Expt. 9 Natural Convection

Diunggah oleh

Pradeep DiwakarDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Expt. 9 Natural Convection

Diunggah oleh

Pradeep DiwakarHak Cipta:

Format Tersedia

CL351: Chemical Engineering Lab-II

Semester 1, 2014-2015

IIT Gandhinagar

Pradeep Diwakar (Group G)

Roll no. 12110063

Heat transfer by natural convection

Heat transfer by natural convection

Objective:

The objective of this experiment is to determine heat transfer coefficient for

natural convection in stagnant air for vertical cylindrical tube.

Theory:

Convection is the mode of heat transfer between the surface and the

adjacent fluids. This heat transfer through convection can occur by two

process, by forced convection or by natural convection. An external medium

is needed for the movement in fluids in forced convection. In natural

convection movement in fluids is mainly due to density variation or any other

change in property of fluid.

The basis of convective heat transfer is Newton's law of cooling, which in a

form of equation can be represented as,

Q= h iAdT

Where,

hi = local heat transfer coefficient

In this experiment the heat was generated by electrical heating of cylindrical

rod and the setup is designed to study natural convection in term of heat

transfer coefficient.

Heat transfer coefficient is given by:

Q = h As (Ts Ta)

Where,

h = average surface heat transfer coefficient

Q = heat transfer rate

As = area of heat transferring surface

Ts = average surface temperature

Ta= ambient air temperature

Heat transfer coefficient for natural convection is given by:

3

hl Agl TC p

= 2

k v K

Where,

T = Ts - Ta

= coefficient of volumetric expansion of fluid

K = thermal conductivity of fluid

Procedure:

After keeping the voltage and current value fixed the switch is on and heat is

allowed to transfer. Thermocouples were marked from 0 to 7 and first

reading was taken after 30 minutes and a few minutes after and then again

so as to be sure that the steady state is achieved or not. Steady state is

confirmed by constant temperature for all 8 thermocouple readings. Once it

is achieved the final readings are taken.

Observations and Calculations:

Outer diameter of cylinder(d)=0.038m

Length of cylinder(l) = 0.5m

Voltage(V) =1.44W

Input to the heater (q)=205 Watt

K=0.0266kcal/m-hr-0C

Ambient temperature = 33 0C

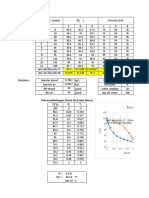

Table1. Experimental heat transfer coefficient:

Local heat transfer

Temperature coefficient, hexp (Kcal/m2-hr-

Obs. No. Measured (0C) Q (Watt) 0

C)

1 82 40 13.96

2 82 40 13.96

3 83 40 13.68

4 87 40 12.64

5 89 40 12.18

6 88 40 12.41

7 86 40 12.89

Temperat heat transfer

Sr. Grasho Nuss

ure Prand coefficient, hi

No Tavg T ffs elt (K-1)

Measured tl No. (Kcal/m2-hr-

. no.*109 No.

(0C) 0

C)

0.012

1 82 56.5 48 2.67 0.71 122

20 5.044

0.012

2 82 56.5 48 2.67 0.71 122

20 5.044

0.012

3 83 57 49 2.70 0.71 123

05 5.059

0.011

4 87 59 53 2.82 0.71 124

49 5.115

0.011

5 89 60 55 2.88 0.71 125

24 5.140

0.011

6 88 59.5 54 2.85 0.71 124

36 5.127

0.011

7 86 58.5 52 2.79 0.71 124

63 5.101

0.029

8 34 0.71

41

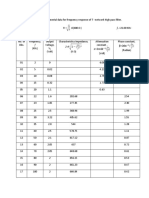

Table 2. Calculated heat transfer coefficient

Sample Calculations for reading no. 1 in both tables:

1. Power supplied to the rod Q = V x I = 80x0.50 = 40 W

2. T = Ts Tsurr = 82 34 = 48 C

3. hexp = Q/(A*T) = 40/ (0.05969x48) = 13.96 W/m2-0C

4. Coefficient of thermal expansion () = 0.01220C-1

5. Pr = (Cp*)/K = (1007x1.8x10-5)/ 0.0266 = 0.6814

6. Gr = (2*g**T*d3)/ 2 = [(1.145)2x10x 0.01220 x 48 x (0.038)3] /

(1.8x10-5)2 = 2.67x109

7. Nu = 0.56*(Gr*Pr)0.25 = 0.56 x (2.67x109 x0.6814)0.25 = 122

8. hi = Nu*(K/L) = 0.6814 x (0.0266/0.038) = 5.044 W/m2-0C

Results:

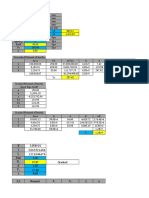

Value of average hexp (experimental) = 13.10 W/m2-0C

Value of average hi (theoretical) = 5.09 W/m2-0C

Conclusion and Discussion:

A reasonable difference can be observed in the theoretical and observed

value of h. This may be attributed to some fault in the experimental setup

also because there is some heat loss by radiation. From the results we can

say that the value of heat transfer coefficient is maximum at bottom of

vertical cylinder.

Anda mungkin juga menyukai

- Government Publications: Key PapersDari EverandGovernment Publications: Key PapersBernard M. FryBelum ada peringkat

- CL351: Chemical Engineering Lab-II Semester 1, 2014-2015 IIT GandhinagarDokumen7 halamanCL351: Chemical Engineering Lab-II Semester 1, 2014-2015 IIT GandhinagarPradeep DiwakarBelum ada peringkat

- Kinetics of OxidationDokumen9 halamanKinetics of OxidationTanyaTouchéBelum ada peringkat

- Ques SolutionDokumen1 halamanQues SolutionAakarsh Singh IET StudentBelum ada peringkat

- Problema 1Dokumen8 halamanProblema 1SALMA MAGALÍ DE LA ROSA POSADASBelum ada peringkat

- Experiment # 12: ObjectDokumen4 halamanExperiment # 12: ObjectRiazBelum ada peringkat

- Electric and Electronic Course: Sensor SpecificationDokumen7 halamanElectric and Electronic Course: Sensor SpecificationNova KurniawanBelum ada peringkat

- Experiment 7Dokumen9 halamanExperiment 7MahmoudSehweilBelum ada peringkat

- MMC 2Dokumen26 halamanMMC 2ch MuzammalBelum ada peringkat

- Ranch 2Dokumen3 halamanRanch 2ELBelum ada peringkat

- Equivalent Current Ieq (Secondary Amps)Dokumen4 halamanEquivalent Current Ieq (Secondary Amps)tajudeenBelum ada peringkat

- Data Kolom DistilasiDokumen28 halamanData Kolom DistilasiM Ragil ZandisyahBelum ada peringkat

- Heat Transfer Lab Lab Report Experiment # 01: Study of Heat Conduction Through Copper BarDokumen5 halamanHeat Transfer Lab Lab Report Experiment # 01: Study of Heat Conduction Through Copper BaryushiBelum ada peringkat

- CL351: Chemical Engineering Lab-II Semester 1, 2014-2015 IIT GandhinagarDokumen6 halamanCL351: Chemical Engineering Lab-II Semester 1, 2014-2015 IIT GandhinagarPradeep DiwakarBelum ada peringkat

- Experiment 1: Constant Voltage Sources 1. Connect The Circuit According From The Diagram by Start With R 10Dokumen6 halamanExperiment 1: Constant Voltage Sources 1. Connect The Circuit According From The Diagram by Start With R 10Zhenyi OoiBelum ada peringkat

- HH-2, Swastik Set Org (In Ppi Model), X-11, 1HP WF (Varuna)Dokumen3 halamanHH-2, Swastik Set Org (In Ppi Model), X-11, 1HP WF (Varuna)TanmayShrivastavaBelum ada peringkat

- E 5: W C A: XP Ater Hannel PplicationsDokumen9 halamanE 5: W C A: XP Ater Hannel PplicationsMahmoudSehweilBelum ada peringkat

- Instrumentation Lab 3Dokumen9 halamanInstrumentation Lab 3ryan warisBelum ada peringkat

- Main Plant WL SupplementaryDokumen6 halamanMain Plant WL SupplementaryArmie May RicoBelum ada peringkat

- Jhardy MidtermDokumen10 halamanJhardy MidtermJacob HardyBelum ada peringkat

- Devraj Singh Sandhu 2021A1PS1589P Physics Lab P11N: Data Set: 11Dokumen5 halamanDevraj Singh Sandhu 2021A1PS1589P Physics Lab P11N: Data Set: 11dxcfyvghBelum ada peringkat

- Logbook For Temperature Measurement PDFDokumen9 halamanLogbook For Temperature Measurement PDFNaim DanialBelum ada peringkat

- Batch Problema 1Dokumen2 halamanBatch Problema 1Aylin Portillo OliveraBelum ada peringkat

- DIAGRAMA nC7-nC8Dokumen2 halamanDIAGRAMA nC7-nC8Aylin Portillo OliveraBelum ada peringkat

- Study of Cross Flow Heat ExchangerDokumen11 halamanStudy of Cross Flow Heat Exchangerandrew munyiva100% (1)

- High Pass TableDokumen2 halamanHigh Pass TableShachin DasBelum ada peringkat

- Acetone - Methanol, ChloroformDokumen6 halamanAcetone - Methanol, ChloroformAlejandra InsuastyBelum ada peringkat

- Expt. 4 Heat Transfer in Fluidized BedsDokumen8 halamanExpt. 4 Heat Transfer in Fluidized BedsPradeep DiwakarBelum ada peringkat

- Lab - 3a - Losses in Pipes and Pipe FittingsDokumen13 halamanLab - 3a - Losses in Pipes and Pipe FittingsShehan FernandoBelum ada peringkat

- Rules OfthumbDokumen24 halamanRules Ofthumbdani.dekovicBelum ada peringkat

- Propiedades Con El Agua y El AseciteDokumen5 halamanPropiedades Con El Agua y El AseciteLuifer AguirreBelum ada peringkat

- RancobDokumen4 halamanRancobAsnurBelum ada peringkat

- Baraj de Greutatre: QM t0 TM TCDokumen9 halamanBaraj de Greutatre: QM t0 TM TCScarlat IuliuBelum ada peringkat

- EE5 Soln Study of EMI AnalysisPlots 1652207439083Dokumen6 halamanEE5 Soln Study of EMI AnalysisPlots 1652207439083The RevolutionBelum ada peringkat

- NTC Thermistor LinearityDokumen4 halamanNTC Thermistor LinearityFeras Al-AzzehBelum ada peringkat

- Discussion Exp 1BDokumen8 halamanDiscussion Exp 1BKholidi ChooBelum ada peringkat

- Blance Con Nueva CapacidadDokumen7 halamanBlance Con Nueva Capacidadmarc0scpBelum ada peringkat

- DIAGRAMA nC6-nC7Dokumen2 halamanDIAGRAMA nC6-nC7Aylin Portillo OliveraBelum ada peringkat

- Bangladesh University of Engineering and TechnologyDokumen10 halamanBangladesh University of Engineering and TechnologyMd Abid AfridiBelum ada peringkat

- Fisicoquimica Ana y ChenteDokumen7 halamanFisicoquimica Ana y ChenteelvaloyaBelum ada peringkat

- QuestionDokumen4 halamanQuestionAmr MohamedBelum ada peringkat

- Sup Med 0 Z Sup Z Med I (M) GZ Sup GZ Med Inf Z Inf GZ InfDokumen2 halamanSup Med 0 Z Sup Z Med I (M) GZ Sup GZ Med Inf Z Inf GZ InfPop PollyBelum ada peringkat

- DinamikaDokumen11 halamanDinamikaUmi LatifahBelum ada peringkat

- E 3.05E+01 3,532,921,654 1,221,044,674 fctm 2.60 37.87 Cracked β 1.00 17.40 L 8.00 X/l Moment ζ α I I M PDokumen2 halamanE 3.05E+01 3,532,921,654 1,221,044,674 fctm 2.60 37.87 Cracked β 1.00 17.40 L 8.00 X/l Moment ζ α I I M PAbel BerhanmeskelBelum ada peringkat

- Kavany GALIAN-dikonversiDokumen13 halamanKavany GALIAN-dikonversiSela Sr.Belum ada peringkat

- Solid in Air DiffusionDokumen3 halamanSolid in Air Diffusionrupapara.fch22100% (1)

- In Calibrating A 10Dokumen4 halamanIn Calibrating A 10GrenlyKerehBelum ada peringkat

- Alpha Vs T: Temp 826°C 900°C 1020°CDokumen1 halamanAlpha Vs T: Temp 826°C 900°C 1020°CPurnima kumariBelum ada peringkat

- NTC Pipe Sensor: Physical SpecificationDokumen4 halamanNTC Pipe Sensor: Physical SpecificationGeorge LunaBelum ada peringkat

- Wa0013Dokumen14 halamanWa0013Yoshuan CcapaBelum ada peringkat

- Exp 19Dokumen5 halamanExp 19SarahBelum ada peringkat

- SlopeDokumen2 halamanSlopeARUN RAWATBelum ada peringkat

- Calculation Note (Seismic)Dokumen17 halamanCalculation Note (Seismic)Princess ToumaBelum ada peringkat

- EXCERCISEDokumen4 halamanEXCERCISEHussen MohammedBelum ada peringkat

- Photoresistor:: Jurusan Fisika Fakultas Mipa Universitas Negeri SemarangDokumen18 halamanPhotoresistor:: Jurusan Fisika Fakultas Mipa Universitas Negeri SemarangTito Prastyo RBelum ada peringkat

- Component Units 1 2 3 4 5 6: F G F GDokumen6 halamanComponent Units 1 2 3 4 5 6: F G F Gbighead3158Belum ada peringkat

- Appendix ADokumen3 halamanAppendix ANaeemo IraqiBelum ada peringkat

- Laboratory of Unit Operations: Packed ColumnDokumen18 halamanLaboratory of Unit Operations: Packed ColumnNguyễn ThuBelum ada peringkat

- Ahsanullah University of Science and Technology: Electrical & Electronic Engineering DeptDokumen4 halamanAhsanullah University of Science and Technology: Electrical & Electronic Engineering DeptbappyBelum ada peringkat

- Cable SizingDokumen5 halamanCable Sizinganm bBelum ada peringkat

- Batch Reactor Manual PDFDokumen4 halamanBatch Reactor Manual PDFPradeep DiwakarBelum ada peringkat

- Thermowell Manual FinalDokumen5 halamanThermowell Manual FinalPradeep DiwakarBelum ada peringkat

- RTD in LFR PDFDokumen4 halamanRTD in LFR PDFPradeep DiwakarBelum ada peringkat

- Non-Interacting Final PDFDokumen5 halamanNon-Interacting Final PDFPradeep DiwakarBelum ada peringkat

- CSTR RXN PDFDokumen5 halamanCSTR RXN PDFPradeep DiwakarBelum ada peringkat

- Expt. 6Dokumen3 halamanExpt. 6Pradeep DiwakarBelum ada peringkat

- Expt. No. 2 - Basic Operational Amplifier Circuit PDFDokumen2 halamanExpt. No. 2 - Basic Operational Amplifier Circuit PDFPradeep DiwakarBelum ada peringkat

- Exp. 1 - An Introduction To Magnetic CircuitsDokumen1 halamanExp. 1 - An Introduction To Magnetic CircuitsPradeep DiwakarBelum ada peringkat

- CL351: Chemical Engineering Lab-II Semester 1, 2014-2015 IIT GandhinagarDokumen6 halamanCL351: Chemical Engineering Lab-II Semester 1, 2014-2015 IIT GandhinagarPradeep DiwakarBelum ada peringkat

- Expt. 7 Finned TubeDokumen6 halamanExpt. 7 Finned TubePradeep DiwakarBelum ada peringkat

- Expt. 5 Calandria EvaporatorDokumen5 halamanExpt. 5 Calandria EvaporatorPradeep Diwakar100% (1)

- Expt. 4 Heat Transfer in Fluidized BedsDokumen8 halamanExpt. 4 Heat Transfer in Fluidized BedsPradeep DiwakarBelum ada peringkat

- Expt. 1Dokumen4 halamanExpt. 1Pradeep DiwakarBelum ada peringkat

- Expt. 3 Heat Transfer in Agitated VesselDokumen7 halamanExpt. 3 Heat Transfer in Agitated VesselPradeep Diwakar67% (3)

- CL351: Chemical Engineering Lab-II Semester 1, 2014-2015 IIT GandhinagarDokumen6 halamanCL351: Chemical Engineering Lab-II Semester 1, 2014-2015 IIT GandhinagarPradeep DiwakarBelum ada peringkat

- Effect of Chilling, Freezing and Thawing On Meat QualityDokumen12 halamanEffect of Chilling, Freezing and Thawing On Meat Qualitybryan1817Belum ada peringkat

- Hot Oil System DesignDokumen25 halamanHot Oil System DesignnitantharaniBelum ada peringkat

- Aspen Polymers+Vol2V7 1-UsrDokumen250 halamanAspen Polymers+Vol2V7 1-UsraftenteaBelum ada peringkat

- PascoSTEM8mod2 Chemical Reactions and TemperatureDokumen5 halamanPascoSTEM8mod2 Chemical Reactions and Temperatureرؤوف الجبيريBelum ada peringkat

- Thermal ScienceDokumen1 halamanThermal Scienceram dasBelum ada peringkat

- TD1002 Heat Transfer Datasheet PDFDokumen2 halamanTD1002 Heat Transfer Datasheet PDFlecala 205Belum ada peringkat

- Chapter 3.1 - Heat and Work (Faizal)Dokumen24 halamanChapter 3.1 - Heat and Work (Faizal)Kai Faha LukumBelum ada peringkat

- XII Physics MCQS With KeyDokumen38 halamanXII Physics MCQS With KeyfateenBelum ada peringkat

- Isenthalpic Process - Wikipedia, The Free EncyclopediaDokumen2 halamanIsenthalpic Process - Wikipedia, The Free EncyclopediaChi-Hao LoBelum ada peringkat

- Me6301 Engineering Thermodynamics Nov Dec 2011Dokumen3 halamanMe6301 Engineering Thermodynamics Nov Dec 2011BIBIN CHIDAMBARANATHANBelum ada peringkat

- ModellingDokumen10 halamanModellingalmadhagiBelum ada peringkat

- 1st Law of ThermodynamicsDokumen16 halaman1st Law of ThermodynamicsMohamed Atef EL GendyBelum ada peringkat

- NCERT Solutions For Class 9 Science Chapter 1 Matter in Our SurroundingsDokumen36 halamanNCERT Solutions For Class 9 Science Chapter 1 Matter in Our SurroundingsFari KhanBelum ada peringkat

- Calculating Thermal BridgeDokumen37 halamanCalculating Thermal BridgeSean ThomasBelum ada peringkat

- International Journal of Heat and Mass Transfer: Cheen Su An, Man-Hoe KimDokumen6 halamanInternational Journal of Heat and Mass Transfer: Cheen Su An, Man-Hoe KimnaveenBelum ada peringkat

- 9518-109-Pvm-B-235-02-Cat IDokumen49 halaman9518-109-Pvm-B-235-02-Cat IAshok reddyBelum ada peringkat

- ASME Simulation Analysis For Pressure VesselsDokumen4 halamanASME Simulation Analysis For Pressure VesselsflcwkBelum ada peringkat

- Heat Pipe Engineering EbookDokumen18 halamanHeat Pipe Engineering EbookVenkitaraj K PBelum ada peringkat

- 082 CH 20Dokumen3 halaman082 CH 20Jagdip ShethBelum ada peringkat

- Novel SurfactantDokumen659 halamanNovel Surfactantnarendragcp100% (1)

- MYP 3 Physics Unit Plan - Heat and LightDokumen7 halamanMYP 3 Physics Unit Plan - Heat and LightFrancisBelum ada peringkat

- Mathematical Modeling of An Aqueous Film Coating Process in A Bohle Lab-Coater, Part 1: Development of The ModelDokumen8 halamanMathematical Modeling of An Aqueous Film Coating Process in A Bohle Lab-Coater, Part 1: Development of The Modelmido nasseBelum ada peringkat

- Statistical Physics, Vol.5Dokumen423 halamanStatistical Physics, Vol.5igor094% (16)

- GCSE Science A Unit 3 Physics P1.1-P1.2Dokumen31 halamanGCSE Science A Unit 3 Physics P1.1-P1.2Steve BishopBelum ada peringkat

- Seal PotDokumen9 halamanSeal Potsaibal_sil100% (1)

- Under Floor Heating BasicsDokumen69 halamanUnder Floor Heating BasicsHamzeh Shihadeh100% (1)

- ND Project Write-UpDokumen46 halamanND Project Write-UpKhushee SadaivBelum ada peringkat

- Catalogo Snowkey - CompressedDokumen44 halamanCatalogo Snowkey - Compressednelson contreras100% (3)

- Physics of Thermo-Acoustic Sound GenerationDokumen13 halamanPhysics of Thermo-Acoustic Sound GenerationtaBelum ada peringkat

- Pipe 1 Solving Pro Blems Coaching Notes: Exclusive For R.T.U. Don'T Share It To Other Schoo LDokumen151 halamanPipe 1 Solving Pro Blems Coaching Notes: Exclusive For R.T.U. Don'T Share It To Other Schoo LPat SulaimanBelum ada peringkat