Operator'S Manual: Supercharged

Diunggah oleh

knockcontrolJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Operator'S Manual: Supercharged

Diunggah oleh

knockcontrolHak Cipta:

Format Tersedia

OPERATORS MANUAL

YS 140Limited Supercharged BREAK-IN fig.3

To maximum engine performance and increase durability, please follow

fig.1 this break-in procedure.

Tappet Clearance

1. Use the same size (or slightly smaller) propeller than you intend to

SPECIFICATIONS use in flying.

Bore 32mm

Stroke 29.0mm 2. Use a good quality fuel which contain 15-30% nitromethane and an

58

oil content of Low Viscosity oil 20-24% oil. Synthetic or castor oil can

Diaplacement 23cc be used, or a combination of both.

weight 890g DO NOT USE FOUR CYCLE FUEL DUE TO LOW OIL CONTENT.

Practical rpm 2,000 -12,000rpm

63 25 3. After the engine has started, slowly bring the throttle up to full.

Set high speed needle so it is running at a good rich setting without

the glow driver. Run engine at this setting for approximately 20

minutes with the throttle moving from low to high speed.

High Speed Needle

TAPPET ADJUSTMENT

4. After the initial 20 minute break-in, mount the engine in the aircraft Tappet clearance is preset at the factory. Adjustment if needed should be

and set the high speed to a richer than normal setting for the first 10 checked after the initial break-in. For maximum performance, valves should

flights. This will help to lubricate all moving parts. be checked as normal maintenance.

Low Speed Needle

Check Valve

112.5

TubeA 1. Clearance adjustment should be done when the engine is cool.

HIGH SPEED NEEDLE ADJUSTMENT

1. Adjustment of the high speed is done by the carburetor needle valve. 2. The proper clearance should be set 0.04-0.1mm or 0.002-0.004 in.

When the needle valve is turned clockwise, the mixture is leaner. When The adjustment is achieved by losing the locknut (fig.3) and turning

it is turned counterclockwise, the mixture is richer. A good starting the adjustment screw. The engine must be at top dead center on the

position for the high speed needle valve is 2 1/2 turns open from the compression stroke before any adjustment are made.

fully close position.

TubeB 2. When the engine is started, open the throttle gradually. Next, find the CAM GEAR TIMING

peak position (highest RPM) by adjusting the needle valve. Then the If for some reason you have to disassemble your engine, please follow

YS Fuel Filters needle valve should be opened approximately 1/8-1/4 turns from these important steps on reassembling the cam gear.

(YS1195/not included) full RPM to achieve best performance. The engine may stop if the

throttle is opened to full immediately after starting. Wait until the 1. Remove the carburetor and backplate assembly. Notice the

engine has warning up and pressure has developed in the tank. impression mark or dot opposite the rod journal on the crankshaft. This

128 mark is to point straight down or lined up with the outer case seam line at

the bottom.

LOW SPEED ADJUSTMENT

This engine is equipped with a new low speed needle valve to adjust the 2. Reinstall the cam with the dot facing you and is pointing slightly to the

mixture from low to mid throttle. See fig.1 for location. left. This will allow the cam to turn to the right when properly installed.

The dot should be pointing starting up when cam is fully installed.

FEATURES PROPELLER INSTALLATION 1. Factory starting position is 1 1/2 turns open from the fully closed Reinstall cam cover and timing is now set.

The YS140 Limited was developed for the serious competitor in mind. Due to the high torque of the140L engine, we have equipped it with position. The low speed needle should be set after the high speed

As aircraft increases in size, so does the need for power. With a few a double locknut system for safety. needle has been adjusted.

modifications internally, YS was able to generate more power in the same

DIAPHRAGM AND CHECK VALVE DISASSEMBLY

140 case. The YS 4 cycles are so unique, almost every square inch is 1. Mount the propeller and tighten the rear nut. Next, tighten the front nut 2. Close the throttle gradually to an idle (approximately 2,000rpm). Let it Diaphragm;

used in some way to produce power. as shown in fig.2. The rear nut has a offset shoulder so the front nut idle for 15-20 seconds and then slowly advance the throttle. 1. Remove the regulator assembly by removing the two allen head screws.

will secure itself to the rear nut. The adjustment is set when low to high speed has a smooth transition.

* Supercharged 2. Disassemble the regulator and clean with alcohol or appropriate cleaner.

* Fuel Injected 2. Select a good quality propeller that will allow the engine to run at 3. If the engine is running rough at idle or to rich, turn the low speed

* Regulated and Pressurized Fuel System maximum speed between 8,000 to 9,000rpm range. We recommend needle counterclockwise to lean out the low end. 3. When reinstalling the regulator, use a new gasket and note that the

* High and Low Speed Adjustments sizes 14x14,(15x12 through 14),(16x11 through 14). small casting tab on the regulator goes towards the propeller.

4. If the engine speeds up at idle , the low speed mixture is to lean.

Turn the low speed needle clockwise to richen the mixture. Check Valve;

GLOW PLUG fig.2 1. Open the check valve by rotating the body counterclockwise.

Select the most appropriate glow plug from those designed specifically for 5. If the engine is to lean on the low end, it can detonate and stop when Note the small clear silicone disc. DO NOT LOSE.

4 cycle engines. Glow plug selection greatly affects the maximum engine transition from low to high RPM.

output and low idle. If RPMs decrease or stop when the booster cord is 2. Clean and reassemble. Check to make sure air will only past though

removed, replace the plug. We recommend the OS Type F plug for the check valve one way.

maximum performance.

REGULATOR ADJUSTMENT

Front Nut Rear Nut

The regulator is preset at the factory. The top of the brass adjusting screw IMPORTANT! Silicone rubber is used in the YS engine. Only use glow

START UP is flush with the top of the regulator housing. Turning the regulator screw fuel or methanol for cleaning. Gasoline and other volatile solutions will

INSTALLATION 1. Remove tube A from the check valve, (CAUTION) Tank pressure must will not change the pressure the engine develops. The adjustment screw damage the silicone if used. Do not use petroleum based oils as after run

1. Connect the engine to the tank as shown in fig.1.Since high pressure be release first before tube B is opened. Remove tube B and begin to is used to adjust the amount of fuel to the carburetor. Turning the screw in lubricants.

is applied to the tank, tighten all connections carefully. Care must be fill fuel tank. will decrease the amount of fuel and turning the screw out will increase

taken to prevent pressure leakage due to undertightening of the check the amount of fuel to the carburetor.

valve or by kinking the fuel lines. 2. Open the high speed needle 2 1/2 turns from the closed position.

2. Always use a fuel filter. We recommend YS filter. 3. Open the throttle fully and slowly turn the propeller 10 times. This will

prime the engine and pressurized the fuel tank.

3. Match the direction of the check valve arrow in fig.1, with the arrow

facing towards the tank. 4. Close the throttle to the idle position and connect the glow driver.

The engine is now ready for starting.

DO NOT ATTEMPT TO START ENGINE AT FULL THROTTLE, AS THIS

IS VERY DANGEROUS. ALWAYS USE EXTREME CAUTION WHEN

ENGINE IS RUNNING.

YS 140Limited Parts LIST 4

# Part# Description QTY

1

F1701 Crankcase 1

F1202S Head Cover Set

2 F1202 Head Cover 1

3 F1203 Head Cover Gasket 1 2

4 F1204 Valve Cover Screw Set 2 72

5 F1505 Head Gasket 1 71

F1506A Head Assembly 3

6 F1506 Cylinder Head 1

7 F1407 Intake Valve 1 11 18

8 F1408 Exhaust valve 1

9 F1409 Valve Spring Set 2 10

10 F1410 Spring Retainer Set 2

11 F1411 Valve Spring Retainer Clips 4 14 9

12 F1212 Rocker Arm Set 2 16

67

13 F1213 Tappet Adjusting Screw Set 2 17

14 F1214 Tappet Adjusting Rock Nuts 2 55 65 72

15

15 F1215 Rocker Arm Shaft 1 63

12

16 F1216 Rocker Arm Shaft Screw 1 6

57 66

17 F1217 E Ring Set 2 13 56

18 F1518 Head Bolt Set 5 7

31

19 F1719 Crankshaft 1 8

20 F1520 Cylinder Liner 1

21 F1521 Piston 1 39 64

31

22 F1222 Wrist Piston 1 5 61

23 F1523 Wrist Pin Retainer Set 2 60

24 F1524 Piston Ring 1 62

25 F1525 Connecting Rodfi 1 37 24

54 59

F1426A Back Plate Assembly 44

22 23 58

26 F1426 Back Plate 1

27 F1427 Disc valve 1 23 31 68

21

28 F1492 Rear Disc Valve Retainer 1 29

29 F1429 Retainer Screw 1

30 F1230 Back Plate Gasket 6 38 28

32 F1232 Cam Gear Cover 1

33 F1233 Cam Gear Cover O-Ring 1 39

25

34 F1234 Cam Gear Cover Screw 2 26

35 F1535 Cam gear 1 36 30

36 F1236 Cam Followers Set 2

37 F1537 Push Rod Set 2 27

34

38 F1538 Push Rod Cover Set 2

32

39 F1239 Push Rod Cover O-Ring 4 20

40 F1240 Front Bearing 1

33 76

43 73

41 F9122 Front Bearing Oil Seal 1 19

42 F1341 Rear Bearing 1 35

43 F1242 Cam Gear Bearing Set 2 43

44 F1543 Fuel Nipples Set With Washers 6

F1244A Regulator Assembly

45 F1244 Regulator Body 1

46 F1245 Regulator Adjusting Screw 1 44 42

47 F1246 Regulator Adjusting Screw O-Ring 1

48 F1247 Diaphragm 1

49 F1248 Regulator Plunger 1 1

50 F1249 Plunger Spring 1 41

51 F1250 Regulator Gasket 1 40

52 F1251 Regulator Screw Set 2 70 44

F1752A Carburetor Assenbly 69

54 F1752 Carburetor Body 1

55 F1753 Throttle Barrel 1 74 51

56 F9156 Low Speed Needle Valve 1

57 F9157 Low Speed Needle Valve O-Ring 1 75 48

F1545S Needle Valve Assembly # Part# Description QTY

58 F1545 High Speed Needle Valve 1

49

75 F1267 Propeller Nut Set 2 WARRANTY

59 F1546 High Speed Needle Valve O-Ring 1 45 76 F1475 Crankshaft Ring 1 Strict quality control is implemented by our factory in all phases, from parts

60 F1555 High Speed Needle Valve Seat 1 F1473S Gasket Set 4 manufactiring to final assembly. If performance deteriorates or a part fails with-in

61 F1556 Needle Valve Socket O-Ring Set 2 F1574S O-Ring Set 14

52 one year of purchase due to a manufacturing error,YS will repair or replace the

62 F1557 Needle Valve Detent 1 M0010 Super Mount Set

49 M0020 Front Mount Assembly engine at no charge. Warranty will not cover normal wear.

63 F1483 Throttle Barrel Seal 1

64 R6124 Throttle Barrel Retainer 1 M0021 Front Mount Case 1

50 M0022 Inner Ring 1 Should the engine be modified or incorrectly assembled, there will be a normal

65 F1258 Throttle Stop Screw 1

66 F1259 Throttle Stop Spring 1 47 M0023 Inner Rubber 1 charge for parts and labor. The use of four cycle fuel due to low oil content will also

67 F1260S Throttle Arm Set 1 M0030 Rear Mount Assembly void warranty.

68 F1463 Carburetor Gasket 1 46 M0031 Rear Mount 1

69 F1564 Drive Washer 1 M0032 Rear Mount Arm 1

70 F1565 Drive Washer Retainer 1 M0033 Arm Screw 2

71 F1568 Intake Pipe 1 M0040 Rear Mount Screw Set 3

M0050 Rear Mount Spacer 1 YAMADA MFG.CO.,LTD

72 F1269 Intake Pipe O-Ring 4

M0060 Oil Damper #200 1 67 Tsuchitori Inuyama Aichi 484-0917 JAPAN

73 F1382 Wrist Pin Access Plug 1

74 F1266 Propeller Washer 1 M0070 Ball Support 2 TEL: 0568 67 0265 FAX: 0568 67 7801

Anda mungkin juga menyukai

- Husqvarna 266Dokumen8 halamanHusqvarna 266Joe EisentragerBelum ada peringkat

- LCR 200 Wiring Routing and Connector PDFDokumen397 halamanLCR 200 Wiring Routing and Connector PDFYannick de WalqueBelum ada peringkat

- EscalasDokumen42 halamanEscalasknockcontrol88% (8)

- EX120Dokumen7 halamanEX120tukangopi dotcom100% (1)

- Thermo King Parts Manual MAGNUM (51745-4-PM Rev 2) PDFDokumen99 halamanThermo King Parts Manual MAGNUM (51745-4-PM Rev 2) PDFSerhiiBelum ada peringkat

- ZF6 6R60 Zip - GDokumen11 halamanZF6 6R60 Zip - GВадим Толокнов100% (1)

- Fault Code 187: Sensor Supply Voltage Number 2 CircuitDokumen2 halamanFault Code 187: Sensor Supply Voltage Number 2 Circuithamilton mirandaBelum ada peringkat

- Impco 425 CarburetorDokumen6 halamanImpco 425 Carburetors_boots100% (2)

- CAT - 950G - SchematicDokumen2 halamanCAT - 950G - Schematicssinokrot95% (20)

- Cat 349Dokumen36 halamanCat 349Darma Raharja HardimanBelum ada peringkat

- Service Manual 2008 EpicaDokumen16 halamanService Manual 2008 EpicaUmmes Ahmed100% (3)

- Caterpillar d6d Crawler Operators Manual CT o d6d 3x1 UpDokumen5 halamanCaterpillar d6d Crawler Operators Manual CT o d6d 3x1 Upagpilot19yahoo.com0% (1)

- M.s.cygnus Z125Dokumen278 halamanM.s.cygnus Z125Luz Adriana Sanchez VillanuevaBelum ada peringkat

- Washpipe Packing AssembliesDokumen10 halamanWashpipe Packing AssembliesJohn Holding100% (1)

- SD300SD200 enDokumen10 halamanSD300SD200 enBhagoo Hathey100% (1)

- RP 43827Dokumen2 halamanRP 43827Edgar Alexander Grisales VallejoBelum ada peringkat

- 91sr S PDFDokumen2 halaman91sr S PDFricardoBelum ada peringkat

- Operator'S Manual: (Helicopter Engine)Dokumen2 halamanOperator'S Manual: (Helicopter Engine)seilfredBelum ada peringkat

- DZ 200 CdiDokumen2 halamanDZ 200 CdipowerveeBelum ada peringkat

- Operator'S Manual: (Helicopter Engine/ Part No - YS0057)Dokumen2 halamanOperator'S Manual: (Helicopter Engine/ Part No - YS0057)Jorge José Figueiredo SiqueiraBelum ada peringkat

- .32 Marine Owner's Manual: Setting The Needle ValvesDokumen2 halaman.32 Marine Owner's Manual: Setting The Needle ValvesGodsniperBelum ada peringkat

- 4VacuumPumps Gauges10-11Dokumen2 halaman4VacuumPumps Gauges10-11ISKT-IsıtmaSogutmaKlimaTesisatBelum ada peringkat

- 2019 Df70a 90a PibDokumen4 halaman2019 Df70a 90a PibMorteza ShamsiBelum ada peringkat

- 9030b-1995 (Ac4) CATDokumen24 halaman9030b-1995 (Ac4) CATMauricio JerezBelum ada peringkat

- Angular Gripper High Power Series-Main PageDokumen2 halamanAngular Gripper High Power Series-Main PageBe HappyBelum ada peringkat

- YS 61ST - 2 enDokumen2 halamanYS 61ST - 2 enknockcontrolBelum ada peringkat

- Smeg KI52E Extractor Fan User ManualDokumen5 halamanSmeg KI52E Extractor Fan User ManualTry it Now UKBelum ada peringkat

- 7B5B4BK4D4E26781008manual 2077287029Dokumen2 halaman7B5B4BK4D4E26781008manual 2077287029FedePereiroBeyerBelum ada peringkat

- Max 105hz RDokumen2 halamanMax 105hz RRui MigueisBelum ada peringkat

- Wheel Loader - CATERPILLAR 914G - IT14G Specalog (Aehq5560-02)Dokumen28 halamanWheel Loader - CATERPILLAR 914G - IT14G Specalog (Aehq5560-02)Reymond WuBelum ada peringkat

- Specifications: Bore 27.7mm Stroke 19.0mm Weight (Engine) 486g (Muffler) 33g Practical RPM 2,000-15,000rpmDokumen2 halamanSpecifications: Bore 27.7mm Stroke 19.0mm Weight (Engine) 486g (Muffler) 33g Practical RPM 2,000-15,000rpmseilfredBelum ada peringkat

- Turbair Blower (Type RT)Dokumen2 halamanTurbair Blower (Type RT)Amir AbbaszadehBelum ada peringkat

- M318C Series Spec SheetDokumen28 halamanM318C Series Spec SheetricsnikBelum ada peringkat

- Atlas Copco ErgoPulse USDokumen20 halamanAtlas Copco ErgoPulse USjackyt09Belum ada peringkat

- Ce Eng HL665VL (22.06)Dokumen8 halamanCe Eng HL665VL (22.06)Sara Sarmiento EcheverryBelum ada peringkat

- ProSpray3 BrochureDokumen4 halamanProSpray3 BrochureMariano GiaquintaBelum ada peringkat

- Vivax Assist 2016 Product CatalogueDokumen24 halamanVivax Assist 2016 Product CatalogueTms ArnBelum ada peringkat

- User Manual Mariner 50Dokumen24 halamanUser Manual Mariner 50Cyrille PVBelum ada peringkat

- Ecd 45-45eDokumen4 halamanEcd 45-45eInversiones Santa Rosa SACBelum ada peringkat

- Series: LK-1900BBDokumen7 halamanSeries: LK-1900BBmohamedelamjjaoui2023Belum ada peringkat

- Pcr200 200dth BroDokumen9 halamanPcr200 200dth BrojiaozhongxingBelum ada peringkat

- Watingen 6Dokumen3 halamanWatingen 6WillBelum ada peringkat

- Pajero 2019 BrochureDokumen5 halamanPajero 2019 BrochureNJ Lin100% (1)

- Airmotor CatalogDokumen33 halamanAirmotor CataloghawyegBelum ada peringkat

- Install HPC NuTLink SuperTLinkDokumen1 halamanInstall HPC NuTLink SuperTLinkAndy LBelum ada peringkat

- Tillotson Manual HR TypeDokumen9 halamanTillotson Manual HR TypelaerciofilhoBelum ada peringkat

- Heavy Duty Base Machine For Foundation Work: Max. Lifting Capacity: 90t at 4.3m Max. Boom Length: 62.6mDokumen8 halamanHeavy Duty Base Machine For Foundation Work: Max. Lifting Capacity: 90t at 4.3m Max. Boom Length: 62.6mSIVARAMANJAGANATHANBelum ada peringkat

- 28.RS600C Reclaimers Stabilizers BrochureDokumen4 halaman28.RS600C Reclaimers Stabilizers Brochureamsm71100% (1)

- Carburetor - Adjust Idling Adjust Hot Start Device Check Float Level Checking Axial Play of Float - KTM 400 Owner's Handbook ManualDokumen4 halamanCarburetor - Adjust Idling Adjust Hot Start Device Check Float Level Checking Axial Play of Float - KTM 400 Owner's Handbook ManualelnyniosBelum ada peringkat

- 1a209 Manual PDFDokumen2 halaman1a209 Manual PDFbayu edityaBelum ada peringkat

- Especificaciones Excavadora Sany 465C (Folleto)Dokumen8 halamanEspecificaciones Excavadora Sany 465C (Folleto)prueba100% (1)

- Serdi 4.5Dokumen4 halamanSerdi 4.5Yeam_90Belum ada peringkat

- Compact Zuiger Luchtmotoren PDFDokumen7 halamanCompact Zuiger Luchtmotoren PDFFabiano RogérioBelum ada peringkat

- SCC3200 Hydraulic Crawler CraneDokumen99 halamanSCC3200 Hydraulic Crawler CraneSamio CalacaBelum ada peringkat

- DISD SD300 - SD200 Wheel Loader Technical SpecificationDokumen10 halamanDISD SD300 - SD200 Wheel Loader Technical SpecificationIslam ShoukryBelum ada peringkat

- Construction EquipmentDokumen7 halamanConstruction EquipmentPaul HarkinsBelum ada peringkat

- In TNV Series 2207Dokumen4 halamanIn TNV Series 2207Nay TunBelum ada peringkat

- Ficha Tecnica Cat cb434Dokumen12 halamanFicha Tecnica Cat cb434Andres AgudeloBelum ada peringkat

- Important Safeguards: Service InstructionsDokumen4 halamanImportant Safeguards: Service Instructionskarol1177Belum ada peringkat

- 16 18 20b 9fDokumen9 halaman16 18 20b 9fVũ Anh TuấnBelum ada peringkat

- Bulletin 1351 Engine Running in PDFDokumen1 halamanBulletin 1351 Engine Running in PDFPhin ChanthouBelum ada peringkat

- Webra MotorDokumen8 halamanWebra MotoraerohobbyBelum ada peringkat

- Excavadora M316DDokumen36 halamanExcavadora M316DFelipe HernándezBelum ada peringkat

- SR285R W10 2020 172953Dokumen2 halamanSR285R W10 2020 172953TigerBelum ada peringkat

- HR70 110 120 140C 9 WebDokumen8 halamanHR70 110 120 140C 9 WebИван ШадринBelum ada peringkat

- Sistema de Freno b876f PDFDokumen8 halamanSistema de Freno b876f PDFhector agueroBelum ada peringkat

- O15725v77 W Brochure WRSeries 1119 V2 ENDokumen60 halamanO15725v77 W Brochure WRSeries 1119 V2 ENMạnh QuânBelum ada peringkat

- SD300-200 EN 130521 LowDokumen9 halamanSD300-200 EN 130521 LowMoises Garcia DuranBelum ada peringkat

- Operation Guide DQ-584/584B: IllustrationDokumen2 halamanOperation Guide DQ-584/584B: IllustrationknockcontrolBelum ada peringkat

- User'S Guide Dq-643: Setting The TimeDokumen2 halamanUser'S Guide Dq-643: Setting The TimeknockcontrolBelum ada peringkat

- Operation Guide DQ-542/542B: IllustrationDokumen2 halamanOperation Guide DQ-542/542B: IllustrationknockcontrolBelum ada peringkat

- OS FL70 enDokumen46 halamanOS FL70 enknockcontrolBelum ada peringkat

- Casio CWL300 enDokumen30 halamanCasio CWL300 enknockcontrolBelum ada peringkat

- Casio PQ30 en PDFDokumen2 halamanCasio PQ30 en PDFknockcontrolBelum ada peringkat

- Owners ManualDokumen10 halamanOwners ManualknockcontrolBelum ada peringkat

- Kodak 1700auto EsDokumen26 halamanKodak 1700auto EsknockcontrolBelum ada peringkat

- DA100 enDokumen10 halamanDA100 enknockcontrolBelum ada peringkat

- Kodak KD60 enDokumen2 halamanKodak KD60 enknockcontrolBelum ada peringkat

- YS 61ST - 2 enDokumen2 halamanYS 61ST - 2 enknockcontrolBelum ada peringkat

- Camera Operations Guide: DCR-PC330Dokumen136 halamanCamera Operations Guide: DCR-PC330knockcontrolBelum ada peringkat

- Mode Emploi Kayak SevylorDokumen128 halamanMode Emploi Kayak SevylorknockcontrolBelum ada peringkat

- Motor E15 para Wood MizerDokumen40 halamanMotor E15 para Wood MizerCesar Edgardo Lopez PortilloBelum ada peringkat

- 2009ZX-10R Racing Kit ManualDokumen83 halaman2009ZX-10R Racing Kit ManualhkbeltfedBelum ada peringkat

- Mechanical Power Transmission SystemsDokumen42 halamanMechanical Power Transmission SystemsEricBelum ada peringkat

- Funtana 125 Manual Low ResolutionDokumen60 halamanFuntana 125 Manual Low ResolutionSergio HernandezBelum ada peringkat

- @hydsafi R: Hydraulic Motor/Pump Series F11/F12Dokumen44 halaman@hydsafi R: Hydraulic Motor/Pump Series F11/F12Enayat IzadiBelum ada peringkat

- Cat Sleeve MeteringDokumen2 halamanCat Sleeve MeteringAnonymous 5tkF5bFwOBelum ada peringkat

- Load Test On D.C. Series MotorDokumen5 halamanLoad Test On D.C. Series Motorramniwas123Belum ada peringkat

- 886 DppNotes Reaction Turbine I DPP 06 Lec 08 GATE Crash CourseDokumen5 halaman886 DppNotes Reaction Turbine I DPP 06 Lec 08 GATE Crash Coursekreddy95054Belum ada peringkat

- AL-Nahrain University College of Engineering Mechanical DepartmentDokumen10 halamanAL-Nahrain University College of Engineering Mechanical DepartmentAbdullh AhmedBelum ada peringkat

- Serie 1 3 SkruvdragareDokumen16 halamanSerie 1 3 SkruvdragareVictoria CoronaBelum ada peringkat

- Caliper Ranger and Explorer Disassembly and Assembly PDFDokumen2 halamanCaliper Ranger and Explorer Disassembly and Assembly PDFMichael HernandezBelum ada peringkat

- Kenmore 385.12216 Sewing Machine Instruction ManualDokumen79 halamanKenmore 385.12216 Sewing Machine Instruction ManualiliiexpugnansBelum ada peringkat

- Emrv PLAMPLATE - 19-02-2016Dokumen2 halamanEmrv PLAMPLATE - 19-02-2016S. R. KhareBelum ada peringkat

- W20845C V K3fah3b2000016 08062020Dokumen931 halamanW20845C V K3fah3b2000016 08062020eng samiBelum ada peringkat

- Steering Column Chevrolet S10Dokumen10 halamanSteering Column Chevrolet S10Maxi SardiBelum ada peringkat

- Pump Types Used in Aquaculture OperationsDokumen5 halamanPump Types Used in Aquaculture OperationsJensiBelum ada peringkat

- Front-Wheel Drive CarDokumen9 halamanFront-Wheel Drive CarKkbhuvan KkBelum ada peringkat

- Brother DT6-B926 PDFDokumen49 halamanBrother DT6-B926 PDFfernando Diaz GonzalezBelum ada peringkat

- 5f9accc0f3f8f455bebc45f3 - 94 Shkolnik, Alexander - Final PaperDokumen13 halaman5f9accc0f3f8f455bebc45f3 - 94 Shkolnik, Alexander - Final PaperpeterBelum ada peringkat

- TOM IES GATE IAS 20 Years Question and Answers by S K Mondal PDFDokumen137 halamanTOM IES GATE IAS 20 Years Question and Answers by S K Mondal PDFgaurav jha100% (3)

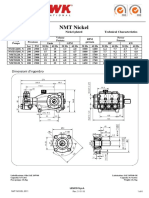

- NMT Nickel: Caratteristiche Tecniche Nickel Plated Technical CharacteristicsDokumen6 halamanNMT Nickel: Caratteristiche Tecniche Nickel Plated Technical CharacteristicsazkBelum ada peringkat