Installation Instructions C+

Diunggah oleh

Anonymous m1cSnEavoHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Installation Instructions C+

Diunggah oleh

Anonymous m1cSnEavoHak Cipta:

Format Tersedia

PFISTERER

Installation instruction TENSOREX C+

TENSOREX C+ is a new spring automatic tensioning device for tramway, light and heavy railways

Overhead Contact Lines ( OCL ). TENSOREX Products are only by PFISTERER

Fixing bracket TYPE A for O and H poles

Fixing bracket TYPE B for O and H poles

Are available different fixing brackets, for special poles or walls. Also its possible to install TENSOREX C+

horizontally. Please ask direct information to Pfisterer srl.

Instruction code 000300303EN ed. 15-05-2012 Page 1

PFISTERER

Installation tools Package checking Important information

- 1 water level Verify that the package contains: - Before to proceed, you have to

- 1 Flat steel rod min 500mm long - Tensorex C+ (TRC+) know the length of the line between

or in alternative long water level Compensating length and pull force TENSOREX C+ and middle point

- 1 thermometer are correct

- 1 of 2 pulling devices - Fixing bracket

- 1 of 2 come-along clamp Fit to the pole - Installers must be good trained and

- 1 Dynamometer (optional) - Installation instruction to know how the device works

1.a) Fixing bracket type A

Fix the bracket to the mast, to the line direction, at the height prescribed 1.a

by the rail administrator, from the top of rail (G) . In the fixing bracket

there is a reference hole, circa in the middle, see photo 1.a.

It must be level mounted.

Round masts and beams have different fixing bracket, and they are

supplied from Pfisterer in according to the customer requirements.

1.b) For Type B

1.b Fix both L profiles keeping the

distance between the upper and lower

L profile 500 mm, tolerance: -0 / +5 height: H

mm.

The two holes 26 must be vertically

aligned. Its helpful to insert the rod

M24 and check all parts by water level

( see photo 1.b ).

G

3 2.a) Hang TRC+ like photo 2,

and lift up it by crane or

hoist-tackle, out from the wood

2 box (photo 3 and 4).

In case, the hoist chain must

be min 15 meters long.

2.b) Take out the two pins 19

and fit TRC+ in the fixing

bracket.

Before the bottom fitting, then

4 the upper one (photos 5 and

6).

Look it by set pins upward and

splits under.

Now TRC+ can be pulled.

5

Before, please make sure that

two stainless

steel tension wires are in the

pulley races down!

Also wind them two times

(photos 5,6 and 7)

7

Instruction code 000300303EN ed. 15-05-2012 Page 2

PFISTERER

3) Tie two belts to the front balance (photo

8) and acting by pulling device take the solid 8 9

arrow on the 0-point of the scale ( photo 9 ).

Now TRC+ is applying to the line

approximately the nominal force.

Warning: we suggest to fit in advance to

front balance all hardware you need (

insulators, turnbuckles,..) , so to make easy

to joint later TRC+ to OCL.

10 4) Acting on two nuts at the top

11

(see red circles in photo 10) to align

TRC+ to the OCL slope.

Do it laying a flat steel rod circa

500mm long on flat side of the pulley.

TRC+ is aligned when its

approximately in line with the

tensioned wire, see photo 11.

At the end, verify that the M14 rods

are out equals lengths.

5) Now, TRC+ must be further set taking in account

tension length and temperature. See photo 12.

Example of TRC+ setting

TRC+ type.450/XXXX kg

Tension length500 meters (1) 12

Ambient Temperature...25 C

(1) distance between TRC+ and middle point

Calculate the setting number crossing the above

value in the table 1.

In this case is 140mm

Then pull TRC+ until the arrow reach the number

( see photo 12 ).

Its recommended to mount a compensating

element as turnbuckle between TRC+ and OCL.

Joint TRC+ to OCL and release it. A fine-tuning is

possible acting on compensating element.

6) Finally, activate the "stoppers", using a

screwdriver to press on both sides of the device,

photo 13.

Instruction code 000300303EN ed. 15-05-2012 Page 3

PFISTERER

6) Finally, activate the "stoppers", by a screwdriver

to push on both sides of the device, photo 13.

IMPORTANT NOTE

Stoppers work preserving the functionality of the

TRC+ in case of anomalous OCL contraction (very

low temperature) or the device is out of setting.

When stoppers are working, TRC+ becomes as a 13

rigid body, so OCL becomes from compensated to

fix end.

Tab 1 ( TRC+ Type 450/ kg and center temperature 15C )

E.g. for the Netherlands/Germany is based on a nominal (center) temperature of 10 C, the radial black line on the

scale diagram shows it as being half the maximum length variation to regulate. In the photo 12 is the type TRC+ is

450/ ... so this is 225 mm.

Warning: setting table above is just an example. Always check the setting tab fixed on the top of

Tensorex C+ or attached to this manual, ANNEX 1

TENSOREX C+ control after installation

After a certain period from the installation, its well to verify and eventually compensate the anomalous extension-

contraction of the contact wires pulled by TENSOREX C+. Do it following the same procedure as at step 5.

Recover OCL by the pulling devices until the index of TENSOREX C+ is in the correct position, taking into account

the ambient temperature during this operation (step 5, photo 12).

The same procedure must be done even in case of other controls, in consequence to changes or replacement of

fittings, middle point,.

Instruction code 000300303EN ed. 15-05-2012 Page 4

PFISTERER

In case of OCL collapse

In case of OCL collapse consequent de-wirement, proceed as follows:

a) Verify the stoppers (see step 6, photo 13). If they are deformed or broken mean that a load > 40KN has been

applied to TRC+.

In this case TRC+ must be substitute by another one.

b) If, after de-wirement, the stoppers are not damaged and work properly (check free rotation) TENSOREX C+ can

be used again.

Before to set it again, make a visual inspection and control carefully the state of stainless steel cables. They must

not present any bending section or single wire broken. If singles wires are broken, replace the ropes. For TRC+

setting, repeat step 4, 5 and 6 in the manual.

Note

PFISTERER srl

via Sirtori,45/D

20017 Passirana di Rho (Mi) Italy

www.pfisterer.it

pfisterer@pfisterer.it

Instruction code 000300303EN ed. 15-05-2012 Page 5

Anda mungkin juga menyukai

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987Dari EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonBelum ada peringkat

- RASCO CatalogDokumen17 halamanRASCO Catalogdesters1120Belum ada peringkat

- Iso 15552 2004 en PDFDokumen8 halamanIso 15552 2004 en PDFashokkumarBelum ada peringkat

- Geomet 500bDokumen1 halamanGeomet 500bellisforheroesBelum ada peringkat

- Hempel Warrington Loading PDFDokumen34 halamanHempel Warrington Loading PDFSyed Fakher Imam AbediBelum ada peringkat

- Carbon Arc Cutting PDFDokumen44 halamanCarbon Arc Cutting PDFMark InnesBelum ada peringkat

- Cable Design Equations-Braid Shield: Braid Picks Per Inch: Braid AngleDokumen1 halamanCable Design Equations-Braid Shield: Braid Picks Per Inch: Braid Anglesubaash libraBelum ada peringkat

- IEC - 61892 6 2019 en FR stGnH9WUUvDokumen101 halamanIEC - 61892 6 2019 en FR stGnH9WUUvElia MadyBelum ada peringkat

- A4 NTN Freedom Paper Jig 2012Dokumen3 halamanA4 NTN Freedom Paper Jig 2012lingonBelum ada peringkat

- Aluminium Bronze To Bs 1400: Ab2Dokumen1 halamanAluminium Bronze To Bs 1400: Ab2Sharad KokateBelum ada peringkat

- Fe SafeDokumen13 halamanFe SafeManjinderSinghBelum ada peringkat

- Vishwanat Kanal, Vinod Nirale, Ravindra Kondaguli: Impact Factor: 1.479Dokumen4 halamanVishwanat Kanal, Vinod Nirale, Ravindra Kondaguli: Impact Factor: 1.479divjak70Belum ada peringkat

- Manual Algor TuberiasDokumen0 halamanManual Algor TuberiascaletonesBelum ada peringkat

- 1111 11 1111 I 111 I Iliiil I 11: Din en IsoDokumen14 halaman1111 11 1111 I 111 I Iliiil I 11: Din en IsoDiego CamargoBelum ada peringkat

- CEAST Drop Tower 9300 SeriesDokumen16 halamanCEAST Drop Tower 9300 SeriesLitarmjBelum ada peringkat

- EN ISO 23251 (2007) (E) CodifiedDokumen9 halamanEN ISO 23251 (2007) (E) CodifiedNadabzfBelum ada peringkat

- Thermoplastic Piping Systems: AGRU Technical 08.12Dokumen51 halamanThermoplastic Piping Systems: AGRU Technical 08.12Ashraf MohammedBelum ada peringkat

- 28.GOMA Pump T-8000 CatalougeDokumen2 halaman28.GOMA Pump T-8000 Catalougeramesh babuBelum ada peringkat

- 9968specification For Elasomeric Cables - 1Dokumen14 halaman9968specification For Elasomeric Cables - 1aashish_rajj100% (1)

- EC 9875 0003 03 Workbook TSI-WAG 2019Dokumen38 halamanEC 9875 0003 03 Workbook TSI-WAG 2019İsmail OktemBelum ada peringkat

- LF End Suction Pump: A Grundfos CompanyDokumen4 halamanLF End Suction Pump: A Grundfos CompanyDya WiBelum ada peringkat

- An Evaluation System Interfacing The TSL230/TSL235/TSL245 Light-To - Frequency Converters To A MicrocontrollerDokumen15 halamanAn Evaluation System Interfacing The TSL230/TSL235/TSL245 Light-To - Frequency Converters To A MicrocontrollerOscarBelum ada peringkat

- 201012182932953Dokumen5 halaman201012182932953Sanjay Singh100% (1)

- Infoprd-Geomet 500-gb PDFDokumen2 halamanInfoprd-Geomet 500-gb PDFSannohashi MFGBelum ada peringkat

- Filter Test Methods - 07-2012Dokumen1 halamanFilter Test Methods - 07-2012SurajPandeyBelum ada peringkat

- IEC 62491-2008 Labelling of Cables and CoresDokumen64 halamanIEC 62491-2008 Labelling of Cables and CoresTu Nguyen TraiBelum ada peringkat

- Concrete Pavements and Linings Installed in Corrugated Steel Structures in The FieldDokumen4 halamanConcrete Pavements and Linings Installed in Corrugated Steel Structures in The FieldDarwin Darmawan100% (1)

- Impact Test RequiredDokumen1 halamanImpact Test RequiredZouhair BenmabroukBelum ada peringkat

- 1 PDFDokumen15 halaman1 PDFnicolasBelum ada peringkat

- G - 1 - A1 General Arrangment DrawingDokumen1 halamanG - 1 - A1 General Arrangment Drawingjonodo89Belum ada peringkat

- SAE J1390-2017 Engine Cooling Fan Structural AnalysisDokumen18 halamanSAE J1390-2017 Engine Cooling Fan Structural AnalysisProvocateur SamaraBelum ada peringkat

- Positive Material Dentification (PMI) : NIOEC-SP-90-04Dokumen11 halamanPositive Material Dentification (PMI) : NIOEC-SP-90-04Mohammad Amini100% (1)

- Dimensional Engineering: Based On The ASME Y14.5M-1994 Dimensioning and Tolerancing StandardDokumen77 halamanDimensional Engineering: Based On The ASME Y14.5M-1994 Dimensioning and Tolerancing StandardPankaj PatilBelum ada peringkat

- Ge Radin 1984Dokumen15 halamanGe Radin 1984Phuor TyBelum ada peringkat

- Techincal Data For PCD Dia & Torque ChartDokumen1 halamanTechincal Data For PCD Dia & Torque ChartTuff quality100% (1)

- Submersible Pumps For High Temperature LiquidsDokumen4 halamanSubmersible Pumps For High Temperature LiquidsIpenu Sujarwo100% (1)

- Design and Optimization of Weld Neck Flange For Pressure VesselDokumen5 halamanDesign and Optimization of Weld Neck Flange For Pressure Vesselcat arroBelum ada peringkat

- G81 - 2 Housing Materials PDFDokumen17 halamanG81 - 2 Housing Materials PDFHassan SaeedBelum ada peringkat

- Tyco - Sintakote - Design - Manual - Nov2004editionDokumen140 halamanTyco - Sintakote - Design - Manual - Nov2004editionmottmac50% (2)

- International Standard: Agricultural Irrigation Equipment - Filters For Microirrigation - Granulated Media FiltersDokumen8 halamanInternational Standard: Agricultural Irrigation Equipment - Filters For Microirrigation - Granulated Media FiltersBarun KumarBelum ada peringkat

- Legrand Plexo Catalogue 02Dokumen20 halamanLegrand Plexo Catalogue 02antonpgmBelum ada peringkat

- As 60068.2.66-2003 Environmental Testing Tests - Test CX - Damp Heat Steady State (Unsaturated Pressurized VapDokumen8 halamanAs 60068.2.66-2003 Environmental Testing Tests - Test CX - Damp Heat Steady State (Unsaturated Pressurized VapSAI Global - APACBelum ada peringkat

- Is 1231.1974Dokumen22 halamanIs 1231.1974Jayam Harinatha GupthaBelum ada peringkat

- MiniProf BT Brochure 2015 PDFDokumen24 halamanMiniProf BT Brochure 2015 PDFVenkatesh SreegirisettyBelum ada peringkat

- QM-RF-7.1-3 Ver.2.0 - Guidelines For Preparing QAP During RegistrationDokumen8 halamanQM-RF-7.1-3 Ver.2.0 - Guidelines For Preparing QAP During Registrationsanjayde100% (1)

- I56-2006-013 Mi-Dmmi Mi-Dmm2i Mi-D2icmoDokumen4 halamanI56-2006-013 Mi-Dmmi Mi-Dmm2i Mi-D2icmoAzita NaimiBelum ada peringkat

- Technical Data Sheet: Perspex CCDokumen2 halamanTechnical Data Sheet: Perspex CCResist IkatBelum ada peringkat

- Tolsen V2022 06Dokumen208 halamanTolsen V2022 06Arun PravarthiBelum ada peringkat

- Catalogue Data Everest Heat Pump (32-108)Dokumen8 halamanCatalogue Data Everest Heat Pump (32-108)rachman hardianBelum ada peringkat

- 1981 PitfallsDokumen44 halaman1981 Pitfallsengineer_atulBelum ada peringkat

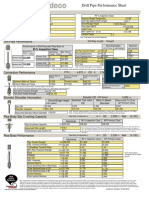

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Dokumen3 halamanDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaBelum ada peringkat

- Unspecified Tolerances Plastic Parts: 1. ObjectDokumen7 halamanUnspecified Tolerances Plastic Parts: 1. ObjectDiegoBelum ada peringkat

- MeasurIT Red Valve Expansion Joints J1 0802Dokumen3 halamanMeasurIT Red Valve Expansion Joints J1 0802cwiejkowskaBelum ada peringkat

- EWAQ EWYQ-BAW IOM 4PW70082-1C Installation Manuals EnglishDokumen48 halamanEWAQ EWYQ-BAW IOM 4PW70082-1C Installation Manuals EnglishssteticBelum ada peringkat

- Type Approval Certificate: Akasol AgDokumen7 halamanType Approval Certificate: Akasol Agzuffflor_925748656100% (1)

- xv1000bk PDFDokumen80 halamanxv1000bk PDFHung PhuBelum ada peringkat

- Instruction Manual: Model: DC-325Dokumen15 halamanInstruction Manual: Model: DC-325Keziah SantosBelum ada peringkat

- f6cb57702022 Endsem MOSDokumen2 halamanf6cb57702022 Endsem MOSshreyas shahBelum ada peringkat

- Fitting Instructions For Resilient Mounting of Gensets L23/30H, L27/38 L28/32H, L32/40Dokumen3 halamanFitting Instructions For Resilient Mounting of Gensets L23/30H, L27/38 L28/32H, L32/40marine ShanghaiBelum ada peringkat

- Manual Carro ElectricoDokumen2 halamanManual Carro ElectricoGONZALO RIVERA ORELLANABelum ada peringkat

- Candy CSW 2D en (41044804)Dokumen32 halamanCandy CSW 2D en (41044804)Anonymous m1cSnEavoBelum ada peringkat

- 18.0 V Cordless Hydraulic Cutting Tool B-tc250bsDokumen4 halaman18.0 V Cordless Hydraulic Cutting Tool B-tc250bsAnonymous m1cSnEavoBelum ada peringkat

- Thule Bike Security Document v04Dokumen48 halamanThule Bike Security Document v04Anonymous m1cSnEavoBelum ada peringkat

- PSS 3047-3 Operating Manual 21062-En-12Dokumen101 halamanPSS 3047-3 Operating Manual 21062-En-12Anonymous m1cSnEavoBelum ada peringkat

- DIN 1628 ST 52.4Dokumen2 halamanDIN 1628 ST 52.4Anonymous m1cSnEavoBelum ada peringkat

- PSS 3047-3 Operating Manual 21062-En-12Dokumen101 halamanPSS 3047-3 Operating Manual 21062-En-12Anonymous m1cSnEavoBelum ada peringkat

- Sitras RSC: FeaturesDokumen4 halamanSitras RSC: FeaturesAnonymous m1cSnEavoBelum ada peringkat

- Contact Wire and Stranded Conductors For Overhead Catenary SystemsDokumen20 halamanContact Wire and Stranded Conductors For Overhead Catenary SystemsAnonymous m1cSnEavoBelum ada peringkat

- Copper and Copper Alloy Ingots and CastingsDokumen2 halamanCopper and Copper Alloy Ingots and CastingspoopBelum ada peringkat

- Electron I QueDokumen16 halamanElectron I QueAnonymous m1cSnEavoBelum ada peringkat

- 4722jb-Kfbf Rev 6 Manuel Idc20k - GBDokumen20 halaman4722jb-Kfbf Rev 6 Manuel Idc20k - GBAnonymous m1cSnEavoBelum ada peringkat

- Presentation IDC20KDokumen12 halamanPresentation IDC20KAnonymous m1cSnEavoBelum ada peringkat

- User Manual IDC20KDokumen12 halamanUser Manual IDC20KAnonymous m1cSnEavoBelum ada peringkat

- Schorling Brock OMF 3TDokumen45 halamanSchorling Brock OMF 3TAnonymous m1cSnEavoBelum ada peringkat

- Kindergarten-DLL Week 1 (June 3-7, 2019)Dokumen7 halamanKindergarten-DLL Week 1 (June 3-7, 2019)Ma. Cristina DumallagBelum ada peringkat

- DD210-V 9604sb PDFDokumen4 halamanDD210-V 9604sb PDFBrandon MoralesBelum ada peringkat

- Digital Logic Design Chapter 5Dokumen28 halamanDigital Logic Design Chapter 5Okezaki TemoyoBelum ada peringkat

- SH 60 TD enDokumen98 halamanSH 60 TD enCésar David Pedroza DíazBelum ada peringkat

- Price DeterminationDokumen2 halamanPrice DeterminationSikander BehalBelum ada peringkat

- SeepageDokumen25 halamanSeepagesheikh jamilBelum ada peringkat

- HSM Info and CommandsDokumen17 halamanHSM Info and CommandsapmountBelum ada peringkat

- A Practical Guide To Fluid Inclusion Studies: Mineralogical Magazine June 1986Dokumen3 halamanA Practical Guide To Fluid Inclusion Studies: Mineralogical Magazine June 1986Aravind KumaraveluBelum ada peringkat

- Norma JIC 37Dokumen36 halamanNorma JIC 37guguimirandaBelum ada peringkat

- Cam Less Engine.1Dokumen15 halamanCam Less Engine.1Pradeep KumarBelum ada peringkat

- AZ-104-MicrosoftAzureAdministrator LAB 02a Manage Subscriptions and RBACDokumen7 halamanAZ-104-MicrosoftAzureAdministrator LAB 02a Manage Subscriptions and RBACgvroctaBelum ada peringkat

- Engineering Materials CE-105: ConcreteDokumen27 halamanEngineering Materials CE-105: Concretenasir khanBelum ada peringkat

- MeDD II Calibration Guide Infusion PumpsDokumen8 halamanMeDD II Calibration Guide Infusion PumpsPaulo Sanches GoncalvesBelum ada peringkat

- AirCheck Detail Report - PK8AP01Dokumen116 halamanAirCheck Detail Report - PK8AP01Trion Ragil NugrohoBelum ada peringkat

- 2019 Sec 4 Pure Chemistry SA2 Anderson SecondaryDokumen65 halaman2019 Sec 4 Pure Chemistry SA2 Anderson SecondaryChloe Tang KYBelum ada peringkat

- Flow in Pipes and Channels - Solved ExamplesDokumen6 halamanFlow in Pipes and Channels - Solved ExamplesEngr Ghulam MustafaBelum ada peringkat

- No Load Test: ObjectiveDokumen5 halamanNo Load Test: ObjectiveyashBelum ada peringkat

- GCSE Higher Student Book Unit Test AnswersDokumen26 halamanGCSE Higher Student Book Unit Test Answersswiftmessi100% (5)

- Rules of MixtureDokumen37 halamanRules of MixtureRahmaF.PuspitaBelum ada peringkat

- Lab ReportDokumen4 halamanLab ReportSyafiq MTBelum ada peringkat

- Face Mask DetectionDokumen34 halamanFace Mask DetectionAmarjeet AmratBelum ada peringkat

- TECHNICAL MATH P1 GR11 MEMO NOV2022 - Afrikaans+EnglishDokumen14 halamanTECHNICAL MATH P1 GR11 MEMO NOV2022 - Afrikaans+EnglishK MhariBelum ada peringkat

- CFD Simulation of NACA Airfoilsat Various Angles of AttackDokumen12 halamanCFD Simulation of NACA Airfoilsat Various Angles of AttackdaifrahunaBelum ada peringkat

- Powerflex 750-Series Ac Drives: Technical DataDokumen242 halamanPowerflex 750-Series Ac Drives: Technical DataJosé Santiago Miranda BernaolaBelum ada peringkat

- Pmi Rda-Rdat Series Batterycharger Userbook - enDokumen44 halamanPmi Rda-Rdat Series Batterycharger Userbook - enABOUDH100% (1)

- Tutorial Summary: 3D Example: Magneto Thermal ApplicationDokumen3 halamanTutorial Summary: 3D Example: Magneto Thermal ApplicationAndrewBelum ada peringkat

- RBH AxiomV Catalog v2011Dokumen16 halamanRBH AxiomV Catalog v2011Sundar RamasamyBelum ada peringkat

- K Type Thermocouple Extension Cable KXYY (1-50) Pairs X 1.5 MM 300 VDokumen1 halamanK Type Thermocouple Extension Cable KXYY (1-50) Pairs X 1.5 MM 300 VArthurBelum ada peringkat

- 88543-Activity Week 3 (Language of Mathematics)Dokumen2 halaman88543-Activity Week 3 (Language of Mathematics)Mylene L RimandoBelum ada peringkat

- Software Engineering 2Dokumen9 halamanSoftware Engineering 2ch muneeb0% (1)