GRP Equal Angle (Cold Formed)

Diunggah oleh

Nurul LailyahJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

GRP Equal Angle (Cold Formed)

Diunggah oleh

Nurul LailyahHak Cipta:

Format Tersedia

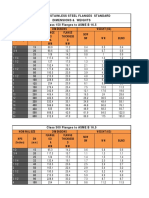

EQUAL ANGLE

PT. GUNUNG RAJA PAKSI

Steel Is Our Business

(COLD FORMED)

METRIC SIZE

STANDARD INFORMATIVE REFERENCE

SECTION

SECTIONAL UNIT CENTER GEOMETRICAL MOMENT RADIUS OF GYRATION MODULUS

AREA OF

DIMENSIONS WEIGHT GRAVITY OF INERTIA OF AREA OF SECTION

H x B t A Cx = C y Ix = Iy Max Iu Min Iv ix = iy Max iu Min iv Zx = Zy

mm x mm mm cm2 kg/m cm cm4 cm4 cm4 cm cm cm cm3

2.0 2.32 1.82 1.60 8.48 13.74 3.22 1.91 2.43 1.18 1.93

2.5 2.88 2.26 1.62 10.44 16.95 3.93 1.90 2.43 1.17 2.39

60 x 60 3.0 3.45 2.71 1.64 12.39 20.02 4.76 1.89 2.41 1.17 2.84

4.0 4.54 3.56 1.68 16.05 26.02 6.09 1.88 2.39 1.16 3.72

5.0 5.59 4.39 1.73 19.49 31.68 7.31 1.87 2.38 1.14 4.57

6.0 6.61 5.19 1.78 22.72 37.00 8.43 1.85 2.37 1.13 5.38

3.0 4.05 3.18 1.89 19.92 32.15 7.70 2.22 2.82 1.38 3.90

3.5 4.70 3.69 1.91 22.96 37.10 8.82 2.21 2.81 1.37 4.51

70 x 70 4.0 5.34 4.19 1.93 25.92 41.93 9.90 2.20 2.80 1.36 5.12

5.0 6.59 5.17 1.98 31.60 51.26 11.95 2.19 2.79 1.35 6.30

6.0 7.81 6.13 2.03 36.99 60.14 13.84 2.18 2.78 1.33 7.44

3.0 4.65 3.65 2.14 30.02 48.38 11.65 2.54 3.22 1.58 5.12

3.5 5.40 4.24 2.16 34.65 55.91 13.38 2.53 3.22 1.57 5.93 Y

80 x 80 4.0 6.14 4.82 2.18 39.17 63.29 15.05 2.53 3.21 1.57 6.73

5.0 7.59 5.96 2.23 47.91 77.60 18.23 2.51 3.20 1.55 8.30 V U

6.0 9.01 7.07 2.28 56.26 91.31 21.21 2.50 3.18 1.53 9.83

3.0 5.85 4.59 2.64 59.39 95.58 23.19 3.19 4.04 1.99 8.07

3.5 6.80 5.34 2.66 68.69 110.67 26.72 3.18 4.03 1.98 9.36 H

100 x 100 4.0 7.74 6.07 2.68 77.83 125.52 30.15 3.17 4.03 1.97 10.64 X

Cx

5.0 9.59 7.53 2.73 95.63 154.51 36.75 3.16 4.01 1.96 13.15

6.0 1.41 8.96 2.78 112.79 182.57 43.00 3.14 4.00 1.94 15.61

3.0 7.05 5.54 3.14 103.50 166.42 40.59 3.83 4.86 2.40 11.68 Cy

U V

3.5 8.20 6.44 3.16 119.89 192.93 46.85 3.82 4.85 2.39 13.56 Y

9.34 7.33 3.18 136.05 219.11 52.99 3.82 4.84 2.38 15.43

B

120 x 120 4.0

5.0 11.58 9.10 3.23 167.64 270.43 64.85 3.80 4.83 2.37 19.11

6.0 13.81 10.84 3.28 198.30 320.40 76.20 3.79 4.82 2.35 22.73

3.0 8.85 6.95 3.89 203.89 327.50 80.27 4.80 6.08 3.01 18.35

3.5 10.30 8.08 3.91 236.52 380.17 92.87 4.79 6.08 3.00 21.33

150 x 150 4.0 11.74 9.21 3.93 268.77 432.29 105.25 4.79 6.07 2.99 24.29

5.0 14.59 11.45 3.98 332.15 534.93 129.36 4.77 6.06 2.98 30.14

6.0 17.41 13.67 4.02 394.04 635.43 152.64 4.76 6.04 2.96 35.90

TECHNICAL SPECIFICATION Technical data : Yield point : 25 kg/mm2 (minimum)

TOLERANCE (mm)

Material : JIS G3350 Tensile Strength 41-55 kg/mm2

t H, B Symbol : SSC 41 Standard length : 6.00 m

HEAD OFFICE & FACTORY

+ 0.5 +2 Chemical Component : C. 0.25% (Maximum)

Jl. Imam Bonjol 4, Warung Bongkok, P. 0.05% (Maximum)

Sukadanau, Cikarang Barat, S. 0.05% (Maximum)

Bekasi 17520, West Java, INDONESIA

Forming Department 1. Non standard length is available request subject to minimum quantity

Phone DID : (62-21) 898 38 291 - 296 2. We provide additional services for standard drilling and punching

(for detail, please refer to standard drilling / punching for lip channel data sheet)

Phone Flexy : (021) 7085 3154 - 158

3. Shot blasting, painting and galvanizing are available on request

Fax. : (62-21) 898 38 298

e-mail : pjl01@grdsteel.com

pjl02@grdsteel.com

www.grdsteel.com

Anda mungkin juga menyukai

- Standard Carbon & Stainless Steel Flange DimensionsDokumen4 halamanStandard Carbon & Stainless Steel Flange Dimensionsl kishore100% (2)

- Cathaloque TMS Bolt & NutsDokumen62 halamanCathaloque TMS Bolt & NutsNurul LailyahBelum ada peringkat

- FlangeDokumen10 halamanFlangeNurul LailyahBelum ada peringkat

- Carboline CathaloqueDokumen99 halamanCarboline CathaloqueNurul LailyahBelum ada peringkat

- Carboline SpecialtiesDokumen6 halamanCarboline SpecialtiesNurul LailyahBelum ada peringkat

- Carboline PhenolinesDokumen12 halamanCarboline PhenolinesNurul LailyahBelum ada peringkat

- Grating WebforgeDokumen20 halamanGrating WebforgeNurul LailyahBelum ada peringkat

- Carboline AlkydsDokumen16 halamanCarboline AlkydsNurul LailyahBelum ada peringkat

- Carboline EpoxiesDokumen24 halamanCarboline EpoxiesNurul LailyahBelum ada peringkat

- CTS Cargo Transfer SystemDokumen28 halamanCTS Cargo Transfer SystemNurul LailyahBelum ada peringkat

- Carboline High Temp FinishesDokumen8 halamanCarboline High Temp FinishesNurul LailyahBelum ada peringkat

- Carboline Chlorinated RubbersDokumen6 halamanCarboline Chlorinated RubbersNurul LailyahBelum ada peringkat

- GRP Welded BeamDokumen2 halamanGRP Welded BeamNurul LailyahBelum ada peringkat

- Expanded Metal 1Dokumen6 halamanExpanded Metal 1Nurul LailyahBelum ada peringkat

- Carboline Color SelectorDokumen4 halamanCarboline Color SelectorNurul LailyahBelum ada peringkat

- Flowserve - BrochureDokumen12 halamanFlowserve - BrochureNurul LailyahBelum ada peringkat

- Carboline PolyurethanesDokumen8 halamanCarboline PolyurethanesNurul LailyahBelum ada peringkat

- Triplefast FastenerDokumen4 halamanTriplefast FastenerNurul LailyahBelum ada peringkat

- Katalog PT Gunung Garuda Steel WF ProfileDokumen4 halamanKatalog PT Gunung Garuda Steel WF ProfileibnugantengBelum ada peringkat

- Carbomastic BitumasticDokumen10 halamanCarbomastic BitumasticNurul LailyahBelum ada peringkat

- GGB Wire NailDokumen1 halamanGGB Wire NailNurul LailyahBelum ada peringkat

- GRP Steel PipeDokumen2 halamanGRP Steel PipeNurul LailyahBelum ada peringkat

- Tabel Baja StellaDokumen1 halamanTabel Baja StellaAlexander IgnatiusBelum ada peringkat

- GRP Expanded MeshDokumen1 halamanGRP Expanded MeshNurul LailyahBelum ada peringkat

- GG T-BeamDokumen1 halamanGG T-BeamSurya DirmansyahBelum ada peringkat

- 11-LippedChannel (CNP)Dokumen1 halaman11-LippedChannel (CNP)Surya DirmansyahBelum ada peringkat

- Tabel Besi BetonDokumen1 halamanTabel Besi BetonAlexander IgnatiusBelum ada peringkat

- GRP Rectangular Tube PipeDokumen1 halamanGRP Rectangular Tube PipeNurul LailyahBelum ada peringkat

- PT. GUNUNG GAHAPI BAHARA Steel Anchor Bolt SpecsDokumen1 halamanPT. GUNUNG GAHAPI BAHARA Steel Anchor Bolt SpecsAndri Mutiar0% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- 8508A Reference Multimeter PDFDokumen7 halaman8508A Reference Multimeter PDFNicole FloydBelum ada peringkat

- Accounting TransactionsDokumen6 halamanAccounting TransactionsCelyn DeañoBelum ada peringkat

- CCGNHS Ste Stem SB Resolution 2023Dokumen7 halamanCCGNHS Ste Stem SB Resolution 2023Rhodail Andrew CastroBelum ada peringkat

- Surfer 8 GuideDokumen664 halamanSurfer 8 GuideYuliana DomínguezBelum ada peringkat

- Wild Shapes - Up To CR 6, Including Elementals - The HomebreweryDokumen33 halamanWild Shapes - Up To CR 6, Including Elementals - The HomebreweryKortlyBelum ada peringkat

- Hubungan Kelimpahan Dan Keanekaragaman Fitoplankton Dengan Kelimpahan Dan Keanekaragaman Zooplankton Di Perairan Pulau Serangan, BaliDokumen12 halamanHubungan Kelimpahan Dan Keanekaragaman Fitoplankton Dengan Kelimpahan Dan Keanekaragaman Zooplankton Di Perairan Pulau Serangan, BaliRirisBelum ada peringkat

- Biology of KundaliniDokumen591 halamanBiology of KundaliniMaureen Shoe100% (24)

- Flyht Case SolutionDokumen2 halamanFlyht Case SolutionkarthikawarrierBelum ada peringkat

- Balochistan Wildlife Rodini KachoDokumen17 halamanBalochistan Wildlife Rodini KachoMohammad Yahya MusakhelBelum ada peringkat

- CASR PART 43 Amdt. 1 PDFDokumen21 halamanCASR PART 43 Amdt. 1 PDFarbypratamax66100% (1)

- Iso 128-34-2001 PDFDokumen18 halamanIso 128-34-2001 PDFAhmed MaaloulBelum ada peringkat

- Performance Analysis of A Dual Cycle Engine With Considerations of Pressure Ratio and Cut-Off RatioDokumen6 halamanPerformance Analysis of A Dual Cycle Engine With Considerations of Pressure Ratio and Cut-Off RatioRajanish BiswasBelum ada peringkat

- Software Verification: AISC 360-16 SFD Example 001Dokumen7 halamanSoftware Verification: AISC 360-16 SFD Example 001Dompu MengajiBelum ada peringkat

- Microsoft Education Product LicensingDokumen66 halamanMicrosoft Education Product LicensingnguyentricuongBelum ada peringkat

- Regional Rural Banks RRBsDokumen11 halamanRegional Rural Banks RRBsChintan PandyaBelum ada peringkat

- MELC 3 Employ The Appropriate Communicative Styles For Various Situations (Intimate, Casual, Conversational, Consultative, Frozen)Dokumen2 halamanMELC 3 Employ The Appropriate Communicative Styles For Various Situations (Intimate, Casual, Conversational, Consultative, Frozen)Mar Sebastian82% (11)

- Katie SwansonDokumen1 halamanKatie Swansonapi-254829665Belum ada peringkat

- Automata and Complexity Theory ModuleDokumen104 halamanAutomata and Complexity Theory ModuleSurafelBelum ada peringkat

- Lviv in Your Pocket - October December 2009Dokumen23 halamanLviv in Your Pocket - October December 2009Anti FreezeBelum ada peringkat

- Polymer Solar Cells PDFDokumen19 halamanPolymer Solar Cells PDFJulio Andrés Casal RamosBelum ada peringkat

- Critical Success FactorsDokumen12 halamanCritical Success Factorsmoon1377Belum ada peringkat

- Customer No.: 22855256 IFSC Code: DBSS0IN0811 MICR Code: Branch AddressDokumen9 halamanCustomer No.: 22855256 IFSC Code: DBSS0IN0811 MICR Code: Branch AddressBalakrishna SBelum ada peringkat

- s7 1500 Compare Table en MnemoDokumen88 halamans7 1500 Compare Table en MnemoPeli JorroBelum ada peringkat

- Chicken Run: Activity Overview Suggested Teaching and Learning SequenceDokumen1 halamanChicken Run: Activity Overview Suggested Teaching and Learning SequencePaulieBelum ada peringkat

- Ala CalculationDokumen4 halamanAla CalculationAgus SupriadiBelum ada peringkat

- A Project About Wild Animals Protection Week and Kalakad Mundanthurai Tiger ReserveDokumen50 halamanA Project About Wild Animals Protection Week and Kalakad Mundanthurai Tiger ReserveSweetBelum ada peringkat

- Parallel RLC Circuit Measurements and CalculationsDokumen14 halamanParallel RLC Circuit Measurements and CalculationsJay BetaizarBelum ada peringkat

- Topic 3 - V1 (Social Context of Computing)Dokumen34 halamanTopic 3 - V1 (Social Context of Computing)Yehasha HarshaniBelum ada peringkat

- Process Maps and Turtle DiagramsDokumen1 halamanProcess Maps and Turtle Diagramskyle1991100% (1)

- PGP-AIML Curriculum - Great LakesDokumen43 halamanPGP-AIML Curriculum - Great LakesArnabBelum ada peringkat