS System GuideSubhroSenBelum ada peringkat

- STS-3000K-H1: Simple EfficiencyDokumen2 halamanSTS-3000K-H1: Simple EfficiencyNatalia AndreaBelum ada peringkat

- HVX-O 36Kv Catalogue DNFDokumen44 halamanHVX-O 36Kv Catalogue DNFAction GamesBelum ada peringkat

- Package Substation Catlogue - Schneider ElectricDokumen5 halamanPackage Substation Catlogue - Schneider Electricsankuma100% (2)

- Logical Node Classes & DataDokumen47 halamanLogical Node Classes & Datank1224Belum ada peringkat