Irregular Metal Transfer: Globular Welding

Diunggah oleh

Gokul RajanDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Irregular Metal Transfer: Globular Welding

Diunggah oleh

Gokul RajanHak Cipta:

Format Tersedia

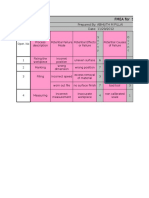

Globular transfer

Key characteristics

Irregular metal transfer

Medium heat input

Medium deposition rate

Risk of spatter

Not widely used in the UK; can be used for mechanised welding of

medium thickness steels (typically 3-6mm) in the flat (PA) position

The globular transfer range occupies the transitional range of arc voltage

between free-flight and fully short-circuiting transfer. Irregular droplet

transfer and arc instability are inherent, particularly when operating near the

transition threshold. In globular transfer, a molten droplet of several times

the electrode diameter forms on the wire tip. Gravity eventually detaches the

globule when its weight overcomes surface tension forces, and transfer

takes place often with excessive spatter. Before transfer occurs, the arc

wanders and its cone covers a large area, dissipating energy.

There is a short duration short-circuit when the droplet contacts with the

molten pool, but rather than causing droplet transfer, it occurs as a result of

it. Although the short-circuit is of very short duration, some inductance is

necessary to reduce spatter, although to the operator the short-circuits are

not discernible and the arc has the appearance of a free-flight type.

To further minimise spatter levels, it is common to operate with a very short

arc length, and in some cases a buried arc technique is adopted. Globular

transfer can only be used in the flat position and is often associated with

lack of penetration, fusion defects and uneven weld beads, because of the

irregular transfer and tendency for arc wander.

Anda mungkin juga menyukai

- Modes of Metal TransferDokumen7 halamanModes of Metal TransfershruthiBelum ada peringkat

- 2 GmawDokumen28 halaman2 Gmaweqho_soesantoBelum ada peringkat

- Modes of Gmaw TransferDokumen5 halamanModes of Gmaw TransfershruthiBelum ada peringkat

- ULINC Curriculum - Sample Lesson PlanDokumen42 halamanULINC Curriculum - Sample Lesson Plankamal touilebBelum ada peringkat

- Gas Metal Arc WeldingDokumen16 halamanGas Metal Arc WeldingAizad IzzuddinBelum ada peringkat

- MIG Welding Tech.Dokumen3 halamanMIG Welding Tech.HoangBelum ada peringkat

- 3-Gas Metal Arc Welding (GMAW)Dokumen13 halaman3-Gas Metal Arc Welding (GMAW)abastosuaptBelum ada peringkat

- Modes of Heat Transfer PresentationDokumen12 halamanModes of Heat Transfer PresentationYashvir SinghBelum ada peringkat

- Gas Metal Arc WeldingDokumen21 halamanGas Metal Arc WeldingLihas AirohalBelum ada peringkat

- Basic Mig Welding ProcessDokumen4 halamanBasic Mig Welding Processamiter84Belum ada peringkat

- Experiment No.: - Effect of Change of Welding Parameters On Weld Quality AimDokumen3 halamanExperiment No.: - Effect of Change of Welding Parameters On Weld Quality AimVandan GundaleBelum ada peringkat

- FCAWDokumen4 halamanFCAWRamanujadaasanBelum ada peringkat

- Gas Metal Arc Welding (MIG) Process GuideDokumen14 halamanGas Metal Arc Welding (MIG) Process GuideAnant AjithkumarBelum ada peringkat

- GMAW GuideDokumen21 halamanGMAW GuidewhoopsoopsBelum ada peringkat

- Lightning ArrestersDokumen35 halamanLightning ArrestersDr. Srinivas MBelum ada peringkat

- 4 GmawDokumen41 halaman4 GmawPutra Daha PratamaBelum ada peringkat

- Class 11 GMAWDokumen39 halamanClass 11 GMAWSaurabh TripathiBelum ada peringkat

- GMAW Guide: Everything You Need to Know About Gas Metal Arc WeldingDokumen16 halamanGMAW Guide: Everything You Need to Know About Gas Metal Arc WeldingAnonymous cgcKzFtXBelum ada peringkat

- Smaw TRHSDokumen32 halamanSmaw TRHSnareshBelum ada peringkat

- Submerge Arc WeldingDokumen7 halamanSubmerge Arc WeldingUsman Saeed KianiBelum ada peringkat

- MIG/MAG Metal Transfer GuideDokumen1 halamanMIG/MAG Metal Transfer Guidejose alberto gamiñoBelum ada peringkat

- Fundamentals of Welding TechDokumen29 halamanFundamentals of Welding TechAshwani DograBelum ada peringkat

- Circuit BreakersDokumen36 halamanCircuit BreakersGAURAV BHARADWAJBelum ada peringkat

- Essential Components of Electrical SubstationsDokumen35 halamanEssential Components of Electrical SubstationsJet FranciscoBelum ada peringkat

- Chap 2Dokumen51 halamanChap 2Gemechu TeferaBelum ada peringkat

- Lecture 5Dokumen29 halamanLecture 5FarwaBelum ada peringkat

- Lica 2 MarksDokumen41 halamanLica 2 MarksVadivelu K RBelum ada peringkat

- 400 KV Switchyard - IDokumen70 halaman400 KV Switchyard - IRajeshwar Raj100% (7)

- Arc PhenomenonDokumen12 halamanArc PhenomenonMudit BarrhwalBelum ada peringkat

- CKT BreakerDokumen48 halamanCKT BreakerSharmishtha KulkarniBelum ada peringkat

- Lec 11Dokumen28 halamanLec 11Navneet KumarBelum ada peringkat

- Welding Technology HomeworkDokumen4 halamanWelding Technology HomeworkDara IsmailBelum ada peringkat

- Welding ForcesDokumen33 halamanWelding Forces019SAURABH GUPTABelum ada peringkat

- SMAW Welding Guide for BeginnersDokumen59 halamanSMAW Welding Guide for BeginnersSurya Lesmana100% (1)

- A Project On Circuit Breaker: Arnab Chatterjee EE-02 ROLL-95Dokumen21 halamanA Project On Circuit Breaker: Arnab Chatterjee EE-02 ROLL-95Somnath KhamaruBelum ada peringkat

- SMAWDokumen32 halamanSMAWvikasbhadoria9894Belum ada peringkat

- Arc WeldingDokumen40 halamanArc Welding20G062 NALVETHA BBelum ada peringkat

- What Is Arc Blow and How Do You Prevent It?Dokumen2 halamanWhat Is Arc Blow and How Do You Prevent It?amalhaj2013Belum ada peringkat

- Introduction To GMAWDokumen63 halamanIntroduction To GMAWRumman Ul AhsanBelum ada peringkat

- Rao Resistance welding galvanized steel sheetsDokumen7 halamanRao Resistance welding galvanized steel sheetsrohit mathankerBelum ada peringkat

- Features: Submerged Arc Welding (SAW) Is A CommonDokumen3 halamanFeatures: Submerged Arc Welding (SAW) Is A CommonPradeep LakumBelum ada peringkat

- Welding Processes PartIIDokumen34 halamanWelding Processes PartIIHandayani KesumadewiBelum ada peringkat

- Stud WeldingDokumen40 halamanStud WeldingKirandeep GandhamBelum ada peringkat

- EE540: Power System Transients and Insulation CoordinationDokumen51 halamanEE540: Power System Transients and Insulation CoordinationHania ZahraBelum ada peringkat

- GMAW Unit 1 Lesson 1: Objective: Demonstrate Proper Setup and Maintenance of GMAW EquipmentDokumen22 halamanGMAW Unit 1 Lesson 1: Objective: Demonstrate Proper Setup and Maintenance of GMAW EquipmentAd Man GeTigBelum ada peringkat

- Introduction To Circuit BreakersDokumen39 halamanIntroduction To Circuit BreakersHaziq TarmiziBelum ada peringkat

- GMAWDokumen7 halamanGMAWmostafaBelum ada peringkat

- Fusion Weld1Dokumen61 halamanFusion Weld1Sapto Adi PamungkasBelum ada peringkat

- Production of Magnetic Field Using SuperconductorsDokumen7 halamanProduction of Magnetic Field Using SuperconductorsSeenipandian RaviBelum ada peringkat

- MODULE6Dokumen52 halamanMODULE6anvay.shirsatBelum ada peringkat

- Arc Welding in DetailDokumen34 halamanArc Welding in DetailSohen PatelBelum ada peringkat

- ARC-2 - CopyDokumen59 halamanARC-2 - CopyMay FadlBelum ada peringkat

- Types of Arc WeldingDokumen20 halamanTypes of Arc WeldingEhigiator JosephBelum ada peringkat

- 11 Introduction To Circuit BreakersDokumen42 halaman11 Introduction To Circuit BreakersShovon RoyBelum ada peringkat

- Submergedarcwelding ForDokumen23 halamanSubmergedarcwelding ForDany aprianBelum ada peringkat

- HV Circuit BreakersDokumen135 halamanHV Circuit BreakerskjushnBelum ada peringkat

- Circuit BreakerDokumen86 halamanCircuit BreakerShashidhar KasthalaBelum ada peringkat

- Understanding Lightning ProtectionDokumen67 halamanUnderstanding Lightning Protectionsatish reddyBelum ada peringkat

- Junction Transistors: The Commonwealth and International Library: Applied Electricity and ElectronicsDari EverandJunction Transistors: The Commonwealth and International Library: Applied Electricity and ElectronicsBelum ada peringkat

- Ar SsmasDokumen1 halamanAr SsmasGokul RajanBelum ada peringkat

- ExpenceDokumen2 halamanExpenceGokul RajanBelum ada peringkat

- 4.1 Features of The Weld PreparationDokumen1 halaman4.1 Features of The Weld PreparationGokul RajanBelum ada peringkat

- JtdegtrtDokumen1 halamanJtdegtrtGokul RajanBelum ada peringkat

- Investing in Teacher: Investing For The FutureDokumen2 halamanInvesting in Teacher: Investing For The FutureGokul RajanBelum ada peringkat

- Hydrogen Induced Cold Cracking (HICC) But It Is Often Referred To by OtherDokumen1 halamanHydrogen Induced Cold Cracking (HICC) But It Is Often Referred To by OtherGokul RajanBelum ada peringkat

- Method B This Method Uses A Numerical Designation From The Table As Listed BelowDokumen1 halamanMethod B This Method Uses A Numerical Designation From The Table As Listed BelowGokul RajanBelum ada peringkat

- Iso 9001Dokumen3 halamanIso 9001Gokul RajanBelum ada peringkat

- MantramDokumen1 halamanMantramGokul RajanBelum ada peringkat

- Method A This Method Uses An Alpha/numerical Designation From The Tables As Listed BelowDokumen1 halamanMethod A This Method Uses An Alpha/numerical Designation From The Tables As Listed BelowGokul RajanBelum ada peringkat

- Crater Cracking: Avoiding Solidification Cracking in WeldsDokumen1 halamanCrater Cracking: Avoiding Solidification Cracking in WeldsGokul RajanBelum ada peringkat

- 5 Crater Cracking: Rev 1 January 2009 TIG Welding © TWI LTD 2009Dokumen1 halaman5 Crater Cracking: Rev 1 January 2009 TIG Welding © TWI LTD 2009Gokul RajanBelum ada peringkat

- Irregular Metal Transfer: Globular WeldingDokumen1 halamanIrregular Metal Transfer: Globular WeldingGokul RajanBelum ada peringkat

- Hydrogen Induced Cold Cracking (HICC) But It Is Often Referred To by OtherDokumen1 halamanHydrogen Induced Cold Cracking (HICC) But It Is Often Referred To by OtherGokul RajanBelum ada peringkat

- JHFDSDFGHDokumen1 halamanJHFDSDFGHGokul RajanBelum ada peringkat

- Constant Current Power Source: CharacteristicDokumen1 halamanConstant Current Power Source: CharacteristicGokul RajanBelum ada peringkat

- JHFDSDFGHDokumen1 halamanJHFDSDFGHGokul RajanBelum ada peringkat

- Constant Current Power Source: CharacteristicDokumen1 halamanConstant Current Power Source: CharacteristicGokul RajanBelum ada peringkat

- GHDFDokumen1 halamanGHDFGokul RajanBelum ada peringkat

- EgrnDokumen3 halamanEgrnGokul RajanBelum ada peringkat

- Om Tryambakam Yajamahe Sugandhim Pushtivardhanam Urvarukamiva Bandhanan Mrityor Mukshiya MaamritatDokumen1 halamanOm Tryambakam Yajamahe Sugandhim Pushtivardhanam Urvarukamiva Bandhanan Mrityor Mukshiya MaamritatGokul RajanBelum ada peringkat

- FMEA TemplateDokumen5 halamanFMEA TemplateGokul RajanBelum ada peringkat

- Electrical Technology 2007 (2006 Ad) PDFDokumen1 halamanElectrical Technology 2007 (2006 Ad) PDFGokul RajanBelum ada peringkat

- MagnesiumDokumen3 halamanMagnesiumIsidoro LópezBelum ada peringkat

- SR - No Description Drgno Elevation No. GriedDokumen6 halamanSR - No Description Drgno Elevation No. GriedGokul RajanBelum ada peringkat

- Paint - Notes Q A - 3Dokumen21 halamanPaint - Notes Q A - 3Gokul Rajan100% (1)

- ZirconiumDokumen4 halamanZirconiumIsidoro LópezBelum ada peringkat

- .Cover Sheet PDFDokumen3 halaman.Cover Sheet PDFGokul RajanBelum ada peringkat

- Important PointsDokumen1 halamanImportant PointsGokul RajanBelum ada peringkat