URS and FDS Documents Explained

Diunggah oleh

fotieDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

URS and FDS Documents Explained

Diunggah oleh

fotieHak Cipta:

Format Tersedia

URS User Requirements Specification

FDS Functional Design Specification

1 13 October, 2008

URS and FDS in Project Work

Basic RA Detail RA

Process

Manufac- Delivery/ Test Runs/ Optimi-

Engineering Installation Commiss- Production

turing Start-up sation

ioning

URS DQ/FDS FAT IQ/SAT OQ PQ PV/CV Re-Val.

Change Control / Requalification

May 2015, page 2

URS and FDS - Any common understanding?

Functional

DQ Documentation Requirement

Specification

User Basis of

Functional Requirements Design

Specification

Basic URS

Functional Requirements

FDS

Requirements

Purchasing

Documents

Design

Technical

Documents

Specification

May 2015, page 3

Specifications

Appropriate Specifications - Key Factors for successful

Engineering Projects!

Specifications should provide clear definition, communication

and understanding of project scope, objectives and

requirements!

Various specification steps are developed during the lifetime of a

project. Details are depending on project type (size,

complexity, ...)

Specification usually undergo various iteration steps

Names and scope of specifications vary within different

companies and organisations

May 2015, page 4

URS and FDS - General Issues

Definitions!

URS = User Requirement Specification

FRS = Functional Requirement Specification

Definition of requirements to fulfil the demands of the

process (from the Userss point of view)

Issued by: User

FDS = Functional Design Specification

FS = Functional Specification

Specification in which the demands of the manufacturer are

transferred into a technical solution (from the Manufacturers

point of view)

Issued by: Manufacturer

Contract Specification (CS): FDS/FS approved by User + Supplier

May 2015, page 5

User Requirements Specification

a new requirement in EU-GMP Annex 15

User requirements specification (URS)

3.2 The specification for new facilities, systems or equipment should

be defined in a URS and/or a functional specification. The essential

elements of quality need to be built in at this stage and any GMP risks

mitigated to an acceptable level. The URS should be a point of

reference throughout the validation life cycle.

- no further definition in the glossary

In general:

! prepared by the user " Production / QC unit

! less technical than an FDS, technical specification, functional

requirements specification

! it is assumed that the URS includes all functional and critical

requirements, i.e. includes GMP-requirements

May 2015, page 6

URS: General considerations!

URS is defined by the User of the equipment / process (e.g.

production engineer, operators, ...)

Other functions such as (maintenance, validation, QA, safety,

product development, ...) shall participate in developing the

URS

URS shall include a general description of the process- /

product requirements

Definition of specific technologies and technical details are

included only if important for the production process

Requirements for the URS shall be result of a Basic Risk

Analysis

May 2015, page 7

URS and FDS - General Issues

URS: What needs to be included?

Process description, operational restrictions, product quality

requirements and general GMP-requirements

Capacity data (output, consumption figures, etc)

Range and tolerances of process parameter (temperatures,

pressures, flows, etc)

Material and surface requirements

Interfaces (Mechanical, Electrical, Signal)

Controls and automation concept, staffing

Safety requirements and environmental conditions

Cleanability, sterilisation requirements (CIP/SIP)

Documentation, acceptance test criteria, qualification

requirements

Applicable codes, standards and guidelines

.

May 2015, page 8

User Requirement Specification a new requirement!

Start with drafting a URS it will be refined later

URS is sent to equipment vendors / suppliers / manufacturers

May 2015, page 9

Equipment suppliers respond to the URS with their FDA

FDS: General Considerations !

FDS is defined by the manufacturer of the equipment

more technical details are contained than in the URS

something you did not want may be included!

something you really want to have, but you did not think it is

existing may be in the FDS

FDS is based on the specific capabilities of the manufacturer

(manufacturing program, know how, etc )

All requirements of the URS need to be covered by the FDS.

A jointly approved FDS is part of the contract between user

and manufacturer (Contract Specification)

May 2015, page 10

How to find out, if the vendor will deliver what

you wanted?

Compare URS with FDS

May 2015, page 11

Some practical hints for URS / RA and DQ

URS, FDS and Contract Specification are linked with each other

(example for standard equipment)

Request for quotation

revision my be required

Supplier A! Supplier B ! Supplier C!

proposal !

FDS! FDS

FDS

comparison ! DQ

CS

negotiation and

URS URS URS URS agreement on

Contract

Specification

When more than one (potential) supplier is involved:

more than 1 DQ may be required

May 2015, page 12

URS and FDS - General Issues

Who is the User and who is the Manufacturer? !

User Production

Engineering Department

Engineering Company

System Integrator

System Manufacturer

Supplier Component Manufacturer

The roles may vary! They depend on the project type!!

May 2015, page 13

URS and FDS - General Issues

URS and FDS are integral part of the purchasing process !

1. User staff defines in URS the general requirements. The URS is

based on a general design philosophy which should be looked

at in a basic risk analysis

2. User sends URS as part of inquiry documentation to several

qualified vendors

3. Manufacturer compare URS with their capabilities and suggest

technical solution / FDS in a proposal

4. User and selected manufacturers compare demands and

proposed solution. Re-check against URS and DQ requirements

5. User agrees with a chosen manufacturer upon a technical

solution that suits the demands of his process (FDS/CS)

May 2015, page 14

URS/FDS Implementation and Overview

From Process Idea to Final Design Specification:

Status Issued by (e.g.) Document

Basic

Process-Idea R+D

Requirem.

General Requirements Production (User) URS

Extended Requirements Technical Dep. / Engineering FRS

Technical Solution Manufacturer FDS I

Agreed Technical Solution User/Techn. / Manufacturer CS

Final Design Specification User/Techn. / Manufacturer FDS II *)

*) in case of development projects

May 2015, page 15

Special situation in development projects

Final technical solution is not available at the time when user gives

an order to the manufacturer

Approved FDS that exists as preliminary version is going to be

detailed during the project execution phase

Users and manufacturers technical/validation staff jointly supervise

the development process (change control, repeat DQ when

necessary)

The development during execution of the project is checked in

design reviews. Reviews have the character of milestones (e.g. PID

Review, Layout Review, etc )

The final and approved FDS is issued when the design phase is

completed

May 2015, page 16

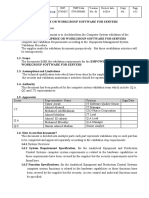

USER REQUIREMENT SPECIFICATION

Title Doc no/Version Page

Bag Handling System for Filling Line 00000 /00 (1/32)

Issued by/Sign Date Valid from

Examples Process Engineer 00-00-00

Reviewed by/Sign Date Replaces doc no./version

URS and FDS Project Manager

Reviewed by/Sign Date

Maintenace Manager

Reviewed by/Sign Date

Safety Engineer

Reviewed by/Sign Date

Validation Engineer

Approved by/Sign Date

Production Manager

Approved by/Sign Date

QA Manager

TABLE OF CONTENTS

1. INTRODUCTION.................................................................................................2

2. GENERAL REQUIREMENTS ...........................................................................3

3. FUNCTIONAL REQUIREMENTS....................................................................11

4. INFORMATION AND CONTROL SYSTEM REQUIREMENTS.................17

5. MAINTENANCE REQUIREMENTS ................................................................20

6. SAFETY AND ENVIRONMENTAL REQUIREMENTS................................20

7. SPARE PARTS .....................................................................................................22

8. QUALITY ASSURANCE ....................................................................................22

9. TESTING ACCEPTANCE ..................................................................................23

10. QUALIFICATION REQUIREMENTS..............................................................24

11. ERECTION AND START-UP.............................................................................25

12. TRAINING REQUIREMENTS ..........................................................................26

13. PACKING; SHIPMENT ......................................................................................26

14. COMMENTS.........................................................................................................27

15. 13 October, 2008

DISTRIBUTION ...................................................................................................28

Common problems in URS and FDS

1. URS does not include all relevant information to fulfil

product, process and GMP requirements

2. Specified parameters and features in the URS are not

clear and are likely to be misunderstood

3. The FDS does not meet the requirements of the URS

Consequences

Manufacturer supplies a technical solution that does not

comply with the intended purpose meant by the User

Equipment does not fit requirements and does not work at all

Equipment works, but contains risk for product, process,

safety

High costs for changes at a late state occur

May 2015, page 18

Common problems in URS and FDS

4. The requirements in the URS are higher than necessary,

demands are not realistic or more details are specified than

necessary!

Consequences

The Manufacturer has limited freedom for choosing proper

solution

Difficulties to find Manufacturers for the equipment

Prices for the equipment are unnecessarily high

The technical solutions might be complicated and may contain

unnecessary potential risks of failure

May 2015, page 19

Common problems in URS and FDS

5. URS and FDS do not consider the requirements for

later testing such as FAT, SAT, IQ, OQ, PQ!

Consequences

Tests can not be performed - fulfilment of acceptance criteria

can not be verified

No documented proof of the quality is available

No GMP compliance of the equipment

Unexpected additional costs and time delay

May 2015, page 20

Common problems in URS and FDS

Mistakes in URS and FDS can be avoided by: !

Execute Risk Analysis before finalizing the URS to identify and

fix all relevant issues

Evaluate the impact on other systems in the project (definition

of interfaces/battery limits)

Cross check of URS against FDS in Design Qualification

Have Change Control implemented in the project work

Open communication between Manufacturer and User with

frequent review of the design to avoid misunderstandings

Careful review of URS and FDS before approval by all involved

experts

May 2015, page 21

URS/FDS Practice - simulation

May 2015, page 22

Common problems in URS and FDS

what the sales man sold ! what was assumed to be required ! what has been designed !

how it was installed ! !

how it was put in operation and what the customer wanted!!! !

23 May 2015, page 23

Summary

Equipment that is reliable and suiting the demands of

production process and final product is:!

a result of carefully specified requirements in URS and FDS that

consider the principles of GMP

based on a common understanding of demands and capabilities

on both sides (User and Manufacturer)

designed to be able to pass the required tests during

manufacturing, acceptance testing and qualification phases

URS + FDS = Basis for safe products and reliable processes!!

An important thing to keep in mind:

It is a GMP requirement that manufacturers control the critical

aspects of their particular operations through qualification and

validation over the life cycle of the product and process.

Critical Aspects = relevant Aspects:

CQAs = Critical Quality Attributes

CPPs = Critical Process Parameters

When you identified as aspect as relevant, keep it in your documents

from the beginning on dont loose it!

Der rote Faden (the red thread) the central themes

permanent and traceable throughout the life-cycle

Group work Team Work Task

Prepare a URS for a backpack, in which you want to carry your

computer

describe the requirements precisely

use one line per requirement

some words that may help:

compartment

velcro

shoulder strap

padding

lining

zipper

dimension

weight

color

top grab handle

May 2015, page 26

Contact:

Pharma Consulting Walther

Dr. Ingrid Walther

Rosenweg 36

61381 Friedrichsdorf Germany

+49-(0)6172-958281

+49-(0)172 654 8834

www.consulting-walther.com

iw@consulting-walther.com

Disclaimer:

This presentation has been prepared upon best knowledge and it presents the view and

experience of Pharma Consulting Walther.

The presentation reflects current guidelines, knowledge and thinking. Changes of regulatory

guidelines or interpretation thereof or new regulatory expectations may change the

applicability of the contents of this presentation.

Parts of the presentation may not be understood or misinterpreted without the verbal

explanation given during the seminar.

Although the statements made in the presentation in general have been presented to and

discussed with inspectors, a different approach may be required and adequate depending on

the individual situation.

The information contained herein may be changed without prior notice.

May 2015, page 27

Anda mungkin juga menyukai

- Validation master plan Complete Self-Assessment GuideDari EverandValidation master plan Complete Self-Assessment GuideBelum ada peringkat

- User Requirement Specification: User Requirement SpecificationDokumen10 halamanUser Requirement Specification: User Requirement SpecificationsakshiBelum ada peringkat

- Validation Master Plan A Complete Guide - 2020 EditionDari EverandValidation Master Plan A Complete Guide - 2020 EditionBelum ada peringkat

- Pharmaceutical User Requirement TemplateDokumen6 halamanPharmaceutical User Requirement TemplateMSL IndiaBelum ada peringkat

- 10 - Design and Performance QualificationDokumen8 halaman10 - Design and Performance Qualificationsainzb83Belum ada peringkat

- Installation Qualification (Iq) Protocol FOR Mechanical SifterDokumen22 halamanInstallation Qualification (Iq) Protocol FOR Mechanical SiftercorneliusBelum ada peringkat

- Validation Master PlanDokumen37 halamanValidation Master PlanOsama Mahmoud0% (1)

- URS-Glass WasherDokumen19 halamanURS-Glass Washerssureshkar7699100% (2)

- ICH Q7 How To Do Version13 Final Jan 2020Dokumen105 halamanICH Q7 How To Do Version13 Final Jan 2020Al RammohanBelum ada peringkat

- URS, DQ, IQ, OQ, PQ Concepts in Pharma ValidationDokumen7 halamanURS, DQ, IQ, OQ, PQ Concepts in Pharma ValidationneweyBelum ada peringkat

- VMPDokumen45 halamanVMPAshok Lenka100% (1)

- 6.E Installation Qualification (IQ) : Here You Will Find Answers To The Following QuestionsDokumen10 halaman6.E Installation Qualification (IQ) : Here You Will Find Answers To The Following QuestionsFilipBelum ada peringkat

- IQ for Computerized Lyophilizer SystemDokumen36 halamanIQ for Computerized Lyophilizer Systemmkm969Belum ada peringkat

- VAL 135 Risk Assessment For Computer Validation Systems Sample - SandraDokumen3 halamanVAL 135 Risk Assessment For Computer Validation Systems Sample - SandraSandra Silva100% (1)

- IQ For Strip Packing Machine SE - 140Dokumen15 halamanIQ For Strip Packing Machine SE - 140Fernanda GarantiaBelum ada peringkat

- Validation VMP Validation Master PlanDokumen13 halamanValidation VMP Validation Master Plank.p.Belum ada peringkat

- Pharmaceutical Master Validation Plan GuideDokumen3 halamanPharmaceutical Master Validation Plan GuideDandung RuskarBelum ada peringkat

- PDA Visual Inspection - Course HighlightsDokumen167 halamanPDA Visual Inspection - Course HighlightsBarbara PachecoBelum ada peringkat

- CIQA Validation Master Plan Sample TemplateDokumen4 halamanCIQA Validation Master Plan Sample TemplateSatyam Gupta100% (1)

- Initiation Phase Activities for System ValidationDokumen16 halamanInitiation Phase Activities for System ValidationcsrinivasulureddyBelum ada peringkat

- Vision and Validation White Paper PDFDokumen47 halamanVision and Validation White Paper PDFQC SriprasitBelum ada peringkat

- SER Equirements Emplate IAL Asher: Vial WasherDokumen22 halamanSER Equirements Emplate IAL Asher: Vial Washermehdi ershadiBelum ada peringkat

- VAL 090 Equipment Validation Guideline Sample PDFDokumen2 halamanVAL 090 Equipment Validation Guideline Sample PDFsiva sankarBelum ada peringkat

- Bio-Validation of Steam Sterilization - 758572676Dokumen11 halamanBio-Validation of Steam Sterilization - 758572676venkats_001Belum ada peringkat

- SOP of URS 1657011596Dokumen5 halamanSOP of URS 1657011596Huỳnh Ngọc SángBelum ada peringkat

- 8.3 Operation Qualification Protocol For Dispensing BoothDokumen4 halaman8.3 Operation Qualification Protocol For Dispensing BoothTanveer Ahmed Quadri100% (1)

- Mill QualificationDokumen10 halamanMill QualificationAbhijeetBelum ada peringkat

- GMP History PDFDokumen49 halamanGMP History PDFSubhradipBelum ada peringkat

- FastVal User Requirement Template PDFDokumen6 halamanFastVal User Requirement Template PDFViệt ThắngBelum ada peringkat

- Protocol Design Qualification (DQ) : Romaco Kilian S 710 PrimeDokumen6 halamanProtocol Design Qualification (DQ) : Romaco Kilian S 710 PrimeTim100% (1)

- IQOQ ProtocolDokumen4 halamanIQOQ ProtocolVijay RajaindranBelum ada peringkat

- V Model - GampDokumen2 halamanV Model - GampNitin KashyapBelum ada peringkat

- Supplementary Training Modules On Good Manufacturing PracticeDokumen31 halamanSupplementary Training Modules On Good Manufacturing Practicesagaram_sBelum ada peringkat

- VAL 170401 BMAA VAL Activity 2 VMP TemplateDokumen17 halamanVAL 170401 BMAA VAL Activity 2 VMP TemplateMohammed S.Gouda100% (1)

- Basics of Equipment Qualification - Pharma Pathway PDFDokumen6 halamanBasics of Equipment Qualification - Pharma Pathway PDFJ VENKATESHBelum ada peringkat

- Empower 3 Enterprise or Workgroup Software For ServersDokumen52 halamanEmpower 3 Enterprise or Workgroup Software For ServersMohamed Sallam100% (2)

- Validation Master Plan 9 25 16Dokumen13 halamanValidation Master Plan 9 25 16Itzel Acosta SalgadoBelum ada peringkat

- GAMP/JETT AGENDA OverviewDokumen50 halamanGAMP/JETT AGENDA OverviewMohamed KamalBelum ada peringkat

- VMP GuideDokumen6 halamanVMP GuidedsevolveBelum ada peringkat

- 21 CFR PART-11 Requirements for Electronic Records and SignaturesDokumen4 halaman21 CFR PART-11 Requirements for Electronic Records and SignaturesSupriyaNathRayBelum ada peringkat

- Automatic Capper User RequirementsDokumen26 halamanAutomatic Capper User RequirementsBREWSKIBelum ada peringkat

- ValidationDokumen5 halamanValidationjyothisahadevanBelum ada peringkat

- 9.1 Design Qualification Protocol For Dynamic Pass BoxDokumen10 halaman9.1 Design Qualification Protocol For Dynamic Pass BoxKeval Patel100% (1)

- Iq Fe001Dokumen32 halamanIq Fe001Dhaval ChaplaBelum ada peringkat

- Procedure For Leak Testing of Strips - BlistersDokumen7 halamanProcedure For Leak Testing of Strips - BlistersashishdrBelum ada peringkat

- Urs PLMDokumen17 halamanUrs PLMMohammadIsmailBelum ada peringkat

- SCADA Process Control System User RequirementsDokumen65 halamanSCADA Process Control System User Requirementskapernikov50% (2)

- S 264 Validation Spreadsheet ApplicationsDokumen14 halamanS 264 Validation Spreadsheet ApplicationsNeoBelum ada peringkat

- Equipment Qualification: Presented By: Davender Plant TSTDokumen43 halamanEquipment Qualification: Presented By: Davender Plant TSTHemant SankhalaBelum ada peringkat

- Performing An Installation QualificationDokumen8 halamanPerforming An Installation QualificationThomasBelum ada peringkat

- Sample URSDokumen3 halamanSample URSMinh Nguyen100% (1)

- A Risk Assessment ApproachDokumen10 halamanA Risk Assessment Approachsusana.duarte.1979Belum ada peringkat

- INSTALLATION QUALIFICATION AIR SHOWERSDokumen9 halamanINSTALLATION QUALIFICATION AIR SHOWERSziauddin bukhariBelum ada peringkat

- Validation Master Plan (VMP)Dokumen11 halamanValidation Master Plan (VMP)Gonzalo MazaBelum ada peringkat

- Sterile Drug Insp CPGM 7356-002a - Ora - Lao-Nm 9-10-15 - Emc Lao FinalDokumen54 halamanSterile Drug Insp CPGM 7356-002a - Ora - Lao-Nm 9-10-15 - Emc Lao Finaltito1628100% (1)

- Autoclave URSDokumen28 halamanAutoclave URSShejil BalakrishnanBelum ada peringkat

- PICS Inspection QC LabDokumen18 halamanPICS Inspection QC LabMax HuangBelum ada peringkat

- RTP 10i Tablet Press IQ/OQ: We Don't Just Sell Machines - We Provide ServiceDokumen34 halamanRTP 10i Tablet Press IQ/OQ: We Don't Just Sell Machines - We Provide ServiceAndreas StathatosBelum ada peringkat

- Site Validation Master Plan OverviewDokumen34 halamanSite Validation Master Plan OverviewJonatan Dominguez PerezBelum ada peringkat

- Chapter One: Lecturer: Nguyen Van Dung PH.DDokumen72 halamanChapter One: Lecturer: Nguyen Van Dung PH.DNhân TrịnhBelum ada peringkat

- Itp Lime StabilizationDokumen2 halamanItp Lime StabilizationMikiRoniWijayaBelum ada peringkat

- Lista de transações - Eng. IndustrialDokumen2 halamanLista de transações - Eng. IndustrialIvan_cojrBelum ada peringkat

- CATIA - Imagine & Shape 2 (IMA)Dokumen5 halamanCATIA - Imagine & Shape 2 (IMA)Vadivelu DhanakotiBelum ada peringkat

- SCDL - PGDBA - Finance - Sem 2 - Production & Operations ManagmentDokumen32 halamanSCDL - PGDBA - Finance - Sem 2 - Production & Operations Managmentapi-376241991% (11)

- Corrective Action ProcessDokumen29 halamanCorrective Action Process124th EAGLECOM KimJaveroBelum ada peringkat

- SOW - Detailed Engineering - Sawan FEC RevampDokumen20 halamanSOW - Detailed Engineering - Sawan FEC RevampHafiz Akhtar100% (1)

- Marginal & Differential CostingDokumen11 halamanMarginal & Differential CostingShahenaBelum ada peringkat

- Supply Chain Management in Indian RailwaysDokumen6 halamanSupply Chain Management in Indian RailwaysLacshay ShekharBelum ada peringkat

- Lean Manufacturing: An Approach For Waste EliminationDokumen6 halamanLean Manufacturing: An Approach For Waste EliminationFrank CordovaBelum ada peringkat

- Assignment 3 EPMDokumen3 halamanAssignment 3 EPMWajiha JawwadBelum ada peringkat

- Lecture 7 OMDokumen52 halamanLecture 7 OMyashd99Belum ada peringkat

- New Product Development WikipediaDokumen9 halamanNew Product Development WikipediaBreylin CastilloBelum ada peringkat

- Ijeit1412201204 13Dokumen5 halamanIjeit1412201204 13Hardik ChaudhariBelum ada peringkat

- Buck Knives Lean Case StudyDokumen11 halamanBuck Knives Lean Case StudyHarsh ModiBelum ada peringkat

- Nema ST 20 PDFDokumen74 halamanNema ST 20 PDFRoberto RiosBelum ada peringkat

- Inventory ManagementDokumen24 halamanInventory ManagementBhanushekhar YadavBelum ada peringkat

- New Microsoft Office Word DocumentDokumen5 halamanNew Microsoft Office Word DocumentMudasar HaiderBelum ada peringkat

- Supply Chain of FoodlandDokumen65 halamanSupply Chain of FoodlandNikhil KhobragadeBelum ada peringkat

- Linden ComansaDokumen14 halamanLinden ComansaJamal CareyBelum ada peringkat

- Paper MakingDokumen1 halamanPaper MakingBurak KucukkelesBelum ada peringkat

- LO170 - 46C - 003basicsDokumen28 halamanLO170 - 46C - 003basicsmkumarshahiBelum ada peringkat

- Performance Measurement Along the Supply ChainDokumen31 halamanPerformance Measurement Along the Supply ChainPankhoori VidyaBelum ada peringkat

- Unit 5 - Procurement of Dsbsdfsafexternal ServicesDokumen10 halamanUnit 5 - Procurement of Dsbsdfsafexternal ServicesbalavenakatarajuBelum ada peringkat

- Researchpaper Design and Implementation of Cellular Manufacturing in A Sewing FloorDokumen17 halamanResearchpaper Design and Implementation of Cellular Manufacturing in A Sewing FloorMohammed BabkirBelum ada peringkat

- Ch12 - InventoryDokumen37 halamanCh12 - InventoryAbhijit TikoreBelum ada peringkat

- Purchasing ManagementDokumen113 halamanPurchasing ManagementHussain Ehtesham67% (3)

- Contract ManufacturingDokumen10 halamanContract ManufacturingNIRMIT PANDYABelum ada peringkat

- Volkswagen Group CSR IATF 16949 Jan 2018Dokumen6 halamanVolkswagen Group CSR IATF 16949 Jan 2018NarasimharaghavanPuliyurKrishnaswamyBelum ada peringkat

- Dcma Qae HandbookDokumen17 halamanDcma Qae HandbookmtcengineeringBelum ada peringkat