Diagnosis Dt466 & 530 e

Diunggah oleh

Cesar Bayes RamosHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Diagnosis Dt466 & 530 e

Diunggah oleh

Cesar Bayes RamosHak Cipta:

Format Tersedia

Motor Information Systems

530E & DT466E Engine Control System

Diagnosis & Testing

Accessing Diagnostic Trouble Codes

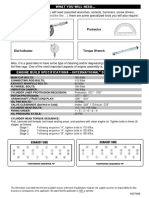

The ECM records and stores engine control system faults as diagnostic trouble codes (DTCs). These DTCs may be retrieved either by

using an electronic scan tool or by reading DTC flash codes.

Using Scan Tool

With all accessories off, connect Electronic Service Tool (EST) to the American Trucking Association (ATA) diagnostic connector. The ATA

connector is located on the lower lefthand side kick panel, Fig.1. On school buses, it may be hidden by the body builders panel near the

driver's left foot.

With the tester plugged in, turn the ignition switch to On but do not start engine. Current engine status data should be displayed. If no data

is displayed, press ENTER to retry. To access diagnostic trouble codes (DTCs), press the FUNC key to switch to the main menu, then

follow the menu map, Fig.2.

Using Flash Codes

1. Depress and hold self-test input (STI) switch, located on vehicle dash. The STI switch may also be labeled"Engine Diagnostics."

2. Turn ignition switch to On position.

3. The OIL/WATER light will flash once to indicate the beginning of active DTCs.

4. If any DTCs are detected, the WARN ENGINE light will then flash to indicate which code(s) are present.

5. After all active DTCs have flashed, the OIL/WATER light will flash twice to indicate the beginning of inactive codes.

6. The WARN ENGINE light will then flash to indicate which code is present. If more than one code is stored, the OIL/WATER light

will flash once between each code.

7. After all codes have been sent, the OIL/WATER light will flash three times to indicate the end of DTC retrieval.

8. To repeat fault code readout, depress Engine Diagnostics (STI) switch which will signal the ECM to re-send all stored codes.

Diagnostic Trouble Code Interpretation

Refer to Fig.3 for diagnostic trouble code identification.

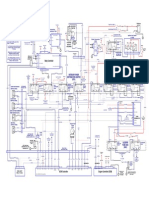

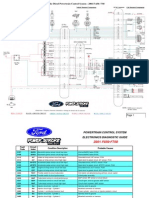

Wiring Diagram & Connector Identification

Refer to Fig.4 for electronic engine control system wiring diagram. Refer to Fig. 5 for ECM connector pin identification.

Diagnostic Tests

Code 111: No Fault Detected.

Code Description Fig. No.

112 Electronic Control Module Power Supply 6

113 Electronic Control Module Power Supply 6

114 Engine Coolant Temperature Sensor 7

115 Engine Coolant Temperature Sensor 7

121 Map Sensor Frequency Out Of Range 8

122 Map Sensor Signal Inactive 8

123 Map Sensor Above Spec Level At Idle 8

124 Injection Control Pressure Sensor Out Of Range Low 9

125 Injection Control Pressure Sensor Out Of Range High 9

131 Accelerator Pedal Position Sensor Out Of Range Low 10

132 Accelerator Pedal Position Sensor Out Of Range High 10

133 Accelerator Pedal Position Sensor In Range Fault 10

134 Accelerator Pedal Position Sensor/IVS Switch 10

135 Idle Validation Switch Circuit Fault 10

141 Vehicle Speed Signal 11

142 Vehicle Speed Signal 11

143 Camshaft Position Sensor 12

144 Camshaft Position Sensor 12

Heavy Truck Service 2005 - Copyright 2005 Motor Information Systems

Motor Information Systems

145 Camshaft Position Sensor 12

151 Barometric Pressure Sensor 13

152 Barometric Pressure Sensor 13

154 Intake Air Temperature Sensor 14

155 Intake Air Temperature Sensor 14

211 Engine Oil Pressure Sensor 15

212 Engine Oil Pressure Sensor 15

213 Speed Control Command Switches 16

214 Speed Control Command Switches 16

221 Speed Control Command Switches 16

222 Brake Switch Circuit Fault 17

224 Keep Alive Memory Power 18

233 Tachometer Input Circuits 19

241 Injector Pressure Regulator 20

242 ECM/IDM Communication 21

243 Injector Driver Module Power Circuits 22

244 Engine Data Line. Allison Transmissions 23

253 ECM/IDM Communication 21

311 Engine Oil Temperature Sensor 24

312 Engine Oil Temperature Sensor 24

313 Engine Oil Pressure Sensor 15

314 Engine Oil Pressure Sensor 15

321 Engine Coolant Temperature Sensor 7

322 Injection Control Pressure Sensor 9

323 Engine Coolant Below Warning Critical Level 25

325 Engine Coolant Temperature Sensor 7

331 Injector Pressure Regulator 20

333 Injector Pressure Regulator 20

421-456 Injector Drive Circuits 26

511-521 Injector Drive Circuits 26

522 Injector Driver Module Power Circuits 22

523 Injector Driver Module Power Circuits 22

524 Injector Drive Circuits 26

531 ECM/IDM Communication 21

532 ECM/IDM Communication 21

541 ECM/IDM Communication 21

543 ECM/IDM Communication 21

544 Injector Drive Circuits 26

545 Injector Drive Circuits 26

612 Camshaft Position Sensor 12

613 Vehicle Personality Module 27

614 Vehicle Personality Module 27

615 Keep Alive Memory Power 18

C621-623 Vehicle Personality Module 27

634-654 Vehicle Personality Module 27

-- Engine Crank Inhibit 28

-- Self Test Input Switch & Engine Warn Light 29

-- Two Speed Axle Input Circuit 30

Clearing Diagnostic Trouble Codes

There are two ways to clear diagnostic trouble codes. If using a scan tool, refer to the tool manufactures instructions. If using flash codes,

disconnect the battery ground cable for at least one minute.

Heavy Truck Service 2005 - Copyright 2005 Motor Information Systems

Motor Information Systems

Heavy Truck Service 2005 - Copyright 2005 Motor Information Systems

Anda mungkin juga menyukai

- JD Service CodeDokumen4 halamanJD Service CodeMarijan Lesičak100% (1)

- EPA07 Maxxforce 7 Diagnostic Manual-2Dokumen232 halamanEPA07 Maxxforce 7 Diagnostic Manual-2Jhon Constantine100% (8)

- TR Navistar International DT466E DT530 TSIDokumen2 halamanTR Navistar International DT466E DT530 TSIDavid Fuentes100% (2)

- EPA07 Maxxforce 11, 13 Diagnostic Manual-1Dokumen190 halamanEPA07 Maxxforce 11, 13 Diagnostic Manual-1Manuel Alejandro Velez NavaBelum ada peringkat

- Diagnostic Trouble Code Charts for 6.0L Diesel EnginesDokumen28 halamanDiagnostic Trouble Code Charts for 6.0L Diesel EnginesRogério MorenoBelum ada peringkat

- International dt466Dokumen1 halamanInternational dt466sidhu100% (1)

- 0042-11 Injection Actuation Pressure Output FaultDokumen1 halaman0042-11 Injection Actuation Pressure Output FaultHamilton Miranda100% (3)

- DT466Dokumen7 halamanDT466John Freddy Franco Yela80% (5)

- Ih Navistar Dt466e 530e Service ManualDokumen206 halamanIh Navistar Dt466e 530e Service Manualaviseur100% (3)

- Navistar Diagnostic Trouble Codes EGES395 - DTCDokumen8 halamanNavistar Diagnostic Trouble Codes EGES395 - DTCjpablop1278% (9)

- EPA10 Maxxforce 11, 13 Diagnostic ManualDokumen985 halamanEPA10 Maxxforce 11, 13 Diagnostic ManualAndy Zepeda100% (1)

- Electrica 4400 4300 PDFDokumen49 halamanElectrica 4400 4300 PDFGuillermoBelum ada peringkat

- Icon Pro StarDokumen1 halamanIcon Pro Staramateur123456100% (1)

- Maxxforce DT, 9, & 10: Engine Operation and Maintenance ManualDokumen102 halamanMaxxforce DT, 9, & 10: Engine Operation and Maintenance ManualOswaldo Monge100% (1)

- FAULT CODE 2215 (ISB/QSB Automotive, Industrial, or Marine Application) - Fuel Pump Delivery Pressure - Data Valid But Below Normal Operating Range - Moderately Severe LevelDokumen19 halamanFAULT CODE 2215 (ISB/QSB Automotive, Industrial, or Marine Application) - Fuel Pump Delivery Pressure - Data Valid But Below Normal Operating Range - Moderately Severe Levelcrash2804Belum ada peringkat

- Vmac I: 2012 Kenworth T800 CUMMINS ISM CM876 Print Date: 16/11/2016Dokumen5 halamanVmac I: 2012 Kenworth T800 CUMMINS ISM CM876 Print Date: 16/11/2016Eduardo Alvarez100% (2)

- SB 273 014 Engine Sensor Locations Nov 19 2008 1 PDFDokumen4 halamanSB 273 014 Engine Sensor Locations Nov 19 2008 1 PDFImade EmadeBelum ada peringkat

- 0000003221Dokumen3 halaman0000003221Ael Ch100% (2)

- 2007 Maxxforce 5 Diagnostic Manual-1Dokumen182 halaman2007 Maxxforce 5 Diagnostic Manual-1hoangnhuphuocBelum ada peringkat

- Freightliner Business Class M2 Maintenance Manual PDFDokumen147 halamanFreightliner Business Class M2 Maintenance Manual PDFCarlos Gomez100% (4)

- 2000-2001-International 4200, 4300, 4400 SERIES - Electrical Circuit DiagramsDokumen49 halaman2000-2001-International 4200, 4300, 4400 SERIES - Electrical Circuit DiagramsAníbal LópezBelum ada peringkat

- Wirings Inter 2003Dokumen208 halamanWirings Inter 2003Norman Valle Sáenz93% (14)

- Fault Code 432 Accelerator Pedal or Lever Idle Validation Circuit - Out of CalibrationDokumen10 halamanFault Code 432 Accelerator Pedal or Lever Idle Validation Circuit - Out of CalibrationAhmedmahBelum ada peringkat

- F650 F750 PowerstrokeDokumen3 halamanF650 F750 Powerstrokemiguelcastillo100% (1)

- Mbe 926 ManualDokumen122 halamanMbe 926 ManualMarcos Reis100% (1)

- DPF sensor fault diagnosisDokumen2 halamanDPF sensor fault diagnosisWalter100% (1)

- Fault Code 196 Coolant Level Sensor Circuit - Voltage Below Normal or Shorted To Low SourceDokumen11 halamanFault Code 196 Coolant Level Sensor Circuit - Voltage Below Normal or Shorted To Low SourceAhmedmah100% (1)

- Navistar Workstar Electrical DiagramsDokumen868 halamanNavistar Workstar Electrical DiagramsPhil B.100% (2)

- Electrical System C9 Industrial Engine: Top ViewDokumen4 halamanElectrical System C9 Industrial Engine: Top Viewusuario29000Belum ada peringkat

- Maxxforce+v 9+10+crank+no+startDokumen40 halamanMaxxforce+v 9+10+crank+no+startVeterano del Camino100% (2)

- Caterpillar Acert Engine Diagnostic CodesDokumen6 halamanCaterpillar Acert Engine Diagnostic CodesNoel Salazar100% (1)

- International Service Manual-ELECTRICAL CIRCUIT DIAGRAMSDokumen114 halamanInternational Service Manual-ELECTRICAL CIRCUIT DIAGRAMSkufisa00783% (63)

- Manual de Operacion y Mantenimiento de Motor DT 530 y HT 530Dokumen107 halamanManual de Operacion y Mantenimiento de Motor DT 530 y HT 530Fernando100% (1)

- FAULT CODE 3559 - Aftertreatment 1 Diesel Exhaust Fluid Dosing Unit - Voltage Below Normal or Shorted To Low SourceDokumen7 halamanFAULT CODE 3559 - Aftertreatment 1 Diesel Exhaust Fluid Dosing Unit - Voltage Below Normal or Shorted To Low SourceDouglas Lowe100% (1)

- 2 Mbe4000 06aDokumen76 halaman2 Mbe4000 06azahar222100% (3)

- CT13 With SCR Engine Wiring HarnessDokumen4 halamanCT13 With SCR Engine Wiring HarnessAnonymous MHfAPigBelum ada peringkat

- Mack Truck Fault Codes ListDokumen2 halamanMack Truck Fault Codes ListAlexanderRomero100% (3)

- Fault Code 331 Injector Solenoid Driver Cylinder 2 Circuit - Current Below Normal, or Open CircuitDokumen26 halamanFault Code 331 Injector Solenoid Driver Cylinder 2 Circuit - Current Below Normal, or Open CircuitAhmedmah100% (1)

- Pressure Specs and TestsDokumen2 halamanPressure Specs and Testsluis eduardo corzo enriquezBelum ada peringkat

- Fault Code: 1664 - SPN: 4796 - FMI: 31: ISX CM871Dokumen4 halamanFault Code: 1664 - SPN: 4796 - FMI: 31: ISX CM871Andi KastrawanBelum ada peringkat

- Chassis Electrical Circuit Diagram Manual Electrical System Troubleshooting GuideDokumen2 halamanChassis Electrical Circuit Diagram Manual Electrical System Troubleshooting GuideMartinez Andryj100% (3)

- EGES175Dokumen598 halamanEGES175Tim Workman100% (1)

- Manual de Servicio Cf500 y Cf600Dokumen119 halamanManual de Servicio Cf500 y Cf600Wilson BuenoBelum ada peringkat

- Fuel filter housing and engine mounted sensors wiring diagramDokumen2 halamanFuel filter housing and engine mounted sensors wiring diagramAlvaro Tayco100% (1)

- 41 Flash Code 41 Too Many SRSDokumen12 halaman41 Flash Code 41 Too Many SRSAlex Robledo OlarteBelum ada peringkat

- Appendix D-Wire/Connector Tables: Allison 1000 and 2000 Product Families Electronic Controls Troubleshooting ManualDokumen12 halamanAppendix D-Wire/Connector Tables: Allison 1000 and 2000 Product Families Electronic Controls Troubleshooting Manualluis eduardo corzo enriquezBelum ada peringkat

- NGV 1 Electdiag 1-10-02 14-09-03Dokumen65 halamanNGV 1 Electdiag 1-10-02 14-09-03sanachBelum ada peringkat

- Fault Code 275 Fuel Pumping Element Number 1 (Front) - Mechanical System Not Responding Properly or Out of AdjustmentDokumen6 halamanFault Code 275 Fuel Pumping Element Number 1 (Front) - Mechanical System Not Responding Properly or Out of AdjustmentAhmedmahBelum ada peringkat

- Diagrama de 3406b PDFDokumen2 halamanDiagrama de 3406b PDFIgnacio Cano100% (1)

- Allison Transmission 1000 - 2000 Fault Codes DTCDokumen3 halamanAllison Transmission 1000 - 2000 Fault Codes DTCVusal AbdullayevBelum ada peringkat

- Nav DPF Diag PDFDokumen197 halamanNav DPF Diag PDFAlex Robledo100% (2)

- 2002 ICON International Wiring DiagramDokumen1 halaman2002 ICON International Wiring DiagramRaul E. SoliBelum ada peringkat

- Code Error Cat Pc320 Fuel Injection Turbocharger Fault Diagnostic GuideDokumen8 halamanCode Error Cat Pc320 Fuel Injection Turbocharger Fault Diagnostic GuideRenato Vasques BeraldoBelum ada peringkat

- Engine Control System Diagram and Component GuideDokumen10 halamanEngine Control System Diagram and Component GuideLucasBelum ada peringkat

- Engine Control System OverviewDokumen26 halamanEngine Control System OverviewERMINSUL VICUÑA SALASBelum ada peringkat

- Listing of Diagnostic Trouble Codes (DTCS)Dokumen4 halamanListing of Diagnostic Trouble Codes (DTCS)As AsBelum ada peringkat

- HPCR ENGINE CONTROL SYSTEM - Compatibility ModeDokumen30 halamanHPCR ENGINE CONTROL SYSTEM - Compatibility ModeLe DuBelum ada peringkat

- Engine Pin Data KyronDokumen3 halamanEngine Pin Data Kyronfrank ortegaBelum ada peringkat

- Copia de Codigos WLSDokumen12 halamanCopia de Codigos WLSjb6048649Belum ada peringkat

- T5 XXXDokumen8 halamanT5 XXXJózsef JuhászBelum ada peringkat

- DD - PlatformEPA10ddc SVC Man 0131Dokumen236 halamanDD - PlatformEPA10ddc SVC Man 0131Cesar Bayes RamosBelum ada peringkat

- Detroit Diesel - Series 60 Ddec V Troubleshooting Guide Ch11Dokumen32 halamanDetroit Diesel - Series 60 Ddec V Troubleshooting Guide Ch11JOHN Wright67% (3)

- DD Unable Complete RegenDokumen6 halamanDD Unable Complete RegenJOHN Wright100% (2)

- Diagnostic Fault Codes For Cummins EnginesDokumen26 halamanDiagnostic Fault Codes For Cummins Enginesartmehr100% (12)

- Codigos ESCDokumen126 halamanCodigos ESCpankituna5487Belum ada peringkat

- 202 10rev PDFDokumen8 halaman202 10rev PDFJOHN WrightBelum ada peringkat

- NUMBER: 1-MBE 4000-07 S.M. REF.: See Table 1 Engine: Mbe 4000 DATE: February 2007Dokumen40 halamanNUMBER: 1-MBE 4000-07 S.M. REF.: See Table 1 Engine: Mbe 4000 DATE: February 2007Christopher Ponce YanacBelum ada peringkat

- ECM Calibration Download Instructions PDFDokumen11 halamanECM Calibration Download Instructions PDFArtemio Garcia BarrientosBelum ada peringkat

- Trig0930en-Us 0614 PDFDokumen134 halamanTrig0930en-Us 0614 PDFCesar Bayes RamosBelum ada peringkat

- MC68HC05B4 PDFDokumen298 halamanMC68HC05B4 PDFCesar Bayes RamosBelum ada peringkat

- John - Deere - PV - 101 DTCs PDFDokumen8 halamanJohn - Deere - PV - 101 DTCs PDFCesar Bayes RamosBelum ada peringkat

- EPA07 Maxxforce 11, 13 Engine Service ManualDokumen490 halamanEPA07 Maxxforce 11, 13 Engine Service ManualCesar Bayes Ramos78% (27)

- 12 Maxx Force 401Dokumen40 halaman12 Maxx Force 401Cesar Bayes RamosBelum ada peringkat

- Codigos ESCDokumen126 halamanCodigos ESCpankituna5487Belum ada peringkat

- 12 Maxx Force 401Dokumen40 halaman12 Maxx Force 401Cesar Bayes RamosBelum ada peringkat

- PV776 88957057Dokumen5 halamanPV776 88957057Cesar Bayes RamosBelum ada peringkat

- Electrical - BB International PDFDokumen480 halamanElectrical - BB International PDFedelmolina100% (3)

- 26 Flash Code 26 Auxiliary Input ActiveDokumen4 halaman26 Flash Code 26 Auxiliary Input ActiveAlex Robledo OlarteBelum ada peringkat

- PV776 88987099Dokumen3 halamanPV776 88987099Cesar Bayes RamosBelum ada peringkat

- 4045 6068+Electronicos,+Manual+ServicioDokumen678 halaman4045 6068+Electronicos,+Manual+ServicioNarciso Alberto Hernandez Tovar91% (33)

- Hino Common Rail J05d-J08eDokumen50 halamanHino Common Rail J05d-J08eJusto Paniagua Champa94% (50)

- Isuzu Elf 4hk1 4jj1 EngineDokumen23 halamanIsuzu Elf 4hk1 4jj1 EngineDinukaDeshan94% (16)

- Navistar, Inc.: Electrical Circuit DiagramsDokumen619 halamanNavistar, Inc.: Electrical Circuit DiagramsCesar Bayes RamosBelum ada peringkat

- PV776 88968379Dokumen7 halamanPV776 88968379Cesar Bayes RamosBelum ada peringkat

- Fault Code Guide for Volvo D12D and D16D EnginesDokumen6 halamanFault Code Guide for Volvo D12D and D16D EnginesCesar Bayes Ramos100% (1)

- Ajuste Valvulas e Inyectores DetroitDokumen6 halamanAjuste Valvulas e Inyectores DetroitGabriel Duarte100% (19)

- PV776 89046912 PDFDokumen82 halamanPV776 89046912 PDFCesar Bayes RamosBelum ada peringkat

- DDEC II and III Wiring DiagramsDokumen13 halamanDDEC II and III Wiring Diagramstwhiteman200681% (48)

- LTC 7PN 188500Dokumen4 halamanLTC 7PN 188500Cesar Bayes RamosBelum ada peringkat

- Data Codes Ddec III and IV.Dokumen10 halamanData Codes Ddec III and IV.FeDe Aavina GlezBelum ada peringkat

- Study Software Economics Resource AllocationDokumen10 halamanStudy Software Economics Resource AllocationAbdul Raheem MemonBelum ada peringkat

- RH200 Engine & Pump Drive GearboxDokumen26 halamanRH200 Engine & Pump Drive GearboxLuis jopi67% (3)

- MBSE in Rail Transportation - Product Families and Product LinesDokumen3 halamanMBSE in Rail Transportation - Product Families and Product Lines陈波Belum ada peringkat

- LECTURE 1 Process IntegrationDokumen8 halamanLECTURE 1 Process IntegrationJewel Ann FataganiBelum ada peringkat

- CAT320B Service Repair Fault Code ZPWDokumen32 halamanCAT320B Service Repair Fault Code ZPWZaw Phyo100% (1)

- CPU Scheduling: ExercisesDokumen8 halamanCPU Scheduling: ExercisesNorvaldo PedroBelum ada peringkat

- Project Management Unit 1Dokumen41 halamanProject Management Unit 1Sakshi JaiswalBelum ada peringkat

- UML 2: Additional Diagram Types: Object DiagramsDokumen0 halamanUML 2: Additional Diagram Types: Object DiagramsJuan Miguel Gómez PalaciánBelum ada peringkat

- Fall 2023 - CS506 - 1Dokumen3 halamanFall 2023 - CS506 - 1ahmadqadri2625Belum ada peringkat

- OOP Concepts in C#Dokumen22 halamanOOP Concepts in C#Indumini DilshaniBelum ada peringkat

- Getting Started With Use-Case Modeling PDFDokumen19 halamanGetting Started With Use-Case Modeling PDFSatriaji IdamBelum ada peringkat

- 1 6 72 75 KW MPI EngineDokumen212 halaman1 6 72 75 KW MPI Engine19crysti80% (5)

- Reqview Software Requirements Specification Example: Project: DemoDokumen13 halamanReqview Software Requirements Specification Example: Project: DemoPriyaBelum ada peringkat

- Library Management System Functional SpecificationsDokumen18 halamanLibrary Management System Functional SpecificationsJack GillBelum ada peringkat

- 14cyl For RTA96CDokumen2 halaman14cyl For RTA96Cmarko4096Belum ada peringkat

- Android Test: What Number Should Replace The Question Mark? 0, 1, 2, 4, 6, 9, 12, 16, ?Dokumen10 halamanAndroid Test: What Number Should Replace The Question Mark? 0, 1, 2, 4, 6, 9, 12, 16, ?Dinh An TranBelum ada peringkat

- Zarar+Hussain New (Java+Developer)Dokumen1 halamanZarar+Hussain New (Java+Developer)ayesha siddiquiBelum ada peringkat

- Hangman Game in CDokumen2 halamanHangman Game in CWilliam AlloteyBelum ada peringkat

- Systems: Economic Analysis of Model-Based Systems EngineeringDokumen18 halamanSystems: Economic Analysis of Model-Based Systems EngineeringtmanBelum ada peringkat

- KuchhbhiDokumen6 halamanKuchhbhiAbhishek KumarBelum ada peringkat

- Software Architecture in PracticeDokumen717 halamanSoftware Architecture in PracticeDominick100% (3)

- W1 Outline PF101complete 1Dokumen13 halamanW1 Outline PF101complete 1Mark StewartBelum ada peringkat

- Total Productive Maintenance (TPM)Dokumen14 halamanTotal Productive Maintenance (TPM)RAM KUMARBelum ada peringkat

- PPT08 Securing Information SystemsDokumen53 halamanPPT08 Securing Information SystemsyarenBelum ada peringkat

- SANMOTION Servo System RDokumen148 halamanSANMOTION Servo System RsunhuynhBelum ada peringkat

- Software Development Life CycleDokumen7 halamanSoftware Development Life CycleJahangir AliBelum ada peringkat

- Comparative Analysis of Software Architecture StylesDokumen13 halamanComparative Analysis of Software Architecture StylesRumali PiyathmaBelum ada peringkat

- IRM - Incremental Repository Merge: Siebel CRMDokumen15 halamanIRM - Incremental Repository Merge: Siebel CRMNicolae StanBelum ada peringkat

- Design of Underground Structures PDFDokumen49 halamanDesign of Underground Structures PDFHaftom GebreegziabiherBelum ada peringkat