01 Intro PDF

Diunggah oleh

Rishabh JainJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

01 Intro PDF

Diunggah oleh

Rishabh JainHak Cipta:

Format Tersedia

Lecture 1

Introduction

Course Organisation

Process Control

Prof. Kannan M. Moudgalya

kannan at iitb dot ac dot in

IIT Bombay

Monday, 23 July 2013

Slides used in the course CL-417 in Autumn 2013

1/51 Process Control Introduction, Course Organisation

Outline

I What is process control?

I Examples

I Fluid heater

I Distillation column

I Mixing system

I Flow system

I Single Board Heater System (SBHS)

I Types of variables from control point of

view

I Applied to the above examples

I Course organisation

2/51 Process Control Introduction, Course Organisation

Birds Eye View of Plant Operation

Plant level: what to make, how much to make

Goal: Overall profitability

Possible tool: Linear Programming

Unit level: Fixing the levels of different variables

Flow rate of coolant, reflux ratio, etc.

Possible tool: Model predictive control

Variable level: Achieving intended levels

How to get a specified flow rate, etc.

Possible tool: PID control

Will study mainly the last part in this course

3/51 Process Control Introduction, Course Organisation

What is Process Control?

I It is an area that deals with control of

processes

I Objective: maintaining variables at

desired values

I If deviation, manipulate some other

quantities

4/51 Process Control Introduction, Course Organisation

Benefits of Process Control

I Safety

I Performance: maximising profits, etc.

I Being good to environment

5/51 Process Control Introduction, Course Organisation

Example Processes

6/51 Process Control Introduction, Course Organisation

Fluid heater

Heats the process stream with the help of a

heating medium

7/51 Process Control Introduction, Course Organisation

Distillation Column

PT

LT hD

Coolant Exit AT

Reflux, R Distillate: D, xD

Feed

Heat

hB

LT

AT

Bottoms: B, xB

Maintain compositions at desired values

8/51 Process Control Introduction, Course Organisation

Mixing Process

Control

Mixture Valve

A, B

x1 , w1

Pure A

x2 = 1

w2 =?

x, w

Mix two streams to get a desired

concentration

9/51 Process Control Introduction, Course Organisation

Flow System

Qi (t)

h(t)

Q(t) = x(t)h(t)

Maintain height by adjusting valve

10/51 Process Control Introduction, Course Organisation

Plant in the Single Board Heater System

Heater

Plant

Fan

Maintain temperature by heating/cooling

11/51 Process Control Introduction, Course Organisation

System

We will use the words process and system

interchangeably

12/51 Process Control Introduction, Course Organisation

Variables from Control Perspective

Disturbance

Controlled

System

Manipulated

13/51 Process Control Introduction, Course Organisation

How the variables are used

I Manipulated variables are adjusted

I to remove the effect of disturbance

variables

I on the controlled variables

14/51 Process Control Introduction, Course Organisation

Controlled, Disturbance, Manipulated

Variables

Controlled variable (CV): Variable to be

controlled.

I We wish to maintain this at a

particular value.

Disturbance variable (DV): Variables that cause

changes in CV.

I We have no handle on these.

Manipulated variable (MV): Variables that can

offset DV.

I Also known as control effort.

MV are not free - have to pay.

15/51 Process Control Introduction, Course Organisation

Variables from input-output point of view

Input Output

Disturbance

Controlled

System

Manipulated

16/51 Process Control Introduction, Course Organisation

Examples

17/51 Process Control Introduction, Course Organisation

Fluid heater: heats a process stream

Temperature of the process stream at the exit

is a

1. Controlled variable

2. Manipulated variable

3. Disturbance variable

Answer: Controlled variable

18/51 Process Control Introduction, Course Organisation

Fluid heater: heats a process stream

Temperature of the process stream at the

inlet is a

1. Controlled variable

2. Manipulated variable

3. Disturbance variable

Answer: Disturbance variable

19/51 Process Control Introduction, Course Organisation

Fluid heater: heats a process stream

The flow rate of the heating medium used is a

1. Controlled variable

2. Manipulated variable

3. Disturbance variable

Answer: Manipulated variable

20/51 Process Control Introduction, Course Organisation

Fluid heater: A Summary

Heats the process stream with a heating

medium

I Controlled variable (CV): Temperature of

the exit stream on process side - set point

I Disturbance variable (DV): Inlet

conditions on process fluid

I Manipulated variable (MV): Temperature

or flow rate of the heating medium

21/51 Process Control Introduction, Course Organisation

Schematic of Distillation Column

PT

LT hD

Coolant Exit AT

Reflux, R Distillate: D, xD

Feed

Heat

hB

LT

AT

Bottoms: B, xB

22/51 Process Control Introduction, Course Organisation

Recall our variables

I Manipulated variables are adjusted

I to remove the effect of disturbance

variables

I on the controlled variables

23/51 Process Control Introduction, Course Organisation

Distillation Column: A Control Strategy

PT

hD LT

Coolant Exit

AT

Reflux, R Distillate: D, xD

Feed

Heat

hB ?

LT

AT

Bottoms: B, xB

24/51 Process Control Introduction, Course Organisation

Distillation Column: A Control Strategy

I Bottoms withdrawal rate controls

bottoms level

I Distillate rate controls top drum level

I Reflux rate controls top composition

I Example of a multivariable system

25/51 Process Control Introduction, Course Organisation

Mixing Process

I Mixing of two

streams

Control I Variable

Mixture Valve

A, B stream has

composition

x1 , w1

(x1 ) varying

Pure A I Want output

x2 = 1 composition

w2 =? constant

I Control

x, w streams flow

can be

changed

26/51 Process Control Introduction, Course Organisation

Feed concentration

I Feed concentration is, in general, a

1. Manipulated variable

2. Disturbance variable

3. Controlled variable

I Answer: Disturbance variable

I Feed temperature is similar

I Feed flow rate is decided by other

considerations, however!

27/51 Process Control Introduction, Course Organisation

Course Organisation

28/51 Process Control Introduction, Course Organisation

Textbooks and References

I Process Dynamics and Control

Seborg, Edgar & Mellichamp

Wiley (2006)

I Digital Control

Kannan M. Moudgalya

John Wiley & Sons (2007)

I Last few years video course and slides

29/51 Process Control Introduction, Course Organisation

Distribution of Marks

Assignment 10

Discussion (classroom and Forum) 10

Scilab programming 10

Labs 10

First quiz (1 hour) 5

Second quiz (1 hour) 10

Midsem exam (2 hour) 20

Endsem exam (2 hour) 25

Total 100

30/51 Process Control Introduction, Course Organisation

Scilab

I A good open source alternative to Matlab

31/51 Process Control Introduction, Course Organisation

What is Scilab?

I Advanced computational environment

I Uses state of the art numerical

computational engines, such as, linpack,

eispack, lapack, odepack and dassl

I Has a large number of built-in functions

(c/fortran)

I eigenvalue, eigenvector computations,

decompositions (svd), inverses

I numerical solution of differential equations

I etc.

I Has a built-in high level language:

scilab:c = c:assembly

I Has several functions built using the high

level language

32/51 Process Control Introduction, Course Organisation

CNES Talk

I Scilab is used extensively in CNES

I CNES launches Ariane rockets

I Ariane has placed several of our satellites

in orbit

I See the talk:

Use of Scilab for Space Mission Analysis

and Flight Dynamics Activities

I by Thierry Martin

I Senior Manager, CNES

33/51 Process Control Introduction, Course Organisation

Scilab

I Story of cost of Matlab to SMEs

I People with Scilab knowledge are in short

supply

I May be useful to get jobs

I Useful to entrepreneurs also

I Visit http://scilab.in - run by us

I Close to 200 textbook companions

I Can also execute them on the GARUDA

cloud

34/51 Process Control Introduction, Course Organisation

Lab

35/51 Process Control Introduction, Course Organisation

Picture of the single board heater system

36/51 Process Control Introduction, Course Organisation

What does this system do?

Controlling the temperature of a plant

I by heating with current

I by cooling with a fan

More details here

37/51 Process Control Introduction, Course Organisation

What does SBHS have?

I Plant

I Micro controller

I Sensor - temperature

I Actuator - current

38/51 Process Control Introduction, Course Organisation

Sample Control Experiments

I Step and ramp response identification

I Frequency testing, leading to Bode plots

I P, PI, PID tuning

I 2-DOF pole placement controller

I Internal model controller

I Self tuning and simple adaptive controller

I Auto tune testing

I Minimum and generalised minimum

variance controller

I PRBS and closed loop identification

39/51 Process Control Introduction, Course Organisation

Pricing

I Available for Rs. 3,000

I Design is available as open source with

bill of materials

I Can be built for less than Rs. 2,000

40/51 Process Control Introduction, Course Organisation

Virtual Experimentation

I 40 units are available

I Accessible through Internet

I 40 students can work simultaneously

I Each can try out their algorithm

41/51 Process Control Introduction, Course Organisation

Time Slots

I Time constant = 30 seconds

I Possible to do one experiment within 7-8

minutes

I One hour is enough for experimentation

I 24 one hour slots in a day

I For 40 SBHS, there are 960 slots in a day!

42/51 Process Control Introduction, Course Organisation

Slot Booking System

I A student books a slot through Moodle

I Chooses a SBHS (amongst 40) also

I Tries to access this SBHS at the

appointed time

I Python server validates

I eligibility to access that SBHS

I calculates the balance time available

I If validated, informs the balance time

available

I Connection is established

I Up to 40 people can access the machines

in this way

43/51 Process Control Introduction, Course Organisation

Slot booking rules

I Will be explained later

44/51 Process Control Introduction, Course Organisation

Part of Virtual Lab

I Potential users can try remotely

I If convinced of its use, can acquire

sufficient numbers for hands on training

45/51 Process Control Introduction, Course Organisation

What is learnt today

I Introduction to Process Control

I Variables

I Set point

I Controlled (= output) variable

I Manipulated (= control effort, input) variable

I Disturbance variable (= input)

I Process Examples

I Heat exchanger

I Distillation column

I Mixing

I Course organisation

46/51 Process Control Introduction, Course Organisation

Thanks

47/51 Process Control Introduction, Course Organisation

Details of single board heater system

I Designed and developed at IIT Bombay

I Consists of a heater assembly, fan,

temperature sensor, microcontroller

(ATmega16) and associated circuitry

I Heater assembly

I Consists of an iron plate placed at a distance

of about 3.5 mm from the nichrome coil

I Gets heated on passage of current

I Computer fan

I Positioned below the plate

I Meant for cooling the assembly

I The temperature is sensed by the

temperature sensor, AD590

I Reading in Kelvin scale

To return, click here

48/51 Process Control Introduction, Course Organisation

ATmega16

I Is a 8-bit Microcontroller with advanced

RISC Architecture

I Provides Up to 16MIPS throughput at

16MHZ

I Has 16K bytes (8K X 16) of In-system

programmable Flash, 512 bytes of

EEPROM and 1K byte of internal SRAM

I Two 8-bit Timer/Counter and one 16-bit

Timer/Counter

I Four PWM channels

I 8-channel, 10-bit ADC

I Programmable serial USART

I Operating voltage: 4.5-5.5V

49/51 Process Control Introduction, Course Organisation

What is special about this system?

I The time constant is less than 1 minute

I Can see meaningful (and noisy)

measurements with naked eye

I Can do a realistic experiment in 10

minutes

I Suitable for carrying out ALL experiments

of a few control courses

I Only need 220V power supply and a PC

I Easy to carry

I Costs only Rs. 3,000

I Design is open source!

To return, click here

50/51 Process Control Introduction, Course Organisation

Thanks

I kannan@iitb.ac.in

51/51 Process Control Introduction, Course Organisation

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Humour and Metaphor 2017Dokumen73 halamanHumour and Metaphor 2017Rishabh Jain100% (1)

- Sound Devices, Rhyme and MetreDokumen74 halamanSound Devices, Rhyme and MetreRishabh JainBelum ada peringkat

- PI500A Series Basic Frequency Inverter User Manual: 1. ForewordDokumen16 halamanPI500A Series Basic Frequency Inverter User Manual: 1. ForewordOdali BatistaBelum ada peringkat

- 1.4 Layer of ProtectionDokumen41 halaman1.4 Layer of ProtectionSrinivas BobbyBelum ada peringkat

- Profitability AnalysisDokumen43 halamanProfitability AnalysisAvinash Iyer100% (1)

- InfoPLC Net EIO0000001762.00 M221 Temperature ControlDokumen30 halamanInfoPLC Net EIO0000001762.00 M221 Temperature ControlMateo QuispeBelum ada peringkat

- Pressure Control تقريرDokumen14 halamanPressure Control تقريرali salmanBelum ada peringkat

- VFD-Variable Frequency Drive-Motor Speed ControlDokumen126 halamanVFD-Variable Frequency Drive-Motor Speed Controlecsa taller0% (1)

- Design and Rating of Fired HeatersDokumen33 halamanDesign and Rating of Fired HeatersRishabh Jain100% (1)

- Sign LanguageDokumen107 halamanSign LanguageRishabh JainBelum ada peringkat

- Cascade Control BasicsDokumen2 halamanCascade Control Basicsjsrplc7952Belum ada peringkat

- MOM - Solution - Set ADokumen5 halamanMOM - Solution - Set ARishabh JainBelum ada peringkat

- Sample SolutionsDokumen10 halamanSample SolutionsRishabh JainBelum ada peringkat

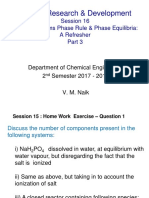

- Product RD Session 16 - Phase Eqm Part 3Dokumen38 halamanProduct RD Session 16 - Phase Eqm Part 3Rishabh JainBelum ada peringkat

- Bma 12e SM CH 01 FinalDokumen3 halamanBma 12e SM CH 01 FinalAmandeep SinghBelum ada peringkat

- Pinto MadnessDokumen16 halamanPinto MadnessRishabh JainBelum ada peringkat

- CL409 GraphDokumen1 halamanCL409 GraphRishabh JainBelum ada peringkat

- Selection of The Economic Objective FunctionDokumen11 halamanSelection of The Economic Objective FunctionRishabh JainBelum ada peringkat

- cl405 MT 2016Dokumen1 halamancl405 MT 2016shashi kant kumarBelum ada peringkat

- Mini ProjectDokumen2 halamanMini ProjectRishabh JainBelum ada peringkat

- Endsem PEDokumen5 halamanEndsem PERishabh JainBelum ada peringkat

- DepreciationDokumen37 halamanDepreciationRishabh JainBelum ada peringkat

- CL-455: Design Lab 1 Task 5: Simulation of A Sulphuric Acid Plant Maximum Marks: 10 Submission On 31-08-2017 at 2 PM Groups: Same As For Task-4Dokumen2 halamanCL-455: Design Lab 1 Task 5: Simulation of A Sulphuric Acid Plant Maximum Marks: 10 Submission On 31-08-2017 at 2 PM Groups: Same As For Task-4Rishabh JainBelum ada peringkat

- Word Formation ProcessesDokumen30 halamanWord Formation ProcessesRishabh JainBelum ada peringkat

- Semantics - Lexical and PhrasalDokumen134 halamanSemantics - Lexical and PhrasalRishabh JainBelum ada peringkat

- Syntax LecDokumen66 halamanSyntax LecRishabh Jain0% (1)

- Sociolinguistics 2017Dokumen66 halamanSociolinguistics 2017Rishabh JainBelum ada peringkat

- LG and Thought 2017Dokumen83 halamanLG and Thought 2017Rishabh JainBelum ada peringkat

- Syntax TransformationsDokumen15 halamanSyntax TransformationsRishabh JainBelum ada peringkat

- Writing Systems 2017Dokumen105 halamanWriting Systems 2017Rishabh JainBelum ada peringkat

- Myth About GrammarDokumen24 halamanMyth About GrammarRishabh JainBelum ada peringkat

- Morphology Lecture 1Dokumen38 halamanMorphology Lecture 1Rishabh JainBelum ada peringkat

- MidSem Answer Key 2017Dokumen4 halamanMidSem Answer Key 2017Rishabh JainBelum ada peringkat

- Design FeaturesDokumen20 halamanDesign FeaturesRishabh JainBelum ada peringkat

- HS309 Lec 1 - 3Dokumen40 halamanHS309 Lec 1 - 3Rishabh JainBelum ada peringkat

- Con Lang 2017Dokumen61 halamanCon Lang 2017Rishabh JainBelum ada peringkat

- ViewerDokumen52 halamanViewerFinal YearBelum ada peringkat

- Sujit2014 PDFDokumen18 halamanSujit2014 PDFirqoviBelum ada peringkat

- GDGDFDokumen8 halamanGDGDFHoàng Minh ÁiBelum ada peringkat

- PID Control of Inverted Pendulum Using Adams and Matlab Co-SimulationDokumen4 halamanPID Control of Inverted Pendulum Using Adams and Matlab Co-SimulationEzequielBritosBelum ada peringkat

- SX80 Im P323 35 en PDFDokumen102 halamanSX80 Im P323 35 en PDFJorge TampanBelum ada peringkat

- Program Function Instruction Manual: MR13 Series Digital ControllerDokumen4 halamanProgram Function Instruction Manual: MR13 Series Digital ControllerChristianBelum ada peringkat

- Prosec: Programmable ControllerDokumen16 halamanProsec: Programmable Controllerdanie1234Belum ada peringkat

- Connecting A Rockwell Logix CPU Using EtherNet - IP Eth1000 - Large - JPG Communications Directly To A A800 VFD Using The A8NEIP - 2P Module Version 1.Dokumen48 halamanConnecting A Rockwell Logix CPU Using EtherNet - IP Eth1000 - Large - JPG Communications Directly To A A800 VFD Using The A8NEIP - 2P Module Version 1.Alfredo Israel Rodríguez SotoBelum ada peringkat

- CDS 101/110a: Lecture 9-1 PID Control: Richard M. Murray 24 November 2008Dokumen14 halamanCDS 101/110a: Lecture 9-1 PID Control: Richard M. Murray 24 November 2008cooldoubtlessBelum ada peringkat

- Slides Workshop Finn HaugenDokumen63 halamanSlides Workshop Finn HaugenIbrahimDewaliBelum ada peringkat

- DBW 4 ManualDokumen21 halamanDBW 4 ManualsilverfrostlscBelum ada peringkat

- GT ControlDokumen3 halamanGT ControlHarinBelum ada peringkat

- Incubator of TermaksDokumen24 halamanIncubator of TermaksVanPrimaBelum ada peringkat

- Parameter GEN #1 GEN #2 GEN #3 Comments ConfigureDokumen1 halamanParameter GEN #1 GEN #2 GEN #3 Comments ConfigureJose FavaBelum ada peringkat

- Simulator ManualDokumen29 halamanSimulator Manualnubbler0% (1)

- PID Controller Tuning For Integrating and Unstable Processes With Time DelayDokumen13 halamanPID Controller Tuning For Integrating and Unstable Processes With Time DelayAnonymous WkbmWCa8MBelum ada peringkat

- Controls YsDokumen17 halamanControls Ysbamboo shackBelum ada peringkat

- 1 s2.0 S1110016815000563 Main PDFDokumen13 halaman1 s2.0 S1110016815000563 Main PDFvale1299Belum ada peringkat

- Pib4146 Edg6000 PDFDokumen7 halamanPib4146 Edg6000 PDFUNIPOWER2013Belum ada peringkat

- Metodo de Ziegler-NicholsDokumen3 halamanMetodo de Ziegler-Nicholsjuan daniel camas cruzBelum ada peringkat

- Ruling Quantum Technologies With Embedded Rust: Robert JördensDokumen19 halamanRuling Quantum Technologies With Embedded Rust: Robert JördenstsgglbyxBelum ada peringkat

- FR-A800 Plus For Roll To RollDokumen40 halamanFR-A800 Plus For Roll To RollCORTOCIRCUITANTEBelum ada peringkat

- HA465038U005 Issue 5 PDFDokumen242 halamanHA465038U005 Issue 5 PDFMohammed MushtahaBelum ada peringkat