Escrito Articulo Tablas y Figuras Articulo LISTO RUBEN

Diunggah oleh

Ruben MarquezHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Escrito Articulo Tablas y Figuras Articulo LISTO RUBEN

Diunggah oleh

Ruben MarquezHak Cipta:

Format Tersedia

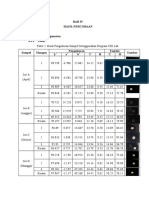

Table 1.

Factorial Design Diagram

Formulation A B C D E F G H

Mesh Factor 1 2

(mm)

Tomato/ Green 70 85 70 85

tomato (%)

*Jalapeo pepper 30 15 30 15

(%)

Thickener Gum Starch Gum Starch Gum Starch Gum Starch

*Red or Green jalapeo pepper

Table 2. Chemical composition of Mexican style sauces (%)

Red sauce Green sauce

Mesh 2mm/70%/gum Mesh 1mm/85%/starch

Protein 0.52a 0.029 0.60a 0.029

Fat 0.33a 0.058 0.11b 0.062

Carbohydrates 5.32a 0.134 2.33b 0.134

Crude fiber 0.27a 0.038 0.39a 0.041

Humidity 91.96b 0.067 95.12a 0.063

Ashes 1.64a 0.063 1.38b 0.060

Average value standard deviation, n=3. Superscripts with different letter

indicate significant differences between the samples of sauces (P <0.05)

Table 3. Analysis of apparent viscosity, consistency index () and flow rate

() on red sauces

% Mesh Apparent

Thickener

(mm) viscosity (Pa.s)

Tomato

70 1 Starch 1.17 0.489 b 0.40 0.031 a 0.044 0.007 c

70 1 Gum 3.34 0.489 ab 0.33 0.031 a 0.085 0.007 ab

70 2 Starch 2.61 0.489 ab 0.37 0.031 a 0.078 0.007 abc

70 2 Gum 3.71 0.599 ab 0.34 0.038 a 0.096 0.009 a

85 1 Starch 1.83 0.489 ab 0.37 0.031 a 0.051 0.007 bc

85 1 Gum 4.66 0.848 ab 0.23 0.054 a 0.077 0.012 abc

85 2 Starch 1.90 0.599 ab 0.37 0.038 a 0.055 0.009 abc

85 2 Gum 4.27 0.489 a 0.29 0.031 a 0.090 0.007 a

Average value standard error, n = 3. Superscripts with different letter indicate

significant differences between the samples of sauces (P<0.05).

Table 4. Capsaicin concentrations and Scoville Units (SHU) in sauces

and purees samples.

mg capsaicin on the

samples Scoville

Samples Units Pungency Levels

g capsaicin in jalapeo (SHU)

pepper

Red

0.26 0.023 b 4189.82 Moderately pungent

puree

Green

0.60 0.023 a 9678.11 Moderately pungent

puree

Red

0.18 0.023 b 2916.73 Slightly pungent

sauce

Green

0.23 0.023 b 3687.31 Moderately pungent

sauce

Average value standard deviation, n = 3. Superscripts with different letter

indicate significant differences between the samples of sauces (P <0.05)

Figure 1. Process flow diagram for making purees and sauces mixes

Figure 2. Color parameters L* a* b* in red (a) and green (b) sauce. Different numbers and letters indicate sig

Figure 3. Main effects for acceptability of the formulation of red sauce (a) and green sauce (b) (n=3) (P <0.0

Figure 4. Average acceptability on the physical characteristics of red sauce (a) (70% tomato/ xanthan gum /

Figure 5. Capsaicinoids quantification in green and red pure and sauces products (n=3).

Anda mungkin juga menyukai

- Tips The Peppers Cookbook 200 Recipes From The Pepper LDokumen242 halamanTips The Peppers Cookbook 200 Recipes From The Pepper LFredi TatarinBelum ada peringkat

- University of UTAH StudyDokumen8 halamanUniversity of UTAH StudySteven SchoenfeldBelum ada peringkat

- Uses and Benefits of Scent LeafDokumen27 halamanUses and Benefits of Scent LeafJessica King100% (1)

- Ayurvedic Diet: - Eating Right For Your Body TypeDokumen13 halamanAyurvedic Diet: - Eating Right For Your Body TypeΦωτεινή Μαρίνη100% (1)

- Flavor Adjustment Calculators PDFDokumen11 halamanFlavor Adjustment Calculators PDFJasmina Lazovic50% (2)

- Beer PresentationDokumen27 halamanBeer PresentationRuben MarquezBelum ada peringkat

- Food Chart Table 21Dokumen11 halamanFood Chart Table 21DinbilimBelum ada peringkat

- Cupping Sheet Boot Coffee 2012 PDFDokumen1 halamanCupping Sheet Boot Coffee 2012 PDFHissatsu86Belum ada peringkat

- Pumpkin Nutrition FactsDokumen196 halamanPumpkin Nutrition FactsPriya Bisht100% (1)

- Spicing Food FormularyDokumen7 halamanSpicing Food FormularyGJ SavarisBelum ada peringkat

- CPB 30103 Biochemical Engineering UniKL MICET Experiment 2: Enzyme Assays and Factors Affecting Enzyme Activity Full Lab ReportDokumen10 halamanCPB 30103 Biochemical Engineering UniKL MICET Experiment 2: Enzyme Assays and Factors Affecting Enzyme Activity Full Lab ReportSiti Hajar MohamedBelum ada peringkat

- Practical 1 Final ReportDokumen5 halamanPractical 1 Final Reportbingxin liBelum ada peringkat

- Lecture 6 Amino Acid ProductionDokumen19 halamanLecture 6 Amino Acid ProductionRuben MarquezBelum ada peringkat

- Ayurveda Post-PartumDokumen16 halamanAyurveda Post-PartumMarta PANCOBelum ada peringkat

- Exp 3 Enzymology Part 1 Determination of Optimum ParametersDokumen5 halamanExp 3 Enzymology Part 1 Determination of Optimum ParametersNur Fadhilah75% (4)

- AOCS Ca 5a-40Dokumen2 halamanAOCS Ca 5a-40Bimmo Dwi Hartono100% (15)

- Analysis of Volatile Toxic Substances Using Headspace GC/MS Part.1 - Paint Thinner and AlcoholDokumen4 halamanAnalysis of Volatile Toxic Substances Using Headspace GC/MS Part.1 - Paint Thinner and AlcoholBilal KilaniBelum ada peringkat

- Data Pengamatan Pada Pemasakan Pulp PT Tanjung Enim Lestari Pulp and Paper PADA 31 JULI 2018Dokumen12 halamanData Pengamatan Pada Pemasakan Pulp PT Tanjung Enim Lestari Pulp and Paper PADA 31 JULI 2018AtikaBelum ada peringkat

- Biochemistry, Osmosis, Cellular Respiration & Photosynthesis Lab StationsDokumen9 halamanBiochemistry, Osmosis, Cellular Respiration & Photosynthesis Lab StationsRaina KimBelum ada peringkat

- 1999 ECCE2 Polluted SoilDokumen8 halaman1999 ECCE2 Polluted SoilDirceu NascimentoBelum ada peringkat

- Persyaratan Mutu Tepung Meizena (SNI 01-3727-1995)Dokumen8 halamanPersyaratan Mutu Tepung Meizena (SNI 01-3727-1995)Sekar Ade Setyo Rini0% (1)

- Effect of citric acid on mixolab dough propertiesDokumen2 halamanEffect of citric acid on mixolab dough propertiesabanoub ebaidBelum ada peringkat

- 1-s2.0-S2772753X23003957-mmc1Dokumen4 halaman1-s2.0-S2772753X23003957-mmc1tunglethanhphamBelum ada peringkat

- Partial Replacement of Concentrate by Browse G Saraye 21 JN 2020Dokumen3 halamanPartial Replacement of Concentrate by Browse G Saraye 21 JN 2020Rajesh ToolseeBelum ada peringkat

- Lab ReportDokumen4 halamanLab Reportluoziyun42Belum ada peringkat

- RESULTS AND DISCUSSION of PharmokinetisDokumen54 halamanRESULTS AND DISCUSSION of PharmokinetissaudBelum ada peringkat

- Density of Beverages ExperimentDokumen6 halamanDensity of Beverages ExperimentDana VillanBelum ada peringkat

- Eos Project Worksheet in EdaDokumen8 halamanEos Project Worksheet in EdaGalrichber ManadongBelum ada peringkat

- Aocs-Ca-5a-40 Free Fatty AcidsDokumen2 halamanAocs-Ca-5a-40 Free Fatty AcidsFatimaezzahra FaouziBelum ada peringkat

- Business StatisticsDokumen13 halamanBusiness StatisticsKarthikeyanBelum ada peringkat

- Peptide Concentration AssaysDokumen1 halamanPeptide Concentration AssaysJenealCarterBelum ada peringkat

- Treatment of Industrial Leachate Through Stabilization PondsDokumen11 halamanTreatment of Industrial Leachate Through Stabilization PondsSong Nguyen NguyenBelum ada peringkat

- JETIRFO06031Dokumen5 halamanJETIRFO06031iyerrohitBelum ada peringkat

- Centela Kitosan AlginatDokumen4 halamanCentela Kitosan AlginatpetriliaBelum ada peringkat

- Ca 5a 40 FfaDokumen3 halamanCa 5a 40 FfaLamya SlassiBelum ada peringkat

- Exp7 Result ReportDokumen7 halamanExp7 Result Report성제박Belum ada peringkat

- Effect of lactic acid bacteria on texture of fermented rice noodlesDokumen2 halamanEffect of lactic acid bacteria on texture of fermented rice noodlesEdward ChoongBelum ada peringkat

- Formulation Ration SwineDokumen5 halamanFormulation Ration SwineAjinkya JadhaoBelum ada peringkat

- Estimasi ThiaminDokumen9 halamanEstimasi ThiaminDwi VaniaBelum ada peringkat

- Purification of Glutamate-Aspartate Aminotransferase From Porcine HeartDokumen7 halamanPurification of Glutamate-Aspartate Aminotransferase From Porcine HeartLuke D'AnciccoBelum ada peringkat

- Lampiran A UfDokumen11 halamanLampiran A UfrennyBelum ada peringkat

- VOCs BloodDokumen6 halamanVOCs BloodTu TranBelum ada peringkat

- FC-4102LAB - Ash and Salt ContentDokumen8 halamanFC-4102LAB - Ash and Salt ContentharrygulatiBelum ada peringkat

- Full Text Paper-Gas ChromatographyDokumen2 halamanFull Text Paper-Gas ChromatographyRitesh AgarwalBelum ada peringkat

- Algal Ball ExperimentDokumen8 halamanAlgal Ball ExperimentPamBelum ada peringkat

- AlgoDokumen16 halamanAlgoAlyss KuroBelum ada peringkat

- Lab Water 1 ResultsDokumen9 halamanLab Water 1 ResultsKhaiiiBelum ada peringkat

- The Determination of The Pyruvic Acid Content of Garlic Tissue HomogenatesDokumen9 halamanThe Determination of The Pyruvic Acid Content of Garlic Tissue HomogenatesJasper Olivares100% (1)

- Precision Data Working Product Wise For Various Modes of TransportDokumen24 halamanPrecision Data Working Product Wise For Various Modes of TransportrsvasanBelum ada peringkat

- Hoja de Seguridad CarbamazepinaDokumen4 halamanHoja de Seguridad CarbamazepinaEveeHernándezBelum ada peringkat

- RP-HPLC Method of The Estimation of Folic Acid in TabletsDokumen5 halamanRP-HPLC Method of The Estimation of Folic Acid in Tabletsminela dacaBelum ada peringkat

- Measuring Pipette - 2Dokumen3 halamanMeasuring Pipette - 2Mirabel M. CyraBelum ada peringkat

- Hasil KBHP BaruDokumen7 halamanHasil KBHP BaruSeptiBelum ada peringkat

- AI Binling, SHENG Zhanwu ZHENG Xiaoyan and YANG XiaojingDokumen4 halamanAI Binling, SHENG Zhanwu ZHENG Xiaoyan and YANG XiaojingPhạm CườngBelum ada peringkat

- Presentation 1Dokumen6 halamanPresentation 1bahix27973Belum ada peringkat

- Three Component SystemDokumen8 halamanThree Component SystemKuo SarongBelum ada peringkat

- Dish FCT 1Dokumen7 halamanDish FCT 1adamsBelum ada peringkat

- Ammonia Determination in Hair Dye: Application Note No. 117 / 2013Dokumen6 halamanAmmonia Determination in Hair Dye: Application Note No. 117 / 2013Amit PaulBelum ada peringkat

- Isobaric Vapour Liquid Equilibrium For Acetone + Methanol + Calcium Bromide at Different ConcentrationDokumen5 halamanIsobaric Vapour Liquid Equilibrium For Acetone + Methanol + Calcium Bromide at Different ConcentrationIJERD100% (1)

- Biology ExperimentDokumen4 halamanBiology ExperimentKasyfur Rif'at Raduan0% (1)

- Biology Lab #2 - Enzyme-Catalase Results (Graph and Table) 1.1 Raw Data (Formatted in Table)Dokumen2 halamanBiology Lab #2 - Enzyme-Catalase Results (Graph and Table) 1.1 Raw Data (Formatted in Table)DroidRaxBelum ada peringkat

- Sulfuric AcidDokumen22 halamanSulfuric AcidEmmanuelBelum ada peringkat

- Conf. Proceed. Do The Conventional and Slow-Growing Production Systems Affect Broilers Meat Compositional and Textural Traits?Dokumen11 halamanConf. Proceed. Do The Conventional and Slow-Growing Production Systems Affect Broilers Meat Compositional and Textural Traits?rprobiosBelum ada peringkat

- Practical 4Dokumen8 halamanPractical 4Syazwani HussainBelum ada peringkat

- Pusat Penelitian Tanah Publikasi No. 59 Tahun 1983Dokumen1 halamanPusat Penelitian Tanah Publikasi No. 59 Tahun 1983Muhamad Suhar KushimaruBelum ada peringkat

- SO2 HSGDTcalculator 08 01 2018Dokumen13 halamanSO2 HSGDTcalculator 08 01 2018salar19Belum ada peringkat

- Acid Value - Metrohm Application Balletin No. 80-3 eDokumen7 halamanAcid Value - Metrohm Application Balletin No. 80-3 e陳丹庭Belum ada peringkat

- Muhammad Farizky Oktaviannizar AliDokumen7 halamanMuhammad Farizky Oktaviannizar AliMuhammad Ramadhannizar AliBelum ada peringkat

- Beer Lambert ExDokumen11 halamanBeer Lambert ExHarsh DesaiBelum ada peringkat

- Vinegar Analysis: Experiment No. 1Dokumen9 halamanVinegar Analysis: Experiment No. 1dumb dumbBelum ada peringkat

- Mass Spectrometry for the Analysis of Pesticide Residues and their MetabolitesDari EverandMass Spectrometry for the Analysis of Pesticide Residues and their MetabolitesBelum ada peringkat

- Articulo MoleculasaDokumen1 halamanArticulo MoleculasaRuben MarquezBelum ada peringkat

- Art 4 3Dokumen1 halamanArt 4 3Ruben MarquezBelum ada peringkat

- Articulo Probioticos 1Dokumen13 halamanArticulo Probioticos 1Ruben MarquezBelum ada peringkat

- Kuliah 2 Enzymetechnology 1Dokumen24 halamanKuliah 2 Enzymetechnology 1Angelika TjiongBelum ada peringkat

- ARTICULO 2019 Molecules Pagina LegalDokumen1 halamanARTICULO 2019 Molecules Pagina LegalRuben MarquezBelum ada peringkat

- Extraction and PurificationDokumen19 halamanExtraction and PurificationAar AeyBelum ada peringkat

- Production of Amino Acids (Glutamate)Dokumen48 halamanProduction of Amino Acids (Glutamate)Shiv SiddhBelum ada peringkat

- Art 4 1Dokumen1 halamanArt 4 1Ruben MarquezBelum ada peringkat

- Industrial & Environmental Biotechnology Course # KIBGE-707: Afsheen Aman, PH.DDokumen18 halamanIndustrial & Environmental Biotechnology Course # KIBGE-707: Afsheen Aman, PH.DZiwaqarBelum ada peringkat

- Kuliah 2 Enzymetechnology 1Dokumen24 halamanKuliah 2 Enzymetechnology 1Angelika TjiongBelum ada peringkat

- The Science of Malting, Brewing, and Fermenting BeerDokumen42 halamanThe Science of Malting, Brewing, and Fermenting BeerRuben MarquezBelum ada peringkat

- Problemas A Resolver TareaDokumen8 halamanProblemas A Resolver TareaRuben Marquez0% (1)

- BIE 5810 Chapter6Dokumen11 halamanBIE 5810 Chapter6Jin WongBelum ada peringkat

- Bioprocesos Exámenes Actualizado Abril 2018 TareaDokumen26 halamanBioprocesos Exámenes Actualizado Abril 2018 TareaRuben MarquezBelum ada peringkat

- Enzymatic Browning in Fruit2Dokumen68 halamanEnzymatic Browning in Fruit2Ruben MarquezBelum ada peringkat

- Lysinefermentation AnastassiadisDokumen15 halamanLysinefermentation AnastassiadisRuben MarquezBelum ada peringkat

- Cell Culture Processes For Monoclonal Antibody ProductionDokumen14 halamanCell Culture Processes For Monoclonal Antibody ProductionSailendra MeherBelum ada peringkat

- Problem Biochemical Engineering Set 1Dokumen9 halamanProblem Biochemical Engineering Set 1Ruben MarquezBelum ada peringkat

- Sporosarcina 1Dokumen7 halamanSporosarcina 1Ruben MarquezBelum ada peringkat

- Advancements in Industrial Microbiology: Fermentation to Bt TechnologyDokumen46 halamanAdvancements in Industrial Microbiology: Fermentation to Bt TechnologyRuben MarquezBelum ada peringkat

- Animal Cells BioreactorsDokumen13 halamanAnimal Cells BioreactorsRuben MarquezBelum ada peringkat

- Escalamiento Bioreactor Scale-UpDokumen11 halamanEscalamiento Bioreactor Scale-UpRuben MarquezBelum ada peringkat

- Sporosarcina 1Dokumen7 halamanSporosarcina 1Ruben MarquezBelum ada peringkat

- Design and Scale Up of Production Scale Stirred Tank FermentorsDokumen115 halamanDesign and Scale Up of Production Scale Stirred Tank FermentorsJulian Rene100% (1)

- 5 EnzymetechnologyDokumen8 halaman5 EnzymetechnologyRuben MarquezBelum ada peringkat

- Bacteria, Biofilm, and : Bio-Pesticide BTDokumen64 halamanBacteria, Biofilm, and : Bio-Pesticide BTduraiakilaBelum ada peringkat

- EscritoHighlights REV AQRDokumen1 halamanEscritoHighlights REV AQRRuben MarquezBelum ada peringkat

- An Influential Human-Rights Group Weighs The Legalization of Sex WorkDokumen2 halamanAn Influential Human-Rights Group Weighs The Legalization of Sex WorkKAMOGELOBelum ada peringkat

- Flavor Enhancer from Vanillyl Alcohol DerivativeDokumen12 halamanFlavor Enhancer from Vanillyl Alcohol DerivativeshishirchemBelum ada peringkat

- Name: Sokya Imaningsih Class: B NPM: 713.6.2.0491 Course: English Lecturer: Dr. Rahadian Ayu Nurfatoni, M.KesDokumen1 halamanName: Sokya Imaningsih Class: B NPM: 713.6.2.0491 Course: English Lecturer: Dr. Rahadian Ayu Nurfatoni, M.KesarmanBelum ada peringkat

- Appropriation of Korean Cuisine As A Function of Imagining Korean CultureDokumen22 halamanAppropriation of Korean Cuisine As A Function of Imagining Korean CultureJohn LloydBelum ada peringkat

- Bitter, Bland, Hot, Sweet, Salty, Spicy, Mild, Rich, SourDokumen2 halamanBitter, Bland, Hot, Sweet, Salty, Spicy, Mild, Rich, SourИван ЛуникаBelum ada peringkat

- Heat Analysis of Spicy Foods by HPLCDokumen2 halamanHeat Analysis of Spicy Foods by HPLCTrevor LundBelum ada peringkat

- Cristina Peña & Eliana Vargas - The-Science-Of-SpicinessDokumen6 halamanCristina Peña & Eliana Vargas - The-Science-Of-Spicinessdulce crissBelum ada peringkat

- 4 The Patterning Theory of Spice Use: I. Patterning For Using Spices EfficientlyDokumen56 halaman4 The Patterning Theory of Spice Use: I. Patterning For Using Spices EfficientlyLitva LazaneoBelum ada peringkat

- Food AdjectiveDokumen17 halamanFood AdjectiveEldiyar AzamatovBelum ada peringkat

- Ayurveda's Six Tastes & Their Effects On The Doshas - Amrita Veda PDFDokumen4 halamanAyurveda's Six Tastes & Their Effects On The Doshas - Amrita Veda PDFVenkatesan KalaivananBelum ada peringkat

- Kine 2p20 Nutrition Literacy AssignmentDokumen7 halamanKine 2p20 Nutrition Literacy Assignmentapi-437399185Belum ada peringkat

- Taste Perception - 18 & 19Dokumen25 halamanTaste Perception - 18 & 19nishadh1Belum ada peringkat

- Soal Literasi Bahasa InggrisDokumen2 halamanSoal Literasi Bahasa InggrisAmanda ClaudiaBelum ada peringkat

- Taste and Classification of FlavoringsDokumen31 halamanTaste and Classification of FlavoringsasokmithraBelum ada peringkat

- Pahamify To L.binggDokumen9 halamanPahamify To L.binggEma ArmidiyantiBelum ada peringkat

- CCHH Practical PhytochemistryDokumen29 halamanCCHH Practical PhytochemistryAlexander IvanoffBelum ada peringkat

- The 15 Health Benefits of Green ChilliesDokumen3 halamanThe 15 Health Benefits of Green ChilliesMark Vincent ColamboBelum ada peringkat

- China ReportDokumen2 halamanChina ReportImee LimbawanBelum ada peringkat

- Trends in Food Science & Technology: Nathânia de Sá Mendes, Édira Castello Branco de Andrade Gonçalves TDokumen15 halamanTrends in Food Science & Technology: Nathânia de Sá Mendes, Édira Castello Branco de Andrade Gonçalves TIlija MileticBelum ada peringkat

- EFR - Sensory Evaluation FinalDokumen81 halamanEFR - Sensory Evaluation FinalJoddie LoplopBelum ada peringkat

- The Science OF Spiciness: Warm UpDokumen4 halamanThe Science OF Spiciness: Warm UpKatyBelum ada peringkat