Flowserve - Brochure

Diunggah oleh

Nurul LailyahHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Flowserve - Brochure

Diunggah oleh

Nurul LailyahHak Cipta:

Format Tersedia

Valdisk Control Valves

TB010 Valdisk R23.p65 1 9/19/01, 2:37 PM

Valtek Valdisk Control Valves

Control Valves

Compact, field

reversible actuator

Jam-lever Toggle soft seal

ANSI Class IV shutoff metal seal

ANSI Class VI shutoff soft seal Splined shaft with

single pivot point

Non-selective disc and for actuator to

shaft for reduced cost disc connection

Valtek

Beta

Self-centering seal

Figure 1: Valdisk Design

The high performance Valtek ValdiskTM rotary control valve

uses pressure assisted Jam-lever ToggleTM seating concepts

to achieve bi-directional, bubble-tight shutoff while maintaining

low breakout torque at both high and low pressure drops.

Valdisk is available in carbon steel, 316 stainless steel and

other alloys and is available in ANSI Classes 150 through 2500,

sizes 2 through 30-inch.

Jam-lever Toggle seating assures low breakout torque by

utilizing the pressure drop across the valve to aid the seating VALVE

CENTERLINE

process. Since much of the seating force is supplied by the

DISC

pressure drop, the need for strong actuator seating force and CENTERLINE

therefore breakout torque is reduced. Combined with

Valdisks high-thrust cylinder actuator and eccentric-cammed

disc, it is possible to achieve especially high performance

throttling even in large pressure drops close to the seat.

Valdisks Eccentric Cammed Disc

A double offset has been designed into the disc to lift it out of

the seat immediately upon actuation. This avoids wear on the Figure 2: Eccentric-cammed

seat and disc, reducing leakage and parts replacement. It also Disc Rotation

improves throttling by eliminating friction.

2 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

TB010 Valdisk R23.p65 2 9/19/01, 2:37 PM

Valtek Valdisk Control Valves

Features and Advantages

Valdisks high performance is assured by the following features:

Features Advantages

Jam-lever Toggle Bubble-tight shutoff equal to ANSI Class VI

soft seat Low breakout torque assures accurate throttling, even close to the seat

Non clogging seat design

Easy removal

Metal and dual seat Shutoff better than ANSI Class IV

Eccentric-cammed disc Disc pulls out of seat immediately, preventing seat wear

Accurate throttling due to disc profile when rotating into the seat

Single pivot-point, splined shaft Lost motion minimized between shaft and actuator

Bolted seat retainer Uninterrupted gasket surface allows for a wide variety of gasketing

Non-selective disc and shaft Easier maintenance

Reduced cost only replace needed part, not entire assembly

Wafer body Rugged and lightweight for easy handling and maintenance

One body serves ANSI Classes 150, 300 and 600 in sizes 2, 3, 4, 6 and 8

Industry standard MSS SP-67 permits shorter flange bolting than ball

or cammed valves, increasing safety and reducing possibility of leakage

Flow capacity Capacity greater than globe, plug and cammed control valves

Concave disc Increased flow capacity

Disc stop in body Prevents damage to seat due to overstroking

Permits in-line disc relocation during maintenance

Wide variety of packing Purged bonnet and lubricator options

box configurations

Factory Mutual Approved Used as fuel service valve on industrial furnaces or ovens

Fully enclosed, air purged Extra safety

transfer case Prevents atmospheric corrosion of actuator internals

Disc position indicator mounted on transfer case

Valdisk also capitalizes on established features of Valtek product lines:

Cylinder actuator High thrust for high performance throttling

Compact and lightweight for easier servicing and maintenance

Fully interchangeable with ShearStream ball valve actuator

Actuator air pressures allowable up to 150 psi (10.3 bar)

Wide interchangeability Spare parts stocking requirements minimized

Inventory costs reduced

Many Mark One and ShearStream parts are interchangeable with Valdisk

Available in variety of materials Carbon steel, 316 stainless steel and other alloys

Seat interchangeability Metal or TFE seats easily installed

Spool-type four-way positioner Convertible between I/P and P/P

Calibration and maintenance easy due to fewer parts

The combined features designed into Valdisk create a valve measurably superior to all other rotary valves.

The information and specifications contained in the following pages are provided for comparison.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 3

TB010 Valdisk R23.p65 3 9/19/01, 2:38 PM

Valtek Valdisk Control Valves

Seats

Jam-lever Toggle seating concepts utilize the pressure

drop across the valve to help energize the soft seat to

bubble-tight shutoff in either flow direction, including Pressure

alternating flow applications. This is done in such a way

shaft F2

F2 downstream

that seating capacity is increased as differential pres-

sure is increased. Jam-lever Toggle soft seats achieve Pressure

ANSI Class VI shutoff. shaft

upstream

Jam-lever Effect (Figure 3) F1

As pressure enters the seat cavity with the shaft down- F1

stream, the seat jams or rotates into the disc, causing it

to seat tighter against the disc.

Toggle Effect (Figure 4)

As pressure enters the seat cavity with the shaft up-

Figure 3: Figure 4:

stream, the seat tends to toggle or flatten out, causing

it to seat tighter against the disc. Jam-lever Effect Toggle Effect

Pressure "jams"

lever edge

Disc of seat Disc Disc Disc

into disc

Pressure

Gasket Soft Seat

flattens seat

forcing it

to "toggle"

Body Metal

into disc

Retainer Retainer Seat Seat

Body Body

Body

Soft Seat Metal Seat Dual Seat

Figure 5: Principles of Figure 6:

Jam-lever Toggle Seating Additional Seat Configurations

4 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

TB010 Valdisk R23.p65 4 9/19/01, 2:38 PM

Valtek Valdisk Control Valves

Seats, FL

Metal Seat Liquid Pressure Recovery Factor, FL

Metal seats are used for applications involving tem- The liquid pressure recovery factor, FL, predicts the

peratures higher than those permitted by the Jam-lever amount of pressure recovery that will occur between the

Toggle soft seat. The design incorporates a highly vena contracta and the valve outlet. This accounts for

flexible lip, which assures full circle contact between the the influence of the valves internal geometry on the

seat and disc when the valve is closed. Because of lip maximum capacity of the valve and the tendency to

flexibility, breakout torque for the metal seat is the same choke or cavitate. Smaller FL will cavitate earlier.

or less than soft seat breakout torque. Valdisk metal Figure 7 shows the FL of the Valdisk valve as compared

seats achieve ANSI Class IV shutoff. to a typical butterfly valve. The Valdisk FL is between a

Dual Seat typical butterfly and globe valve. The tendency to cavi-

tate or choke will be more than a globe valve but less

Valdisk dual seats incorporate both the Jam-lever Toggle

than the typical butterfly valve.

soft seat and flexible lip metal seat for added protection.

The dual seat can achieve Class IV leakage. .95

Flow Direction .90

Valdisk

Jam-lever Toggle seating allows Valdisk to flow either .85

shaft downstream or shaft upstream, depending on

.80

service conditions. With the shaft downstream, the flow

tends to open the valve. With the shaft upstream, the FL .75

flow tends to close the valve. Typical

.70 Butterfly

Flow Characteristics .65

The inherent flow characteristic of the Valdisk valve is .60

a modified parabolic relationship. Other characteristics

are obtained by substituting an interchangeable cam in .55

0 10 20 30 40 50 60 70 80 90 100 110

the Valtek Beta positioner that is shaped to furnish the

Percent Open

desired output. Cams are available to provide inherent

linear and equal percent flow characteristics, as well as Figure 7: Valdisk FL Curves

a linear relationship between signal and shaft rotation.

Taper Pins

Disc Shaft Bearing

Body

Seat Shaft

Shaft Plug Inner Packing

Outer Packing

Gland Flange

Packing Box Stud

Packing Box Nut

O-ring

Packing Follower

Packing Spacer

Shaft Bearing Disc Stop Packing Retainer

Figure 8: Body Subassembly, Section View

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 5

TB010 Valdisk R23.p65 5 9/19/01, 2:38 PM

Valtek Valdisk Control Valves

Specifications

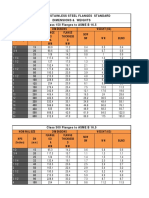

Table I: Maximum Allowable Shutoff Pressure Drops (psi)*

Valve Flow Temperature Valve Size (inches)

Description Dir. (F) (C) 2 3 4 6 8 10 12 14 16 18 20 24 30

Body: carbon steel -20 to 100 -29 to 38 954 1000 1011 650 833 550 740 285 285 285 285 285 285

Shaft & pins: 17-4 PH 200 93 705 705 705 650 705 550 705 260 260 260 260 260 260

Disc: 316 stainless steel (1) 300 149 420 420 420 420 420 420 420 230 230 230 230 230 230

Shaft Upstream or

or carbon steel 400 204 150 150 150 150 150 150 150 150 150 150 150 150 150

Downstream

Seat: TFE/Glass-filled (2) 450 232 50 50 50 50 50 50 50 50 50 50 50 50 50

Body: 316 stainless steel -20 to 100 -29 to 38 954 1000 1011 650 833 550 720 275 275 275 275 275 275

Shaft & Pins: 17-4 PH or 200 93 705 705 705 650 705 550 705 240 240 240 240 240 240

Nitronic 50 (3) 300 149 420 420 420 420 420 420 420 215 215 215 215 215 215

Disc: 316 stainless steel 400 204 150 150 150 150 150 150 150 150 150 150 150 150 150

Seat: TFE/Glass-filled (2) 450 232 50 50 50 50 50 50 50 50 50 50 50 50 50

Downstream

Body: 316 stainless steel -450 to 200 -268 to 93 593 593 593 593 593 593 593 275 275 275 275 275 275

Shaft

or carbon steel** 400 204 370 370 370 370 370 370 370 240 240 240 240 240 240

Shaft & Pins: Nitronic 50 (4) 600 316 318 318 318 318 318 318 318 215 215 215 215 215 215

Disc: 316 stainless steel 800 427 310 310 310 310 310 310 310 150 150 150 150 150 150

Body: 316 stainless steel -450 to 200 -268 to 93 296 296 296 296 296 296 296 275 275 275 275 275 275

Upstream

Shaft

or carbon steel** 400 204 185 185 185 185 185 185 185 185 185 185 185 185 185

Shaft & Pins: Nitronic 50 (4) 600 316 159 159 159 159 159 159 159 159 159 159 159 159 159

Disc: 316 stainless steel 800 427 155 155 155 155 155 155 155 150 150 150 150 150 150

Body: 316 stainless steel -20 to 100 -29 to 38 954 1000 1011 650 833 550

Shaft & Pins: 17-4 PH 200 93 720 720 720 650 720 550

Disc: 316 stainless steel 300 149 530 530 530 530 530 530

Seat: PEEK 400 204 300 300 300 300 300 300

500 260 70 70 70 70 70 70

Body: Monel 400 -20 to 100 -29 to 38 865 910 920 592 758

Shaft & Pins: Monel K-500 200 93 705 705 705 592 705

Disc: Monel 300 149 420 420 420 420 420

Shaft Upstream or

Seat: TFE/Glass-filled (2) 400 204 150 150 150 150 150

Downstream

450 232 50 50 50 50 50

Body: Hastelloy C -20 to 100 -29 to 38 735 780 790 509 655

Shaft & Pins: Hastelloy C 200 93 700 705 705 492 631

Disc: Hastelloy C 300 149 420 420 420 420 420

Seat: TFE/Glass-filled (2) 400 204 150 150 150 150 150

450 232 50 50 50 50 50

Body: Alloy 20 (5) -20 to 100 -29 to 38 295 321 340 220 276

Shaft & Pins: Alloy 20 200 93 258 281 297 191 239

Disc: Alloy 20 300 149 218 238 251 161 202

Seat: TFE/Glass-filled (2) 400 204 150 150 150 150 150

450 232 50 50 50 50 50

* Consult factory for higher pressure drops and different material component combinations.

** Do not use WCB carbon steel below -20 F

(1) 316 stainless steel disc standard through 8-inch, carbon steel chrome plated disc standard 10 to 30-inch

(2) Maximum allowable shutoff delta pressure reduced 70 psi (4.8 Bar) for virgin TFE

(3) Hardened

(4) At temperatures above 800 F, Inconel 718 shaft and pins must be used.

(5) Alloy 20 has not been formally listed by ANSI or ASME for temperatures above 300 F.

6 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

TB010 Valdisk R23.p65 6 9/19/01, 2:38 PM

Valtek Valdisk Control Valves

Specifications

Table II: Maximum Allowable Inlet Pressures*

for Various Body Ratings and Temperatures (psi)

WCB Steel 316 Stainless Alloy 20 Hastelloy CTM MonelTM

Temperature (A216)** Steel (SA-351- (A351-CN7M)** -276** 400**

CF8M)**

F C Pressure Class Pressure Class Pressure Class Pressure Class Pressure Class

150 300 600 150 300 600 150 300 600 150 300 600 150 300 600

-20 to 100 -29 to 38 285 740 1480 275 720 1440 230 600 1200 290 750 1500 230 600 1200

200 93 260 675 1350 240 620 1240 215 555 1115 260 732 1465 200 530 1055

300 149 230 655 1315 215 560 1120 200 525 1045 230 693 1388 190 495 990

400 204 200 635 1270 195 515 1030 200 693 1388 185 480 955

500 260 170 600 1200 170 480 955 185 600 1200 170 475 950

600 316 140 550 1095 140 450 905 140 550 1095 140 475 950

700 371 110 535 1065 110 430 865 110 535 1065 110 475 950

800 427 80 410 825 80 415 830 80 410 825 80 460 915

900 482 50 170 345 50 395 790

1000 538 20 50 105 20 365 725

1100 593 325 645

1200 649 205 410

* For Maximum P, refer to Table I.

** Values as recorded in ANSI B16.34-1988.

Table III:

Flow Coefficients/Flange Compatibility Table IV: Seat Leakage

ANSI Rating Metal Seat ANSI Class IV

Body CV Flange Jam-lever Toggle Soft Seat ANSI Class VI

Size (90 rotation) Compatibility

Flow ring 2.5% of rated CV

(inches) Shaft Shaft (pressure class)*

up down Dual Seat ANSI Class IV

2 63 58 150, 300, 600

3 134 123

4 349 242

Table V: Estimated Shipping Weights

(with Actuator and Positioner)

6 817 819

8 1644 1563 Valve Size Weight Valve Size Weight

10 2780 2640 150, 300 2 40 14 280

12 4000 3860 3 50 16 320

14 6640 6380 150 4 60 18 390

16 8400 8070 6 80 20 540

18 10350 9950

8 120 24 680

20 13670 13300

10 190 30 830

24 20200 19600

* Consult factory for higher pressure classes 12 250

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 7

TB010 Valdisk R23.p65 7 9/19/01, 2:38 PM

Valtek Valdisk Control Valves

Specifications

Table VI: Material Selection Temperature Chart

-268

-240

-212

-184

-157

-129

-18

93

121

149

177

204

232

260

288

316

343

371

399

427

454

482

510

538

566

593

621

649

Temperature (C)

Temperature (F)

0

-450

-400

-350

-300

-250

-200

200

250

300

350

400

450

500

550

600

650

700

750

800

850

900

950

1000

1050

1100

1150

1200

316 Stainless Steel

Body / Disc

Carbon Steel (1)

Monel

Hastelloy C

Alloy 20 (2)

17-4 PH

Nitronic 50

Shaft

Inconel

Monel

Hastelloy C

Bearings

304 Stainless Steel / TFE Lined

Ultimet

Alloy 6

Glass-filled TFE

Soft Seat

Virgin TFE

PEEK

PCTFE

Metal

316 Stainless Steel

Seat

316 Stainless Steel w/Alloy 6 Overlay

TFE V-rings

Packing

Glass-filled TFE V-rings

Graphite

Braided Asbestos Free (3)

(1) Permissible at temperatures above 800 F (427 C), but not recommended for prolonged exposure at these elevated tempera-

ture because of the possibility of graphitization.

(2) Alloy 20 has not been formally listed by ANSI or ASME for temperatures above 600 F (315 C) for castings, 800 F (427 C) for

forgings or plate

(3) Garlock 127 AFP or equivalent

The darker shaded areas indicate increased temperature capacity of an extended body.

8 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

TB010 Valdisk R23.p65 8 9/19/01, 2:38 PM

Valtek Valdisk Control Valves

Mounting Orientations

Shaft Upstream

Right-hand Mounting (standard)

Air-to-Open

Fail Closed

Air-to-Close

Fail Open

Shaft Downstream

Right-hand Mounting (optional)

Air-to-Open Air-to-Open

Fail Closed Fail Closed

Air-to-Close

Fail Open

Left-hand Mounting (optional) Air-to-Close

Fail Open

Air-to-Open

Fail Closed

Air-to-Close

Fail Open

Left-hand Mounting (standard)

Actuator Orientation Handwheel Orientation

Note: Orientations 2 and 4 are not Note: These orientations are in relation

available on some actuator sizes. to the pipeline.

D

1 1

C

2 4

4 2 A

3 3

B

Figure 9: Transfer Case Mounting

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 9

TB010 Valdisk R23.p65 9 9/19/01, 2:38 PM

Valtek Valdisk Control Valves

Dimensions

DISASSEMBLY

J E CLEARANCE

F

T (Dia.) H

S (Seat Dia.)

S

Valtek

Beta

S

G

A B C K

D

DISASSEMBLY

CLEARANCE

Table VII: Valdisk Dimensions (inches / mm)

BODY CLASSES 150, 300, 600 2 thru 8-inch; 150, 300 10 thru 12-inch

(with Class 150 or 300 disc and shaft)

Actuator Face-to-

Size Size Shaft Face* B C D E F G H J K S T

(in.) (sq.in.) Size A

2 25 0.625 1.8 44 4.3 110 11.4 288 18.3 465 6.0 152 13.1 333 5.6 142 1.1 29 6.5 165 6.5 166 1.7 43 4.0 102

2 50 0.625 1.8 44 4.3 110 11.4 288 19.1 485 8.0 203 18.0 457 6.7 170 2.0 50 9.1 232 7.4 188 1.7 43 4.0 102

3 25 0.625 1.9 48 5.1 130 11.7 298 18.7 475 6.0 152 13.1 333 5.6 142 1.1 29 6.5 165 6.5 166 2.6 66 5.4 137

3 50 0.625 1.9 48 5.1 130 11.7 298 19.5 495 8.0 203 18.0 457 6.7 170 2.0 50 9.1 232 7.4 188 2.6 66 5.4 137

4 25 0.750 2.1 54 5.9 151 12.4 315 19.4 493 6.0 152 13.1 333 5.6 142 1.1 29 6.5 165 6.5 166 3.7 93 6.8 171

4 50 0.750 2.1 54 5.9 151 12.4 315 20.2 513 8.0 203 18.0 457 6.7 170 2.0 50 9.1 232 7.4 188 3.7 93 6.8 171

6 50 0.875 2.3 57 7.6 192 14.3 363 22.1 561 8.0 203 18.0 457 6.7 170 2.0 50 9.1 232 7.4 188 5.5 141 8.5 216

6 100 0.875 2.3 57 7.6 192 14.3 363 24.5 622 11.0 279 22.6 574 9.1 230 2.4 61 12.5 318 8.5 215 5.5 141 8.5 216

8 50 1.125 2.5 64 8.6 219 16.3 415 24.1 612 8.0 203 18.0 457 6.7 170 2.0 50 9.1 232 7.4 188 7.2 182 10.8 273

8 100 1.125 2.5 64 8.6 219 16.3 415 26.5 673 11.0 279 22.6 574 9.1 230 2.4 61 12.5 318 8.5 215 7.2 182 10.8 273

10 50 1.125 2.8 71 9.7 246 17.5 444 25.2 640 8.0 203 18.0 457 6.7 170 2.0 50 9.1 232 7.4 188 9.2 233 12.8 324

10 100 1.125 2.8 71 9.7 246 17.5 444 27.7 704 11.0 279 22.6 574 9.1 230 2.4 61 12.5 318 8.5 215 9.2 233 12.8 324

12 100 1.500 3.2 81 11.2 283 18.7 474 28.9 734 11.0 279 22.6 574 9.1 230 2.4 61 12.5 318 8.5 215 11.0 280 15.0 381

All dimensions are to be used for estimation only. Certified drawings will be supplied upon request.

For 14 thru 30-inch Valdisk, contact factory.

* MSS SP67 Body Only

10 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

TB010 Valdisk R23.p65 10 9/19/01, 2:38 PM

Valtek Valdisk Control Valves

Dimensions, Ordering Information

DISASSEMBLY

E CLEARANCE

FF

SH

N

PE P

UT

O

M

S

O

N R

Table VIII: Handwheel and Extended, Heavy-duty Spring Dimensions (inches/mm)

Actuator Size

E FF M N P R

(sq. in.)

25 9.3 236 17.3 439 10.0 254 9.8 249 2.6 66 7.4 188

50 9.8 249 23.8 605 12.0 305 10.3 262 3.4 86 10.1 257

100 8.5 216 23.0 584 18.0 457 13.3 338 5.4 137 9.7 246

200 9.0 229 24.3 617 18.0 457 13.3 338 5.4 137 9.7 246

Ordering Information

The following information must be provided when 5. Materials required: body, disc, shaft, packing

ordering a Valdisk control valve: and bearings

6. Line size and schedule

1. Preferred body size and critical dimensions

7. Specify if used as FM APPROVED fuel

2. Start-up and operating conditions: inlet and service valve (sizes 2, 3, 4, 6-inches)

outlet pressures; temperature, flow rate, fluids 8. Actuator requirements: type (pneumatic or

specific gravity or molecular weight, vapor pres- manual), failure position, size and minimum

sure or gas compressibility air supply

3. Maximum operating temperatures and 9. Actuator position: style and orientation

pressures (Figure 9)

4. Body and disc pressure rating 10. Accessories required

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 11

TB010 Valdisk R23.p65 11 9/19/01, 2:38 PM

Valtek Valdisk Control Valves

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this

Flowserve product is designed to perform its intended function safely during its useful life. However, the purchaser or user of Flowserve

products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial service

conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all

possible applications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation,

operation and maintenance of Flowserve products. The purchaser/user should read and understand the Installation Operation Mainte-

nance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in

connection with the specific application.

While the information and specifications presented in this literature are believed to be accurate, they are supplied for informative purposes

only and should not be considered certified or as a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be

construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve is

continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to

change without notice. Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation

at any of its worldwide operations or offices.

Hastelloy C is a trademark of Cabit Corporation. Monel is a trademark of Huntington Alloy.

For more information about Flowserve and its products,

contact www.flowserve.com or call USA 972 443 6500

For more information, contact:

Regional Headquarters Quick Response Centers

1350 N. Mt. Springs Prkwy. 5114 Railroad Street

Springville, UT 84663 Deer Park, TX 77536 USA

Phone 801 489 8611 Phone 281 479 9500

Facsimile 801 489 3719 Facsimile 281 479 8511

12 Tuas Avenue 20 104 Chelsea Parkway

Republic of Signapore 638824 Boothwyn, PA 19061 USA

Phone (65) 862 3332 Phone 610 497 8600

Facsimile (65) 862 4940 Facsimile 610 497 6680

12, av. du Qubec, B.P. 645 1300 Parkway View Drive

91965, Courtaboeuf Cedex, France Pittsburgh, PA 15205 USA

Phone (33 1) 60 92 32 51 Phone 412 787 8803

Facsimile (33 1) 60 92 32 99 Facsimile 412 787 1944

APPROVED

as Fuel Service Valve

Flowserve and Valtek are registered trademarks of Flowserve Corporation.

(NFPA 86 A - B)

FCD VLATB010-23 2001 Flowserve Corporation. Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

TB010 Valdisk R23.p65 12 9/19/01, 2:38 PM

Anda mungkin juga menyukai

- ValtekDokumen20 halamanValtekhugolm9-1100% (1)

- 5950 Service Manual AA2206 - En-BDokumen320 halaman5950 Service Manual AA2206 - En-BAsad Kazmi100% (1)

- BS 6399 PDFDokumen22 halamanBS 6399 PDFTeoh ChunliBelum ada peringkat

- Standard Carbon & Stainless Steel Flange DimensionsDokumen4 halamanStandard Carbon & Stainless Steel Flange Dimensionsl kishore100% (2)

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsDari EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsPenilaian: 4 dari 5 bintang4/5 (1)

- Iso 179 1 2023Dokumen12 halamanIso 179 1 2023Quin TasyaBelum ada peringkat

- MarlinDokumen28 halamanMarlincumpio425428Belum ada peringkat

- STORAGE - Bentall Rowlands Storage Systems Limited Talks Grain StorageDokumen4 halamanSTORAGE - Bentall Rowlands Storage Systems Limited Talks Grain StorageMilling and Grain magazineBelum ada peringkat

- Notes On Tripping RelaysDokumen7 halamanNotes On Tripping RelaysSenthil KumarBelum ada peringkat

- GRP Expanded MeshDokumen1 halamanGRP Expanded MeshNurul LailyahBelum ada peringkat

- Tabel Baja StellaDokumen1 halamanTabel Baja StellaAlexander IgnatiusBelum ada peringkat

- 07 - Vee BoDokumen68 halaman07 - Vee BochinnaBelum ada peringkat

- PT. GUNUNG GAHAPI BAHARA Steel Anchor Bolt SpecsDokumen1 halamanPT. GUNUNG GAHAPI BAHARA Steel Anchor Bolt SpecsAndri Mutiar0% (1)

- PLN-1200-3.07-01, Iss 01 - Product Catalogue PDFDokumen12 halamanPLN-1200-3.07-01, Iss 01 - Product Catalogue PDFsakscribBelum ada peringkat

- DXXX-1710-26901710-26901710-2690-656565-18i18i18i-MMM-R (ANT-ATR4518R14-...Dokumen2 halamanDXXX-1710-26901710-26901710-2690-656565-18i18i18i-MMM-R (ANT-ATR4518R14-...Cesar Augusto Ribeiro Aroeira80% (5)

- ISO - IEC 25000 2014 Ed.2 - Id.64764 Publication PDF (En)Dokumen34 halamanISO - IEC 25000 2014 Ed.2 - Id.64764 Publication PDF (En)dushyantsahniBelum ada peringkat

- Valdisk Manual PDFDokumen12 halamanValdisk Manual PDFNag RajBelum ada peringkat

- Valdisk150TBDokumen8 halamanValdisk150TBpanametshBelum ada peringkat

- Flowserve Mark OneDokumen20 halamanFlowserve Mark OnetinozasableBelum ada peringkat

- Vlentb0001-02-Aq (LR)Dokumen20 halamanVlentb0001-02-Aq (LR)Milos BajicBelum ada peringkat

- Valtek Mark One Control Valves Valtek Mark One Control ValvesDokumen21 halamanValtek Mark One Control Valves Valtek Mark One Control ValvesMgc ElektronikBelum ada peringkat

- Control Valve - FlowserveDokumen12 halamanControl Valve - FlowserveDGWBelum ada peringkat

- Cpe Pacific Forged Ps Tds en A4 2019-04-15 WebDokumen12 halamanCpe Pacific Forged Ps Tds en A4 2019-04-15 WebKumarBelum ada peringkat

- Valtek MK1Dokumen32 halamanValtek MK1DrakzBelum ada peringkat

- Flowserve Valdisk TX3Dokumen8 halamanFlowserve Valdisk TX3RodrigoAndrés Cepeda PérezBelum ada peringkat

- Angle Valve - FlowserveDokumen4 halamanAngle Valve - FlowserveSreekanth Suresh KamathBelum ada peringkat

- Series 2200 Butterfly Valve Product BrochureDokumen18 halamanSeries 2200 Butterfly Valve Product BrochureSandesh KambleBelum ada peringkat

- Duo-Chek II - The High Performance Check ValveDokumen27 halamanDuo-Chek II - The High Performance Check ValveZak CahuichBelum ada peringkat

- ButterflyValves PDFDokumen4 halamanButterflyValves PDFmkiani2Belum ada peringkat

- ActuadrotativaltekDokumen8 halamanActuadrotativaltekEduardo Landa GonzalezBelum ada peringkat

- Delta T Series High Performance Butterfly Valves BrochureDokumen8 halamanDelta T Series High Performance Butterfly Valves BrochureOnkar DograBelum ada peringkat

- W4.9 Ozkan Seal On Disc Butterfly Valve PDFDokumen8 halamanW4.9 Ozkan Seal On Disc Butterfly Valve PDFmanmohansingh1999Belum ada peringkat

- Experience High Performance Across A Broad Range of ApplicationsDokumen12 halamanExperience High Performance Across A Broad Range of ApplicationsOlegario PalmaBelum ada peringkat

- Double Offset High Performance Butterfly Valves: DescriptionDokumen16 halamanDouble Offset High Performance Butterfly Valves: Descriptionmanmohansingh1999Belum ada peringkat

- Valtek Maxflo: Control ValvesDokumen11 halamanValtek Maxflo: Control Valvessaroat moongwattanaBelum ada peringkat

- Wärtsilä Seals and Bearings Linesafe DatasheetDokumen4 halamanWärtsilä Seals and Bearings Linesafe DatasheetFERMIN ARTEAGABelum ada peringkat

- Section S - Double Offset High Performance Butterfly Valves: DescriptionDokumen17 halamanSection S - Double Offset High Performance Butterfly Valves: Descriptionjhonny sanchezBelum ada peringkat

- Apollo-HP 215L-215WDokumen16 halamanApollo-HP 215L-215WDaniel SanBelum ada peringkat

- Documentatie Flowserve Schmidt Armaturen 3 3 Vana Control FlowProDN25 300 PN63 160 DIN Sialco Reprezentanta Flowserve RomaniaDokumen28 halamanDocumentatie Flowserve Schmidt Armaturen 3 3 Vana Control FlowProDN25 300 PN63 160 DIN Sialco Reprezentanta Flowserve Romaniajns1606Belum ada peringkat

- VST - Axial Flow Catalog - 2021.R010Dokumen6 halamanVST - Axial Flow Catalog - 2021.R010Jaydeep PanchalBelum ada peringkat

- Large Vertical Circulating Water Pumps 12182013Dokumen8 halamanLarge Vertical Circulating Water Pumps 12182013yogeshBelum ada peringkat

- The Axial Flow Valve: Class 300/600Dokumen12 halamanThe Axial Flow Valve: Class 300/600julio cesar ramirez gonzalezBelum ada peringkat

- Abnt NBR 15514Dokumen20 halamanAbnt NBR 15514Andre alexander dos santosBelum ada peringkat

- BRAY_7500_7700Dokumen4 halamanBRAY_7500_7700omorales.cyvsaBelum ada peringkat

- Fire HydrantsDokumen22 halamanFire HydrantsRaduBelum ada peringkat

- Brands You Trust.: CENTER LINE® - Resilient Seated Butterfly Valves Now All Ductile Iron Body Standard On Series 200Dokumen8 halamanBrands You Trust.: CENTER LINE® - Resilient Seated Butterfly Valves Now All Ductile Iron Body Standard On Series 200Yamil Diaz SantosBelum ada peringkat

- V100 globe control valve specificationDokumen24 halamanV100 globe control valve specificationEduardo GarridoBelum ada peringkat

- Rotating Disc ValvesDokumen4 halamanRotating Disc ValvesSergeyBelum ada peringkat

- Flygt Submersible Pumps for Water & Wastewater ApplicationsDokumen7 halamanFlygt Submersible Pumps for Water & Wastewater ApplicationsFredy NoalcaBelum ada peringkat

- ProValve Double Offset High PerformanceDokumen12 halamanProValve Double Offset High PerformanceHarry HonchoBelum ada peringkat

- 8580 Rotary Valve BuletinDokumen20 halaman8580 Rotary Valve BuletinRizalfariz HasbiBelum ada peringkat

- BRAY F15 Ball ValveDokumen12 halamanBRAY F15 Ball ValveRicardoBelum ada peringkat

- Velan Pressure Seal Valve CatalogDokumen4 halamanVelan Pressure Seal Valve CatalogulfatBelum ada peringkat

- 4600 BrochureDokumen4 halaman4600 Brochuresergix zBelum ada peringkat

- 46 10 HSC Brochure - PDF - Marked UpDokumen4 halaman46 10 HSC Brochure - PDF - Marked UpkwesiwellsBelum ada peringkat

- Southworth CatalogDokumen12 halamanSouthworth CatalogLizeth MontoyaBelum ada peringkat

- CM Electric Chain Hoists Specs and DrawingsDokumen105 halamanCM Electric Chain Hoists Specs and DrawingsBaris YeltekinBelum ada peringkat

- Precision Globe Valves for Reliable PerformanceDokumen12 halamanPrecision Globe Valves for Reliable PerformancesakscribBelum ada peringkat

- Data Sheets Kunkle Series 6000 Safety Valves Kunkle Valve en en 5197462Dokumen12 halamanData Sheets Kunkle Series 6000 Safety Valves Kunkle Valve en en 5197462Bodega 3001Belum ada peringkat

- Gflo - Globe ValveDokumen20 halamanGflo - Globe ValveVarun PatelBelum ada peringkat

- Guardian K81D Hydrant Meets AWWA and UL/FM StandardsDokumen18 halamanGuardian K81D Hydrant Meets AWWA and UL/FM Standardsvicvic34Belum ada peringkat

- KennedyDokumen18 halamanKennedyHimat KhimaniBelum ada peringkat

- MA Stewart L-D-4-S-E-LH Butterfly Valves Drawings and SpecificationsDokumen8 halamanMA Stewart L-D-4-S-E-LH Butterfly Valves Drawings and SpecificationsFawn DixonBelum ada peringkat

- Manual S 821 826Dokumen4 halamanManual S 821 826Javi González100% (1)

- WA439 Válvula de Control Modelo 3251-EDokumen12 halamanWA439 Válvula de Control Modelo 3251-EGaby CoCaBelum ada peringkat

- Клапан Регулирующий Поворотный Finetrol Fc Fg 5ft20 EnDokumen12 halamanКлапан Регулирующий Поворотный Finetrol Fc Fg 5ft20 EnAli KianersiBelum ada peringkat

- Data Sheets Kunkle Series 6000 Safety Valves Kunkle Valve en en 5197462Dokumen12 halamanData Sheets Kunkle Series 6000 Safety Valves Kunkle Valve en en 5197462Luis Alberto Portugal MariacalBelum ada peringkat

- FCC Series 20 High Performance Butterfly ValvesDokumen18 halamanFCC Series 20 High Performance Butterfly ValvesBASKARBelum ada peringkat

- SERIES 7000/8000: 3 Piece Full Port " - 12"Dokumen8 halamanSERIES 7000/8000: 3 Piece Full Port " - 12"ErickBelum ada peringkat

- Dezurik Uninterrupted Seat Resilient Seated Butterfly Valves Bos Us Bos Us Uninterrupted Seat Resilient Seated Butterfly Valves Sales 46-00-1aDokumen4 halamanDezurik Uninterrupted Seat Resilient Seated Butterfly Valves Bos Us Bos Us Uninterrupted Seat Resilient Seated Butterfly Valves Sales 46-00-1akasebBelum ada peringkat

- BVC BrochureDokumen16 halamanBVC BrochureMOHSINBelum ada peringkat

- Carboline High Temp FinishesDokumen8 halamanCarboline High Temp FinishesNurul LailyahBelum ada peringkat

- Carboline CathaloqueDokumen99 halamanCarboline CathaloqueNurul LailyahBelum ada peringkat

- FlangeDokumen10 halamanFlangeNurul LailyahBelum ada peringkat

- Carboline EpoxiesDokumen24 halamanCarboline EpoxiesNurul LailyahBelum ada peringkat

- Carboline AlkydsDokumen16 halamanCarboline AlkydsNurul LailyahBelum ada peringkat

- Carboline SpecialtiesDokumen6 halamanCarboline SpecialtiesNurul LailyahBelum ada peringkat

- Grating WebforgeDokumen20 halamanGrating WebforgeNurul LailyahBelum ada peringkat

- Cathaloque TMS Bolt & NutsDokumen62 halamanCathaloque TMS Bolt & NutsNurul LailyahBelum ada peringkat

- Carbomastic BitumasticDokumen10 halamanCarbomastic BitumasticNurul LailyahBelum ada peringkat

- Carboline Chlorinated RubbersDokumen6 halamanCarboline Chlorinated RubbersNurul LailyahBelum ada peringkat

- Carboline PhenolinesDokumen12 halamanCarboline PhenolinesNurul LailyahBelum ada peringkat

- Carboline PolyurethanesDokumen8 halamanCarboline PolyurethanesNurul LailyahBelum ada peringkat

- Expanded Metal 1Dokumen6 halamanExpanded Metal 1Nurul LailyahBelum ada peringkat

- Carboline Color SelectorDokumen4 halamanCarboline Color SelectorNurul LailyahBelum ada peringkat

- CTS Cargo Transfer SystemDokumen28 halamanCTS Cargo Transfer SystemNurul LailyahBelum ada peringkat

- Katalog PT Gunung Garuda Steel WF ProfileDokumen4 halamanKatalog PT Gunung Garuda Steel WF ProfileibnugantengBelum ada peringkat

- Triplefast FastenerDokumen4 halamanTriplefast FastenerNurul LailyahBelum ada peringkat

- GGB Wire NailDokumen1 halamanGGB Wire NailNurul LailyahBelum ada peringkat

- GRP Welded BeamDokumen2 halamanGRP Welded BeamNurul LailyahBelum ada peringkat

- GRP Equal Angle (Cold Formed)Dokumen1 halamanGRP Equal Angle (Cold Formed)Nurul LailyahBelum ada peringkat

- GRP Steel PipeDokumen2 halamanGRP Steel PipeNurul LailyahBelum ada peringkat

- GRP Rectangular Tube PipeDokumen1 halamanGRP Rectangular Tube PipeNurul LailyahBelum ada peringkat

- GG T-BeamDokumen1 halamanGG T-BeamSurya DirmansyahBelum ada peringkat

- 11-LippedChannel (CNP)Dokumen1 halaman11-LippedChannel (CNP)Surya DirmansyahBelum ada peringkat

- Tabel Besi BetonDokumen1 halamanTabel Besi BetonAlexander IgnatiusBelum ada peringkat

- User Manual HP NC8000Dokumen33 halamanUser Manual HP NC8000Larry AnkoskoBelum ada peringkat

- Chapter 6 - TQMDokumen4 halamanChapter 6 - TQManki23100% (1)

- TKM Engineering Project Evaluation RubricDokumen6 halamanTKM Engineering Project Evaluation RubricAbhiram DonBelum ada peringkat

- Uos Babsfy-Ipsda Assignment March 2022Dokumen6 halamanUos Babsfy-Ipsda Assignment March 2022Naushin Fariha Jalal 1821146630Belum ada peringkat

- Catalog-Ekarat Solar 200 W Module-MonoDokumen2 halamanCatalog-Ekarat Solar 200 W Module-MonoFalcon EgyBelum ada peringkat

- Interfacing The MCP215X To A Host Controller: Author: Mark Palmer Microchip Technology, IncDokumen38 halamanInterfacing The MCP215X To A Host Controller: Author: Mark Palmer Microchip Technology, IncglizBelum ada peringkat

- WWW Araxxe Com P Our Services Revenue Assurance Inter OperatDokumen5 halamanWWW Araxxe Com P Our Services Revenue Assurance Inter OperatErick Alexander Llanos BuitronBelum ada peringkat

- R011 - The Initial and Periodic ExaminationDokumen13 halamanR011 - The Initial and Periodic Examinationgabriel2Belum ada peringkat

- Es280-Es282-Sm-V04a (Print 2)Dokumen177 halamanEs280-Es282-Sm-V04a (Print 2)bienhocvoboBelum ada peringkat

- Octavia 2017Dokumen33 halamanOctavia 2017Vagauna AlexandruBelum ada peringkat

- Powerdrive MD2SL - Leroy Somer - 2017 PDFDokumen44 halamanPowerdrive MD2SL - Leroy Somer - 2017 PDFManuel OrtegaBelum ada peringkat

- Tc7200.u User Manual Eng v17 PDFDokumen83 halamanTc7200.u User Manual Eng v17 PDFalbertBelum ada peringkat

- 42Dokumen8 halaman42Syed Ali KhanBelum ada peringkat

- Professional Ethics: Dr. Muhammad Zeeshan MirzaDokumen20 halamanProfessional Ethics: Dr. Muhammad Zeeshan MirzaRaaz KhanBelum ada peringkat

- 7000 118-363, C1, R5 SUPREME AIS Installation Short InstructionDokumen4 halaman7000 118-363, C1, R5 SUPREME AIS Installation Short Instructionchefradio CFCARTHAGEBelum ada peringkat

- TeSys GV3 - GV3P18 PDFDokumen2 halamanTeSys GV3 - GV3P18 PDFtomtom56Belum ada peringkat

- TC SwitchDokumen5 halamanTC SwitchGolgojan NicusorBelum ada peringkat

- NAV MB7 840 ExamsDokumen7 halamanNAV MB7 840 ExamsRahul DhandBelum ada peringkat

- Predictability & Measurement With KanbanDokumen32 halamanPredictability & Measurement With Kanbandigz6666Belum ada peringkat

- Ups World Ship SetupDokumen14 halamanUps World Ship Setuprandt1972Belum ada peringkat

- Fix276 (3) TradeDokumen115 halamanFix276 (3) TradeaiilnwwcyxewmskahnBelum ada peringkat

- Plesiochronous Digital HierarchyDokumen6 halamanPlesiochronous Digital HierarchybilalrassoolBelum ada peringkat