Orifice and Chemical Tracer Flow Test Measurements On Production Geothermal Wells PDF

Diunggah oleh

indeskey0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

77 tayangan1 halamanJudul Asli

Orifice and chemical tracer flow test measurements on production geothermal wells.pdf

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

77 tayangan1 halamanOrifice and Chemical Tracer Flow Test Measurements On Production Geothermal Wells PDF

Diunggah oleh

indeskeyHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 1

Proceedings of the 2nd International Seminar on Chemistry 2011 (pp.

10-15)

Jatinangor, 24-25 November 2011

ISBN 978-602-19413-1-7

Orifice and chemical tracer flow test measurements on production

geothermal wells

Saltsa Prehtina Muryani1, Yoyo Sunarya1, Anni Anggraeni2

1

StarEnergy Geothermal (Wayang Windu) Ltd.

2

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Padjadjaran

Abstract

The common methods for measuring the mass flow rate on production-geothermal

wells are orifice and chemical-tracer flow test. Comparing the both of methods is the

objective in this paper. Tracer flow test has a good agreement with orifice in

measuring the mass flow rate for steam or single-phase and not for the two-phase

wells. The next experiment should be performed with carefully analysis and sampling

technique.

Keywords: mass flow rate, production-geothermal well, orifice, chemical-tracer flow

test

Introduction measurement of brine and steam flows and total

enthalpy within a pipeline carrying single and or

In geothermal fields that produce two-phase two-phase geothermal fluid.

fluids, monitoring trends in the enthalpy (heat

content) of produced fluids is important for Definition of TFT

understanding the reservoirs performance. Changes

in enthalpy are often the first sign of changes in TFT is a method/technique has been developed for

reservoir conditions. on-line measurement of steam, water mass flow-rate,

Two methods of mass flow rate and enthalpy and also total enthalpy of two phase fluids produced

measurements are most common for geothermal at the same time from geothermal wells using

application: direct physical measurement of the chemical tracers.

respective phases, and tracer-based measurement

using phase-specific tracer chemicals. Basic principle of TFT

Direct physical measurements, in this case

orifice plate, are usually accomplished with James The TFT principle in mass flow measurement by

tube method. Tracer-based measurement method tracer is dilution. Dilution means that it being

was developed in part to address the direct physical reduced the concentration of injected

measurement limitations. In a typical application, chemicals/liquid materials by mixing with the

tracers are injected under steady-state conditions at measured mass fluid. Two chemical tracers (one for

precisely known rates into two-phase flow. The the steam and one for the brine) become diluted by

samples of the steam and separated water or brine the fluids in the pipeline, by a degree dependent on

are collected downstream during tracer injection. the flow rate the higher the flow the lower

The concentration of each tracer in its respective concentration (the greater the dilution).

phase is inversely proportional to the flow rate of

that phase. TFT materials

The objective of this paper is as follows:

a. Understanding the basic-working principle of

Tracer Flow Test (TFT) Having determined that a tracer test is a suitable

b. Comparing orifice and TFT methods at method for obtaining the answers to the questions at

production wells based on mass flow rate and hand, candidate tracer compounds must then be

enthalpy measurements. screened for used. A tracer is therefore injected in

one of the phases (vapor phase or liquid phase), and

sampled for in the second; if the tracer is observed in

Tracer Flow Test (TFT) theory the second, the test objectives are met. If no tracer is

observed, the test objective remains unresolved: the

The Tracer Flow Testing (TFT) method for dual tracer may have completely adsorbed. The absence

phase flow rate and enthalpy measurements has of evidence is not evidence of absence.

become a standard diagnostic tool for geothermal The selection of liquid and vapor-phase tracers

reservoir engineering and power plant optimization. for TFT was based on an evaluation as shown in

TFT method has been developed for the on-line Table 1.

Saltsa Prehtina Muryani et al. 10

Anda mungkin juga menyukai

- Density, Viscosity, and VLE Measurements of Fluoro AlcoholsDokumen9 halamanDensity, Viscosity, and VLE Measurements of Fluoro AlcoholsFrank ElizaldeBelum ada peringkat

- Remaining Life of A PipelineDokumen2 halamanRemaining Life of A Pipelinefaisalf100% (4)

- WS XI PH Rotational Motion RollingDokumen11 halamanWS XI PH Rotational Motion Rollingkaushik247Belum ada peringkat

- Orifice and Chemical Tracer Flow Test Measurements On Production Geothermal WellsDokumen1 halamanOrifice and Chemical Tracer Flow Test Measurements On Production Geothermal WellsindeskeyBelum ada peringkat

- Jem WWTPDokumen12 halamanJem WWTPvacomanoBelum ada peringkat

- Determination of Volume Fractions in A Two-Phase Flows From Sound Speed MeasurementDokumen8 halamanDetermination of Volume Fractions in A Two-Phase Flows From Sound Speed MeasurementRoberto WallisBelum ada peringkat

- Double Porosity Model With Transient Interporosity Flow For The Response of Tracers in Naturally Fractured Reservoirs, Considering Constant Mass Flux InjectionDokumen13 halamanDouble Porosity Model With Transient Interporosity Flow For The Response of Tracers in Naturally Fractured Reservoirs, Considering Constant Mass Flux InjectionJuanBelum ada peringkat

- Thesis Draft FinalMDokumen84 halamanThesis Draft FinalMMitul6490Belum ada peringkat

- Spe 13143 Pa PDFDokumen9 halamanSpe 13143 Pa PDFMariaCamilaAcevedoCaballeroBelum ada peringkat

- International Journal of Multiphase Flow: H. Shaban, S. TavoularisDokumen12 halamanInternational Journal of Multiphase Flow: H. Shaban, S. TavoularisAkbarBelum ada peringkat

- Art-Método Tergotómetro PDFDokumen4 halamanArt-Método Tergotómetro PDFEdinsonMuñozBelum ada peringkat

- Novel Continuous Oscillatory Flow Screening Reactor Mixing and Residence TimesDokumen8 halamanNovel Continuous Oscillatory Flow Screening Reactor Mixing and Residence TimesPetras PetricaBelum ada peringkat

- 4130 Inorganic Nonmetals by Flow Injection Analysis (2004)Dokumen1 halaman4130 Inorganic Nonmetals by Flow Injection Analysis (2004)cristian perla martinezBelum ada peringkat

- Suspended Solids Removal Models Comparison in Tube SettlerDokumen5 halamanSuspended Solids Removal Models Comparison in Tube SettlerjcbobedaBelum ada peringkat

- A Single Drop Micro Extraction and Future Trends: Keyur Patel, Pratik Mehta, Ujjwal Sahoo, A.K.Sen and Dhanya BDokumen15 halamanA Single Drop Micro Extraction and Future Trends: Keyur Patel, Pratik Mehta, Ujjwal Sahoo, A.K.Sen and Dhanya BSata AjjamBelum ada peringkat

- Norma ASTM D5613 PDFDokumen20 halamanNorma ASTM D5613 PDFmcc0153Belum ada peringkat

- Magi 2018Dokumen5 halamanMagi 2018betahahnBelum ada peringkat

- D5613 PDFDokumen20 halamanD5613 PDFEngr. Jahanzeb MaharBelum ada peringkat

- Comparative Study of Septic Tank, Anaerobic Filter, and Anaerobic Baffled Reactor For Treating Domestic WastewaterDokumen1 halamanComparative Study of Septic Tank, Anaerobic Filter, and Anaerobic Baffled Reactor For Treating Domestic WastewaterRathborey ChanBelum ada peringkat

- Case Studies Downhole Fluid AnalyserDokumen2 halamanCase Studies Downhole Fluid Analysergeoahamza85Belum ada peringkat

- Raman and FTIR Spectroscopies of Fluorescein in Solutions: Lili Wang, A. Roitberg, C. Meuse, A.K. GaigalasDokumen11 halamanRaman and FTIR Spectroscopies of Fluorescein in Solutions: Lili Wang, A. Roitberg, C. Meuse, A.K. GaigalasREALVentorBelum ada peringkat

- Analyzing Reservoir Fluid Composition inDokumen9 halamanAnalyzing Reservoir Fluid Composition inAhmed GharbiBelum ada peringkat

- Analysis of Enhanced Oil Recovery Formulations and Surfactant Detection MethodsDokumen5 halamanAnalysis of Enhanced Oil Recovery Formulations and Surfactant Detection MethodsAdrian RosasBelum ada peringkat

- Ann 1Dokumen11 halamanAnn 1Saul Antonio Montoya SerranoBelum ada peringkat

- Analytical Method Development and Validation For The Simultaneous Estimation of Ofloxacin and Metronidazole in Bulk and Dosage Form Using RP-HPLCDokumen12 halamanAnalytical Method Development and Validation For The Simultaneous Estimation of Ofloxacin and Metronidazole in Bulk and Dosage Form Using RP-HPLCBaru Chandrasekhar RaoBelum ada peringkat

- Anoxic Activated Sludge Monitoring With Combined Nitrate and Titrimetric MeasurementsDokumen11 halamanAnoxic Activated Sludge Monitoring With Combined Nitrate and Titrimetric MeasurementsLâmHoàngDuyBelum ada peringkat

- Method Epa 502.2Dokumen35 halamanMethod Epa 502.2luisin0Belum ada peringkat

- A Numerical Method For Simulating Non-Newtonian Fluid Flow and Displacement in Porous MediaDokumen12 halamanA Numerical Method For Simulating Non-Newtonian Fluid Flow and Displacement in Porous MediaAbraham SilesBelum ada peringkat

- 1 s2.0 S0021967321000157 MainDokumen17 halaman1 s2.0 S0021967321000157 MainGabriel Chitolina RodriguesBelum ada peringkat

- IOP Conference Series: Earth and Environmental Science - Fractional order PID optimal control in pH neutralization processDokumen14 halamanIOP Conference Series: Earth and Environmental Science - Fractional order PID optimal control in pH neutralization processkaisa qorrinaBelum ada peringkat

- High Performance Liquid Chromatography HPLCDokumen4 halamanHigh Performance Liquid Chromatography HPLCEditor IJTSRDBelum ada peringkat

- Square Wave Adsorptive Cathodic Stripping Voltammetry Automated by Sequential Injection Analysis Potentialities and Limitations Exemplified by The Determination of Methyl Parathion in Water SamplesDokumen8 halamanSquare Wave Adsorptive Cathodic Stripping Voltammetry Automated by Sequential Injection Analysis Potentialities and Limitations Exemplified by The Determination of Methyl Parathion in Water SamplesSHERLY KIMBERLY RAMOS JESUSBelum ada peringkat

- Water Determination by Gas Chromatography: A General SurDokumen1 halamanWater Determination by Gas Chromatography: A General SurNur AlfiahBelum ada peringkat

- 1279 PDFDokumen4 halaman1279 PDFMila AndelaBelum ada peringkat

- HollandDokumen15 halamanHollandsugar ffrreeBelum ada peringkat

- Oxygen Content Using A 14-Mev Neutron Activation and Direct-Counting TechniqueDokumen8 halamanOxygen Content Using A 14-Mev Neutron Activation and Direct-Counting Techniqueruben carcamoBelum ada peringkat

- E 385 - 90 R02 - RTM4NQDokumen7 halamanE 385 - 90 R02 - RTM4NQAnh MinhBelum ada peringkat

- Parameter Study On Tracer Flow Test: February 2019Dokumen8 halamanParameter Study On Tracer Flow Test: February 2019Salih MohayaddinBelum ada peringkat

- Anal Bioanal Chem (2015) 407,3115-3123Dokumen9 halamanAnal Bioanal Chem (2015) 407,3115-3123Luciano PaoloBelum ada peringkat

- Exposición InstrumentalDokumen7 halamanExposición InstrumentaljoseBelum ada peringkat

- CromatografiaDokumen4 halamanCromatografiaLuis Cárcamo SanchezBelum ada peringkat

- 4a93 PDFDokumen8 halaman4a93 PDFPecel LeleBelum ada peringkat

- Prof Ateeq Rahman OFFICE-W 282 Dept of Chemistry & BiochemistryDokumen6 halamanProf Ateeq Rahman OFFICE-W 282 Dept of Chemistry & BiochemistrySalix MattBelum ada peringkat

- Instrumental HPLCDokumen7 halamanInstrumental HPLCTok WanBelum ada peringkat

- Clarkson 2020Dokumen20 halamanClarkson 2020Nur SyabaniaBelum ada peringkat

- Phytoplankton in Transitional Waters - Sedimentation and Counting MethodsDokumen10 halamanPhytoplankton in Transitional Waters - Sedimentation and Counting Methodskhánh hoà đỗBelum ada peringkat

- Prince Et Al-2010-Rapid Communications in Mass SpectrometryDokumen7 halamanPrince Et Al-2010-Rapid Communications in Mass Spectrometryshady mohamedBelum ada peringkat

- Economical Effects of On-Line Elemental Analysis Performance On Flotation ControlDokumen6 halamanEconomical Effects of On-Line Elemental Analysis Performance On Flotation ControlLuis Steiler Cespedes CastilloBelum ada peringkat

- Study of Water Purification Reactor Operating ModesDokumen6 halamanStudy of Water Purification Reactor Operating Modesali abdulrahman al-ezziBelum ada peringkat

- Preparation of A Naltrexone HCL Potentiometric Sensor and 1 PDFDokumen7 halamanPreparation of A Naltrexone HCL Potentiometric Sensor and 1 PDFNilaBelum ada peringkat

- 1 ST Paper PDFDokumen11 halaman1 ST Paper PDFPankaj PardeshiBelum ada peringkat

- Artìculo HPLCDokumen5 halamanArtìculo HPLCleotatanBelum ada peringkat

- Experimental Thermal and Fluid Science: A C A B BDokumen21 halamanExperimental Thermal and Fluid Science: A C A B BrajuvadlakondaBelum ada peringkat

- 524 2Dokumen48 halaman524 2celsogustavomello5Belum ada peringkat

- Spe 113903 Pa PDFDokumen7 halamanSpe 113903 Pa PDFPOOL SERVICES & SUPLLIESBelum ada peringkat

- Determination of Etidronate in Pharmaceutical Formulations by RP-HPLC Method With Indirect UV DetectionDokumen4 halamanDetermination of Etidronate in Pharmaceutical Formulations by RP-HPLC Method With Indirect UV DetectionMohammed RizkBelum ada peringkat

- A MinituDokumen11 halamanA Minitujhonny rocksBelum ada peringkat

- Jelic Pharm Sewer Systems Water Research 2015Dokumen11 halamanJelic Pharm Sewer Systems Water Research 2015vacomanoBelum ada peringkat

- Microextração AtrazinaDokumen3 halamanMicroextração AtrazinaStarmeloBelum ada peringkat

- 4120 Segmented Continuous Flow Analysis (Editorial Revisions, 2011)Dokumen2 halaman4120 Segmented Continuous Flow Analysis (Editorial Revisions, 2011)TaniaCarpioBelum ada peringkat

- Fast Real-Time Monitoring of Entacapone Crystallization and Characterization of Polymorphs Statistics and SWAXSDokumen13 halamanFast Real-Time Monitoring of Entacapone Crystallization and Characterization of Polymorphs Statistics and SWAXSRudolf KiraljBelum ada peringkat

- Applications of Zeeman Graphite Furnace Atomic Absorption Spectrometry in the Chemical Laboratory and in ToxicologyDari EverandApplications of Zeeman Graphite Furnace Atomic Absorption Spectrometry in the Chemical Laboratory and in ToxicologyC. MinoiaBelum ada peringkat

- IMG Scheda ISOLATION-JOINTS Web PDFDokumen2 halamanIMG Scheda ISOLATION-JOINTS Web PDFdevpal78Belum ada peringkat

- 5w 30 Synthetic Oil ComparisonDokumen12 halaman5w 30 Synthetic Oil ComparisonindeskeyBelum ada peringkat

- Castrol DOT 3 IndonesiaDokumen2 halamanCastrol DOT 3 IndonesiaindeskeyBelum ada peringkat

- BR-V 1.5 2017ymDokumen1 halamanBR-V 1.5 2017ymwangzai88Belum ada peringkat

- RUPES Big Foot Polishing System Price ListDokumen4 halamanRUPES Big Foot Polishing System Price ListindeskeyBelum ada peringkat

- 3 Sinopec MTF 75W 90 Fully Synthetic Transmission Gear Oil 201703 PDFDokumen2 halaman3 Sinopec MTF 75W 90 Fully Synthetic Transmission Gear Oil 201703 PDFindeskeyBelum ada peringkat

- IMG Scheda ISOLATION-JOINTS Web PDFDokumen2 halamanIMG Scheda ISOLATION-JOINTS Web PDFdevpal78Belum ada peringkat

- Castrol Axle EPX 80W-90Dokumen1 halamanCastrol Axle EPX 80W-90indeskeyBelum ada peringkat

- 3 Sinopec MTF 75W 90 Fully Synthetic Transmission Gear Oil 201703 PDFDokumen2 halaman3 Sinopec MTF 75W 90 Fully Synthetic Transmission Gear Oil 201703 PDFindeskeyBelum ada peringkat

- 3 Sinopec MTF 75W 90 Fully Synthetic Transmission Gear Oil 201703 PDFDokumen2 halaman3 Sinopec MTF 75W 90 Fully Synthetic Transmission Gear Oil 201703 PDFindeskeyBelum ada peringkat

- Hyundai H-1Dokumen2 halamanHyundai H-1Arya MrcBelum ada peringkat

- Opti 755 TechspecsDokumen45 halamanOpti 755 TechspecsPlacidus DsilvaBelum ada peringkat

- Safety Data Sheet: 1. IdentificationDokumen9 halamanSafety Data Sheet: 1. IdentificationindeskeyBelum ada peringkat

- Advances in Petrol Additives Research: Heino Rang and Jüri KannDokumen13 halamanAdvances in Petrol Additives Research: Heino Rang and Jüri KannindeskeyBelum ada peringkat

- Hyundai H-1Dokumen2 halamanHyundai H-1Arya MrcBelum ada peringkat

- Geothermal Production MeasurementDokumen5 halamanGeothermal Production MeasurementindeskeyBelum ada peringkat

- Oil MythsDokumen2 halamanOil MythsindeskeyBelum ada peringkat

- All New Kijang 2015 KatalogDokumen6 halamanAll New Kijang 2015 KatalogHeryanto EenBelum ada peringkat

- Opti 755 TechspecsDokumen45 halamanOpti 755 TechspecsPlacidus DsilvaBelum ada peringkat

- Castrol Axle EPX 80W-90Dokumen1 halamanCastrol Axle EPX 80W-90indeskeyBelum ada peringkat

- Grand Livina Brochure PDFDokumen6 halamanGrand Livina Brochure PDFindeskeyBelum ada peringkat

- WTP 3PS MV00 T0002 - Rev - 003Dokumen9 halamanWTP 3PS MV00 T0002 - Rev - 003indeskeyBelum ada peringkat

- Article in ASMEDokumen14 halamanArticle in ASMEindeskey100% (1)

- Nozzle ProDokumen3 halamanNozzle Projojo_323Belum ada peringkat

- Thermal Insulation and Pipe StressDokumen3 halamanThermal Insulation and Pipe StressDevin KendrickBelum ada peringkat

- Flange Pipe Support for 4-36Dokumen1 halamanFlange Pipe Support for 4-36indeskeyBelum ada peringkat

- Op Numberwriting12 PDFDokumen1 halamanOp Numberwriting12 PDFHang DuongBelum ada peringkat

- Trafo Las, Mesin Las, Kompressor Dan SandblastingDokumen10 halamanTrafo Las, Mesin Las, Kompressor Dan SandblastingCv RONATAMA GUSLHANBelum ada peringkat

- Monbat 12V200AhDokumen1 halamanMonbat 12V200AhMaria MuresanBelum ada peringkat

- Draft MP Net Metering Policy - 4.11Dokumen11 halamanDraft MP Net Metering Policy - 4.11Anand PuntambekarBelum ada peringkat

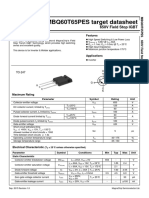

- MBQ60T65PES Target Datasheet: 650V Field Stop IGBTDokumen1 halamanMBQ60T65PES Target Datasheet: 650V Field Stop IGBTamrBelum ada peringkat

- 1.ENERGY SCENARIO-merged PDFDokumen188 halaman1.ENERGY SCENARIO-merged PDFraj walkeBelum ada peringkat

- As-Built Drawing ListDokumen14 halamanAs-Built Drawing Listsugeng wahyudi100% (1)

- PRAI-M0-YT01-LA-7500 - As-Built - Data Sheet For Feed Water PumpDokumen3 halamanPRAI-M0-YT01-LA-7500 - As-Built - Data Sheet For Feed Water PumpSuman GhoshBelum ada peringkat

- 450 Kva Diesel Generator Set Model HG 450Dokumen1 halaman450 Kva Diesel Generator Set Model HG 450ghostshotBelum ada peringkat

- Electrical Machines DC Motor NewDokumen27 halamanElectrical Machines DC Motor NewPranav MahadikBelum ada peringkat

- Green ConcreteDokumen22 halamanGreen ConcreteQseem Khan100% (1)

- Ючай каталог 1Dokumen78 halamanЮчай каталог 1Евгений100% (1)

- External Corrosion of PipeDokumen0 halamanExternal Corrosion of Pipejafarimehdi17Belum ada peringkat

- SERIES AC CIRCUIT PROBLEMSDokumen4 halamanSERIES AC CIRCUIT PROBLEMSHubert Semeniano100% (1)

- The Acidity and Basicity of Organic Acids and Bases For VULADokumen24 halamanThe Acidity and Basicity of Organic Acids and Bases For VULAZama MakhathiniBelum ada peringkat

- Need For Earthing and Double Insulation PDFDokumen2 halamanNeed For Earthing and Double Insulation PDFMeBelum ada peringkat

- A4 G970 - G990 Product Brochure enDokumen17 halamanA4 G970 - G990 Product Brochure endalibor_bogdan100% (3)

- ALSOQOOF IntroductionDokumen5 halamanALSOQOOF Introductionsudeesh kumarBelum ada peringkat

- BIOCNGDokumen23 halamanBIOCNGDhruva DBelum ada peringkat

- Arlan Alvar: Compex Certified E&I Ex Inspector (Qa/Qc) Available For New OpportunityDokumen3 halamanArlan Alvar: Compex Certified E&I Ex Inspector (Qa/Qc) Available For New OpportunityDo naBelum ada peringkat

- Work and PowerDokumen26 halamanWork and Powernicka castilloBelum ada peringkat

- Igcse: Definitions & Concepts of ElectricityDokumen4 halamanIgcse: Definitions & Concepts of ElectricityMusdq ChowdhuryBelum ada peringkat

- Kings Motorbikes 80cc Bicycle Engine Kit Installation ManualDokumen11 halamanKings Motorbikes 80cc Bicycle Engine Kit Installation ManualnwobastardsBelum ada peringkat

- Screw Compressors: Models: VEDokumen42 halamanScrew Compressors: Models: VEVoştinar IoanBelum ada peringkat

- Industrial Statistics Nepal 2069 70Dokumen84 halamanIndustrial Statistics Nepal 2069 70Koshish AcharyaBelum ada peringkat

- InternationalDokumen11 halamanInternationalheeral patelBelum ada peringkat

- Methods of Test For Cables: Indian StandardDokumen2 halamanMethods of Test For Cables: Indian StandardARUN BBelum ada peringkat

- Chapter 11-Homogeneous ReactionDokumen55 halamanChapter 11-Homogeneous ReactionBryan ManaliliBelum ada peringkat

- Kinetics: Effects of Concentration & Temperature on Reaction RatesDokumen4 halamanKinetics: Effects of Concentration & Temperature on Reaction Ratescrybaby0% (1)

- User Manual for Laser Tattoo Removal SystemDokumen37 halamanUser Manual for Laser Tattoo Removal SystemJuan Antonio CamarilloBelum ada peringkat