Super Invar: Ational Lectronic Lloys

Diunggah oleh

MuhlisaApriliaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Super Invar: Ational Lectronic Lloys

Diunggah oleh

MuhlisaApriliaHak Cipta:

Format Tersedia

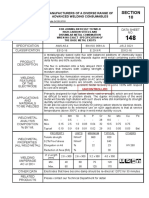

SUPER INVAR

CHEMICAL COMPOSITION %

Chemical Element Super Invar

Nickel 31.26

Chromium .03

Manganese .39

Silicon .09

Carbon .05

Aluminum .07

Sulfur

Cobalt

.01

5.36

Invar (36% NI-Balance Iron) Alloy has been the metal of choice for low expansion

Copper .08

applications for years. Super-Invar (31% NI, 5% Co, Balance Iron) has found

MECHANICAL PROPERTIES

Property Super Invar some favor because it has a near zero coefficient of thermal expansion over

Density 0.294 lb/cubic in

Hardness 77 RB a limited temperature range. The useful range of Super Invar originally was

Tensile Strength 69800 psi

Yield Strength 43900 psi limited to between 32 to + 275C because the material begins to transform

Elongation 2 38%

Modulus of Elasticity 21.5 x 10 psi from Austenite to Martinsite at temperatures below 32F. Because of the slight

variations in chemistry in todays version of this alloy, these ranges may fluctuate.

Poissons Ratio .234

Linear coefficient of thermal expansion cm. per cm.

In addition, the cold or hot working of material can affect these variables.

per F x 106

Temp. range F Super Invar

30 to 100 9.4

30 to 200 9.4 Super Invar is tough and gummy, not hard or abrasive. Tools tend to plow instead

30 to 300 8.8

30 to 350 9.0 of cut, resulting in long stringy chips. Tools must be sharp, feed and speed

30 to 400

30 to 425

8.7

8.9

low to avoid heat and distortion. The use of a coolant is recommended for all

30 to 450

30 to 500

9.0

9.4

machining operations. Machinability similar to Kovar, Stainless 300 series, and

30 to 550 10.2 Monel Alloys has been reported. Ni-Fe Alloys generally have a tendency to develop

30 to 600 10.4

30 to 700 11.3 a surface scale during hot working that penetrates the surface. For this reason

30 to 800 12.1

30 to 900 13.0 machining allowances must be increased to eliminate the deep surface oxide. The

30 to 1000 13.9

initial cut is frequently the most difficult.

EAST COAST

An ISO Certified Corporation 3 Fir Court, Oakland, NJ 07436

Specialty Metal Service Center 201-337-9400 Fax: 201-337-9698

Dedicated to Customer Service & Quality Toll Free: 800-524-4309

Email: Sales@nealloys.com

National Electronic Alloys WEST COAST

1335 East Warner Ave., Santa Ana, CA 92705

www.nealloys.com 714-556-5561 Fax: 714-556-5562

Toll Free: 877-632-9378

Email: Sales@nealloyswest.com

Anda mungkin juga menyukai

- CW603N - Stång - Eng - Utg 4Dokumen4 halamanCW603N - Stång - Eng - Utg 4NadaBelum ada peringkat

- 316l Austenitic Stainless Steel BarDokumen3 halaman316l Austenitic Stainless Steel Barதமிழன் இராமசாமிBelum ada peringkat

- Alloy 410S Spec SheetDokumen2 halamanAlloy 410S Spec SheetPrakash SundharamBelum ada peringkat

- Specification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Dokumen2 halamanSpecification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Felipe A. Gutiérrez M.Belum ada peringkat

- Alloy 410s Spec SheetDokumen2 halamanAlloy 410s Spec SheetALONSO GOMEZBelum ada peringkat

- DS Alloy 316 316LDokumen2 halamanDS Alloy 316 316LshenBelum ada peringkat

- Invar 36Dokumen3 halamanInvar 36TrentStewartLaCourBelum ada peringkat

- Data Sheet CuZn20Al2AsDokumen1 halamanData Sheet CuZn20Al2AsJean Carlos Reyna PascualBelum ada peringkat

- Uns s32760Dokumen3 halamanUns s32760NitinBelum ada peringkat

- Al Extrusion Power ElectronicsDokumen43 halamanAl Extrusion Power ElectronicsR JBelum ada peringkat

- Aero Metal Alliance Aluminium Alloy QQ A 2504 0 Sheet 196Dokumen2 halamanAero Metal Alliance Aluminium Alloy QQ A 2504 0 Sheet 196jayalakshmivinothBelum ada peringkat

- Alloy904L SpecSheetDokumen2 halamanAlloy904L SpecSheetROYAL LION GAMERBelum ada peringkat

- Alloy 276 Spec SheetDokumen3 halamanAlloy 276 Spec SheetJAYA BHARATHA REDDYBelum ada peringkat

- Nitro Nic 60Dokumen4 halamanNitro Nic 60rizky efrinaldoBelum ada peringkat

- Kobel NicroDokumen1 halamanKobel NicroBHARAT KBelum ada peringkat

- Wilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200Dokumen2 halamanWilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200williamBelum ada peringkat

- UNS S32205: Duplex Stainless 2205 (UNS S32205) Is A Chromium-Nickel-Molybdenum-Nitrogen Stainless SteelDokumen3 halamanUNS S32205: Duplex Stainless 2205 (UNS S32205) Is A Chromium-Nickel-Molybdenum-Nitrogen Stainless SteelCemerlang StudiBelum ada peringkat

- Alloy321 SpecSheetDokumen2 halamanAlloy321 SpecSheetVinod tiwariBelum ada peringkat

- Nitronic 50 SheetDokumen3 halamanNitronic 50 SheetSam PeñaBelum ada peringkat

- Medium Carbon Steel: Nearest StandardDokumen2 halamanMedium Carbon Steel: Nearest StandardMouna KallelBelum ada peringkat

- High Speed Steel Round BarDokumen4 halamanHigh Speed Steel Round BarMANJEET KUMARBelum ada peringkat

- CW617N - Stång - Eng - Utg 3Dokumen4 halamanCW617N - Stång - Eng - Utg 3Jarco PetrinBelum ada peringkat

- BohlerDokumen2 halamanBohlerjupiter zBelum ada peringkat

- Types of Materials: MetalsDokumen33 halamanTypes of Materials: MetalsKutsu ShidaBelum ada peringkat

- Data Sheet MaragingDokumen2 halamanData Sheet MaragingspibluBelum ada peringkat

- Stainless Steel 310 Refractory AnchorsDokumen3 halamanStainless Steel 310 Refractory AnchorsSaravana KumarBelum ada peringkat

- Silicon Bronze 655: Herculoy®, High-Silicon Bronze A, UNS C65500, H06 (50%) Temper RodDokumen2 halamanSilicon Bronze 655: Herculoy®, High-Silicon Bronze A, UNS C65500, H06 (50%) Temper RodJay PBelum ada peringkat

- 301-301LN Stainless SteelsDokumen4 halaman301-301LN Stainless SteelsTeka KamBelum ada peringkat

- 253 MA-NF AC/DC: Covered ElectrodesDokumen1 halaman253 MA-NF AC/DC: Covered ElectrodesElMacheteDelHuesoBelum ada peringkat

- Alloy 330 Spec SheetDokumen2 halamanAlloy 330 Spec SheetArman MominBelum ada peringkat

- Specification Sheet: Alloy 316/316L Stainless SteelDokumen3 halamanSpecification Sheet: Alloy 316/316L Stainless SteelSaúl L Hdez TBelum ada peringkat

- Duplex Stainless Steel 2304 Spec Sheet for Weight Savings & Corrosion ResistanceDokumen2 halamanDuplex Stainless Steel 2304 Spec Sheet for Weight Savings & Corrosion ResistanceDeepak TdBelum ada peringkat

- Mechanical and chemical values for Super Duplex UNS 32760 butt weldDokumen1 halamanMechanical and chemical values for Super Duplex UNS 32760 butt weldisupmanBelum ada peringkat

- Carbon Hollow Bar: (32 To 250 MM OD) (254 To 610 MM OD)Dokumen2 halamanCarbon Hollow Bar: (32 To 250 MM OD) (254 To 610 MM OD)Richard Vica CalvoBelum ada peringkat

- High-Strength Maraging Steel Data SheetDokumen2 halamanHigh-Strength Maraging Steel Data SheetdavideBelum ada peringkat

- 17-4 Fi Us enDokumen10 halaman17-4 Fi Us ennaeem akramBelum ada peringkat

- 3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMDokumen1 halaman3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMumarBelum ada peringkat

- Monel 400 Data SheetDokumen1 halamanMonel 400 Data SheetalextentwentyBelum ada peringkat

- Hitchiner-Quick Facts and General TolerancesDokumen2 halamanHitchiner-Quick Facts and General Tolerancesjavo01280% (1)

- Alloy: C97300: Typical UsesDokumen2 halamanAlloy: C97300: Typical UsesalextentwentyBelum ada peringkat

- Ceramic Fibre Boards: AvailabilityDokumen2 halamanCeramic Fibre Boards: AvailabilitysmrndrdasBelum ada peringkat

- High Performance Stainless Takes The Gall: Properties & General DataDokumen2 halamanHigh Performance Stainless Takes The Gall: Properties & General Datajoker63000Belum ada peringkat

- D2 1.2379 SKD11 Flat BarDokumen4 halamanD2 1.2379 SKD11 Flat BarMANJEET KUMARBelum ada peringkat

- PNA282 - C51900 - CuSn6 - PB103 - Technical Data SheetDokumen2 halamanPNA282 - C51900 - CuSn6 - PB103 - Technical Data Sheetstrip1Belum ada peringkat

- LATONDokumen1 halamanLATONAlan GutierrezBelum ada peringkat

- ST 321 SpecificationDokumen2 halamanST 321 SpecificationEl BaranBelum ada peringkat

- Nimoten Plus 535 A: LOW ALLOY STEEL (Nimoten Series)Dokumen1 halamanNimoten Plus 535 A: LOW ALLOY STEEL (Nimoten Series)satnamBelum ada peringkat

- Austnitic Stainless Steel 316 316LDokumen2 halamanAustnitic Stainless Steel 316 316LbladdeeBelum ada peringkat

- Alloy904L SpecSheet PDFDokumen2 halamanAlloy904L SpecSheet PDFPieter BrodeouxBelum ada peringkat

- UNSDokumen42 halamanUNSPaolo Osorio WongBelum ada peringkat

- Ceramic Fabrication Methods (Iib) : Glass Forming CementationDokumen26 halamanCeramic Fabrication Methods (Iib) : Glass Forming CementationAtakan BüyükBelum ada peringkat

- Page - 5Dokumen1 halamanPage - 5Bharat KumaneBelum ada peringkat

- Nicalloy Fe 3 Basic Coated Nickel Based ElectrodeDokumen1 halamanNicalloy Fe 3 Basic Coated Nickel Based ElectroderravibharathBelum ada peringkat

- SS430Dokumen2 halamanSS430RavinJohnBelum ada peringkat

- Nimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)Dokumen1 halamanNimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)satnamBelum ada peringkat

- Aalco Metals LTD Stainless Steel ASTM A815 S31803 261Dokumen2 halamanAalco Metals LTD Stainless Steel ASTM A815 S31803 261Irvin PajueloBelum ada peringkat

- Data 9018 B3 LDokumen2 halamanData 9018 B3 LAntonio Torres (Volcomtony)Belum ada peringkat

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryDari EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryBelum ada peringkat

- Titi PanDokumen6 halamanTiti PanMuhlisaApriliaBelum ada peringkat

- ngc2013 Proceedings PDFDokumen243 halamanngc2013 Proceedings PDFMuhlisaAprilia100% (1)

- 400 407 PDFDokumen8 halaman400 407 PDFMuhlisaApriliaBelum ada peringkat

- Moisture - Content - Ocr Rms Kadar AirDokumen9 halamanMoisture - Content - Ocr Rms Kadar AirPali MeitaBelum ada peringkat

- Buku Rumus Kadar AirDokumen12 halamanBuku Rumus Kadar Airwinda febrianaBelum ada peringkat

- Jmmce20090500007 37708377 PDFDokumen12 halamanJmmce20090500007 37708377 PDFMuhlisaApriliaBelum ada peringkat

- Jan-27, 1959 ' - G. Baecklund 2,870,866: Method of Obtaining Acetaldehyde ' Filed June 14, 1952Dokumen3 halamanJan-27, 1959 ' - G. Baecklund 2,870,866: Method of Obtaining Acetaldehyde ' Filed June 14, 1952MuhlisaApriliaBelum ada peringkat

- XRF Sample Preparation MethodsProcedure - Mineral ProcessingMetallurgy ResearchTestingDokumen22 halamanXRF Sample Preparation MethodsProcedure - Mineral ProcessingMetallurgy ResearchTestingMuhlisaApriliaBelum ada peringkat

- Amil AlkoholDokumen6 halamanAmil AlkoholJ FadliBelum ada peringkat

- PLC of MaggiDokumen19 halamanPLC of Maggikrati agarwalBelum ada peringkat

- LTC2410 Datasheet and Product Info - Analog DevicesDokumen6 halamanLTC2410 Datasheet and Product Info - Analog DevicesdonatoBelum ada peringkat

- Clinical behavior analysis and RFT: Conceptualizing psychopathology and its treatmentDokumen28 halamanClinical behavior analysis and RFT: Conceptualizing psychopathology and its treatmentAnne de AndradeBelum ada peringkat

- VANSINA, Jan. Art History in AfricaDokumen250 halamanVANSINA, Jan. Art History in AfricaRaphaelTim100% (1)

- Key Elements of Participation and Conflict Resolution in a DemocracyDokumen6 halamanKey Elements of Participation and Conflict Resolution in a DemocracyAbhinayBelum ada peringkat

- Case Study On Maruti 800Dokumen4 halamanCase Study On Maruti 800Nizar MesaniBelum ada peringkat

- Linear Piston Actuators: by Sekhar Samy, CCI, and Dave Stemler, CCIDokumen18 halamanLinear Piston Actuators: by Sekhar Samy, CCI, and Dave Stemler, CCIapi-3854910Belum ada peringkat

- Solwezi General Mental Health TeamDokumen35 halamanSolwezi General Mental Health TeamHumphreyBelum ada peringkat

- V60 Ventilator Specifications PDFDokumen4 halamanV60 Ventilator Specifications PDFJonathan Issac Dominguez RamirezBelum ada peringkat

- OJT Form 03 Performance EvaluationDokumen2 halamanOJT Form 03 Performance EvaluationResshille Ann T. SalleyBelum ada peringkat

- What Are Your Observations or Generalizations On How Text/ and or Images Are Presented?Dokumen2 halamanWhat Are Your Observations or Generalizations On How Text/ and or Images Are Presented?Darlene PanisaBelum ada peringkat

- Classification of MatterDokumen2 halamanClassification of Matterapi-280247238Belum ada peringkat

- Ukraine and Russia E IRDokumen287 halamanUkraine and Russia E IRtatgirBelum ada peringkat

- FAI - Assignment Sheet (Both Assignments)Dokumen5 halamanFAI - Assignment Sheet (Both Assignments)Wilson WongBelum ada peringkat

- 2018 Diesel TOYOTA Jun11Dokumen90 halaman2018 Diesel TOYOTA Jun11eko sulistyo75% (4)

- Padmavati Gora BadalDokumen63 halamanPadmavati Gora BadalLalit MishraBelum ada peringkat

- Hong Kong A-Level Chemistry Book 3ADokumen69 halamanHong Kong A-Level Chemistry Book 3AMARENG BERNABEBelum ada peringkat

- Unit Test Nervous System 14.1Dokumen4 halamanUnit Test Nervous System 14.1ArnelBelum ada peringkat

- Haier's Performance Management in Other CulturesDokumen8 halamanHaier's Performance Management in Other CulturesSubhransu SahooBelum ada peringkat

- Mpce 24Dokumen39 halamanMpce 24Sachin Mehla0% (1)

- 1 CAT O&M Manual G3500 Engine 0Dokumen126 halaman1 CAT O&M Manual G3500 Engine 0Hassan100% (1)

- SLU Missalette 2016 Capping (Not-Final)Dokumen18 halamanSLU Missalette 2016 Capping (Not-Final)Teanu Jose Gabrillo TamayoBelum ada peringkat

- Eports: India's Defiance of Religious Freedom: A Briefing On Anti-Conversion' LawsDokumen16 halamanEports: India's Defiance of Religious Freedom: A Briefing On Anti-Conversion' LawsGabriela StevensBelum ada peringkat

- Readme cljM880fw 2305076 518488 PDFDokumen37 halamanReadme cljM880fw 2305076 518488 PDFjuan carlos MalagonBelum ada peringkat

- IntegrityDokumen5 halamanIntegrityPritam Kumar100% (1)

- Why study operating systems and how they workDokumen12 halamanWhy study operating systems and how they workMario ManihurukBelum ada peringkat

- DelhiDokumen40 halamanDelhiRahul DharBelum ada peringkat

- Chapter 1 Critical Thin...Dokumen7 halamanChapter 1 Critical Thin...sameh06Belum ada peringkat

- Product Differentiation and Market Segmentation As Alternative Marketing StrategiesDokumen7 halamanProduct Differentiation and Market Segmentation As Alternative Marketing StrategiesCaertiMBelum ada peringkat

- ccpc15 Supportive and Preventive WorkbookDokumen30 halamanccpc15 Supportive and Preventive WorkbookJeremy HamptonBelum ada peringkat