Msds Carbon Steel

Diunggah oleh

Rober Moises Chumbe SoveroHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Msds Carbon Steel

Diunggah oleh

Rober Moises Chumbe SoveroHak Cipta:

Format Tersedia

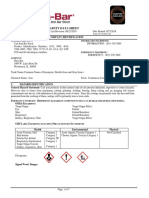

PETERSON STEEL Corporation

61 West Mountain Street ~ Worcester, MA 01606-0328

Emergency Phone Number: (508) 853-3630 Issue Date: March 1, 2004

MATERIAL SAFETY DATA SHEET

TRADE NAME: Carbon and Alloy Steel Chemical Name: AISI/SAE 10xx thru 93xx

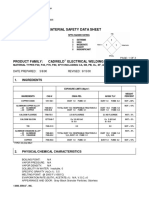

1. Ingredients EXPOSURE LIMITS

Material or Compound CAS Number % Weight OSHA PEL (mg/m3) ACHIG-TLV (mg/m3)

Aluminum (Al) 7429-90-5 <0.01 - 0.5 15 10

Bismuth (Bi) 7440-69-9 <0.2 - 0.5 N/A N/A

Boron (B) 7440-42-8 <0.01 - 1.0 15 10

Carbon (C) 7440-44-0 <0.1 - 1.5 10 10

Chromium (Cr) 7440-47-3 <0.4 - 10 1.0 0.5

Columbium (Cb) 7440-03-1 <0.15 - 0.35 N/A N/A

Copper (Cu) 7440-50-8 <0.3 - 1.9 1 1

Iron (Fe) 7439-89-6 <86.5 - 99.5 10 5

Lead (Pb) 7439-92-1 <0.15 - 0.35 0.05 0.05

Manganese (Mn) 7439-96-5 <0.04 - 0.7 5 5

Molybdenum (Mo) 7439-98-7 <0.15 - 1.10 15 10

Nickel (Ni) 7440-02-2 <0.10 - 10 1 1

Phosphorous (P) 7723-14-0 <0.04 - 0.12 0.1 0.1

Silicon (S) 7740-21-3 <0.15 - 2.0 15 10

Sulfur (S) 7704-34-9 <0.05 - 0.35 13 (Sulfur Dioxide) 5 (Sulfur Dioxide)

Vanadium (V) 7440-62-2 <0.01 - 0.15 0.5 0.5

Note: The above is a summary of elements used in alloying steel. Various grades of steel will contain different combinations of these elements.

Trace elements may also be present in minute amounts.

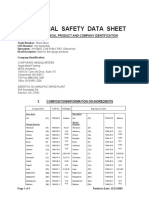

2. Physical Data

% Volatile by Volume: N/A Vapor Density: N/A Material is (at normal conditions): SOLID

Vapor Pressure (mm Hg@20C): N/A Boiling Point: N/A Appearance and Odor: Silver-Grey, Odorless

Melting Point (approximate): 2800 F Acidity/Alkalinity: PH - N/A Specific Gravity (H2O = 1): Approximately 7

Solubility in Water: N/A

3. Personal Protective 4. Emergency Medical

Equipment Procedures

Respiratory Protection: Inhalation:

Appropriate dust/mist/fume respirator should be used to Remove to fresh air; if condition continues, consult a

avoid excessive inhalation of particulates. If exposure limits physician.

are reached or exceeded, use NIOSH approved equipment. Eye Contact:

Eyes and Face: Flush thoroughly with running water to remove

Safety glasses should be worn when grinding or cutting. particulate; obtain medical attention.

Face shields should be worn when welding or cutting. Skin Contact:

Hands, Arms and Body: Remove particles by washing thoroughly with soap

Protective gloves should be worn as required for welding, and water. Seek medical attention if condition persists.

burning or handling operations. Ingestion:

Other Clothing and Equipment: If significant amounts of metal are ingested,

As required depending upon operations and safety codes. consult a physician.

5. Health and Safety Information

Health

Steel products in their solid state present no inhalation, ingestion, or contact health hazard. Operations such as burning,

welding, sawing, brazing, grinding, and machining, which result in elevating the temperature of the product to, or above

its melting point, or result in the generation of airborne particulates, may present hazards. The major exposure hazard is

inhalation. Effects or overexposure to fume and dust are as follows:

Acute: Excessive inhalation of metallic fumes and dust may result in irritation of eyes, nose and throat. High concentrations

of fumes and dust of iron-oxide, manganese, copper, zinc and lead may result in metal fume fever. Typical symptoms last

from 12 to 48 hours and consist of a metallic taste in the mouth, dryness and irritation of the throat, chills and fever.

Chronic: Chronic and prolonged inhalation of high concentrations of fumes or dust of the following elements may lead

to the conditions listed opposite the element:

Aluminum: May initiate fibrotic changes to lung tissue. Manganese: Bronchitis, pneumonitis, lack of coordination.

Bismuth: No chronic debilitating symptoms indicated. Molybdenum: Respiratory tract irritation, possible liver

Boron: No chronic debilitating symptoms indicated. and kidney damage, bone deformity.

Chromium: Lesions of the skin and mucous membranes, Nickel: Lesions of the skin and mucous membranes,

possible cancer of the nose or lungs-bronchogenic possible cancer of the nose or lungs-bronchogenic

carcinoma. carcinoma.

Copper: No chronic debilitating symptoms indicated. Phosphorous: Necrosis of the mandible.

Iron: Siderosis, pulmonary effects. Sulfur: (as Sulfur Dioxide) Edema of the lungs.

Lead: Anemia, urinary dysfunction, weakness, Vanadium: (as Vanadium Pentoxide) Emphysema, pneumonia.

constipation, nausea, nervous disorder. Zinc: Gastrointestinal inflammation reported in animal

studies.

Medical Conditions aggravated by Exposure: Individuals with chronic respiratory disorders (i.e.: asthma, chronic

bronchitis, emphysema, etc.) may be adversely affected by any fume or airborne particulate matter exposure.

Occupational Exposure Limits: See Products Ingredients Section 1. Chromium and Nickel have been identified by

the International Agency for Research on Cancer (IARC) and/or the National Toxicology Program (NTP) as potential

cancer causing agents.

Fire and Explosion

Flash Point: N/A Auto Ignition Temperature: N/A Flammable Limits in Air (Upper & Lower): N/A

Extinguishing Media: For molten metal use dry powder or sand (DO NOT USE WATER ON MOLTEN METAL).

Fire and Explosion Hazards: Steel products do not present fire or explosion hazards under normal conditions.

Fine metal particles such as produced in grinding or sawing can burn. High concentrations of metallic fines in air may

present an explosion hazard.

Reactivity

Stability: Stable Incompatibility: (Materials to avoid) Reacts with strong acids to form Hydrogen gas.

Conditions to Avoid: Steel at temperatures above the melting point may liberate fumes containing oxides of iron

and alloying elements. Avoid generation of airborne fumes and dust.

Hazardous Decomposition Products: Metallic dust or fumes may be produced during welding, burning, grinding

and possible machining. Refer to ANSI Z49.1.

6. Environmental

Spill or Leak Procedures: Fine turnings and small chips should be swept or vacuumed. Scrap metal can be

reclaimed for reuse.

Waste Disposal Method: Used or unused products should be disposed of in accordance with Federal, State

and local laws and regulations. Disposer must comply with Federal, State and local disposal or discharge laws.

7. Additional Information

In welding, precautions should be taken for airborne contaminants which may originate from components of

the welding rod. Arc or spark generated when welding or burning could be a source of ignition for combustion

of flammable materials.

DISCLAIMER

The information in this MSDS was obtained from sources which we believe are reliable. However, the information is

provided without any representation or warranty, express or implied, regarding the accuracy or correctness. The conditions

or methods of handling, storage, use and disposal of the product are beyond our control and maybe beyond our knowledge.

For this and other reasons, we do not assume responsibility and expressly disclaim liability for loss, damage or expense

arising out of or in any way connected with the handling, storage, use or disposal of the product.

Anda mungkin juga menyukai

- Gold Extraction and Recovery ProcessesDokumen20 halamanGold Extraction and Recovery ProcessesNataniel LinaresBelum ada peringkat

- Compost Tea Manual PDFDokumen38 halamanCompost Tea Manual PDFbaspipsBelum ada peringkat

- Steel Wire RopesDokumen23 halamanSteel Wire RopeskevinBelum ada peringkat

- Store Safety Policy and ProceduresDokumen10 halamanStore Safety Policy and ProceduresImtiyaz AkhtarBelum ada peringkat

- Properties and Characteristics of Liquid FuelsDokumen18 halamanProperties and Characteristics of Liquid FuelsTin Aung Kyi100% (2)

- Organization of Genes and Chromosomes CompleteDokumen13 halamanOrganization of Genes and Chromosomes Completebiotecnika_testBelum ada peringkat

- Rubber Additives - Compounding Ingredients: R. N. Datta and F. A. A. InghamDokumen42 halamanRubber Additives - Compounding Ingredients: R. N. Datta and F. A. A. InghamRubber TeamBelum ada peringkat

- SAE Ferrous Materials Standards Manual - 2004Dokumen3 halamanSAE Ferrous Materials Standards Manual - 2004Xin Yu50% (2)

- MS 1539 PT3 2003 Portable Fire Extinguisher PDFDokumen31 halamanMS 1539 PT3 2003 Portable Fire Extinguisher PDFLee GP100% (3)

- ASTM A500 2010 TubosDokumen6 halamanASTM A500 2010 TubosRober Moises Chumbe SoveroBelum ada peringkat

- ISO 1035-4:1982 Hot-Rolled Steel Bar TolerancesDokumen10 halamanISO 1035-4:1982 Hot-Rolled Steel Bar TolerancesRober Moises Chumbe SoveroBelum ada peringkat

- BS en 10136-2019Dokumen16 halamanBS en 10136-2019Martijn GrootBelum ada peringkat

- Screw Conveyor Engineering Manual PDFDokumen68 halamanScrew Conveyor Engineering Manual PDFnadBelum ada peringkat

- Chapter 1 To 4Dokumen121 halamanChapter 1 To 4Haiqal Aziz100% (1)

- Calcul Conveioare SurubDokumen2 halamanCalcul Conveioare SurubgvisanBelum ada peringkat

- Calcul Conveioare SurubDokumen2 halamanCalcul Conveioare SurubgvisanBelum ada peringkat

- Calcul Conveioare SurubDokumen2 halamanCalcul Conveioare SurubgvisanBelum ada peringkat

- Corrosion: Corrosion ControlDari EverandCorrosion: Corrosion ControlL L ShreirPenilaian: 5 dari 5 bintang5/5 (1)

- Adc12 MSDSDokumen3 halamanAdc12 MSDSClaudia Mata100% (1)

- SDS-metal DustDokumen10 halamanSDS-metal DustAzuan MABKBelum ada peringkat

- SDS PC Strand Sumiden Wire Products 2017 06 23 PDFDokumen8 halamanSDS PC Strand Sumiden Wire Products 2017 06 23 PDFfehmi boudabousBelum ada peringkat

- MSDS-Hebei Botou-BeCuDokumen8 halamanMSDS-Hebei Botou-BeCuTaherBelum ada peringkat

- MSDS - Slag PDFDokumen2 halamanMSDS - Slag PDFAyu Wanda SaraswatiBelum ada peringkat

- Safety Data Sheet for RB-26 Welding ElectrodeDokumen7 halamanSafety Data Sheet for RB-26 Welding Electrodehorry andresBelum ada peringkat

- Aluminum A380 MSDS SheetDokumen3 halamanAluminum A380 MSDS SheetAndy KrolBelum ada peringkat

- Material Safety Data Sheet (M.S.D.S.) : Updated March 24, 2014Dokumen3 halamanMaterial Safety Data Sheet (M.S.D.S.) : Updated March 24, 2014UtamiBelum ada peringkat

- Metal StudsDokumen9 halamanMetal StudsMeita RizkyBelum ada peringkat

- Safety Data Sheet for Welding Consumable NC-38Dokumen7 halamanSafety Data Sheet for Welding Consumable NC-38Indra WibawaBelum ada peringkat

- Steel-Shot-Grit-MSDS-sheet_wabbrasiveDokumen2 halamanSteel-Shot-Grit-MSDS-sheet_wabbrasivelukmanBelum ada peringkat

- Sds For Gray CastDokumen7 halamanSds For Gray CastPravin PatilBelum ada peringkat

- Asn96a3c05-0.63 enDokumen5 halamanAsn96a3c05-0.63 enZoran ConstantinescuBelum ada peringkat

- SDS Underwater Cutting Rods 2018 PDFDokumen8 halamanSDS Underwater Cutting Rods 2018 PDFVictor AcostaBelum ada peringkat

- J79 195 Rev H AMPCO SDS Rod WireDokumen10 halamanJ79 195 Rev H AMPCO SDS Rod WireNair R RakeshBelum ada peringkat

- Gas Metal Arc Welding WiresDokumen3 halamanGas Metal Arc Welding Wiresmuhamad bukhari abu hassanBelum ada peringkat

- Material Safety Data Sheet: Product Name: RD-260 Classification: AWS A5.1 E6013Dokumen3 halamanMaterial Safety Data Sheet: Product Name: RD-260 Classification: AWS A5.1 E6013tamharBelum ada peringkat

- Pig Iron SDS PrimetradeDokumen4 halamanPig Iron SDS PrimetradePravin PatilBelum ada peringkat

- 101r06intragbrFS AlloysDokumen4 halaman101r06intragbrFS AlloysAshikBelum ada peringkat

- MSDS BatreiDokumen9 halamanMSDS BatreiMuhamad HasbiBelum ada peringkat

- SDS 316 Stainless SteelDokumen5 halamanSDS 316 Stainless SteelAshish BhanderiBelum ada peringkat

- SDS HTW 50 2020Dokumen3 halamanSDS HTW 50 2020Ari RosyadiBelum ada peringkat

- Msds Cobalt PDFDokumen3 halamanMsds Cobalt PDFwangchao821Belum ada peringkat

- MIG Welding Electrode MSDSDokumen6 halamanMIG Welding Electrode MSDSDheeraj E MohananBelum ada peringkat

- Msds Silica FumeDokumen5 halamanMsds Silica Fume11sajidBelum ada peringkat

- Material Safety Data Sheet: Section 1 - IdentificationDokumen4 halamanMaterial Safety Data Sheet: Section 1 - IdentificationAmjad MehmoodBelum ada peringkat

- CSW-0115 MSDS GuideDokumen5 halamanCSW-0115 MSDS GuideMohamed AdelBelum ada peringkat

- MSDS SoldaduraDokumen4 halamanMSDS SoldaduraJosé YáñezBelum ada peringkat

- MSDS - Yuasa Battery WetDokumen9 halamanMSDS - Yuasa Battery WetBatanBelum ada peringkat

- Gray Cast Iron Castings Safety Data SheetDokumen7 halamanGray Cast Iron Castings Safety Data SheetDavid Lay IIBelum ada peringkat

- Alu DrossDokumen10 halamanAlu DrossfahmiBelum ada peringkat

- Safety Data Sheet: 1. Product InformationDokumen6 halamanSafety Data Sheet: 1. Product InformationJessie O.BechaydaBelum ada peringkat

- 105r05intraGBRCaBaFeSiDokumen4 halaman105r05intraGBRCaBaFeSiAshikBelum ada peringkat

- MSDS for LC-318HR Welding ElectrodeDokumen5 halamanMSDS for LC-318HR Welding ElectrodeMohamed AdelBelum ada peringkat

- Valve Regulated Lead Acid Battery: - Material Safety Data SheetDokumen3 halamanValve Regulated Lead Acid Battery: - Material Safety Data Sheethornet22Belum ada peringkat

- Safety Data Sheet: 1. Product InformationDokumen6 halamanSafety Data Sheet: 1. Product InformationJessie O.BechaydaBelum ada peringkat

- SeaBattery - Safety Data Sheet - 2012Dokumen6 halamanSeaBattery - Safety Data Sheet - 2012Massimo De StefanoBelum ada peringkat

- Safety Data Sheet for DW-308 Welding WireDokumen7 halamanSafety Data Sheet for DW-308 Welding WireKang Kawe Waone SetiaoneBelum ada peringkat

- Material Safety Data Sheet: 1. Chemical Product and Company IdentificationDokumen7 halamanMaterial Safety Data Sheet: 1. Chemical Product and Company Identificationrmsa17Belum ada peringkat

- Esab Sds Can332-C Ercuni 70-30Dokumen5 halamanEsab Sds Can332-C Ercuni 70-30jromero_rpgBelum ada peringkat

- MSDS N2XHDokumen3 halamanMSDS N2XHH. NurzeinBelum ada peringkat

- Material Safety Data Sheet: I. Product IdentificationDokumen2 halamanMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoBelum ada peringkat

- Material Safety Data Sheet: Appearance and Odor: ElectrolyteDokumen5 halamanMaterial Safety Data Sheet: Appearance and Odor: Electrolytemfadil1234Belum ada peringkat

- Material Safety Data Sheet: For Welding Consumables and Related ProductsDokumen2 halamanMaterial Safety Data Sheet: For Welding Consumables and Related ProductsVinodhkanna GandhiBelum ada peringkat

- Safety Data Sheet: 1. Product and Company InformationDokumen6 halamanSafety Data Sheet: 1. Product and Company Informationfehmi boudabousBelum ada peringkat

- Material Safety Data Sheets: (MSDS)Dokumen5 halamanMaterial Safety Data Sheets: (MSDS)DucBelum ada peringkat

- Brass Material Safety Data SheetDokumen4 halamanBrass Material Safety Data SheetHendri WaeBelum ada peringkat

- Element Six: What Is Sulfur Dioxide? & Properties of Other Gases and ComparisonsDokumen10 halamanElement Six: What Is Sulfur Dioxide? & Properties of Other Gases and Comparisonsapi-3738896Belum ada peringkat

- Silica FumeDokumen5 halamanSilica FumeMohamed HassanBelum ada peringkat

- Material Safety Data Sheet (MSDS) : Section I - IdentificationDokumen2 halamanMaterial Safety Data Sheet (MSDS) : Section I - IdentificationSalem GarrabBelum ada peringkat

- Material Safety Data Sheet: 1. Product and Company IdentificationDokumen10 halamanMaterial Safety Data Sheet: 1. Product and Company IdentificationahmedBelum ada peringkat

- Coal Fly Ash: Material Safety Data SheetDokumen3 halamanCoal Fly Ash: Material Safety Data SheetZaenal Ma'rufBelum ada peringkat

- Carbon Steel Electrodes: Safety Data SheetDokumen9 halamanCarbon Steel Electrodes: Safety Data SheetAnonyBelum ada peringkat

- Material Safety Data Sheet For BOSS WELD ELECTRODES - 84651098. 1106, 1117, 1128Dokumen4 halamanMaterial Safety Data Sheet For BOSS WELD ELECTRODES - 84651098. 1106, 1117, 1128mohamed AdelBelum ada peringkat

- Acero HSDokumen2 halamanAcero HSEdgar MOrenoBelum ada peringkat

- MATERIAL SAFETY DATA SHEET CORED SOLDER WIREDokumen4 halamanMATERIAL SAFETY DATA SHEET CORED SOLDER WIREIrsyad IlhamiBelum ada peringkat

- 1 EutecDisk - MSDS - EnglishDokumen4 halaman1 EutecDisk - MSDS - EnglishMohamed AdelBelum ada peringkat

- MSDS Leadframe (16 Items)Dokumen8 halamanMSDS Leadframe (16 Items)bennisg8Belum ada peringkat

- Material Safety Data Sheet: I. Product IdentificationDokumen2 halamanMaterial Safety Data Sheet: I. Product IdentificationadityadhBelum ada peringkat

- GeometriaDokumen414 halamanGeometriaRober Moises Chumbe SoveroBelum ada peringkat

- Canal U VS UpnDokumen1 halamanCanal U VS UpnRober Moises Chumbe SoveroBelum ada peringkat

- ScrapDokumen18 halamanScrapRober Moises Chumbe SoveroBelum ada peringkat

- CE591MomentConn F13Dokumen58 halamanCE591MomentConn F13Arnel DodongBelum ada peringkat

- ASTM A641 A641M 2003 Standard Specification For Zinc Coated Galvanized Carbon Steel Wire 26 PDFDokumen5 halamanASTM A641 A641M 2003 Standard Specification For Zinc Coated Galvanized Carbon Steel Wire 26 PDFRober Moises Chumbe SoveroBelum ada peringkat

- ASTM A853 Alambre RecocidoDokumen3 halamanASTM A853 Alambre RecocidoRober Moises Chumbe SoveroBelum ada peringkat

- Sds Sheet GalvanizedDokumen8 halamanSds Sheet GalvanizedRober Moises Chumbe SoveroBelum ada peringkat

- Cold Rolled Steel SheetDokumen0 halamanCold Rolled Steel SheetJajat Derajat MutaqinBelum ada peringkat

- A792 GalvalumeDokumen6 halamanA792 Galvalumejohnnyquest_86Belum ada peringkat

- A706A706M - 09 BDokumen6 halamanA706A706M - 09 BRober Moises Chumbe SoveroBelum ada peringkat

- Cold Rolled Steel SheetDokumen0 halamanCold Rolled Steel SheetJajat Derajat MutaqinBelum ada peringkat

- Calc TanksDokumen1 halamanCalc TanksRober Moises Chumbe SoveroBelum ada peringkat

- Calc TanksDokumen1 halamanCalc TanksRober Moises Chumbe SoveroBelum ada peringkat

- LPG Manual For Sales Staff: Properties, Characteristics and Hazards of LPG 1. What Is LPG?Dokumen15 halamanLPG Manual For Sales Staff: Properties, Characteristics and Hazards of LPG 1. What Is LPG?Ravindra A GBelum ada peringkat

- Peet Material 1Dokumen130 halamanPeet Material 1SaikrisdBelum ada peringkat

- LUMS SSE Admissions Test Sample QuestionsDokumen16 halamanLUMS SSE Admissions Test Sample Questions999 X100% (1)

- Mining Technology Elements for Preventing Mine InundationDokumen5 halamanMining Technology Elements for Preventing Mine InundationAsmit KumarBelum ada peringkat

- Filter Medium FE 2507-SINE: For Viledon Dust Removal ElementsDokumen2 halamanFilter Medium FE 2507-SINE: For Viledon Dust Removal ElementsBülent KabadayiBelum ada peringkat

- IR Spectroscopy Problem Set 1Dokumen0 halamanIR Spectroscopy Problem Set 1Jules BrunoBelum ada peringkat

- Alucobond CladdingDokumen5 halamanAlucobond CladdingShehzaadRamjan100% (1)

- Beam On Elastic FoundationDokumen15 halamanBeam On Elastic FoundationKshitiz ShresthaBelum ada peringkat

- RB Cagmat Review Center - Cs-Photosynthesis PDFDokumen33 halamanRB Cagmat Review Center - Cs-Photosynthesis PDFBergo AgustinBelum ada peringkat

- Key Physical Variables in The Ocean Temperature, Salinity, and DensityDokumen10 halamanKey Physical Variables in The Ocean Temperature, Salinity, and DensityLeon TaufaniBelum ada peringkat

- Bhagwad Gita in Hindi ISKON-IntroductionDokumen30 halamanBhagwad Gita in Hindi ISKON-IntroductiontazinabhishekBelum ada peringkat

- Moscow Refining, Gas & Petrochemical WeekDokumen11 halamanMoscow Refining, Gas & Petrochemical Weekdheeraj sehgalBelum ada peringkat

- ResearchDokumen31 halamanResearchAlexa BarnBelum ada peringkat

- 08 Chapter 2Dokumen71 halaman08 Chapter 2Ibn LibyaBelum ada peringkat

- 3p531-Api 617-C505u-Re C505 - LPCDokumen8 halaman3p531-Api 617-C505u-Re C505 - LPCYusri FakhrizalBelum ada peringkat

- 2022 Puc I Chem Imp QuestionsDokumen13 halaman2022 Puc I Chem Imp QuestionsCHAKRI BABLUBelum ada peringkat

- Factors Affecting Chemical Reaction RatesDokumen18 halamanFactors Affecting Chemical Reaction RatesExeteurBelum ada peringkat

- Jairo Alonso Paredes-C., Luís Miguel Romero-R., Julián David de Bedout-O. & Carlos Mauricio Bernal-RDokumen7 halamanJairo Alonso Paredes-C., Luís Miguel Romero-R., Julián David de Bedout-O. & Carlos Mauricio Bernal-RJhon barreraBelum ada peringkat

- Mandals - Superman HVTDokumen1 halamanMandals - Superman HVTDavid ChoquenairaBelum ada peringkat