Personnel Safety Review Checklist: Process Improvement Engineering

Diunggah oleh

Sayed Saad ShehataJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Personnel Safety Review Checklist: Process Improvement Engineering

Diunggah oleh

Sayed Saad ShehataHak Cipta:

Format Tersedia

Personnel Safety

CAPI

Process Improvement Engineering

Contents | ChE@UF | Undergraduate | Contacts

Unit Operation Laboratories Up

Quick Links

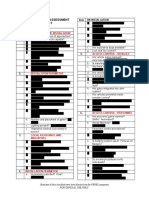

Personnel Safety Review Checklist

Project Site Location

1. Any exposure to or from the neighborhood from fire, explosion, noise,

air and stream pollution?

2. Adequate access for emergency vehicles?

3. Any potential blockages of access roads by railroads, highway

congestion, etc.?

4. Access roads well engineered to avoid sharp curves? Traffic signs

provided?

Building and Structures

1. What standards are being followed in the design of stairways,

platforms, ramps and fixed ladders?

2. Are sufficient general exit and escape routes available? Alternate

means of escape from roofs provided? Is protection provided to

persons along the line of the escape routes?

3. Adequate lighting provided?

4. Doors and windows hung to avoid projecting into or blocking walkways

and exits?

5. Structural steel grounded?

Operating Areas

1. Are equipment, steam, water, air and electric outlets arranged to keep

aisles and operating floor areas clear of hoses and cables?

2. Ventilation furnished for hazardous fumes, vapors, dust and excessive

heat?

3. Temporary storage provided for raw materials at process points, and

for finished products?

4. Where operations are potentially hazardous from the standpoints of

fire and explosion, are controls housed in separate structures? If not,

are control room windows kept to a minimum and glazed with

laminated safety glass?

http://pie.che.ufl.edu/guides/hazop/personnel_checklist.html (1 of 3)5/6/2006 7:50:31 PM

Personnel Safety

5. Are alternate escape routes to safe locations provided?

6. If needed, what type of pressure relief venting of area is furnished?

7. Do platforms provide safe clearance for safe maintenance of

equipment?

8. Are nozzles and manholes sized and located for safe cleanout,

maintenance operations, and emergency removal of people from

vessels?

9. What protection is provided to protect against contact with hot

surfaces?

10. Is head clearance adequate in walkway and working areas?

11. Is power-driven equipment adequately guarded?

12. Are manually operated valves, switches and other controls readily

accessible to the operator from a safe location?

13. Are vents located so that discharges, including liquids, do not

endanger personnel, public or property? Are all vents above the

highest liquid level possible in the system?

14. Are free-swinging hoists avoided? Are hoists equipped with safety

hooks, limit switches, if motorized?

15. Are elevators equipped with shaftway door interlocks and car gate

contacts? Are there safety astragals on bi-parting doors?

16. Is every effort being made to handle materials mechanically rather

than manually?

17. Are emergency showers and hose-type eye baths provided?

18. Has a safe storage and dispensing location for flammable liquid drums

been provided?

19. Are there at least two exits from hazardous work?

20. Where excessively noisy operations are concerned, what measures

are contemplated to reduce the noise level to a safe range?

21. Is there safe exit from manufacturing offices or laboratories?

22. Are positive electrical power disconnects being installed for purposes

of lockout?

Yard

1. Are roadways laid out with consideration for the safe movement of

pedestrians, vehicles and emergency equipment?

2. Are railroad car puller control stations fully protected against broken

cable whiplash? How will operator be protected from being caught

between cable or rope and capstan or cable drum?

3. Are flammable liquid tank car and tank truck loading and unloading

docks bonded or grounded?

4. Are safe means provided on loading platforms for access to work

areas of tank cars and trucks?

5. Is protection against falling furnished for employees who work on tops

of railroad cars and trucks?

6. Is safe access provided to tops of storage tanks on which persons go

for contents measurement and vent maintenance?

7. Is there sufficient head clearance and good visibility in walking and

working areas?

8. Is yard lighting adequate?

http://pie.che.ufl.edu/guides/hazop/personnel_checklist.html (2 of 3)5/6/2006 7:50:31 PM

Personnel Safety

Adapted from: Guidelines for Hazard Evaluation Procedures. Prepared by

Battelle Columbus Division for The Center for Chemical Process Safety of the

American Institute of Chemical Engineers. 345 East 47th Street, New York,

NY. (1985).

Copyright 1996-2001 Dale W. Kirmse, University of Florida, Gainesville, FL 32611; (352) 392-0881.

This page was last updated Sunday, September 16, 2001 04:25:19 PM

http://pie.che.ufl.edu/guides/hazop/personnel_checklist.html (3 of 3)5/6/2006 7:50:31 PM

Anda mungkin juga menyukai

- PLU Building Safety Inspection ChecklistDokumen5 halamanPLU Building Safety Inspection Checklistwidodo6286Belum ada peringkat

- Safety Insp ChecklistDokumen2 halamanSafety Insp ChecklistHolartoonde_Ho_7736Belum ada peringkat

- Inspection Checklists - ManufacturingDokumen6 halamanInspection Checklists - Manufacturingmkkamaraj100% (1)

- VDO Commercal Product CatalogueDokumen40 halamanVDO Commercal Product CataloguejasminbijedicBelum ada peringkat

- HAZOP Saudi Aramco HAZOP GuidelinesDokumen92 halamanHAZOP Saudi Aramco HAZOP Guidelinesjakejohns100% (15)

- McDonalds Checklist Points For CheckingDokumen8 halamanMcDonalds Checklist Points For CheckingShekharBelum ada peringkat

- JSA For Fall ProtectionDokumen2 halamanJSA For Fall ProtectiontnssbhaskarBelum ada peringkat

- Job Safety Analysis - Doc With Penumatic TestingDokumen5 halamanJob Safety Analysis - Doc With Penumatic TestingDeshbandhu Aman Pandey100% (1)

- Physical and Environmental Audit ChecklistDokumen4 halamanPhysical and Environmental Audit Checklistpgupta101Belum ada peringkat

- Buna EP LanxessDokumen51 halamanBuna EP LanxessANHVUDRCBelum ada peringkat

- Hydronic Cooling - OikosDokumen5 halamanHydronic Cooling - OikosShashank JainBelum ada peringkat

- FMS - EOC ChecklistDokumen6 halamanFMS - EOC Checklisthany winihastutiBelum ada peringkat

- Safety Behavior and Safety at Work Program DaraDokumen3 halamanSafety Behavior and Safety at Work Program DaraSayed Saad ShehataBelum ada peringkat

- Construction Site Checklist Pg.1 10Dokumen1 halamanConstruction Site Checklist Pg.1 10Marjan BrčićBelum ada peringkat

- JSA FOR Fall ProtectionDokumen2 halamanJSA FOR Fall Protectionwahyu nugroho100% (4)

- Osha3151 PPEDokumen57 halamanOsha3151 PPESayed Saad Shehata100% (2)

- ISO Oil & GasDokumen3 halamanISO Oil & GasSayed Saad ShehataBelum ada peringkat

- Buckling H BeamDokumen2 halamanBuckling H BeamНемања КараклајићBelum ada peringkat

- Wa320 5Dokumen228 halamanWa320 5Felipe Naxo Becerra Arriagada50% (2)

- Integrated Security Systems Design: Concepts, Specifications, and ImplementationDari EverandIntegrated Security Systems Design: Concepts, Specifications, and ImplementationPenilaian: 5 dari 5 bintang5/5 (1)

- Facilities Security Audit Checklist: M. E. Kabay, PHD, Cissp-IssmpDokumen21 halamanFacilities Security Audit Checklist: M. E. Kabay, PHD, Cissp-Issmpbaduuuu100% (1)

- Division of Occupational Health and Safety Office Safety Checklist Institute: Facility: Survey Date: Building/Rooms Covered On This ChecklistDokumen4 halamanDivision of Occupational Health and Safety Office Safety Checklist Institute: Facility: Survey Date: Building/Rooms Covered On This ChecklistMuse TaqimBelum ada peringkat

- TBTDokumen10 halamanTBTSayed Saad ShehataBelum ada peringkat

- Asme Pad 2003Dokumen74 halamanAsme Pad 2003Sayed Saad ShehataBelum ada peringkat

- Checklist For Scaffolding: Project: SL# Description Observation Yes/No/ NA Remarks & RecommendationsDokumen4 halamanChecklist For Scaffolding: Project: SL# Description Observation Yes/No/ NA Remarks & RecommendationsDeshbandhu Aman PandeyBelum ada peringkat

- Magnum Composite Plug Catalog 06-30-10Dokumen21 halamanMagnum Composite Plug Catalog 06-30-10Emad JamshidiBelum ada peringkat

- Process Hazard Analysis Facility Siting Checklist: Item Answer (Y, N, N/A) Justification RecommendationsDokumen5 halamanProcess Hazard Analysis Facility Siting Checklist: Item Answer (Y, N, N/A) Justification Recommendationsmj santosBelum ada peringkat

- Bow-Tie Analysis & HSECES: Course Information SheetDokumen3 halamanBow-Tie Analysis & HSECES: Course Information SheetSayed Saad ShehataBelum ada peringkat

- Civil Construction Risk Assessment ChecklistDokumen3 halamanCivil Construction Risk Assessment ChecklistJeduardo Ch-mezaBelum ada peringkat

- Area Classification To Ip 15Dokumen33 halamanArea Classification To Ip 15Kanakarao Malappareddy100% (4)

- Physcial Security Survey Checklist P B - T F: Erimeter Arriers Ransit AcilitiesDokumen12 halamanPhyscial Security Survey Checklist P B - T F: Erimeter Arriers Ransit AcilitiesChristian Dave Tad-awan100% (1)

- Lockout - Tagout (LOTO) Annual Inspection and Training Assessment Checklist Department: Shop: Location: EquipmentDokumen2 halamanLockout - Tagout (LOTO) Annual Inspection and Training Assessment Checklist Department: Shop: Location: EquipmentSayed Saad ShehataBelum ada peringkat

- Office Inspection ChecklistDokumen2 halamanOffice Inspection ChecklistSubzone Three100% (1)

- 02 PropaneRefrigerationLoopDokumen26 halaman02 PropaneRefrigerationLoopChristian ChineduBelum ada peringkat

- SIL ProcedureDokumen10 halamanSIL ProcedureSayed Saad ShehataBelum ada peringkat

- Facility Siting Checklist: I. Space Between Process ComponentsDokumen17 halamanFacility Siting Checklist: I. Space Between Process ComponentsRASHEED YUSUFBelum ada peringkat

- Physical Security Survey and Emergenciy PrepaprenessDokumen3 halamanPhysical Security Survey and Emergenciy PrepaprenessRose Sopenasky-De Vera100% (1)

- Buidling Safety Inspection ChecklistDokumen4 halamanBuidling Safety Inspection ChecklistPillai Sreejith100% (17)

- Safety Integrity LevelDokumen108 halamanSafety Integrity LevelSayed Saad Shehata100% (1)

- Safety Integrity LevelDokumen108 halamanSafety Integrity LevelSayed Saad Shehata100% (1)

- BLDG Inspection Form 2-PageDokumen2 halamanBLDG Inspection Form 2-PageMHDBelum ada peringkat

- Internal Sizing of Paper - AKD - ASADokumen71 halamanInternal Sizing of Paper - AKD - ASAelgendawyBelum ada peringkat

- Survey Check ListDokumen11 halamanSurvey Check Listjothi subraBelum ada peringkat

- Fragmentation and Its Impact On Downstream ProcessingDokumen4 halamanFragmentation and Its Impact On Downstream Processingalvaroaac4Belum ada peringkat

- Plazmax Servicio PDFDokumen109 halamanPlazmax Servicio PDFLeonel Losada Cardozo0% (1)

- FM Audit ChecklistDokumen3 halamanFM Audit ChecklistLakshmi Bala100% (1)

- Annex12 Technical Cards For Accessible ConstructionDokumen44 halamanAnnex12 Technical Cards For Accessible Constructionarchitectfemil6663Belum ada peringkat

- IM-09-A4 Scaffolding ChecklistDokumen2 halamanIM-09-A4 Scaffolding ChecklistVishnu SBelum ada peringkat

- Security Tools: FormsDokumen15 halamanSecurity Tools: Formsnautas8nautasBelum ada peringkat

- MPA Version Site Isolation Procedures - Self AuditDokumen2 halamanMPA Version Site Isolation Procedures - Self AuditLorenzoBelum ada peringkat

- HSEF - 023 Health, Safety 06Dokumen2 halamanHSEF - 023 Health, Safety 06zxred284Belum ada peringkat

- Checklists - For Manufacturing FacilitiesDokumen6 halamanChecklists - For Manufacturing Facilitiesanoushia alviBelum ada peringkat

- Driver Safety at Customer Sites: Bulk Delivery: 6th EditionDokumen3 halamanDriver Safety at Customer Sites: Bulk Delivery: 6th EditionSergio ManzurBelum ada peringkat

- Job Safety AnalysisDokumen3 halamanJob Safety AnalysisDeshbandhu Aman PandeyBelum ada peringkat

- Safety Compliance Checklist: GeneralDokumen2 halamanSafety Compliance Checklist: GeneralMarcelo Alves da CostaBelum ada peringkat

- Bauhaus - Home For The AgedDokumen5 halamanBauhaus - Home For The AgedJohn Irvin NorbertoBelum ada peringkat

- Building Inspection Checklist For Fire and General SafetyDokumen3 halamanBuilding Inspection Checklist For Fire and General SafetyShayazAhSmdBelum ada peringkat

- Afcons Infrastructure LTD.: Job. No. 6152 (Environment, Health & Safety Department) Excavation ChecklistDokumen1 halamanAfcons Infrastructure LTD.: Job. No. 6152 (Environment, Health & Safety Department) Excavation ChecklistSravanPolepalliBelum ada peringkat

- Construction HSE Checklist: Health, Safety and EnvironmentDokumen18 halamanConstruction HSE Checklist: Health, Safety and EnvironmentMyolwinooBelum ada peringkat

- Excavation Safety ChecklistDokumen4 halamanExcavation Safety ChecklistCarlos Fernando Roca AkamineBelum ada peringkat

- Safety Compliance Checklist: House-KeepingDokumen2 halamanSafety Compliance Checklist: House-KeepingBehnam RezaeiBelum ada peringkat

- Idoc - Pub - Check List Api RP 14jDokumen18 halamanIdoc - Pub - Check List Api RP 14jLuis LazardeBelum ada peringkat

- Safety Inspection Repor1Dokumen9 halamanSafety Inspection Repor1MikaBelum ada peringkat

- JHA Helicopter Operations - ROMODokumen3 halamanJHA Helicopter Operations - ROMORinaldi SatriaBelum ada peringkat

- Physical Security Assessment Checklist: Approaches To The InstallationDokumen2 halamanPhysical Security Assessment Checklist: Approaches To The InstallationehembergBelum ada peringkat

- CL TrenchExcavationDokumen2 halamanCL TrenchExcavationMathan RajBelum ada peringkat

- Office Safety ChecklistDokumen5 halamanOffice Safety ChecklistJohn OoBelum ada peringkat

- Office Safety ChecklistDokumen3 halamanOffice Safety ChecklistSubzone ThreeBelum ada peringkat

- Appendix E-Baseline Design StandardsDokumen26 halamanAppendix E-Baseline Design StandardsReshad AtmarBelum ada peringkat

- Construction ChecklistDokumen19 halamanConstruction ChecklistKaluBelum ada peringkat

- Design For Safety (DFS) Library Examples of Hazards - Mechanical & Electrical DesignDokumen7 halamanDesign For Safety (DFS) Library Examples of Hazards - Mechanical & Electrical Designg tsBelum ada peringkat

- Office Safety ChecklistDokumen3 halamanOffice Safety ChecklistSubzone ThreeBelum ada peringkat

- HumanfactorschecklistDokumen7 halamanHumanfactorschecklistpassopuloBelum ada peringkat

- Stationary Scaffold Inspection ChecklistDokumen1 halamanStationary Scaffold Inspection ChecklistSatyadip TeraiyaBelum ada peringkat

- Take Home ExaminationDokumen9 halamanTake Home ExaminationEmmanuel SanthanasamyBelum ada peringkat

- Concreting Safety Checklist: Oh & S Management SystemDokumen2 halamanConcreting Safety Checklist: Oh & S Management Systemmunna yadavBelum ada peringkat

- Building Maintenance Services Limited Hse Management System Doc No.: BMSL-HSE-FM-03REV 0 Effective Date: 03/11/17 Doc Title: Office Safety ChecklistDokumen3 halamanBuilding Maintenance Services Limited Hse Management System Doc No.: BMSL-HSE-FM-03REV 0 Effective Date: 03/11/17 Doc Title: Office Safety Checklistolanda MohammedBelum ada peringkat

- FRM-9114-0144 Workplace Inspection ChecklistDokumen2 halamanFRM-9114-0144 Workplace Inspection ChecklistdrakoniiBelum ada peringkat

- Robot Operating System (ROS): The Complete Reference (Volume 3)Dari EverandRobot Operating System (ROS): The Complete Reference (Volume 3)Belum ada peringkat

- Safety in Excavations and Trenches FINALDokumen25 halamanSafety in Excavations and Trenches FINALSayed Saad ShehataBelum ada peringkat

- Course Information Sheet: HSSE Chemical HandlingDokumen3 halamanCourse Information Sheet: HSSE Chemical HandlingSayed Saad ShehataBelum ada peringkat

- 05 Balanced Pressure Proportioning Pump Skid PDFDokumen2 halaman05 Balanced Pressure Proportioning Pump Skid PDFSayed Saad ShehataBelum ada peringkat

- Don't Dig Your Own Grave: Toolbox Talk: Excavation SafetyDokumen2 halamanDon't Dig Your Own Grave: Toolbox Talk: Excavation SafetySayed Saad ShehataBelum ada peringkat

- Fire Extinguishersطفايات الحريقDokumen3 halamanFire Extinguishersطفايات الحريقSayed Saad ShehataBelum ada peringkat

- CVILBPDokumen2 halamanCVILBPRangga AsengBelum ada peringkat

- Safety Critical Operation Pre-AssessmentDokumen5 halamanSafety Critical Operation Pre-AssessmentSayed Saad ShehataBelum ada peringkat

- Systematic Cause AnalysisDokumen1 halamanSystematic Cause AnalysisSayed Saad ShehataBelum ada peringkat

- Critial Process DefinitionsDokumen3 halamanCritial Process DefinitionsSayed Saad ShehataBelum ada peringkat

- API-2016 Clean TanksDokumen112 halamanAPI-2016 Clean TanksSayed Saad Shehata100% (1)

- What If ChecklistDokumen8 halamanWhat If ChecklistSayed Saad ShehataBelum ada peringkat

- Moving Towards International Standards in The Oil and Gas IndustryDokumen17 halamanMoving Towards International Standards in The Oil and Gas IndustrySayed Saad ShehataBelum ada peringkat

- Iso Standards For Oil and Gas PDFDokumen3 halamanIso Standards For Oil and Gas PDFSayed Saad ShehataBelum ada peringkat

- Scaffolding Code2004Dokumen47 halamanScaffolding Code2004mrnaeemBelum ada peringkat

- K 10 ReportingInHYSYSDokumen10 halamanK 10 ReportingInHYSYSShariq KhanBelum ada peringkat

- Aspen HYSYS Dynamics: Who Should Attend?Dokumen2 halamanAspen HYSYS Dynamics: Who Should Attend?Sayed Saad ShehataBelum ada peringkat

- Owner's Manual: Downloaded From Manuals Search EngineDokumen12 halamanOwner's Manual: Downloaded From Manuals Search EnginegragrBelum ada peringkat

- Finite Element Analysis of An Overhead Crane BridgeDokumen6 halamanFinite Element Analysis of An Overhead Crane BridgeSebastian PopBelum ada peringkat

- 5-3 CLEAL Porousfine PP (English) JH-35302116Dokumen2 halaman5-3 CLEAL Porousfine PP (English) JH-35302116Milimas Tirta SolusiBelum ada peringkat

- Xylazine HydrochlorideDokumen1 halamanXylazine HydrochlorideKasidit SornchaiBelum ada peringkat

- Development of SandDokumen53 halamanDevelopment of Sandwondifraw girmaBelum ada peringkat

- SBRG Air Filter Brochure PDFDokumen24 halamanSBRG Air Filter Brochure PDFSBRGBelum ada peringkat

- Lesson 6-GlassDokumen32 halamanLesson 6-Glasslewis imaBelum ada peringkat

- Connector SectionDokumen28 halamanConnector SectionRamesh ShindeBelum ada peringkat

- European Steel Standards PDFDokumen2 halamanEuropean Steel Standards PDFMeikaBelum ada peringkat

- 90° Elbow Short Radius: StandardDokumen1 halaman90° Elbow Short Radius: StandardSiddiqui Muhammad AshfaqueBelum ada peringkat

- Tolerances Tables PDFDokumen16 halamanTolerances Tables PDFPramod SaljoshiBelum ada peringkat

- MOS COUPLER FOR TcsDokumen25 halamanMOS COUPLER FOR TcsRituraj RBelum ada peringkat

- FH Double-Grip Packer Technical DatasheetDokumen5 halamanFH Double-Grip Packer Technical DatasheetEvolution Oil ToolsBelum ada peringkat

- Analytical Solution For A Deep Tunnel Excavated in A Porous Elasto-Plastic Material Considering The Effects of Seepage Forces PDFDokumen14 halamanAnalytical Solution For A Deep Tunnel Excavated in A Porous Elasto-Plastic Material Considering The Effects of Seepage Forces PDFSaphal LamichhaneBelum ada peringkat

- Lennox HarmonyIII IOMDokumen56 halamanLennox HarmonyIII IOMMike AristaBelum ada peringkat

- Carl Deckard - Father of The SLS Method and One of The Pioneers of 3D Printing Technologies, Died... - 3DPC We Speak 3D PrintiDokumen1 halamanCarl Deckard - Father of The SLS Method and One of The Pioneers of 3D Printing Technologies, Died... - 3DPC We Speak 3D PrintiA GHAILANE EL HASSANI RABII SOUMAYABelum ada peringkat

- 2D Numerical Analysis of Hydraulic Fracturing in Heterogeneous Geo-Materials - 2009 - c49 PDFDokumen11 halaman2D Numerical Analysis of Hydraulic Fracturing in Heterogeneous Geo-Materials - 2009 - c49 PDFMoataz Hesham SolimanBelum ada peringkat

- Caterpillar Motor GradersDokumen32 halamanCaterpillar Motor GradersAshraf m aliBelum ada peringkat

- Joint Operating Body: Pertamina Medco E&P SkkmigasDokumen2 halamanJoint Operating Body: Pertamina Medco E&P SkkmigasAriBelum ada peringkat

- Product Industry Consumer Analysis - Steel: Suman Sourabh, Sudipto Sen Gupta, Goutham KrishnamurthyDokumen28 halamanProduct Industry Consumer Analysis - Steel: Suman Sourabh, Sudipto Sen Gupta, Goutham KrishnamurthyGouthamKrishnamurthy100% (1)

- Legrand Cable Lighting & Data Trunking Technical PDFDokumen35 halamanLegrand Cable Lighting & Data Trunking Technical PDFHarshith KunjathurBelum ada peringkat