Risk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal Format

Diunggah oleh

nsadnanDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Risk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal Format

Diunggah oleh

nsadnanHak Cipta:

Format Tersedia

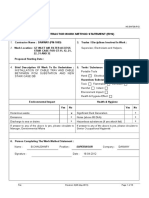

HS.SAF.09.

F12

CONTRACTOR WORK METHOD STATEMENT (EHS)

1. Contractor Name : SOJITZ 3. Trades / Disciplines Involved In Work :

2. Work Location : EXISTING RT CONTROL Supervisor, Electricians and Helpers.

BUILDING PL 1 & PL 2.

Proposed Starting Date :

4. Brief Description Of Work To Be Undertaken : 5. Tools / Substance

Portable Tools

TRANSFORMER RECTIFIER GROUPS - PHASE 1

- Installation Of Cable Tray, Cable Ladder at Hand Electrical Pneumatic

existing RT control bldg. PL1 & PL2. Hazardous Substances

- DAN-AD400-MS-011 Rev. 01 Toxic Flammable Corrosive

Harmful Irritant

Environment Impact

Health & Hygiene Effect

Environmental Impact Health & Hygiene

Yes No Yes No

Hazardous waste x Significant Dust Generation x

Emissions x Noise (above 85 DbA) x

Discharge to sea or drains x Hazardous substances (if yes attach list) x

If answer to any of the above is yes, please circulate to If answer to any of the above is yes, please circulate to

Manager, Environmental Affairs Senior Occupational Hygienist

6. Person Completing The Work Method Statement :

Name : Takane Position : Company : Fuji

Signature : Date :

File: Revision: 0(26-May-2011) Page 1 of 6

HS.SAF.09.F12

7. Approvals

Contractors Site Rep. Name Signature : Date :

EMAL Representative Name Signature : Date :

Area Owner Name Signature : Date :

Name Signature: Date:

EMAL EHS Department

The completed Work Method Statement must be submitted at least seven full working days prior to the

commencement of activities.

Where the Work Method Statement indicates the use of Hazardous Substances, a Material Hazard Data

Sheet must be attached.

After the Area Owners approval the Work Method Statement shall be forwarded to EHS department for

approval

The approved Work Method Statement must be attached to the permit(s) to work and all persons involved

in the job instructed in its requirements.

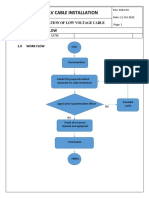

2. RISK ESTIMATOR CHART

The Risk Estimator chart should be used as an assistant for filling out the work

method statement.

Severity

Probability Low x1 Medium x 2 High x3

Low x1 Low Probability x Low Severity LP x MS LP x HS

1x1=1 1x2 = 2 1x3 =3

Medium x2 MP x LS MP X MS MP x HS

2x1 =2 2x2 =4

2x3 =6

High x3 HP x LS HP X HS HP x HS

3 x 1 =3 3x2 = 6 3x3=9

Significant Risk = High Risk (6-9) or Medium Risk (3-4) in terms of probability and severity

Tolerable Risk = Risk reduced to an acceptable level = Low Risk (1-2)

Residual Risk = Risk remaining after implementing recommended control actions (usually very minor).

File: Revision: 0(26-May-2011) Page 2 of 6

HS.SAF.09.F12

8. Safety Analysis

Severity x Probability =

Risk

Individual Activities To Identified Hazard(s) Persons Exposed To Precautions and Plan of actions To Be Taken

Complete Work. List In Residual Risk

Associated With Activity Hazard To Remove / Control Hazards

Sequence of Activity (Use Risk Estimator

Chart)

All hand tools to be used must

Using damaged be in good condition.

INSTALLATION OF hand tools. Electricians & Inspect before use, periodically

CABLE SUPPORT, 2 x 1 =2

Sharp edges of Helpers maintained.

CABLE TRAY & CABLE

cable support / tray Extra care to be taken while

LADDER.

& ladder. installing cable support / tray & ladder,

use hand gloves.

Incompetent Electricians & Competent workers to be deployed, 2 x 1 =2

workers. Helpers supervisor to check the competency of

the workers.

Electricians ,

Slips, trips and fall at supervisor & Maintain housekeeping around the 2 x 1 =2

the same level. Helpers working area.

Electricians & 3x1=3

Using of bad Helpers Hand power tools must be in good

condition of hand condition with colour coding inspection

power tools. tag.

Drilling without Use clear safety glass inside control

clear safety glass, room, dust mask & ear plug.

dust mask & ear Drilling to be done in phase manner if

File: Revision: 0(26-May-2011) Page 3 of 6

HS.SAF.09.F12

plug the fire alarm system is close to the

Dust from electric drilling point.

drill may cause of

fire alarm

activation.

Unauthorized Electricians & Only competent and authorized worker

3x1=3

using of hand power Helpers for the using of power tools.

tools.

Supervisor to ensure all power source

to be connected with ELCB and only

Electricians ,

110V industrial socket to be used at

supervisor & 3x1=3

Electrocution / Fire. site.

Helpers

Appropriate fire extinguisher to be

provided if necessary.

Do not use metal step ladder.

Inspect ladder before use, assign

one man to hold the ladder on the

ground while in used.

Using of bad Always climb up and down

condition step ladder. Electricians & facing the ladder.

3x1=3

Fall from height Helpers Don't carry tools or materials in

scaffold or from your hand while climbing up and down

ladder ladder.

Ensure workers on top of

Scaffolders must wear their safety

harness and 100% tie off.

File: Revision: 0(26-May-2011) Page 4 of 6

HS.SAF.09.F12

Electricians &

Manual handling Helpers

Supervisor to give toolbox talk 2 x 1 =2

hazards. regarding proper manual handling.

Not using proper Wear P.P.E.'s at all times ( e.g. hard

Scaffolding group hat, appropriate safety glass, safety 2x1=2

P.PE.s

shoes, hand gloves, dust mask, long

sleeve shirt & reflective vest.)

This sheet must be properly completed detailing all of the steps required to complete the job along with the sequence of events and each of the hazards

arising. Failure to properly complete the form will result in non-approval.

(Additional sheets to be used as required)

9. Chemical Analysis (This form to be used as required)

Product Name

MSDS supplied Yes / No

Dangerous Goods Class

Hazardous Material Yes / No

Nature of Hazard Irritation / Carcinogen / Corrosive / Toxic / Other

Form Solid /Liquid / Gas / Dust / Vapour / Mist

Exposure Route Inhalation / Skin / Eye / Ingestion

Number of People Exposed 3 workers only

File: Revision: 0(26-May-2011) Page 5 of 6

HS.SAF.09.F12

Duration of Exposure 2 hours

Frequency of Exposure Very rare

As per MSDS

Controls to be implemented

Estimate of Exposure Negligible / Marginal / High

This sheet must be properly completed detailing all the necessary information. Failure to properly complete the form will result in non-approval.

File: Revision: 0(26-May-2011) Page 6 of 6

Anda mungkin juga menyukai

- PM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBDokumen16 halamanPM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBnsadnanBelum ada peringkat

- Risk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPDokumen20 halamanRisk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPnsadnanBelum ada peringkat

- Risk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMDokumen16 halamanRisk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMnsadnanBelum ada peringkat

- Risk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBDokumen13 halamanRisk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBnsadnanBelum ada peringkat

- Contractor Work Method Statement (Ehs) : Installation of Wooden ScaffoldingDokumen8 halamanContractor Work Method Statement (Ehs) : Installation of Wooden ScaffoldingnsadnanBelum ada peringkat

- Risk Assessment For GIS Preparation For HV Cable TestDokumen11 halamanRisk Assessment For GIS Preparation For HV Cable Testnsadnan100% (3)

- Rectification of Defective High Mast Lighting in Cast House Yard LightingDokumen6 halamanRectification of Defective High Mast Lighting in Cast House Yard LightingnsadnanBelum ada peringkat

- Risk Ass - INSTALLATION OF PLC CABINET IN SECTION ELECTRICAL ROOMDokumen8 halamanRisk Ass - INSTALLATION OF PLC CABINET IN SECTION ELECTRICAL ROOMnsadnan100% (1)

- Risk Ass. - INSTALLATION OF 25 MM G.I. PIPE WITH EXISTING LINEDokumen12 halamanRisk Ass. - INSTALLATION OF 25 MM G.I. PIPE WITH EXISTING LINEnsadnanBelum ada peringkat

- Cable Pulling, Glanding and TerminationsDokumen6 halamanCable Pulling, Glanding and TerminationsnsadnanBelum ada peringkat

- 012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2Dokumen11 halaman012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2nsadnanBelum ada peringkat

- JSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Dokumen11 halamanJSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Jayson EscamillanBelum ada peringkat

- Itp-Inspection & Test Plan: Title / Name:Installation of Distribution Boards & Accessories (For Al Riffastations)Dokumen2 halamanItp-Inspection & Test Plan: Title / Name:Installation of Distribution Boards & Accessories (For Al Riffastations)wagwahkiabatheBelum ada peringkat

- Environmental, Health and Safety Risks AnalysisDokumen2 halamanEnvironmental, Health and Safety Risks AnalysisKrishna PatilBelum ada peringkat

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Dokumen4 halamanRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanBelum ada peringkat

- Risk Assessment For Trial Pit Excavation-RevDokumen15 halamanRisk Assessment For Trial Pit Excavation-RevRawoofuddin ChandBelum ada peringkat

- Method Statement & Risk Assessment PDFDokumen5 halamanMethod Statement & Risk Assessment PDFAmit BhattBelum ada peringkat

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Dokumen3 halamanRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Pipe Nitrogen Testing in Non Confined SpaceDokumen4 halamanPipe Nitrogen Testing in Non Confined SpaceKannan KamalBelum ada peringkat

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDokumen6 halamanRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- Installation and Repair of Fibre Optic Cable PDFDokumen3 halamanInstallation and Repair of Fibre Optic Cable PDFBento BoxBelum ada peringkat

- Risk Assessment - Pre-Internal Wiring of Patch PanelDokumen3 halamanRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- JSA For Scaffolding Erection Dismantling and Modification WorkDokumen30 halamanJSA For Scaffolding Erection Dismantling and Modification Workkmohamedkeita906Belum ada peringkat

- Procedures For Safe Working and Testing of Energized Electrical EquipmentDokumen25 halamanProcedures For Safe Working and Testing of Energized Electrical EquipmentSelvn SubramanianBelum ada peringkat

- HIRA Electrical Works HRC 002Dokumen7 halamanHIRA Electrical Works HRC 002syed khaja misbhuddinBelum ada peringkat

- RA Installation of Earthing SystemDokumen15 halamanRA Installation of Earthing Systemamal0% (1)

- JGS SHES JHRA 002 13 Wire Mesh InstallationDokumen2 halamanJGS SHES JHRA 002 13 Wire Mesh Installationarnel sungkip100% (1)

- Risk Assessment GRP Tank InstallationDokumen19 halamanRisk Assessment GRP Tank Installationanwer.ahmadBelum ada peringkat

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDokumen9 halamanRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- SWMS 1 Loading, Unloading & ShiftingDokumen8 halamanSWMS 1 Loading, Unloading & ShiftingJ.j.JijoBelum ada peringkat

- Method Statement Cable TerminationDokumen3 halamanMethod Statement Cable TerminationfaizbukhariBelum ada peringkat

- Lifting and Removing Using The Forklift or Telescopic Loader in SiteDokumen3 halamanLifting and Removing Using The Forklift or Telescopic Loader in SiteAMINBelum ada peringkat

- Job Hazard Analysis: Format For JHA WorksheetDokumen3 halamanJob Hazard Analysis: Format For JHA WorksheetWaseem AhmadBelum ada peringkat

- ChecklistDokumen14 halamanChecklistInstrument SCIBelum ada peringkat

- Methodstatement and RiskAssessmentDokumen13 halamanMethodstatement and RiskAssessmentAnonymous ExWAN2xjFJ100% (1)

- RA Ug Fire Pipe Installation and Hyrant SystemDokumen17 halamanRA Ug Fire Pipe Installation and Hyrant SystemvinayBelum ada peringkat

- JSA 01 (Mechanical Excavation and Soil Loading Unloading, Night Shift)Dokumen1 halamanJSA 01 (Mechanical Excavation and Soil Loading Unloading, Night Shift)abdulthahseen007Belum ada peringkat

- JHA For Concreting WorkDokumen3 halamanJHA For Concreting WorkRavi thokalBelum ada peringkat

- 011 Duct Lifter SWMSDokumen2 halaman011 Duct Lifter SWMSJ JohnsonBelum ada peringkat

- JSA Building WorksDokumen9 halamanJSA Building WorksMon Trang Nguyễn100% (1)

- Blasting and Painting - BUHPDokumen6 halamanBlasting and Painting - BUHPMuhammed yahiyaBelum ada peringkat

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Dokumen3 halamanRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (2)

- 19.17 (SWMS) All Work HvacDokumen17 halaman19.17 (SWMS) All Work Hvacsyed khaja misbhuddinBelum ada peringkat

- JSA PRE-TEST UploadDokumen2 halamanJSA PRE-TEST UploadDenny Kurniawan PrawiraBelum ada peringkat

- JSA Backfilling, Leveling, (Night Shift)Dokumen14 halamanJSA Backfilling, Leveling, (Night Shift)Mohammad Al Masa'dehBelum ada peringkat

- 26076-110-GPP-GCX-00094 Work Method Statement For Loading Unloading GeneratorDokumen10 halaman26076-110-GPP-GCX-00094 Work Method Statement For Loading Unloading Generatorbangun0% (1)

- Jsa Cable LayingDokumen2 halamanJsa Cable LayingAbcd efgh100% (1)

- HV Cable Termination: Standard Work Method StatementDokumen6 halamanHV Cable Termination: Standard Work Method StatementOsama SharafBelum ada peringkat

- Electrical Maintenance & Testing Hazard IdentificationDokumen10 halamanElectrical Maintenance & Testing Hazard IdentificationRavi ValiyaBelum ada peringkat

- Risk Assessment For Installation of Drainage Pipes PDF FreeDokumen17 halamanRisk Assessment For Installation of Drainage Pipes PDF FreeMalik RizwanBelum ada peringkat

- Electrical Loto ProcedureDokumen2 halamanElectrical Loto ProcedureRitesh Dev MaityBelum ada peringkat

- 2640.011SWP - Excavations and TrenchesDokumen7 halaman2640.011SWP - Excavations and TrenchesHasanuddin HAMIDBelum ada peringkat

- RAMS For Modification of Phase 1 Existing Water TankDokumen22 halamanRAMS For Modification of Phase 1 Existing Water TankAnandu AshokanBelum ada peringkat

- RAMS For Commissioning of LCP and IlluminationDokumen23 halamanRAMS For Commissioning of LCP and IlluminationAnandu AshokanBelum ada peringkat

- Job Risk Assessment Design and Installation of New Scada SystemDokumen17 halamanJob Risk Assessment Design and Installation of New Scada Systemzee khanBelum ada peringkat

- Method Statement For Installation of Emt Conduit-OldDokumen13 halamanMethod Statement For Installation of Emt Conduit-OldSalman SaifuddinBelum ada peringkat

- Risk Ass - RECTIFICATION FOR DAMAGED CABLE TRAY SUPPORTDokumen9 halamanRisk Ass - RECTIFICATION FOR DAMAGED CABLE TRAY SUPPORTnsadnanBelum ada peringkat

- Risk Ass. - Load Current Measurement and Cleaning of Oil CoolerDokumen7 halamanRisk Ass. - Load Current Measurement and Cleaning of Oil CoolernsadnanBelum ada peringkat

- Contractor Work Method Statement (Ehs)Dokumen11 halamanContractor Work Method Statement (Ehs)nsadnanBelum ada peringkat

- Fuel Gas Compressor Enclosures: Contractor Work Method Statement (Ehs)Dokumen8 halamanFuel Gas Compressor Enclosures: Contractor Work Method Statement (Ehs)nsadnanBelum ada peringkat

- ONVIF Profile Feature Overview v2-2Dokumen6 halamanONVIF Profile Feature Overview v2-2nsadnanBelum ada peringkat

- DDC Systems2Dokumen28 halamanDDC Systems2nsadnan100% (1)

- ONVIF Profile - S Specification v1-2Dokumen42 halamanONVIF Profile - S Specification v1-2nsadnan0% (1)

- ONVIF Profile T Specification v1-0Dokumen77 halamanONVIF Profile T Specification v1-0nsadnanBelum ada peringkat

- BSIA Cyber Secure It January 2019Dokumen16 halamanBSIA Cyber Secure It January 2019nsadnanBelum ada peringkat

- Checklist For Access Control System InstallationDokumen6 halamanChecklist For Access Control System Installationnsadnan71% (7)

- Peer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GageDokumen5 halamanPeer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GagensadnanBelum ada peringkat

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Dokumen3 halamanRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (2)

- 1 45Dokumen3 halaman1 45nsadnan0% (1)

- Testing and Commissioning Pre-Check List (ID 1506)Dokumen1 halamanTesting and Commissioning Pre-Check List (ID 1506)nsadnan0% (2)

- Excel Intelligent Pdu User InstructionsDokumen2 halamanExcel Intelligent Pdu User InstructionsnsadnanBelum ada peringkat

- Checklist For Commissioning of CCTV SystemDokumen2 halamanChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- CCTV Testing and Commissioning Pre-Check List (ID 1506)Dokumen1 halamanCCTV Testing and Commissioning Pre-Check List (ID 1506)nsadnan67% (3)

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDokumen6 halamanRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanBelum ada peringkat

- Checklist For Pre Commissioning of CCTV SystemDokumen1 halamanChecklist For Pre Commissioning of CCTV Systemnsadnan71% (7)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDokumen3 halamanRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Dokumen4 halamanRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanBelum ada peringkat

- Risk Assessment - Pre-Internal Wiring of Patch PanelDokumen3 halamanRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDokumen10 halamanRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- Risk Assessment - Installation of Ventilation FanDokumen6 halamanRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingDokumen12 halamanRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDokumen9 halamanRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- Risk Assessment - Distribution Board (DB) & Junction Box (JB) InstallationDokumen6 halamanRisk Assessment - Distribution Board (DB) & Junction Box (JB) Installationnsadnan91% (11)

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDokumen6 halamanRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- Risk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control BuildingDokumen14 halamanRisk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control Buildingnsadnan91% (82)

- RISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The MaterialsDokumen6 halamanRISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The Materialsnsadnan100% (5)

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Dokumen4 halamanRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanBelum ada peringkat

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Dokumen3 halamanRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Risk Assessment For GIS Preparation For HV Cable TestDokumen11 halamanRisk Assessment For GIS Preparation For HV Cable Testnsadnan100% (3)

- Risk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light FittingsDokumen6 halamanRisk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light Fittingsnsadnan86% (21)

- Chapter 1 Cumulative Review: Multiple ChoiceDokumen2 halamanChapter 1 Cumulative Review: Multiple ChoiceJ. LeeBelum ada peringkat

- High Performance Liquid Chromatography: University of Santo Tomas Faculty of Pharmacy Department of BiochemistryDokumen32 halamanHigh Performance Liquid Chromatography: University of Santo Tomas Faculty of Pharmacy Department of BiochemistryMa. Ellah Patricia M. GutierrezBelum ada peringkat

- DattadasDokumen4 halamanDattadasJéssica NatáliaBelum ada peringkat

- MS 005 For DUCT FABRICATION - INSULATION & INSTALLATION REV-1Dokumen21 halamanMS 005 For DUCT FABRICATION - INSULATION & INSTALLATION REV-1vusal huseynli100% (2)

- Iec TR 62343-6-8-2011Dokumen14 halamanIec TR 62343-6-8-2011Amer AmeryBelum ada peringkat

- SMA - Core 1 - IEC62109-2 - 0 Test ReportDokumen6 halamanSMA - Core 1 - IEC62109-2 - 0 Test ReportFurqan HamidBelum ada peringkat

- Industrial Training Report (Kapar Power Plant)Dokumen40 halamanIndustrial Training Report (Kapar Power Plant)Hakeemi Baseri100% (2)

- Responsible Living: Mantri DevelopersDokumen15 halamanResponsible Living: Mantri Developersnadaf8Belum ada peringkat

- Astrophysics & CosmologyDokumen2 halamanAstrophysics & CosmologyMarkus von BergenBelum ada peringkat

- Green Engine 2 PDFDokumen7 halamanGreen Engine 2 PDFharivardhanBelum ada peringkat

- Welding Inspection Technology: Module 7 - Visual Inspection WorkshopDokumen20 halamanWelding Inspection Technology: Module 7 - Visual Inspection Workshoprex valenciaBelum ada peringkat

- Design and Management of Mettur Dam by Predicting Seepage Losses Using Remote SensingDokumen10 halamanDesign and Management of Mettur Dam by Predicting Seepage Losses Using Remote SensingInternational Journal of Application or Innovation in Engineering & ManagementBelum ada peringkat

- Concrete ON MALDIVESDokumen55 halamanConcrete ON MALDIVESKãrthìçk JkrBelum ada peringkat

- BiosintezaDokumen8 halamanBiosintezaLovin BiancaBelum ada peringkat

- Chapter - 2 - Unit Hydrograph2Dokumen33 halamanChapter - 2 - Unit Hydrograph2Abhilekh PaudelBelum ada peringkat

- DuctBank For Electrical SystemDokumen4 halamanDuctBank For Electrical SystemAnonymous XYAPaxjbYBelum ada peringkat

- List of Irc Publications Referred To in The Specifications: AppendicesDokumen17 halamanList of Irc Publications Referred To in The Specifications: AppendicesPrasad BoniBelum ada peringkat

- (Nano and Energy) Gavin Buxton - Alternative Energy Technologies - An Introduction With Computer Simulations-CRC Press (2014) PDFDokumen302 halaman(Nano and Energy) Gavin Buxton - Alternative Energy Technologies - An Introduction With Computer Simulations-CRC Press (2014) PDFmarcosBelum ada peringkat

- A-ZKD-13 (ZKD-59 (A) ) : Mechanical ParameterDokumen1 halamanA-ZKD-13 (ZKD-59 (A) ) : Mechanical Parameterwissam zaatuorBelum ada peringkat

- Long Quiz 1 Eim Tools, MaterialsDokumen1 halamanLong Quiz 1 Eim Tools, MaterialsLea Ann PalaciosBelum ada peringkat

- Concrete Saw Core Drilling Swms 10067-8Dokumen12 halamanConcrete Saw Core Drilling Swms 10067-8JamesBelum ada peringkat

- Vargas, Bartolome Dr. Thornton, Karen 17675251Dokumen1 halamanVargas, Bartolome Dr. Thornton, Karen 17675251ahmedBelum ada peringkat

- Anil Singh Rathore: Career HighlightsDokumen4 halamanAnil Singh Rathore: Career HighlightsHRD CORP CONSULTANCYBelum ada peringkat

- Module 1 Hvac Basics Chapter-1Dokumen5 halamanModule 1 Hvac Basics Chapter-1KHUSHBOOBelum ada peringkat

- The Art of Logical ThinkingDokumen210 halamanThe Art of Logical ThinkingAndyAyam100% (1)

- Flooding Deagon Flood Flag MapDokumen1 halamanFlooding Deagon Flood Flag MapNgaire TaylorBelum ada peringkat

- GP 24-21 - Fire Hazard AnalysisDokumen53 halamanGP 24-21 - Fire Hazard AnalysisJohn DryBelum ada peringkat

- Stratigraphy MCQs With AnswerDokumen10 halamanStratigraphy MCQs With Answerkumar Harsh67% (3)

- Reason: God Had Made The Mistake of Sending Only 70 PesosDokumen2 halamanReason: God Had Made The Mistake of Sending Only 70 PesosS Vaibhav81% (21)

- Elements, Compounds, MixturesDokumen35 halamanElements, Compounds, MixturesNorvieBelum ada peringkat