VeriCube Manual en

Diunggah oleh

Florin PătrulescuJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

VeriCube Manual en

Diunggah oleh

Florin PătrulescuHak Cipta:

Format Tersedia

REA VeriCube

Verifier for Matrix Codes and

Bar codes

Operating Manual

Document Version 1.1

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 1 of 76

Table of contents

1 Introduction ............................................................................................... 4

2 Delivery scope ............................................................................................ 4

2.1 Basic configuration ................................................................................ 4

2.2 Optional accessories .............................................................................. 5

2.3 Software options ................................................................................... 5

3 REA VeriCube Version.................................................................................. 6

3.1 REA VeriCube Standard .......................................................................... 6

3.2 REA VeriCube Pharma ............................................................................ 6

4 Commissioning ........................................................................................... 7

4.1 Power supply ........................................................................................ 7

4.2 System requirements............................................................................. 7

4.3 Temperature change.............................................................................. 8

4.4 Connecting ........................................................................................... 9

4.4.1 Own Ethernet port ......................................................................... 10

4.4.2 Network operation ......................................................................... 10

4.4.3 PoE in switch................................................................................. 11

4.4.4 MAC addresses .............................................................................. 11

4.4.5 Firewall and network type ............................................................... 11

4.4.6 Firewall and Network ports ............................................................. 12

4.4.7 Using a gateway ............................................................................ 12

4.4.8 Fixed IP Addresses......................................................................... 12

4.5 Software ............................................................................................ 13

4.5.1 Software installation ...................................................................... 13

4.5.2 Software and device options ........................................................... 14

4.6 Mounting and exchanging the optic module ............................................ 20

5 Operation and transport ............................................................................ 21

6 Correct handling ....................................................................................... 22

6.1 General considerations ......................................................................... 22

6.2 Checklist for measuring........................................................................ 23

7 Operating the device ................................................................................. 25

8 Adjustment and Calibration of the REA VeriCube ........................................... 27

8.1 Level correction .................................................................................. 28

8.2 Reflectance adjustment ........................................................................ 31

8.3 Scale adjustment ................................................................................ 33

9 REA VeriCube calibration ........................................................................... 34

9.1 Admissible device tolerances ................................................................ 36

9.2 Calibration for white and red light ......................................................... 37

10 Synthetic aperture / measuring opening ................................................... 37

11 Execution of the measurements ............................................................... 39

11.1 Positioning of the device .................................................................... 39

11.1.1 Camera downwards ..................................................................... 39

11.1.2 Camera upwards ......................................................................... 40

11.1.3 Camera sideways ........................................................................ 41

11.1.4 Turning the keyboard .................................................................. 42

11.1.5 Testing 3D parts ......................................................................... 42

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 2 of 76

11.2 Measuring process in the Windows software......................................... 43

11.3 Automatic ROI ................................................................................. 44

11.4 Recording the image ......................................................................... 45

11.5 Opening the image file ...................................................................... 45

11.6 Saving the image file ........................................................................ 45

11.7 Static reflection measurement............................................................ 46

11.8 Preset the measurement image size.................................................... 47

11.9 Rotating the image ........................................................................... 47

11.10 Display of the evaluation ................................................................... 48

11.10.1 Test reports ............................................................................... 48

11.10.2 Details in the test reports ............................................................ 48

12 Configuring the evaluation and symbologies .............................................. 51

12.1 Evaluation ....................................................................................... 51

12.2 Symbology selection ......................................................................... 52

12.3 Profile management .......................................................................... 53

12.4 Identification of test reports............................................................... 54

12.5 Lighting and aperture........................................................................ 55

12.6 Device data ..................................................................................... 57

12.7 User management ............................................................................ 58

12.7.1 Simple user name ....................................................................... 58

12.7.2 Simple password......................................................................... 58

12.7.3 Set up the user management ....................................................... 59

12.7.4 User management during operation .............................................. 62

12.7.5 TransWin32 configuration with password ....................................... 64

13 Trouble shooting .................................................................................... 65

14 Intellectual property reserve ................................................................... 68

15 Software update .................................................................................... 68

16 Protected trademarks ............................................................................. 69

17 Certificate of conformity for REA VeriCube................................................. 70

18 Certificate of conformity for the REA calibration cards ................................. 71

19 EU declaration of conformity for the REA VeriCube ..................................... 72

20 Technical data ....................................................................................... 73

21 Warranty conditions ............................................................................... 76

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 3 of 76

1 Introduction

The REA VeriCube is a measurement device for the quality control of printed matrix

codes and 1D-codes. This is a stationary device, which has to be connected to a PC

via an Ethernet network. The delivered software along with the device driver and the

display of the test reports run on a computer running Microsoft Windows.

In contrast to a scanner for bar codes and matrix codes, REA VeriCube is an optically

operating measurement device. Measurement devices are subject to a regular

adjustment and calibration (monitoring of testing equipment). Adjustment and

calibration (monitoring of testing equipment) can be performed by the operator.

2 Delivery scope

The REA VeriCube in its basic configuration is delivered in cardboard packaging and

fitting foam padding with the following parts:

2.1 Basic configuration

1 REA VeriCube, measuring device standard with threaded mounting holes for

affixing the client-specific devices or accessories (030.035.100)

or

1 REA VeriCube, measuring device Pharma closed panel without holes

(030.035.101)

1 optic module, exchangeable, according to the delivery note (built into the

unit)

1 Plexiglas dust-protection cover built-in in transport (must be replaced with

a glass plate during commissioning)

1 anti-reflective glass plate (08316280) (separately packaged)

1 GigaBit PoE power supply unit (100240V, 30W) (06113003)

1 power cable for the ordered plug standard (Euro, UK, US)

2 network cables, highly flexible, RJ45 CAT5 (08316605)

1 printed operating manual (this document)

1 USB stick with software and documentation (08316300)

1 calibration card, serialized, in a protective envelope (08300907)

1 test report of the reference code of the calibration card, created with the

delivered VeriCube for documenting the delivery status

1 test report of the reference code (req. for test equipment monitoring)

1 white level correction calibration card (protected in new condition with blue

protection foil) in a protective envelope (07601402) (can be cleaned with 3M

Novec 71IPA)

1 field of view cover as a black PVC plate (07601403)

1 field of view cover as a black cloth (07799084)

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 4 of 76

2.2 Optional accessories

Optional parts are only included if they have been ordered and are listed separately

on the delivery note. License keys are not necessary. In devices that are already in

operation, optional functions can be activated later by means of license keys.

Camera modules

There are four camera modules. At least one of the four camera modules must be

selected and specified when ordering

030.037.101 Camera module for matrix codes >= 0.18 mm

(focal length 12 mm, field of view 80 x 60 mm)

030.037.100 Camera module for matrix codes >= 0.25 mm

(focal length 8 mm, field of view 113 x 70 mm)

030.037.102 Camera module for matrix codes >= 0.14 mm

(focal length 16 mm, field of view 63 x 47 mm)

030.037.103 Camera module for matrix codes >= 0.09 mm

(focal length 25 mm, field of view 37 x 27 mm)

Delivery in a case instead of cardboard packaging

09930162 + 09930200 Device case in a suitable cardboard shipping box

Optional test cards for extended monitoring of the testing equipment

08300912 Calibrated test card with EAN/UPC codes

08300911 Calibrated test card GS1 Data Matrix Codes

Measuring table one measuring table as a table for parts / cans which can neither

be left on the REA VeriCube for measuring nor placed on the REA VeriCube.

2.3 Software options

030.207.101 Optional symbologies (internal)

08300920 ScanLink testing the structured code content (additional installation)

030.207.170 Article database32 (additional installation)

030.035.180 Code analysis (internal software option) Software extension for client-

specific analysis of data structures using a definition table

030.035.181 DPM -ISO/IEC TR 29158 (AIM DPM Guideline 2006) (internal software

option) Measurement evaluation for direct part marking, limited to

45 illumination

When re-orders of internal software options are placed, the delivery consists of an

access code, which must be entered in TranWin32.

The delivery of re-ordered software options consists of a data carrier, a handbook,

and an activation key.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 5 of 76

3 REA VeriCube Version

3.1 REA VeriCube Standard

The REA VeriCube, in the standard design, has 13 screws on the upper side. Up to

any two screws, all the others can be removed.

The plate is either in blue or in silver color. The screws have Torx T10 heads.

The screws are there to close the threaded holes. The threaded holes are provided

for fastening the used fixtures when, for example, auxiliaries and other measurement

aids must be affixed to the device. The advantage of this is that frequently made

measurements of identical products can be performed by the device without the

positioning aided by the live image function.

3.2 REA VeriCube Pharma

The REA VeriCube in the Pharma design has a closed plate at the top without screw

holes.

This design is intended for use in areas in which it must be possible to clean the

surface easily and quickly.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 6 of 76

4 Commissioning

4.1 Power supply

The power for the VeriCube is supplied via a network cable connected to the device.

This type of power supply is designated as Power over Ethernet (PoE) (power supply

over a network cable). The delivered power supply unit provides power to a

connected device only when the device is designed for a power over Ethernet supply.

Nevertheless, it is recommended never to connect not PoE-enabled power supply

devices to the OUT connection of the power supply unit. A second cable or additional

separate power supply unit is not necessary. The delivered network cables are, apart

from the increased flexibility, standard off-the-shell equipment.

4.2 System requirements

For the device power supply a mains connection in the range of 100 - 240 V AC,

between 50 and 60 Hertz is necessary.

The Windows software TransWin32 needs a standard off-the-shelf computer with a

Microsoft Windows operating system,

- at least Windows 7, 32 bit or a newer one. 32-bit Windows versions are an

exception for Windows 7 and Windows 8 installations. Therefore, it is strongly

recommended to use only the 64-bit Windows versions.

- Microsoft .net framework version 4 or later(if possible, the current version

Version 4.5.2 or later)

- One or optionally two Ethernet network interfaces

(2 Ethernet network interfaces are recommended

(at least 1Gbit/s, Auto detect between normal and Crossover)

- Main memory: The minimum requirements of the used operating system must

be observed. Typically, they must be 4GB or more.

- Hard disk: The minimum requirements of the used operating system must be

observed

- CPU: The minimum requirements of the used operating system must be

observed (a slow CPU increases the waiting time).

- Mouse (with mouse wheel) / keyboard (supplementary touchscreen, if

necessary)

- Screen / graphics: Non-glare, minimum 48cm (19),

at least 1280 x 1024 pixels in resolution, color

- Optionally: PDF program for the creation of test reports as PDF files (as printer

simulation)

- PDF display program

- Firewall. The firewall must permit the network operation with the REA

VeriCube

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 7 of 76

The REA software TransWin32 is a single user software. The license is connected to

the REA Verifier and not to the PC installation. The software does not need a dongle

and can, if needed, be installed manifold.

Operation on a server is not a tested and verified property. As long as the server

offers the REA program TransWin32 an environment, which reacts as a single

workplace for the program, the server installation should work properly (virtual

environment, sandbox, etc.).

An installation under Windows XP does not function because the software contains

program parts which absolutely need the functions of the newer operating system

version.

The minimum computer requirements are sufficient, but it is recommended

to use the configuration which the operating system in use also prescribes

as the recommended configuration.

4.3 Temperature change

When the REA VeriCube is subjected to temperature changes (e.g. when it is

mounted in heated rooms after transport in winter), the optical parts can be fogged

up. In such a case, it is necessary to wait for about 15 min before the REA VeriCube

can be used.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 8 of 76

4.4 Connecting

The REA VeriCube is delivered with two identical network cables.

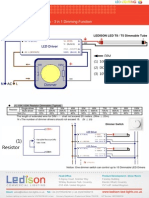

Picture of a network cable

The REA VeriCube is connected with one of the two Ethernet cables to the PoE power

supply unit. The socket, which is labeled on the power supply unit with "P+D/OUT",

is intended for the connection with the device. When the other "Data/In" socket is

used, the device does not receive power.

The "Data/In" socket on the PoE power supply unit is connected with the second

network cable and with the computer (directly or indirectly).

The picture shows an example of the connection of the Data-In socket to the network

installation (here shown by the Ethernet switch).

The power supply unit has an IEC socket for connecting to the electric grid. The

mains cable is delivered adapted to the country standard.

The socket type is C14 (IEC-60320). The plug type is C13.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 9 of 76

Picture of a socket, low-power mains plug type

The power supply through the PoE is characterized by the fact that the power supply

unit first checks whether a connected device is designed for a PoE power supply. In

this test period, the device cannot yet be turned on.

As long as the testing takes place, no LED lights up on the Ethernet socket of REA

VeriCube. As soon as the device receives power supply, the left LED lights up (light-

orange)

Picture of LED OFF Picture of LED ON

ATTENTION: REA has a complete device series of code verifiers in its offer.

In all devices, the power supply takes place with the help of PoE power

supply units. The REA VeriCube needs the 30W type POI-3000 (or POI-3002

or POI-3004). The other devices use the 15W type POI-2002. When these

power supply units are interchanged, the REA VeriCube only seems to

function. However, the measurement and the lighting do not function

correctly. Therefore, the power supply units shall not be interchanged.

4.4.1 Own Ethernet port

The PC has one or a second network connection which is reserved exclusively for the

operation of the tester. The "Data/IN" socket of the power supply unit is connected

directly with a cable to this socket.

4.4.2 Network operation

The PC is connected firmly in a company network. The REA VeriCube is connected

from the "Data/IN" connection with an available and connected (patched) network

socket. The server (DHCP) in the network automatically assigns the network

addresses. When the company network is subjected to heavy network traffic,

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 10 of 76

disruptions (the device shows network errors) may occur during operation. When

these disruptions become too frequent, the network must be segmented by the

network administration or the REA VeriCube must be connected to the computer with

a separate network connection (see the previous section).

4.4.3 PoE in switch

Operation on an Ethernet switch, which takes over the PoE power supply instead of

using the delivered PoE power supply, is possible. A connection, which can provide

30W power, is necessary. This mode of operation is a responsibility of the operator

and is not tested by the manufacturer. The PoE power supply is an industry standard

and is, therefore, usually non-critical as long as a PoE switch is not overloaded by too

many consumers.

4.4.4 MAC addresses

Every network-enabled device receives a MAC address from the manufacturer. The

MAC address is provided on the type label. Some network environments are

configured in such a way that only known devices are admitted. In this case, the

MAC address is transmitted to the IT department for release

4.4.5 Firewall and network type

When a firewall is active, it must be configured in such a way that the network

operation between the PC and the REA VeriCube can pass the firewall. During initial

installation, the security rules are usually inquired.

When the operating system recognizes a new network, it is asked whether this is a

public network. This must be answered in the negative.

(Public networks are WLAN at a railway station, airport, etc.)

When there are particularly strict security rules in a company or if the network is

heavily loaded with data traffic, REA recommends using a second Ethernet port of a

PC which is reserved for the REA VeriCube.

On the delivered data carrier, there is a document which describes the network

integration in detail and also designates the used port.

In difficult installations, this document must also be observed.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 11 of 76

4.4.6 Firewall and Network ports

The installation contains several modules (see chapter 4.5.2). Communication

between modules is performed via network mechanisms (Sockets, Ports). Ports in

use are listed in the following table. The Firewall must open the ports and let the

program module communication pass.

Transwin32.exe Port: 23945

ServiceTool.exe Port: 23947

MorpheusHost.exe Port: 23946

MLV_Control_PC.exe Port: 10061

VeriCube_Control_PC.exe Port: 10051

readb.exe (Artikel Datenbank) n/a

If any of the program modules or ports is blocked then the application will not work

anymore or show odd behavior.

4.4.7 Using a gateway

The REA VeriCube is using the camera protocol GigE Vision. This is primarily specified

for a direct communication between two devices (Computer and Camera). Operation

over a Gateway is not recognized and does not work.

4.4.8 Fixed IP Addresses

In some network environments fixed IP Addresses are demanded or required. This is

usually solved by a manual configuration of the network settings of the computer and

the Verifier. A manual network configuration restricts the flexibility of use of the

verifier. Therefore the use of a DHCP server is always recommended. The DHCP

server manages devices which are identified by their MAC addreses. For each device

requiring a fixed IP address the server is configured to provide such devices always

and automatically the same (fixed) IP Address.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 12 of 76

4.5 Software

The REA TranWin32 software is necessary for operation. Only one REA VeriCube can

be used per computer. Other REA Verifiers can be used in this installation except a

second REA VeriCube.

4.5.1 Software installation

Prior to the actual installation, the Microsoft .net framework must be installed. The

REA installation checks whether .net is present and aborts the operation if it is not

installed. On the Microsoft website, there is a search function in the download

section. When searching for ".net offline", the .net installation package is offered

(Version 4.5.2, Status July 2014). Meanwhile (Summer 2015) the Microsoft update

function provides the .net Framework in this version.

When the system prerequisites are met, the TransWin32 program must be installed.

For this purpose, the "Setup.exe" is launched. Depending on the version, the

TransWin32 installation is offered directly or the TransWin32 button comes first and

then "Install TransWin32".

Administrator rights are required for installation. For normal operation, the normal

user rights are sufficient. When the software for all users is installed, the "All users"

documents folder is used. This general application folder must be available to all

users without administrator rights.

The most secure and complications-free installation variant turns the user account

for the installation into an administrator account. The installation is performed only

for this user and thus only the Documents folder of the logged-in user is used. When

the installation is carried out with "Execute as administrator", the installation is

performed with the administrator account and not with the user account. In this

case, it should be installed for all users and it should be ensured that all users have

read and write rights to the "All users" document folder.

In case of communication trouble (disconnects, error messages like Sensor errors)

two basic solutions are available:

1. Within the TransWin32 menu Tool the installation of the Vericube Network

driver is performed

2. A second Ethernet port is added to the PC and the REA VeriCube is exclusively

connected to this port.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 13 of 76

4.5.2 Software and device options

At first comes the selection of the language for the installation process

The next step is to agree to the license terms.

The following dialog offers a selection of the components to be installed

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 14 of 76

TransWin32 The main program for displaying and managing the test reports

Check ER The REA Verifier model REA Check ER is used

PC Scan LD3 The REA Verifier model REA PC-Scan/LD3 is used

ScanCheck 3n The REA Verifier model REA ScanCheck 3n is used

MLV-2D The REA Verifier model REA MLV-2D is used

VeriCube The REA Verifier model REA VeriCube is used

The installation option ADB Client installs the REA article database software. The

option ScanLink Assistant is an option for installing and using the ScanLink software

for extended analysis and evaluation of ISO standardized data structures.

These two software options should be installed only when these software options are

bought with the REA Verifier.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 15 of 76

Then comes the question about the desired installation type

When the programs for all users are installed, the documents folder "All Users" is

used as a data target folder.

The user needs read and write rights for that folder.

When the programs "...are installed for me only", the data folder of the logged-in

user is used as a data target folder (except when the setup was executed as

administrator; then it is the document folder of the administrator; in this case,

always select "...for all users.")

The restoration of the old configuration is valid only for the REA VeriCube device

type. When an older dataset with calibrated data is available, it is re-imported in the

new installation. The import is only available if while uninstalling a backup of the

configuration and calibration data was created.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 16 of 76

Next, installation paths are displayed and can be changed, if necessary.

The programs are installed in the Programs (or Program Files) folder. X86 shows that

it is a 32bit program and not a 64bit program.

The path C:\ProgramData is the file system for installation and programrelevant

data, which normally remain invisible for the user. This path should be changed only

when there are urgent administrative reasons for that. The actual user data folder is

always in the Documents section of the user or in the one for all users.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 17 of 76

At the end, the installation can be tested again.

If at this point the installation is cancelled, this means that the old version has

already been removed and the new one has not yet been installed.

Afterwards, the software is installed and the process is displayed in the window with

a progress bar.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 18 of 76

When the installation was successful, this is shown as follows.

Depending on the selected installation, the following icons can then be found on the

desktop. In the actual release only the TransWin32 and maybe the REA ADB icon is

there. The other two icons are not required because these programs are started and

stopped automatically together with the TransWin32 program.

With the icon TransWin32, the REA Verifier software is launched. "VeriCube Barcode

Verifier" and "MLV-2D Barcode Verifier" are programs which are launched as device

service (no window, only an icon in the task bar). Both are launched automatically at

the start of TransWin32 and are also closed at the end.

REA ADB is the article database; it is used for management, recording and data

import, which can be used with the REA Verifiers. The program is launched by the

operator when needed. The article database (REA ADB icon) is optional and can only

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 19 of 76

work with the REA Verifier when the program license is bought and also activated in

the device.

4.6 Mounting and exchanging the optic module

Four different optic modules can be obtained for the testing of very small or very

large codes. The optic modules are pluggable and can be exchanged by the operator

and without a tool. The different variants with focal length, minimum code size and

field of view size are described in section 2.2. For changing the optic module, the

device must be turned off. The knurled-head screw is loosened and the module can

be removed.

Picture of an optic module

The black dust-protection cap on the lens must be removed prior to mounting. For

each optic module type, one calibration dataset is saved. When a given optic module

is used for the first time, the calibration must be performed prior to the

measurement.

ATTENTION: The lens of the optic module is optically measured and is firmly

preset. The alignment shall not be changed and the lens shall not be

mounted on other electronics.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 20 of 76

5 Operation and transport

Humidity, cold, heat and mechanical impacts and falls can lead to a situation where

the measuring chamber cover as well as the mechanical and electronic parts can be

damaged or destroyed. If the device still provides measurement results with these

damages, there is a high risk that these results are incorrect or deviate too far from

the correct values.

After transportation, the device must be warmed up to room temperature because

the optical parts can be fogged by the temperature change.

The device is delivered with a plastic cover and a glass cover, which close the

measuring chamber. The plastic cover serves as dust protection during the storage

and transportation of the REA VeriCube. The glass cover serves as a cover in the

event that the codes to be measured need to be placed on the surface. The glass

cover must always be removed prior to the transportation and then the plastic cover

must be used as protection.

The REA VeriCube is delivered in a case or in a cardboard box with adequate foam

padding. This package should be preserved for possible transportation. If the REA

VeriCube is shipped without the original packaging, it should be packaged with good

padding, so that the device cannot move in the cardboard shipment box.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 21 of 76

6 Correct handling

6.1 General considerations

The REA VeriCube is an optical measurement device with a camera and built-in

lighting. The device should be lifted only by the recessed grips provided for this

purpose. The optic module should never be used as a handle.

Falls and impacts will damage the REA VeriCube

Picture Recessed grip

Picture of a built-in camera module

The network cable is locked in the socket. The lock is loosened with a small plastic

lever on the plug for removal. This socket/plug combination is relatively sensitive

mechanically (robust industrial plugs were deliberately not used because they are

very large and require expensive and special cables, which are hard to find). The

cable should not be pulled without releasing the lock. The plug should not be

subjected to any pulling, pressure or other impact forces. Any lateral strains lead to

high risk of damage. The pulling strains can lead to damage or destruction of the

cable and, additionally, of the socket installed in the device.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 22 of 76

6.2 Checklist for measuring

The following points must always be observed for performing correct measurements:

1. The distance between the code and the device should vary only slightly. The

depth of field is, contingent on the small distance between the lens and the

inspected area, limited to +/- 1 mm.

2. The code should always be positioned centrally in the middle of the field of

view.

3. The code should be aligned, as much as possible, in parallel or at an angle of

90 to the field of view in order to minimize any imprecisions due to staircase

effects at the code edges.

4. The automatic determination of the position defines the measuring area for 2D

codes and bar codes. The measuring area in the case of 2D codes is shown by

a superimposed green square and in the case of bar codes, by red

measurement lines. The square must surround the code in parallel to the code

sides.

The measurement lines must cross the bars of the code at an angle of 90.

If this is not the case, the measuring area must be determined manually. (See

section 11.2)

Picture: 2D code with manual ROI (region of interest = determining the

measuring range)

Picture: Bar code with manual determination of the ROI

5. When determining the measuring area manually, the parallel alignment or the

90 angle must be observed. When the bar codes are positioned diagonally in

the field of view of the camera (when they are otherwise too wide), the

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 23 of 76

measuring area must be determined at an angle of 90 with respect to the

bars and not in parallel to the edges of the field of view.

Picture: Manual ROI at a more slanted position of the code

6. It should not be measured in direct sunlight, under direct (spot) light rays or

close to infrared sources (heat emitters). Ambient light will lead to changes in

the measured results and the sunlight leads to unusable results

7. The test sample must be positioned flat and leveled on the measurement

surface. If this is not observed, there are distortions in the measured picture

level, which lead to incorrect measurement results. The risk is particularly high

in foils and labels, which are processed as rolls. From the device position, the

camera must always record the code in perpendicular and the lighting must

always be at an angle of 45 (only the DPM measurements have

particularities)

8. The transparent materials must always be measured on a flat, unchanging and

impermeable black base (usually with a reflection of maximum 5 %). When

different measurement bases are used, the measurement results are also not

comparable

9. The synthetic aperture should always be in the range of about 80% of the

module width in order to obtain good decoded results. In case of 2D code

measurements according to ISO/IEC 15415 or DPM (ISO/IEC TR 29158), the

synthetic aperture is automatically determined

10.When there are several codes in the field of view and a code, which is not the

one centered in the middle, is recorded, the codes that are not required must

be covered.

11.The REA VeriCube must be regularly adjusted and has to be controlled with the

help of test equipment monitoring for measurement accuracy (calibrated)(see

sections 8 and 9)

12. Automatic recognition and decoding may recognize the codes incorrectly or

not at all. In such a case, the operator must evaluate whether the result is

valid or not and, if necessary, he should repeat the measurements with

corrected settings or perform them several times.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 24 of 76

7 Operating the device

In some basic functions, the REA VeriCube can be operated with the device buttons

The on/off button

With this button, the device is turned on and off. Since the PoE power

supply must be negotiated with the connected device, there is some

turn-on delay. It ends as soon as the left orange LED on the Ethernet

socket of the device lights up. Prior to that, the device cannot be turned

on.

The Scan button

A measurement is performed by observing the ROI, which is determined

(manually or automatically) on the PC

The F1 button

The F1 button turns on the live picture display so that the code can be

positioned. The live picture has a lower resolution than the

measurement picture, and the brightness is adjusted automatically so

that something becomes visible in the picture. This adjustment of the

brightness can be completely different than the adjustment for the

measurement with calibrated exposure settings.

The F2 button

The F2 button toggles between red and white light illumination.

The F3 button

The F3 button is provided for subsequent extension, e.g. a function, which can be

assigned to the button by the operator.

The LEDs above the buttons have the following meaning:

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 25 of 76

ON button LED

The LED lights up permanently as soon as the device is ready for operation.

SCAN button LED

The LED shows the testing result. Red means "failed" and green means OK/ passed.

F2 button LED

The LED shows the type of light used for measurement. It is either white or red.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 26 of 76

8 Adjustment and Calibration of the REA VeriCube

The terms adjustment and calibration are used in the sense of DIN 1319-1 and

JCGM 200:2012.

Calibration: The device measuring accuracy is checked against a known reference.

For this process the device adjustment shall not be changed.

Adjustment: The device settings (Exposure, white level, compensation of lens

distortions) are changed until a specific result is achieved. The following calibration

checks if the required measuring accuracy is achieved.

The REA VeriCube must be adjusted in regular intervals of between 4 and 12 weeks.

An additional adjustment is necessary if, in the meantime, the ambient and the

lighting conditions change a great deal. The instructions for performing a correct

measurement must be observed particularly closely during calibration (see section

6.2).

The adjustment data of the REA VeriCube are, in contrast to the other REA

Verifiers, saved in the PC not on the device.

Therefore, software installations on other PCs must always be adjusted

again or the adjustment data must be imported from the first PC (see section

12.6).

The REA calibration cards are used for adjustment and calibration.

The following instructions for handling the calibration cards must be observed.

The calibration cards must not be dirty or scratched and their surface should

not be touched.

The card for adjustment of the white level correction is protected in the

delivered condition with a blue plastic foil. It must be removed prior to

adjustment.

If the card is damaged or contaminated, it has to be replaced.

The date of the first use must be noted. This date determines the start of the

lifespan of 2 years.

The cards should not be stored unused for more than one year.

No calibration and adjustment can be performed with a photocopy of the

original calibration card because as a result of the copying, the metrical and

reflective properties change significantly. For the same reason, the calibration

card shall not be laminated.

The calibration cards may be cleaned.

The recommended cleaning agent is 3M Novec 71IPA

Calibration and adjustment must be performed in the same manner employed

for measurement. If a mounted glass cover is used for measurement,

calibration and adjustment must also be performed with a mounted glass

cover. When work is conducted without a glass cover, calibration and

adjustment shall also be executed without a glass cover.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 27 of 76

Calibration and adjustment must be performed with the respective optic module.

After it is changed to another optic mode or after the expiration of the respective

calibration interval, a completely new adjustment and calibration is necessary.

The device adjujstment is initiated through the REA TransWin32 software.

For this purpose, the Device adjustmen and calibration menu item must be selected

in TransWin32.

The REA VeriCube is delivered with a transparent plastic cover, which covers the

inside space of the camera, as well as with a glass cover.

The plastic cover simply serves as dust protection during storage and transportation.

The glass cover is used for measurement. In this regard, it must generally be

remembered that measurement is performed with a glass cover if a glass cover was

used for adjustment and calibration. If the device is calibrated without a glass cover,

it must also be measured without a glass cover.

Adjustment is performed in three consecutive steps:

1. Level correction (level correction calibration card Art. No. 07601402)

2. Reflectance adjustment (calibration card Art. No. 08300907)

3. Scale adjujstment (calibration card Art. No. 08300907)

Note: In the previous software versions, the Verifier model REA MLV-2D has first

performed the reflectance adjustment (see section 8.2) and then the level correction.

In the meantime, both devices use the same adjustment sequence.

If an individual step is not executed correctly, there is a possibility to repeat this

individual step separately. If an adjustment step was not successful, its old data are

retained for this step. In this way, the device always remains functional.

The calibration cards show a black reverse side. This is necessary in order to be able

to perform calibration and adjustment without influence from the reflectance on the

work table (the normal materials let the light penetrate). During the operation of an

adjustment step, the device should not be moved.

8.1 Level correction

For the level correction, the white card with article number 07601401 is used. The

level correction is performed under Configure / Calibrate and adjust device. There

are three tabs for selection and one of them is the level correction. After the REA

VeriCube is placed on the white card, the level correction is started.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 28 of 76

Picture of a level correction card (original size 22 x 25 cm)

Picture: The level correction card on the device

The level correction corrects the uneven lighting of the measurement field

(tolerances of the LEDs, construction, optics, etc.).

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 29 of 76

The level correction is started with a mouse click on <OK>.

Level correction adjustment can fail, can give a warning or is successful. If level

correction fails or if there is a warning, the lens of the objective in the optic module

must be cleaned (optics cleaning cloth for glasses and lenses). Then the card must

be cleaned and the level correction must be repeated. If level correction does not

function and a defect in the device can be excluded, a new level correction card must

be provided. This can be checked with a simulated level correction using a new high-

quality photographic paper. If this adjustment is accepted, the card must be

replaced. If not, there is possibly a defect in the device and the device must be

checked at the manufacturer or by an authorized service center and repaired if

necessary.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 30 of 76

8.2 Reflectance adjustment

Reflectance adjustment is performed on the four fields which lie in the "Reflectance

calibration field" field. The four reflection values, which have been entered in the card

in the "Reflectance values target" field, must be tested and possibly entered in the

software if the values there do not match.

Picture: Reflection values on the Reflectance calibration card

Picture: Software menu "Reflectance adjustment"

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 31 of 76

The device must be positioned with the help

of the live video representation in such a way

that the red cross hair is in the middle of the

picture of the four reflectance fields, which

are in the middle of the "Reflectance

calibration field" field. The device must be

configured in such a way that the white field

is at the top on the left and the black field is

at the bottom on the right.

Picture: Cross hair in the gray value field

Then the Reflectance adjustment is started with the OK button.

During the reflectance adjustment, a progress window appears. The adjustments for

the red and white lighting are always performed one after the other and last for

about 2-3 minutes.

During adjustment it is possible to check the correct

position of the card.

The squares shall each be positioned in one field.

The adjujstment becomes invalid if the squares cross

the field borders.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 32 of 76

8.3 Scale adjustment

As a third step, the scale adjustment is performed.

Picture: Code position for

the scale adjustment

Picture: Scale adjustment software menu

For this purpose, with the help of the live video representation, the data matrix code,

which is designated with Dnom = 0.5, is positioned as precisely as possible in the

middle of the cross hair and perpendicular to the image section. The software has a

setting for the Dnom value in millimeter (mm). The value of 0.500 is the required

setting. The adjustment sets the pixel size automatically in such a way that exactly

the known correct size of the calibration symbol appears in the measurement result.

Following the scale adjustment, the code is automatically measured twice. This

measurement takes place with red light and the other one with white light. The

results must be documented and are used as reference for the subsequent calibration

(=test equipment monitoring).

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 33 of 76

9 REA VeriCube calibration

Calibration (Test equipment monitoring) is a process with which the values measured

by the device are compared with known reference results of a test code. The values

measured by the device shall deviate from the reference values only within the

specified tolerances.

Calibration should be repeated in regular intervals (e.g. monthly). Calibration shows

if the device is misaligned since the last calibration. If results show values out of

tolerance all measurements since the last calibration needs to be checked and re-

evaluated. The amount of deviation is taken into account.

Calibration should be performed at latest before a new adjustment. After adjustment

calibration must always be performed to make sure that adjustment was successful

and values are in tolerance. For calibration the test code (the code designated with

Dnom = 0.5) supplied by REA is measured and the result is documented. A test

report with the REA reference results is only delivered for this code. The test report

with the reference results carries the following stamp:

Picture: Stamp on the reference test report

The two other test symbols are reserved for later expansion. To avoid confusions, the

calibration card has a serial number which is mentioned in the reference test report.

Picture: User comment with the serial number of the calibration card

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 34 of 76

For extended calibration, the calibrated GS1-DataMatrix test card (Art. No.

08300911) and / or the calibrated test card for the EAN/UPC Code Verifier (Art. No.

08300912), which can be obtained as optional accessories, can be used in addition.

Calibration card 0830911

Calibration Card 08300912

For this purpose, the extended calibration uses test cards, which are included in the

sale by REA, but are otherwise manufactured fully independently of REA and are

measured with other reference devices (traceable back to national standards).

Calibration using these cards is one step closer at the national standards (N.I.S.T,

PTB, etc) as using the REA calibration cards which are derived from these cards.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 35 of 76

9.1 Admissible device tolerances

The individual measurement values of the control measurements must be compared

with the corresponding reference values. The requirements for the precision of the

measurements are specified in the standards ISO/IEC 15426-2 for matrix code

verifiers and ISO/IEC 15426-1 for bar code verifiers.

The following data must be examined in order to make sure that the correct symbol

with the settings for the test equipment monitoring has been used. Further

measurement data and threshold values, which are shown, in addition, in

the test report in the context, shall be ignored for this testing.

Aperture1 16 mil, 0.406 mm

Light type 660 nm just below 45 from all

four sides

Symbol Passed 4.0

Symbology Data Matrix ECC200

Code content 30Q324343430794<OQQ

The following table lists the criteria, which must be examined according to ISO/IEC

15426-2.

Measurement parameter Unit Tolerance Reference

Rmax2 (see the histogram) % +/- 5% Measurement

reflection values on the

Rmin3 (see the histogram) % +/- 3% stamped

reflection reference test

UEC4 Grade +/- 0 report

Grid non uniformity (GN) - +/- 0.06

Axial non uniformity (AN) - +/-0.02

Contrast uniformity % +/- 8%

(see Modulation, text below)

Fixed Pattern Damages Grade +/- 0

(FPD)

The values for GN and AN are reported in per cent. The corresponding value to 0.06

is 6% and to 0.02 is 2%.

In the standard ISO/IEC 15426-2, Modulation is specified instead of contrast

uniformity. This is also correct in the sense of the control, but difficult to follow. A

footnote in ISO/IEC 15426-2 states that it is a per cent value. This per cent value

refers to the Contrast Unifomity value specified for the test symbol 5 Black Widow

(see the card with the REA article number 08300911). Contrast uniformity is one

detail value of many used to determine Modulation for the entire symbol.

1

Aperture Synthetic aperture according to the definition of ISO/IEC 15415

2

Rmax Maximum Reflectance according to ISO/IEC 15415

3

Rmin Minimum Reflectance according to ISO/IEC 15415

4

UEC Unused Error Correction defined in ISO/IEC 15415

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 36 of 76

Further testing criteria

Measurement Unit Tolerance Reference

parameter

Symbol contrast % +/- 8% Measurement

(calculated from values on the

Rmax and stamped

Rmin) reference test

Modulation Grade +/- 0 report

Module size m +/- 5 m

Print growth m +/- 10m

9.2 Calibration for white and red light

Together with the calibration card only one reference report created by using red

light is supplied. This report is created at the end of the manufacturing process.

In case white light is used and white light shall also be calibrated then the process

described in chapter 9.1 is used. The reference is also in this case the report created

by using red light. This simplification is possible because black and white is supposed

to provide the same reflectance values under red and white light. To proof that the

method is working the performance has been checked by using calibrated reflectance

standards (barium sulfate) which provide reflectance value for the visible light range

from 400 to 700nm wavelength.

10 Synthetic aperture / measuring opening

Under aperture or opening we normally understand the diaphragm opening of a

camera lens. In this context, this is not the case. The diaphragm opening of the lens

of the REA VeriCube has a fixed presetting from the plant, which achieves the best

compromise between the maximum possible depth of field and the minimum possible

diffraction effects.

The synthetic aperture simulates the spot of light of a laser scanner. This takes place

through mathematical filtering of the recorded measurement image. Depending on

the aperture used in the code testing, the measurement results can vary. The

synthetic aperture is always automatically set to 80% of the module width of the

tested 2D matrix codes.

Alternatively, the synthetic aperture can also be set manually

The synthetic aperture forms an optical filter from the picture processing view, which

causes certain blurring. This makes sense for suppressing the smaller and up to the

smallest distortions in the picture, which are not relevant for verification.

The symbols, which show many distortions, can disrupt the automatic determination

of the synthetic aperture. When this is the case, the measurement results oscillate or

there are invalid measurements. In this case, a manual determination of the

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 37 of 76

synthetic aperture is recommended (under the condition that the symbols always

have the same module size).

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 38 of 76

11 Execution of the measurements

11.1 Positioning of the device

The REA VeriCube can be operated in different measuring positions.

11.1.1 Camera downwards

In this mode, the device is positioned, for example, on a printed sheet or on another

flat product with the camera pointing downwards. On a printed sheet, the device can

be moved from code to code and the measurements are made in this position. In this

case, the glass cover must be removed, so that the cover is not contaminated or

scratched by moving on the product or the printed sheet. As in this case the device

largely covers the measurement area, the effect of the ambient lighting is negligible.

Nevertheless, intensive light sources such as direct sunlight must be prevented.

Picture: Camera downwards on the printed sheet

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 39 of 76

11.1.2 Camera upwards

In this mode, the product is positioned on top of the measurement window of the

device and the product is moved into the measurement field. For this type of

measurement, the glass cover should be used, so that the inside space of the camera

(mirror, lens) is not contaminated. The ambient light influences the measurement

and, therefore, the measurement area must be covered with the delivered black

cover plate or with the black cover cloth in order to protect it from the ambient light.

Picture: Camera upwards with the product on the glass cover

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 40 of 76

11.1.3 Camera sideways

The device stands either on its long side or on its short side. Plastic strips are

inserted in the side walls, so that they are not scratched when the device is moved

on the table. The codes to be measured are, for example, on cans, bottles or parts,

which can be positioned in front of the device, so that the measurement conditions

are maintained correctly. Since the long sides and the short side change the distance

from the floor space, the respectively optimal position can be selected in this way. If

this is not sufficient, the product or the REA VeriCube and the product can

additionally be placed on a lifting table and thus the optimal measurement position

can be set.

Picture: Device positioned sideways with the product in front of the device

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 41 of 76

11.1.4 Turning the keyboard

The keyboard of the device can be taken out and then replaced in an appropriate

position with respect to the measurement position or the position of the device.

Attention: The keyboard is connected to the main electronic using zero force

connectors. It is not allowed to pull at the cable!

11.1.5 Testing 3D parts

By 3D parts, coded parts from the industry (automotive, electronics, machine

building, air- and spacecraft industry, etc.) are meant, which have irregular

geometries. In some cases, these parts can be measured with one of the three or

four standard positions. In other cases, this cannot be done.

For such cases, a measurement fixture must be manufactured, which ensures that

the code to be measured can be positioned correctly according to the handling

instructions (angle, distance, shadows from components).

In simple cases the fitting of the glass screen is used for a fixture. A part fitting

instead of the glass screen is manufactured and this holds a part exactly in the

correct position. The advantage is the easiness of replacing of such a fixture.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 42 of 76

11.2 Measuring process in the Windows software.

A prerequisite for performing the measurement is the observation of the handling

instructions (see section 6) as well as the selection of the desired position of the

device (see section 11.1)

The live video is turned on for the positioning. For this purpose, the F1 button on the

device can be used or the symbol button for the live video on the PC screen.

Start the live video Stop the live video

The measurement area can be set in various ways. Most simply, only the red cross

hair is displayed. The code is moved in the middle of the cross hair and then the

measurement is started. To start the measurement, either the "Scan" button on the

device or the "Evaluation" button in the Windows software can be used.

Cross hair in the bar code Cross hair in the 2D code

The evaluation is started with the "Evaluation" button.

Pushing the evaluation button stops the live video and starts taking the measuring

image in the full camera resolution. Afterwards, the evaluation is initiated. In a

normal case, the symbology and the code type (1D or 2D) are recognized

automatically.

If the automatic recognition fails, the measurement area must be set manually.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 43 of 76

The icon with the blue square is the default for the measurement of a 2D code

If the function is active, the three corners of the matrix code in the measuring image

are clicked on by the mouse one after the other. This causes a blue square to

appear, with which the measurement area (Region of Interest ROI) for the code is

determined. The thickness of the blue frame is not relevant for the measurement; it

can be changed by turning the PC mouse wheel. Only the outside contour is taken

into account. By changing the blue frame (the size, the precision with which the code

is targeted), the stability of the evaluation can be improved in difficult measurement

cases.

If a bar code is measured, then a red measurement area is set in the image as a bar

at an angle of 90 in relation to the bar code lines. The height of the bar determines

the measurement area through the height of the code.

The measuring width is determined automatically (up to Version 1.0.20.1) Version

1.0.20.1/13914r and later constrains the measuring width to the left and right

position points.

11.3 Automatic ROI

The setting "Automatic recognition of the measurement area" is made with the icon:

The 2D codes are framed automatically. In the case of bar codes, the measurement

lines are determined automatically. In contrast to the mode with the cross hair, the

measurement area is limited to the code size. This reduces the amount of data to be

processed and increases working speed.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 44 of 76

11.4 Recording the image

The REA VeriCube can take an image without making an evaluation.

Icon.

Old icon New icon

11.5 Opening the image file

With the icon

Old icon New icon

an image file can be opened. BMP, PNG and JPG formats as well as several others

can be processed. The loaded picture can be evaluated and thus a rough assessment

of the code in the image can be made. The image data read in this way is not

calibrated and no calibration data is included in such images.

In addition, the test reports in TWS format or the images in XML format can be

opened. On the one hand, the contained images can be saved again for

documentation purposes, for example, as BMP or JPG files. On the other hand, there

is a possibility to reevaluate the images. Since the previously set ROI as well as the

calibration data are contained, a full-value evaluation is possible.

11.6 Saving the image file

The images, which have been loaded and which have been obtained by measuring or

by recording, can be saved (for analytical or documentation purposes)

This takes place with this ICON

Old icon New icon

The images in PNG, BMP and JPG format can be used for documentation purposes.

The images which are saved in XML format contain the calibration data and can,

when opened again, provide a full-value testing evaluation. This is useful for

comparing different software releases or for support purposes.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 45 of 76

11.7 Static reflection measurement

In a given measurement image (without evaluation, see sections 11.4 and 11.5), a

static reflection measurement is performed

A red measurement point appears in the image

If the mouse pointer points to the measurement point, the point can be changed to

the desired size with the help of the mouse wheel in order to obtain an adequate

measurement section. With the help of the function, the reflection values can be

determined in order to see in advance whether the contrast between the bright and

dark areas (or the color selection between bright or dark) is sufficient. Depending on

the type of the light (white or red), the measurement values can change.

The displayed value of 26.3 is the reflection value that corresponds to the Rmin or

Rmax reflection values. The X and Y data are the pixel positions in the image. D is

the diameter of the simulated light point adjusted by the user. The usual synthetic

apertures (the simulated light point diameter) are between 100m (4mil) up to

500m (20mil). This area is exceeded above or below in exceptional cases only.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 46 of 76

11.8 Preset the measurement image size

The measurement image can be presented considerably magnified or reduced in size.

With the help of the buttons

the display is changed. The piece of data in percentage shows the magnification. The

value 45.8m/pixel depends on the focal length of the lens used and is set by the

adjustment.

If the mouse pointer is positioned in the image, the image can be displayed smaller

or larger by turning the mouse wheel. It can be magnified to such an extent that the

individual pixels of the camera chip are visible and distinguishable.

11.9 Rotating the image

Depending on the position of the REA VeriCube, the movement of the image does not

follow what is intuitively expected. For this reason, the image can be rotated with the

help of the green arrow symbols

until the movement coincides with the intuitively expectation.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 47 of 76

11.10 Display of the evaluation

11.10.1 Test reports

Depending on the preset values in the options, the level of detail of the individual

test reports displayed can be adjusted and changed based on the individual

requirements. The selection of the different forms of representation takes place with

the icons

The left icon presents detailed graphical test report on the PC monitor. This view is

presented for qualified staff with corresponding background knowledge and shows all

obtained test results in every detail, partially in the form of callable sub-windows.

The second icon shows the evaluation as it would appear as a printout (long

printout). Some details can be better seen listed one after the other than in the

graphical view.

The third icon shows a short view. This view provides all testing results in a

compressed form, which can be used by the trained routine personnel.

In the settings (Configure / Options / View), the default view is set. This appears as

first view after verification. The icons and the corresponding menu change the view

on demand without changing the default setup.

11.10.2 Details in the test reports

In the graphical view of a given test report, the following icons are available:

Binarization

With this icon, everything in the image which is evaluated as dark is highlighted in

yellow. This makes it possible to recognize the places where shadings or too bold /

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 48 of 76

thin prints shift the thresholds to such an extent that the individual code elements

become invisible

Edge grid

With the help of the edge grid, the reconstructed grid matrix is displayed. In this

way, it can be recognized where the matrix cells lie and whether the symbol has

been recognized correctly. The symbols with irregular brightness or with distortions

(for example, through rounding) are subject to the risk that the matrix is

inadequately recognized. With the help of this highlighting, it can be checked very

quickly as to whether the recognized matrix corresponds to the actual code picture.

If there are large deviations, this is an indication of invalid erroneous measurement,

which must be repeated.

Center grid

In this grid representation, the lines cross in the middle of the matrix cells. Apart

from that, the function and the meaning are the same as in the edge grid.

The light margin (quiet zone)

The light margin (also called a white field, bright field or quiet zone) is indicated by

the aid of this icon. This is in order to be able to easily recognize whether this area

contains spots or other disorders which should not be there (homogeneous white in

positive symbols or homogeneous black in negative symbols is necessary)

Details measurement

With this icon, the details measurement is turned on. A red point appears in the

measured image, whose diameter shows the size of the synthetic aperture. The point

can be moved with the mouse to different places of the code. The display then

provides information about the code word number, bit number, reflection values and

modulation values at the selected location.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 49 of 76

Matrix middle points

The middle points of the matrix cells are highlighted with green dots

Warnings

With this button, all matrix cells (when active) are marked yellow, which, in relation

to the modulation and the contrast measurement values, are close to the limit

between two grades. The more such modules appear, the higher is the risk for a

given measurement result to oscillate between two classes.

Error indication

All matrix cells which can be handled by the error correction are highlighted with red

dots. This always occurs when a given matrix cell is recognized as dark instead of

bright or vice versa. Depending on the symbology and code size, the error correction

can recognize these errors and facilitate the correct decoding to a certain limit. When

the capacity is exhausted, it is attempted to obtain a result with a non-standard

decoding (error: Reference decode failed). If this also does not help, no further

decoding is possible.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 50 of 76

12 Configuring the evaluation and symbologies

In this section, the essential REA VeriCube configurations are described. This

configuration is performed with the help of the Windows software TransWin32. The

detailed description of TransWin32 is in a separate operating manual.

12.1 Evaluation

The presetting for the evaluation is done in the menu Configure / Evaluation.

The important setting is "selected grade". For this purpose, the desired minimum

quality in the area of the grade Sufficient (Grade 1), Satisfactory (Grade 2), Good

(Grade 3) or Very good (Grade 4) is determined according to the respective test

standard. A measurement result which has achieved, for example, Grade 2 the

grade Satisfactory, is thus evaluated in the previously selected Grade 1 as "Passed"

and in the selected Grade 3 as "Failed".

The bar code evaluation (1D) permits the choice between the ISO/IEC 15416 and

ANSI X3.182 evaluation (this ANSI standard has been withdrawn in the meantime).

The evaluation and the measurement result do not change depending on the setting

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 51 of 76

of ISO or ANSI. Solely the presentation of the measurement result changes from

numerical data to letters for the class (A instead of 4, B instead of 3, C instead of 2,

D instead of 1 and F instead of 0).

The matrix code evaluation (2D) permits the choice between the method according

to ISO/IEC 15415 for printed codes, for example on labels, or the DPM method

according to ISO/IEC TR 29158, which is used, for example, for etched codes, dot

peen marking or lasered on metal (DPM is optional).

(Note: The REA VeriCube only has lighting from 45. This illumination type can only

be used for certain DPM codes.)

12.2 Symbology selection

The symbology selection determines which of the symbologies and with which

respective properties they are verified. The selection and the properties are

determined by the respective use.

REA Elektronik GmbH, Teichwiesenstrae 1 D-64367 Muehltal

REA VeriCube Operating Manual Version 2 08/2015 Page 52 of 76

The left column shows the symbologies available in the software version. The right

column shows the active symbology selection. To the right of this there are the

properties of the respectively selected code. In this case, it is "GS1 Data Matrix ECC

200". This designation of the symbology is a short form for practical use, which,

correctly formulated, would be "Data Matrix Code according to ISO/IEC 16022 with

the error correction method ECC200 for the applications which are specified by the

organization GS1-International". However, this is much too complicated.

Only symbologies which have also been activated in the pre-settings can be

tested and evaluated. All other non-activated symbologies are evaluated

with a "Not decoded" error message and cannot be recognized and

evaluated!

12.3 Profile management

The settings for evaluation, symbology selection, minimum quality and aperture

setting are comprehensive. Many routine users are overstrained by this. For this