Linear Motors Catalog - ETEL

Diunggah oleh

5397573Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Linear Motors Catalog - ETEL

Diunggah oleh

5397573Hak Cipta:

Format Tersedia

Linear Motors

Innovative Motion Control

about etel LINEAR motors What is a linear motor?

Linear motors are a special class of synchronous brushless servo motors. They work like torque

Over the last 20 years, direct drive linear motors have provided significant performance motors, but are opened up and rolled out flat. Through the electromagnetic interaction between

improvements in numerous applications covering a wide range of high-tech industries. Today, a coil assembly (primary part) and a permanent magnet assembly (secondary part), the electrical

direct drive technology is recognized as a leading solution towards meeting the requirements of energy is converted to linear mechanical energy with a high level of efficiency. Other common

high productivity, improved accuracy, and increased dynamics of modern machinery. names for the primary component are motor, moving part, slider or glider, while the secondary

part is also called magnetic way or magnet track.

Direct drive essentially means the load and motor are directly connected; or in other words, the

motor directly drives the load. Significant improvement to stiffness and a more compact solution Since linear motors are designed to produce high force at low speeds or even when stationary,

are among the benefits of this technology. In addition to providing high dynamic performance, the sizing is not based on power but purely on force, contrary to traditional drives.

linear motors reduce cost of ownership, simplify the design of the machine and eliminate wear

and maintenance. The moving part of a linear motor is directly coupled to the machine load, saving space,

simplifying machine design, eliminating backlash, and removing potential failure sources such as

Since its founding in 1974, ETEL has been exclusively dedicated to the development of direct ballscrew systems, couplings, belts, or other mechanical transmissions. Finally, the bandwidth

drive technology. Through numerous innovations and patented designs, ETEL continues to provide and the stiffness of the motion system are much higher, giving better positional repeatability and

unmatched force efficiency for the most optimized designs. accuracy over unlimited travel at higher speeds.

Given that frameless linear motors do not include a housing, bearings, or feedback device, the machine

builder is free to select these additional components in order to best fit the application requirements.

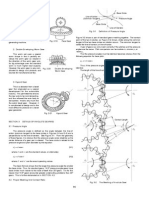

Linear motor advantages IRONLESS MOTOR IRONCORE MOTOR

Key benefits inherent to the adoption of the linear motor technology include:

High dynamics

High accuracy

Double sided Lamination stack

Optimal speed control magnetic way

Very compact design

Magnets

Outstanding MTBF

Low maintenance Cable Cable

These advantages are further explained in the following pages.

Coils Magnetic way

Coils

Magnets

INDUSTRY SECTORS

Below are some examples of industry sectors where linear motors are successfully used, providing our customers in these areas a distinct competitive advantage.

Wafer and die level packaging Process control Lithography Test and control equipment Placement machines Flat panel display (FPD] Photovoltaic Optics Stamping / laser cutting Medical

2 | Linear Motors Linear Motors | 3

Innovative Motion Control

why adopt linear motors? why choose etel?

Reduced cost of ownership Patented technology

Direct drive

Direct coupling of the payload to the motors moving part eliminates the need for mechanical ETELs patented ironcore design provides the industrys most efficient direct drive linear motor.

transmission elements such as leadscrews, timing belts, rack and pinion, and worm gear drives. The design is especially optimized to reach high force density together with the lowest possible

Unlike brushed motors, there is no contact between the moving parts in a direct drive system. force ripple.

Therefore there is no mechanical wear resulting in excellent reliability and long lifetime. Fewer

mechanical parts minimize maintenance and reduce the system cost. The direct drive technology Unmatched performance

intrinsic to a linear motor based system results in an efficient and effective gearless assembly.

A complete direct drive solution with ETEL motion and position controllers provide optimum

system performance. A full ETEL solution enables machine builders to simplify integration in

Easy integration their machine thanks to a very consistent design. It also gives the customer the opportunity to

ETEL linear motors are available in a wide range of sizes and can be easily adapted to most focus on his core competence and technology while ETEL takes care of the motion system (refer

applications. ETELs unmatched standard product offering includes ironless and ironcore linear to page 8 for more details).

motors. Each technology has specific advantages:

Ironcore

linear motors configuration minimizes the volume required for integration in machines. Direct drive expertise

They are very compact and produce the greatest force per package size. Focusing strictly on direct drive technology for over 30 years, ETELs highly skilled workforce

Ironless

linear motors shape is very thin and gives machine builders great flexibility in locating the provides customers with a valuable technical resource. Providing attentive customer support

motors. In addition, ironless motors provide no force ripple and have very low moving masses. from the early design phase to machine commissioning is part of ETELs commitments.

Dynamic performance High quality

Lead screw

Linear motor applications have a wide range of dynamic performance requirements. Depending High product quality is ensured by ETELs use of modern development tools and thorough

on the specifics of a systems duty cycle, the peak force and maximum speed will drive the qualification procedures. All ETEL motors are manufactured in Switzerland according to highest

selection of a motor: quality standards.

Conveyor / Timing belt

An application with a light payload that requires very high speed and acceleration will typically

utilize an ironless linear motor (that has a very light moving part containing no iron). As they Ease of integration

have no attraction force, ironless motors are preferred with air bearings, when the speed Compatibility of ETEL linear motors to a wide range of control electronics results in easy

stability has to be below 0.1%. integration of a direct drive solution.

Ironcoremotors produce greater force per package size by using laminations to concentrate

the magnetic flux. With a larger continuous force, these motors fit very well to mid- and Product range

high-dynamic applications requesting high duty cycle.

Rack & pinion With standard motors from 72 to 704 mm in length and from 90 to 3700 N of peak force, ETEL

offers one of the largest selection of ironless and ironcore linear motors on the market.

Wide force-speed range

Direct drive linear motors deliver high force over a wide range of speeds, from a stalled or low

speed condition to high velocities. Linear motors can achieve very high velocities (up to 15 m/s)

Force vs. speed for: LMG10-070-3QB

1400

with a trade off in force for ironcore motors, as technology becomes limited by eddy current losses.

Linear motors achieve very smooth velocity regulation, with low ripple. The performance of a 1200

linear motor over its velocity range can be seen in a force-speed curve as shown opposite. 1000

Force [N]

800

600

400

200

0

0 2 4 6 8 10 12 14 16

Peak force Speed [m/s] Continuous force

Fp at 600 VDC Fc at 600 VDC

Fp at 300 VDC Fc at 300 VDC

4 | Linear Motors Linear Motors | 5

Innovative Motion Control

linear motors Linear motors range

ETEL offers the most comprehensive standard linear motor range in the industry. With more than

During the last two decades, many linear motor variations have emerged on the market. 50 models to choose from, almost any requirement can be satisfied.

Nevertheless, only a few were found to be practical, performing and economically viable. ETEL 4000

has always remained dedicated to the flat, synchronous, 3-phase linear motors with permanent

magnet excitation. This family of motors represents more than 90 percent of industrial LMA22-100

3500

applications worldwide. They can be classified into ironcore and ironless motors.

tio

ra

ce

or

3000

The ironcore construction enables an exceptional peak force density, as well as unparalleled

sf

ou

tio

ra

inu

thermal efficiency, which is a significant advantage for thermal-drift-sensitive precision machines. LMS15-100

ce

nt

or

sf

co

The LMA is a mid-size motor optimized for application requesting high continuous force. The 2500 LMG15-100 ILM12-060 ou

to

nu

nti

ak

Peak force [N]

LMG is smaller, optimized for high dynamic applications and provides a high peak-to-continuous o

pe

t oc

igh

force ratio. In case an upgrade is requested by the application, the LMS is highly similar to LMG ak

pe

-h

2000

low

ns

in terms of integration but provides about 30% more continuous force. This makes the LMS s-

tio

on

ati

ca

c

pli

perfectly suited for high duty cycle axes. The ILF is a small size motor perfectly suited for very pli

ap

1500 ap

cle

ic

high dynamic and low moving mass applications. The ILM is a more powerful version of the ILF.

am

y

ut yc

yn

These motor types also provide a highly linear behavior perfectly suited for the most demanding hd

hd

hig

hig

scanning applications where zero attraction force and outstanding speed stability are requested. 1000

ILF15-050

500 LMA11-030

TYPE DESCRIPTION APPLICATIONS ILM03-040 LMS10-030

LMG05-030

ILF03-030

Highest continuous force 0

0 100 200 300 400 500 600 700 800 900 1000

LMA Optimized for high duty cycle application

PERMANENT MAGNETS SYNCHRONOUS LINEAR MOTORS

ILF ILM LMA LMG LMS Continuous force [N]

600 VDC compliant Wafer inspection systems

Chip placement machines

Ironcore motors Flip-chip / die bonders

Compact design

Speed up to 15 m/s Wire bonders

Acceleration up to 20 g LMG

Economic

PCB drilling

Custom motors

High peak force

Peak force from 279 to 3700 N PCB testing machines With over 30 years of direct drive innovation, ETEL has the expertise to quickly and efficiently

600 VDC compliant

Low force ripple Flat panel display equipment adapt existing products into custom solutions. The process is made simple due to the modular

STANDARD PRODUCTS

All linear motors types work with Medical equipment

and flexible design of our linear motors. ETEL can also develop a completely new motor design

same MWD magnetic way Compact design General automation

Economic to address a particularly demanding or unusual requirement.

LMS High continuous force

600 VDC compliant ETELs experience also includes:

Ironcore and ironless motors High and low temperatures

Wafer inspection systems

High force Single and double excitation Vacuum

Chip placement machines

Ironless motors Air cooling option available

ILM Flip-chip / die bonders Transverse flux UL certified

Low mass glider

Speed up to 20 m/s Wire bonders Long stator Aerospace motors

Zero force ripple

Acceleration up to 30 g Very high dynamic axes Combined motor (linear/rotary) Specific magnetic ways

Peak force from 90 to 2500 N PCB testing machines

Option: forced air cooling

Linear motors for very large diameter rotary axes Multiple motors integration

Medium force

Air bearing systems

No attraction force CMM measuring machines

ILF Very low mass glider

No force ripple Optical equipment manufacturing

Zero force ripple

Medical equipment

INTEGRATED MOTORS

Chip placement machines

ETEL motor design competences serve also more complex requests such as fully Flip-chip / die bonders

integrated axes. In fact, motors can be designed to perfectly fit a very specific form Wire bonders

factor to satisfy customer applications. This process ultimately provides highly PCB testing machines

integrated motion systems with unique performance. Very high dynamic axes

6 | Linear Motors Linear Motors | 7

Innovative Motion Control

direct drive solution Bearing

Bearing selection is dependent on a systems dynamic load and accuracy requirements.

To achieve optimum performance from a direct drive motor it must be built to the necessary Applications that require high stability, accuracy, and repeatability will typically utilize high

standards of precision and stiffness as part of a complete direct drive solution. In addition to the stiffness bearings to meet their performance needs. Mechanical bearings are often the only

motor, the four key components of a direct drive system are the electronics, encoder, bearings and wear-prone components in a direct drive based system. The most commonly used bearings are:

machine structure. Each of the four components is briefly described in the following paragraphs.

Electronics plain friction cross rollers recirculation air

SPECIFICATIONS

precision

* *** **** ****

The best linear motor performance is achieved when integrated with a fully digital controller with SPEED

* ** **** **

extremely high bandwidth capability like the ETEL AccurET position controllers family. SMOOTHNESS

* *** *** ****

In a direct drive system, the controller can benefit from a very precise position feedback due to STIFFNESS

* *** *** **

the fact that there is no transmission in between the feedback device and the load. Because of TRAVEL

*** * *** **

this high quality feedback signal, a high-end controller (such as ETELs AccurET) can compute LOAD

** ** *** *

advanced control algorithms at a very high frequency. Ultimately, the precision and the dynamics COST

**** ** ** *

of the axis are drastically increased. least desirable / most desirable

Electronics They can provide: * ****

Some key factors to be taken into account when selecting a controller are listed below: ETELs AccurET/UltimET controller High position accuracy

family is especially designed Close to zero settling time

High frequency control loops (current, speed, and position loops)

for a variety of electronics and High dynamics

High current and position loop bandwidths (typically >2 kHz and >100 Hz respectively)

semiconductor related applications, Multi-axis interpolation

High encoder interpolation factor to ensure adequate speed and position resolution

where extremely high precision is Fast communication bus

Advanced control algorithms (PID with feed-forward, state space regulators, observers, notch

needed without any compromise on And much more...

filters, etc)

throughput.

Advanced features: gantry control, 3D mapping, ability to compensate for detent force, stick

slip, temperature drift, and other system repeatable phenomena For more

information,

refer to our

Motion Structure

ETEL offers a complete range of state-of-the-art position and motion controllers which are widely Control

used in various leading industries. brochure. Special attention must be paid to the machines structural stiffness. In most applications the

structure should be designed with a natural frequency above 200 Hz. Finite element analysis is

+ typically used as a design validation tool. A high performance control loop and high performance

components (motors, electronics, and encoder) combined with an optimized mechanical design

will lead to better system rigidity.

10 000

Encoders

Stiffness [N / m]

High precision, high resolution feedback is

essential for achieving optimum performance Structure 1 000

using direct drive. Direct coupling of the load

Motor

to the drive improves accuracy but the best

Encoder head

performance can only be achieved with the

appropriate feedback device. This requires an Magnetic way

absolute or incremental optical encoder with Bearings

a high line count. When combined with the Optical scale

high interpolation capability of the electronics, 100

Picture

resolutions down to the nanometer range can courtesy of Dr J. 1 10 100 1000

Natural stiffness given by the payload

be achieved. HEIDENHAIN GmbH Closed loop stiffness Frequency [Hz]

8 | Linear Motors Linear Motors | 9

Innovative Motion Control

linear motor selection Motor constant

The motor constant, Km, is one of the key parameters for comparing permanent magnets

Many factors must be taken into consideration when choosing a linear motor to ensure synchronous motors relative efficiency. It shows the relationship between force produced and

outstanding system performance. This brochure provides a basic overview of some of the key resulting power losses. A motor with a higher value of Km is a more efficient generator of force.

selection factors that should be taken into account when choosing a linear motor. For detailed Km is determined by the design and construction of the motor. This parameter is related to the

calculation and sizing information, please refer to the ETEL linear motors handbook, or ask an internal design of the motor (copper filling factor, electromagnetic design, etc). Therefore, it is

ETEL application and support engineer for assistance. a better indicator of motor performance than the force constant, Kt (Nm/Arms), which relates

force output to the supplied current. Kt is easily adjusted by changing the wire gage in the

winding. Kt is useful for matching a motor to a servo amplifier, but it does not provide information

Motor sizing about the motors efficiency.

The first step in a linear motor sizing is to define the force and motion requirements for the Thanks to a patented design, ETEL is able to significantly increase the packing efficiency of ironcore

application. The maximum required acceleration and the payload mass are used to determine linear motors slots (increase in Kt) and to decrease the amount of copper wire extending beyond

the peak force. The force required for each move within the cycle can then be used to determine the slots (reduction of ohmic loss). Moreover, it leads to an important increase in continuous

the continuous force. thrust and better thermal behavior (resulting in an improved Km).

The amount of heat produced by motor power dissipation will determine the temperature

increase of the structure. Power dissipation is estimated by calculating the continuous force and

all additional sources of force such as friction, machining force, static force due to an offset load

Thermal considerations

and external perturbations. The performance of the motors as well as the overall machine behavior are closely related to heat

transfer. As with any other kind of electrical motor, heat is generated during operation. Unless it

Under static conditions with an applied load, one motor phase can get disproportionately hot,

is removed by an efficient cooling system, this heat will be transferred in the machine structure

because the power dissipation is not shared equally among all three phases. To ensure smooth

and the motors surroundings. Depending on the application (precision requested, dynamics, duty

operation under these conditions a stall force calculation should be performed.

cycle) heat could prevent machine from reaching its specifications. Thus it has to be taken into

In rare cases, the detent force may impact speed stability, especially if the position control account in the early design phase.

regulation bandwidth is limited. ETELs position controllers provide the ability to compensate the

To help in selecting the right motor and getting the best machine performance, ETEL defines in its

detent force for high accuracy applications.

motor data sheets an assumed exchange surface for each motor type. It represents the surface

ETELs motors are available in several winding configurations. The winding should be chosen to to which the motor is mounted for optimal heat transfer. This value is very important and closely

match the speed requirements of the application and the voltage and current specifications of related to the motor continuous force (Fc). However, once mounted in the machine, the exchange

the electronics. Note that the force/speed characteristic of a motor changes with the winding. surface will most likely be different. Two scenarios can occur:

The real machine exchange surface is higher than the assumed one. Then the motor performance

Detent effects can be increased. Higher continuous force or less heat at a given duty cycle.

Thanks to a patented design, ETEL has the expertise to manufacture ironcore linear motors with very The real machine exchange surface is lower than the assumed one. This is the case for example

low detent effects. The patented design uses an innovative combination of open slots, orthocyclic when a thermally insulating layer is added in between the motor and the carriage. In this case,

windings and fractional pole pitch. This solution significantly reduces detent effects without any thermal transfer is limited as well as motor performance.

skewing of laminations or magnets which would result in lower force density. Furthermore, detent Do not hesitate to contact your ETELs representative for technical support during machine

effects at the motor extremities are eliminated by the use of specially-shaped teeth. design phase.

Data sheets Handbook ETEL Sizing Tool

ETEL linear motors information is For more information ETEL has developed a powerful

available in the corresponding ironcore on motor selection and sizing tool that can simulate the

and ironless motors data sheets. integration, ask for the ETEL customers machine operation.

They include the specifications, linear motors handbook This tool will help you getting the

performance as well as the force vs. from our website. very best performance/price ratio

speed curves of each standard ETEL that can be obtained on your specific

motors. For more information about application. Do not hesitate to

the linear motors or to download the contact your ETELs representative

data sheets, refer to our website: for technical support during the

www.etel.ch machine design phase.

10 | Linear Motors Linear Motors | 11

Innovative Motion Control

case studies ETEL product range in flying probe tester machines

ETEL has been present in the electronics industry since many years providing best performing motion

ETEL linear motors in PCB drilling control solutions. In flying probe tester machines, throughput and precision are key factors to success.

Nowadays, machines equipped with ETELs LMG motors provide the highest throughput on the market

without any compromise on precision. The main axes of the illustrated machine are driven by ETELs

In the PCB drilling applications, the requirement for precision is made more challenging due to high

LMG motors, allowing extremely high speed dual-sided

masses and very high throughput. In these kinds of machines, accuracy is very frequently below 4 m

probing with a motion resolution of less than 20 nm. ETELs

while masses to be accelerated at about 1.5 g are typically in the range of 300 kg for the main X and Y

standard ironcore linear motors together with an optimized

axes. ETEL linear motors have been selected to achieve this task. In addition to X and Y, the very dynamic

machine design contribute to make these flying probe tester

drilling Z-axes are also moved by ETEL linear motors.

machines a point of reference on the market.

A typical motion cycle includes the positioning of X and Y axes followed by the synchronized drilling

In this case, the fast and precise motion control of up to 24 axes is ensured by ETEL position and

movement of all Z axes. In this type of application, the motors peak force is important because of the high

motion controllers. The optimal fit between ETEL motors and motion controllers as well as the

accelerations needed to reach an incredible throughput of 800 cycles per minute. In addition to that, the extremely high duty cycle imposes

advanced features provided by ETEL controllers provide outstanding performance in such applications.

a very efficient motor design. With ETEL LMGs one can obtain a

very high continuous force in a small volume and with limited heat Additionally, the 15 g Z-axis motion of the testing probe is provided by a unique custom motor

dissipation. The use of ETEL motors combined with an optimal design developed in synergy with our customer. This unique and fully integrated Z-axis design is

machine design and top performing drilling processes makes this made to exactly fit the application needs maximizing performance and reducing costs of ownership.

machine belong to the very high-end of PCB drilling machines. Finally, this ETEL based direct driven machine is able to achieve outstanding probing accuracy

In addition to the ETELs ironcore linear motors, this application and throughput level. Such performance would be impossible to reach with other types of

is fully equipped with ETEL position and motion controllers. motion technologies like reluctant planar motors or rotary based systems. Pictures courtesy of SPEA Spa

The high performance of the ETEL controllers together with an optimal

software design allows reliable interpolation and synchronization of

all axes (X, Y and up to 12 Z) during drilling programs that can last

more than 12 hours representing 600000 drillings. Picture courtesy of Posalux SA

ETEL linear motors in AOI systems ETEL product range in wire bonding applications

In many manufacturing processes, inspection is a crucial step to ensure final product functionality and ETEL is present in the majority of the critical stages during the

reliability. ETEL is present in a wide range of Automated Optical Inspection (AOI) systems providing high IC manufacturing process. From the very early lithography process to

precision and maximized throughput by using direct drive linear motors. the final pick and place machines, ETEL provides the best suited direct

For instance, in PCB inspection systems, where line space is in the range of 15 microns, a combination drive motors to fulfill highly demanding applications. Wire bonding is one

of high performance optical system and motion system is necessary to get the best possible yield out of of these important processes during semiconductor device fabrication

the production line. In case of IC substrate inspection, the were ETEL is strongly present to help our customers reaching outstanding

structures to be controlled can go down to a few microns machine performance.

in size for substrates typically used in chip-scale or ball grid array packages. Moreover, the Many variants of wire bonding exist and might lead to slightly different key specifications when designing the

precision requested have to be ensured over a wide surface without any compromise to motion system. However, speed, precision, and reliability are in any case the most important requirements.

performance or machine throughput. A precise point-to-point motion with extremely short Some of the most famous technology leading companies in the wire bonding industry use ETEL solutions to

in-position-time is made possible by using ETEL direct drive technology. reach unmatched performance levels.

Thanks to the ETEL LMG series of ironcore linear motors, one can safely design flexible The very wide range of ETEL linear motors and controllers provides a solution to perfectly fit the most

machines that achieve exceptional detection skills in a wide range of AOI tasks. The high demanding requirement of such high-end machines. On one hand, the use of ETEL ironless motors provides

force density of ETEL motors allows a very compact design that helps maximizing the low moving mass for very high dynamic axes to finally obtain the fastest bonder in this market segment.

working area, as well as increasing the overall machine throughput. In addition, quality and On the other hand, ironcore motors are also used to maximize the force density and thus to reach the largest

reliability are two of the many key points that customers benefit from ETEL products to possible bonding area in a given volume. By using ETEL AccurET controllers and some of the most advanced

ensure a stable, maintenance-free and very long machine lifetime. Finally the extended range features currently available on the motion control market, one can reach extreme precision levels in the micro

of standard LMG motors makes machine development roadmap easier by providing a stable meter range without any compromise on the machine throughput.

motion system design to continuously meet the evolving specifications. Pictures courtesy of Camtek Ltd. Pictures courtesy of Hesse GmbH

12 | Linear Motors Linear Motors | 13

Innovative Motion Control

ETELs linear motors in high-end motion platforms ETEL specific motor design in short stroke actuators

In many different industries, highly integrated actuators are requested. In such cases where the form factor is the

ETEL technology in wafer inspection motion systems most critical specification of the motion system, it might happen that conventional linear motors cannot fulfill the

application needs. In this case, ETEL motor experts are able to provide a motor design with the best performance

ETEL linear motor technology is used in the most advanced motion systems required by the semiconductor to volume ratio.

industry. A combination of the very best technology available is required when absolute accuracy levels go ETEL develops a wide range of short stroke actuators to address diversified needs in applications such

down to the sub-micrometer level and when position stability requirements are in the nanometer range. At as: pick & place, ICs testing, flying probe testing, etc. In each of these applications, the form factor is of

these levels, any component weakness can compromise the entire machine performance. This is the reason major importance to fit a high-end direct driven axis in the machine environment. The motors are designed

ETEL delivers complete motion platforms based on the very best components and mechanical design skills. ETEL short stroke actuators specifically and integrated together with bearings and feedback devices in the most suitable

In wafer inspection tools, very high accuracy and for flying probe testers form factor. This deep integration process leads to a cost effective and high performance

throughput are key specifications. To fulfill solution that fits to the exact requirements of the targeted process.

demanding applications, ETEL combines the use of LMG linear motor together with ETEL short stroke actuators can be based on different motor technologies depending on the motion

ETEL AccurET/UltimET position and motion controllers and their unique requirements. In such products, ETEL mainly uses miniaturized 2-phase or 3-phase ironless motors as

features specifically designed for this high-end industry. Ultimately, these well as single phase moving magnets or voice coil type motors. Ultimately, one can achieve extremely

key components are part of a larger optimized mechanical design to high dynamics (up to 180 g acceleration) together with a micrometer precision level thanks to

reach unmatched performance. integrated optical encoders. These very small and light actuators can operate maintenance

As an example, the stage shown on the right can achieve 1g free for billions of cycles with an extremely high throughput (30 cycles per second). ETELs

accelerations and 1m/s speed together with precision levels of 1.5 uniqueness is to merge compactness, performance, and reliability to achieve what can

microns and repeatability of 200 nanometers at the tool point. Thanks certainly not be achieved by combining conventional technologies.

to the overall motor, control, feedback, and mechanical package, short

move-and-settle within a sub-nanometer window can be reached.

ETEL XYT nanometer motion ETEL short stroke

system for wafer inspection actuators for IC testing handlers

AOI / pick and place

In the majority of microelectronic component manufacturing processes, a non-destructive inspection machine. This enables the OEMs to focus on their core competences in terms of inspection

phase is mandatory. This phase is crucial to ensuring the product functionality and reliability. Since it is an system, defect recognition software, etc. while having the assurance that the required

in-line process, it must be as fast and as precise as possible to precision, repeatability and throughput are guaranteed by ETEL as the experienced

guarantee the overall throughput of the line is not impacted motion system supplier.

by these control procedures.

In the electronic back-end industry, AOI stages are generally less demanding than wafer

Depending on the type of product inspected, inspection systems but are typically more dynamic with a larger working environment. In

whether passive components to more complex some applications, the inspection area covered by the X-Y axes can be larger than 1m2 while

ICs, different inspection technologies such as optical, X-ray, or acoustic are used. maintaining an absolute accuracy below 10 microns and repeatability in the micron range.

ETEL is present in a wide range of 2D and 3D Automated Optical Inspection (AOI) Moving speeds faster than 2 m/s are common and accelerations of 3 g can be ensured to

machines to bring high precision and maximized throughput by using complete achieve high dynamics, without compromising precision.

motion systems equipped with linear motors.

In an inspection machine, there are normally two key systems to be

synchronized to reach the best performance level: the motion platform and the

ETEL XYZ high

inspection system itself. By delivering complete motion platform including the dynamics motion platform ETEL XY gantry platform for

motion controllers, ETEL can guarantee the key motion specifications of the for ultra-sonic inspection system automated optical inspection system

14 | Linear Motors Linear Motors | 15

GROUP SUBSIDIARIES AND SALES OFFICES

AMERICAS sales@heidenhain.com

CHINA sales@heidenhain.com.cn

CZECH REPUBLIC heidenhain@heidenhain.cz

FRANCE sales@heidenhain.fr

GERMANY etel@etelgmbh.de

GREAT BRITAIN sales@heidenhain.co.uk

HONG KONG sales@heidenhain.com.hk

ITALY etel@etelsa.it

KOREA info@heidenhain.co.kr

SINGAPORE info@etel.sg

SWITZERLAND sales@etelsa.ch

TAIWAN info@heidenhain.tw

HEADQUARTERS THE NETHERLANDS etel@etelbv.nl

ETEL S.A. OTHER COUNTRIES internationalsales@etel.ch

Zone Industrielle

CH - 2112 Mtiers REPRESENTATIVES

Switzerland

T +41 (0)32 862 01 00 AUSTRIA b.hoerburger@iul-elektronik.at

F +41 (0)32 862 01 01 ISRAL comotech@medital.co.il

etel@etel.ch www.etel.ch SPAIN farresa@farresa.es

version 2.0 - 10/13 - subject to modifications without previous notice

Anda mungkin juga menyukai

- Alternative Linear Motion Systems: ME EN 7960 - Precision Machine Design Topic 5Dokumen14 halamanAlternative Linear Motion Systems: ME EN 7960 - Precision Machine Design Topic 5David Ranford100% (1)

- Linear Motors ApplicationDokumen36 halamanLinear Motors Applicationanon_651363671Belum ada peringkat

- Motores Lineares ParkerDokumen27 halamanMotores Lineares ParkerLuizinho SilvaBelum ada peringkat

- Everything You Need to Know About Linear MotorsDokumen18 halamanEverything You Need to Know About Linear MotorsSairam SirasapalliBelum ada peringkat

- Jung Do Suh (Damping Factor)Dokumen9 halamanJung Do Suh (Damping Factor)fatinBelum ada peringkat

- Fibermak G-Force Fiber Laser PDFDokumen13 halamanFibermak G-Force Fiber Laser PDFJake MillerBelum ada peringkat

- Hydrostatic PM Controller Contributes To Accuracy of Machining Operations and Machine Service LifeDokumen5 halamanHydrostatic PM Controller Contributes To Accuracy of Machining Operations and Machine Service LifeRadhakrishnan ChinnavadanBelum ada peringkat

- AIREX Linear Motor Vacuum CompatabilityDokumen3 halamanAIREX Linear Motor Vacuum Compatabilitymsahin1955Belum ada peringkat

- NPM Linear Shaft Motor CatalogDokumen24 halamanNPM Linear Shaft Motor CatalogElectromateBelum ada peringkat

- LinMot Catalogo Geral PDFDokumen408 halamanLinMot Catalogo Geral PDFnemzinhoBelum ada peringkat

- Valvula Proporcional Série d633 e d634Dokumen16 halamanValvula Proporcional Série d633 e d634Lucas Vinícius CostaBelum ada peringkat

- Moog Valves D633 D634 Catalog enDokumen14 halamanMoog Valves D633 D634 Catalog enPritam SinghBelum ada peringkat

- Linear Motor BasicDokumen7 halamanLinear Motor BasicSairam SirasapalliBelum ada peringkat

- 192 490023 Linear Modules CatalogDokumen80 halaman192 490023 Linear Modules CatalogAndre100% (1)

- Brochure Jenny Science EDokumen12 halamanBrochure Jenny Science EOLIVETOBelum ada peringkat

- Cam Follower GuideDokumen35 halamanCam Follower GuideSukendi TanBelum ada peringkat

- IX Iron Core Linear MotorDokumen20 halamanIX Iron Core Linear MotorjuliangoalBelum ada peringkat

- Sigma linear motors direct drive technology overviewDokumen26 halamanSigma linear motors direct drive technology overviewMario StoyanovBelum ada peringkat

- Eddy Current and Flux Density Distribution AnalysisDokumen3 halamanEddy Current and Flux Density Distribution AnalysisMATHANKUMAR.SBelum ada peringkat

- Safety Guidelines For Direct DrivesDokumen9 halamanSafety Guidelines For Direct DrivesJOseBelum ada peringkat

- Intro To CNC and Main Parts of CNCDokumen18 halamanIntro To CNC and Main Parts of CNCsank_knasBelum ada peringkat

- Experimental Study of Thrusts of A Cylindrical Linear Synchronous Motor With One or More YBCO Bulk Magnets As The Excitation SystemDokumen6 halamanExperimental Study of Thrusts of A Cylindrical Linear Synchronous Motor With One or More YBCO Bulk Magnets As The Excitation SystemravinderreddynBelum ada peringkat

- Automotive Active Suspension - Case Study On H-Infinity ControlDokumen6 halamanAutomotive Active Suspension - Case Study On H-Infinity Controlmallikarjuna.handiBelum ada peringkat

- Hevi-Rail-Cam Roller Technology Catalog PDFDokumen68 halamanHevi-Rail-Cam Roller Technology Catalog PDFKathirrasuBelum ada peringkat

- Grinding Wheel Profile Definition For The Manufacture of Drill FlutesDokumen4 halamanGrinding Wheel Profile Definition For The Manufacture of Drill Flutesanon_459311574Belum ada peringkat

- TS1 Catalog v3Dokumen80 halamanTS1 Catalog v3geo12345Belum ada peringkat

- A Guide to Linear Dynamic Analysis with DampingDokumen15 halamanA Guide to Linear Dynamic Analysis with DampingPrashanth ReddyBelum ada peringkat

- UCT Pulsed Linear Induction Motor DesignDokumen203 halamanUCT Pulsed Linear Induction Motor DesignKael XelBelum ada peringkat

- Linear Synchronous Motor Control for Urban MaglevDokumen11 halamanLinear Synchronous Motor Control for Urban MaglevSupatmono NAIBelum ada peringkat

- Research ArticleDokumen8 halamanResearch ArticleJoseph IRANZIBelum ada peringkat

- Design & Modification of Arduino Based Rocker Bogie Mechanism For Security & Spy PurposeDokumen35 halamanDesign & Modification of Arduino Based Rocker Bogie Mechanism For Security & Spy PurposeAhMEd KhanBelum ada peringkat

- Resolute - Fanuc - L 9517 9442 04 C (En) PDFDokumen7 halamanResolute - Fanuc - L 9517 9442 04 C (En) PDFeletropaulomococaBelum ada peringkat

- MAGLEV TrainsDokumen5 halamanMAGLEV TrainsAditya 苏巴马廉 IyerBelum ada peringkat

- SERVOMOTORES OMRON g5 - Series - I815-E1 - 29 - 19 - csm2106 PDFDokumen59 halamanSERVOMOTORES OMRON g5 - Series - I815-E1 - 29 - 19 - csm2106 PDFHebert Javier RengifoBelum ada peringkat

- Welcome: Bestek Engineering PVT LTDDokumen39 halamanWelcome: Bestek Engineering PVT LTDankush kokitkarBelum ada peringkat

- E-Series EP EL Analog 551245 enDokumen7 halamanE-Series EP EL Analog 551245 enHugo LOPEZ CLEMENTEBelum ada peringkat

- Automatic Drilling Machine Using PLC I Ji SetDokumen7 halamanAutomatic Drilling Machine Using PLC I Ji SetMudassir KhanBelum ada peringkat

- Motion Control NC62 Complete English 2019Dokumen796 halamanMotion Control NC62 Complete English 2019Arnoud NegraoBelum ada peringkat

- Exposed Linear Encoders HeidenheinDokumen76 halamanExposed Linear Encoders HeidenheinKenan HebibovicBelum ada peringkat

- Hydrostatic Linear Motor Guide TacrockfordDokumen1 halamanHydrostatic Linear Motor Guide Tacrockfordanantj18Belum ada peringkat

- Iot PPT CK-2022Dokumen23 halamanIot PPT CK-2022sachin mBelum ada peringkat

- B65270EN07Dokumen553 halamanB65270EN07uduwdjwBelum ada peringkat

- ELASTIC GRINDING TOOLS FOR MATTING, DEBURRING, EFFECT GRINDING, FINE GRINDING AND POLISHINGDokumen26 halamanELASTIC GRINDING TOOLS FOR MATTING, DEBURRING, EFFECT GRINDING, FINE GRINDING AND POLISHINGLakshmananan NagarajanBelum ada peringkat

- Ch-10 Grinding and FinishingDokumen121 halamanCh-10 Grinding and FinishingMANJEET KUMARBelum ada peringkat

- Linear DC MotorDokumen13 halamanLinear DC MotorrahulkudluBelum ada peringkat

- Guide Y-axis configurationDokumen3 halamanGuide Y-axis configurationMiguel Eduardo Rangel CorderoBelum ada peringkat

- Linear Induction Motor: Seminar Presentation ONDokumen19 halamanLinear Induction Motor: Seminar Presentation ONDev KumarBelum ada peringkat

- Precision Bearing House, Industrial AutomationDokumen244 halamanPrecision Bearing House, Industrial AutomationPrecision Bearing HouseBelum ada peringkat

- A Tension-Torsion Creep-Rupture Testing MachineDokumen7 halamanA Tension-Torsion Creep-Rupture Testing MachineMyles JingBelum ada peringkat

- Linear Induction MotorDokumen21 halamanLinear Induction MotorRavi Kiran MBelum ada peringkat

- Design of High Performance Linear Brushless DC Motor With Ironless CoreDokumen6 halamanDesign of High Performance Linear Brushless DC Motor With Ironless CoreShubhzsBelum ada peringkat

- A Linear Motor or Linear Induction Motor Is An Alternating CurrentDokumen6 halamanA Linear Motor or Linear Induction Motor Is An Alternating CurrentAnand KanaujiyaBelum ada peringkat

- Katalog Linear BearingDokumen56 halamanKatalog Linear BearingjetpackcontrollerBelum ada peringkat

- Linear Guides PBCDokumen27 halamanLinear Guides PBCDracoRodriguezBelum ada peringkat

- Studies On The Benefits of Using Linear Motors Insted To Ball Screws Used in Drive of The Machine ToolsDokumen8 halamanStudies On The Benefits of Using Linear Motors Insted To Ball Screws Used in Drive of The Machine ToolsVASILIIBelum ada peringkat

- 0185-1100-US 1V1 Product OverviewDokumen36 halaman0185-1100-US 1V1 Product OverviewAlexander Aristizábal PeñalozaBelum ada peringkat

- Stepper MotorDokumen11 halamanStepper MotorPrince RajBelum ada peringkat

- Rotary-Linear Machines - A SurveyDokumen4 halamanRotary-Linear Machines - A Surveyarnika33Belum ada peringkat

- Linear Motors ENDokumen9 halamanLinear Motors ENIvan IntroBelum ada peringkat

- Torque Motors enDokumen9 halamanTorque Motors enAbhishek AroraBelum ada peringkat

- (Bovespa) UMDF Message Reference v2.1.2Dokumen32 halaman(Bovespa) UMDF Message Reference v2.1.25397573Belum ada peringkat

- PHD 2006 04 PDFDokumen202 halamanPHD 2006 04 PDF5397573Belum ada peringkat

- Lect9 Laser OscillatorsDokumen91 halamanLect9 Laser OscillatorsEligius MartinezBelum ada peringkat

- Bollen Et Al-2010-European Transactions On Electrical PowerDokumen16 halamanBollen Et Al-2010-European Transactions On Electrical Power5397573Belum ada peringkat

- Tech Sec 3Dokumen2 halamanTech Sec 35397573Belum ada peringkat

- Canonical Machining CommandsDokumen38 halamanCanonical Machining Commands5397573Belum ada peringkat

- Kumar Paper - 2005 Spring SeminarDokumen49 halamanKumar Paper - 2005 Spring SeminarChad GilmanBelum ada peringkat

- MMT Ethercat User GuideDokumen20 halamanMMT Ethercat User Guide5397573Belum ada peringkat

- TDMADokumen13 halamanTDMA5397573Belum ada peringkat

- Uart DesignDokumen20 halamanUart Designtrung100% (2)

- SIMtrace User ManualDokumen21 halamanSIMtrace User Manual5397573Belum ada peringkat

- GSM Phone Anatomy LatestDokumen11 halamanGSM Phone Anatomy LatestabhineetkumarBelum ada peringkat

- Q (1) Type of State?: Paper Possible QuestionsDokumen5 halamanQ (1) Type of State?: Paper Possible QuestionsWAqar RaoBelum ada peringkat

- Education Is A Controlling Grace To The Young, Consolation To The Old, Wealth To The Poor, and Ornament To The Rich. - Diogenes LaertiusDokumen3 halamanEducation Is A Controlling Grace To The Young, Consolation To The Old, Wealth To The Poor, and Ornament To The Rich. - Diogenes LaertiusSachithBelum ada peringkat

- Science DLP Parts of PlantsDokumen8 halamanScience DLP Parts of PlantsMishell AbejeroBelum ada peringkat

- Universidad Nacional de Cuyo Facultad de Educación: Lengua Extranjera: EnglishDokumen8 halamanUniversidad Nacional de Cuyo Facultad de Educación: Lengua Extranjera: EnglishLiliana AlisaresBelum ada peringkat

- Edtpa Lesson Plan Guide LPGDokumen5 halamanEdtpa Lesson Plan Guide LPGapi-660566244Belum ada peringkat

- To Study The Prevalence of Anaemia in Indoor Patients of Tertiary Care CentreDokumen3 halamanTo Study The Prevalence of Anaemia in Indoor Patients of Tertiary Care CentreIJAR JOURNALBelum ada peringkat

- Brinton NietzscheDokumen296 halamanBrinton Nietzschej1943Belum ada peringkat

- Assessment and Evaluation of Learning Part 3Dokumen3 halamanAssessment and Evaluation of Learning Part 3jayson panaliganBelum ada peringkat

- George ResumeDokumen3 halamanGeorge Resumeapi-287298572Belum ada peringkat

- Missionary Education in East AfricaDokumen15 halamanMissionary Education in East AfricaCanny ChalBelum ada peringkat

- Shermila DissertationDokumen305 halamanShermila DissertationRangothri Sreenivasa SubramanyamBelum ada peringkat

- MCHS 1965 YearbookDokumen112 halamanMCHS 1965 YearbookMater Dei Catholic High SchoolBelum ada peringkat

- Year 3 Civic Lesson Plan (September - Love) : Content StandardDokumen1 halamanYear 3 Civic Lesson Plan (September - Love) : Content StandardIdham HakimiBelum ada peringkat

- Semi Detailed Lesson PlanDokumen2 halamanSemi Detailed Lesson PlanHazel Paguio-Lastrollo0% (3)

- Spanish 2 Examen Final Presentacion Dia 1Dokumen20 halamanSpanish 2 Examen Final Presentacion Dia 1api-263267469Belum ada peringkat

- Mapeh 10 Curriculum MapDokumen9 halamanMapeh 10 Curriculum MapJoshua LamzonBelum ada peringkat

- Second Language Writing Challenges for Saudi LearnersDokumen31 halamanSecond Language Writing Challenges for Saudi LearnersRamizBelum ada peringkat

- School Learning and Development Plan For Head TeachersDokumen3 halamanSchool Learning and Development Plan For Head TeachersLiza Bacudo100% (1)

- The Brain Fitness Book Activities and Puzzles To Keep Your Mind Active and Healthy (Rita Carter) (Z-Library)Dokumen192 halamanThe Brain Fitness Book Activities and Puzzles To Keep Your Mind Active and Healthy (Rita Carter) (Z-Library)Richard Wokard100% (1)

- Are Women Better Leaders Than MenDokumen5 halamanAre Women Better Leaders Than MenArijanaBelum ada peringkat

- Family Breakdown PDFDokumen11 halamanFamily Breakdown PDFSamantha GordonBelum ada peringkat

- TERNA ENGINEERING COLLEGE ACADEMIC CALENDARDokumen5 halamanTERNA ENGINEERING COLLEGE ACADEMIC CALENDARPuppysinghBelum ada peringkat

- Adult Learning An OverviewDokumen11 halamanAdult Learning An OverviewKhalif AziziBelum ada peringkat

- Multidimensional Locus of Control Attitude Scale Levenson Miller 1976 JPSPDokumen10 halamanMultidimensional Locus of Control Attitude Scale Levenson Miller 1976 JPSPAnnaNedelcuBelum ada peringkat

- Premiere Products Exercise Chapter 8 Complete SolutionDokumen6 halamanPremiere Products Exercise Chapter 8 Complete SolutionMatthew BeckwithBelum ada peringkat

- Hubungan Motivasi Kerja dan Prestasi Karyawan di Hotel Resty PekanbaruDokumen9 halamanHubungan Motivasi Kerja dan Prestasi Karyawan di Hotel Resty PekanbaruMuhamad ApriaBelum ada peringkat

- Lga Lesson PlanDokumen15 halamanLga Lesson PlanPriya Darshini MuruganBelum ada peringkat

- M.Tech 2023 CutoffDokumen6 halamanM.Tech 2023 Cutoffmshail30Belum ada peringkat

- Original Marks ListDokumen291 halamanOriginal Marks ListFurqan WarisBelum ada peringkat

- Presentacin Intro Distribucin Por Variables A Taste of The MoonDokumen8 halamanPresentacin Intro Distribucin Por Variables A Taste of The MoonClemente TorresBelum ada peringkat