RTD Basics

Diunggah oleh

Mourougapragash Subramanian0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

57 tayangan5 halamanNOTES

Judul Asli

Rtd Basics

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniNOTES

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

57 tayangan5 halamanRTD Basics

Diunggah oleh

Mourougapragash SubramanianNOTES

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 5

RTD BASICS

The Basics of Resistance Temperature Detectors An RTD

or Resistance Temperature Detector is a passive circuit

element whose resistance increases with increasing

temperature in a predictable manner. The traditional

RTD element is constructed of a small coil of platinum,

copper, or nickel wire, wound to a precise resistance

value around a ceramic or glass bobbin. The winding is

generally done using one of two styles: birdcage or

helix. The birdcage winding keeps the platinum wire

loosely wound on the bobbin allowing it to expand and

contract freely over temperature in order to minimize

any stress-induced change in resistance. This style of

winding is generally limited to laboratory use as it has

poor resistance to shock and vibration. The helix wire-

wound RTD uses a bifilar wound coil wrapped around a

bobbin and then sealed with molten glass, ceramic

cement, or some other high-temperature insulating

coating. The helix winding style helps protect the wire

element from shock and vibration induced changes to

its resistance, but it may still be prone to stress induced

resistance change due to the different coefficients of

thermal expansion of the wire coil and bobbin material.

More recently, RTDs are also being constructed using a

thin-film of platinum or nickel-iron metal deposited on a

ceramic substrate and then laser-trimmed to a desired

reference resistance. The advantage offered by this

construction is that the thin-film elements can achieve a

higher resistance with less metal, and over smaller

areas. This makes them smaller, cheaper, and faster

responding than their older wire-wound counterparts.

The most common RTD element material is Platinum, as

it is a more accurate, reliable, chemically resistant, and

stable material, making it less susceptible to

environmental contamination and corrosion than the

other metals. Its also easy to manufacture and widely

standardized with readily available platinum wire

available in very pure form with excellent reproducibility

of its electrical characteristics. Platinum also has a

higher melting point, giving it a wider operating

temperature range.

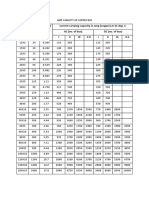

For an RTD sensor, it is the wires which connect to the

sensing element and the wire insulation which generally

limits the maximum application temperature of the

sensor. The following table lists common wire and

insulation materials and their maximum rated usage

temperature:

Points of Consideration When Using RTDs to Measure

Temperature

RTDs are susceptible to three dominant groups of

errors: there are errors that result due to the inherent

tolerances built into the element, errors due to the

thermal gradients that develop between the element

and the material being sensed, and electrical errors

encountered in the wiring between the sensor element

and the measuring instrument. While many of these

errors are electrical, others simply occur as a result of

the mechanical construction of the RTD. The following

outlines many of the considerations in this regard.

Temperature Coefficient of Resistance (TCR) and Alpha

()

A particular RTD curve is distinguished by its

Temperature Coefficient of Resistance (TCR), also

referred to as its

alpha coefficient (). The TCR or alpha value indicates

the average resistance change of the sensor per degree

C over the range of 0C to 100C. The TCR or alpha

value is also used as an indirect measure of the

sensitivity

of the resistive wire used in the RTD element (see

Sensitivity in the next section). Its units are usually

expressed

in units of //C, or ppm/C. Its value is derived by

dividing the difference between the sensor resistance at

100C and the sensor resistance at 0C, by the sensor

resistance at 0C, and then again by 100C as follows:

TCR = = [(R100C - R0C)/R0C]/100C in //C,

or alternately = 106

*[(R100C - R0C)/(100C *R0C)] in ppm/C,

where R0C is the element resistance at 0C; and

R100C is element resistance at 100C

For Pt 100 sensors of the DIN 43760 and IEC 751

standards, this is calculated via the expression [(138.5

-

100.0 )/100.0]/100C, or 0.00385 / /C. This is

sometimes expressed as 3850ppm/C, or 0.385%/C.

The RTD temperature coefficient of resistance is also

representative of the sensors sensitivity to

temperature

change. That is, the larger the temperature coefficient

(), the larger the resistance change (R) in response to

an ambient temperature change (T). Thus, we

calculate:

R = Ro T,

where: = TCR in //C; Ro = nominal sensor

resistance at 0C in ; T = temperature change from

0C in C.

The most common RTD element material is platinum

with =0.00385//C and specified per DIN EN 60751.

The value of will vary and depends on the grade of

platinum used. Other commonly use values include

0.3911%/C and 0.3926%/C. While the value indirectly

defines the sensitivity of the metallic element, it is

normally used to distinguish between

resistance/temperature curves of various RTDs.

RTDs are constructed using Platinum, Copper, Nickel,

and Nickel-Iron alloy element materials, with each type

achieving different TCRs. Metal impurities and stresses

during manufacture lower the relative TCR for a given

metal element. For example, there are many variations

of platinum RTDs available as follows:

Anda mungkin juga menyukai

- Quartus II Introduction-VHDLDokumen38 halamanQuartus II Introduction-VHDLMarc FilbàBelum ada peringkat

- Cad Commands LibraryDokumen11 halamanCad Commands LibraryAvdija HamzićBelum ada peringkat

- Brief Notes On Signals and Systems 7.2Dokumen77 halamanBrief Notes On Signals and Systems 7.2Bhaskar Rao GopisettiBelum ada peringkat

- Solved Question Papers For Gate Mechanical EngineeringDokumen16 halamanSolved Question Papers For Gate Mechanical EngineeringAsaduz ZamanBelum ada peringkat

- Half-Wave RL Circuit With A Free-Wheeling DiodeDokumen7 halamanHalf-Wave RL Circuit With A Free-Wheeling Diodehamza abdo mohamoud100% (2)

- Danfoss FC 102 ManualDokumen94 halamanDanfoss FC 102 Manualsandum1Belum ada peringkat

- Medidas Eroelectronic PDFDokumen4 halamanMedidas Eroelectronic PDFJuan Diego CondeBelum ada peringkat

- Half-Wave RectifierDokumen21 halamanHalf-Wave RectifierMuhammad Anaz'sBelum ada peringkat

- Full-Wave Rectifier - VerstudDokumen26 halamanFull-Wave Rectifier - VerstudLIEW HUI FANG UNIMAPBelum ada peringkat

- Motor Starter Ac Motor StartersDokumen6 halamanMotor Starter Ac Motor StartersShukor Az100% (1)

- Motor Starter NordDokumen36 halamanMotor Starter NordEuojrBelum ada peringkat

- Tempsens Handbook PDFDokumen180 halamanTempsens Handbook PDFKristijan CudarBelum ada peringkat

- PV Module PDFDokumen53 halamanPV Module PDFNur Asyiqin JamaluddinBelum ada peringkat

- Effect of Shadding and TestingDokumen29 halamanEffect of Shadding and TestingRabi SarmaBelum ada peringkat

- Ats22 User Manual en Bbv51330 04Dokumen85 halamanAts22 User Manual en Bbv51330 04Luis RolaBelum ada peringkat

- Rectifier and FiltersDokumen36 halamanRectifier and FiltersPankaj SinghBelum ada peringkat

- Method of Moments: Topic 13Dokumen9 halamanMethod of Moments: Topic 13Zeeshan AhmedBelum ada peringkat

- 308manual 5 03Dokumen57 halaman308manual 5 03basileiouspyrosBelum ada peringkat

- A Presentation ON Overhead Line Insulators Faculty: Gunjan VarshneyDokumen67 halamanA Presentation ON Overhead Line Insulators Faculty: Gunjan VarshneyGunjan VarshneyBelum ada peringkat

- Multivariate Random VariablesDokumen29 halamanMultivariate Random VariablesEdmond ZBelum ada peringkat

- Boiler Drum Level ControlDokumen9 halamanBoiler Drum Level ControlMourougapragash Subramanian100% (1)

- Power Electronics PPT by DeveshDokumen34 halamanPower Electronics PPT by Deveshshadan alamBelum ada peringkat

- How To Test Distance Relay 7SA522 PDFDokumen55 halamanHow To Test Distance Relay 7SA522 PDFBalaji100% (1)

- COORDINATION TABLESDokumen98 halamanCOORDINATION TABLESHoangBelum ada peringkat

- Equal Area Criterion 1.0 Development of Equal Area CriterionDokumen33 halamanEqual Area Criterion 1.0 Development of Equal Area Criterionscrib_111Belum ada peringkat

- Protection Against Electric Shock: Electrical Power Engineering Lab IDokumen30 halamanProtection Against Electric Shock: Electrical Power Engineering Lab Irajpre1213Belum ada peringkat

- Characteristics of ThermocoupleDokumen6 halamanCharacteristics of ThermocouplekusumgdasBelum ada peringkat

- N2xy PDFDokumen5 halamanN2xy PDFArnold StevenBelum ada peringkat

- ASHIDA Numerical 3OC + EF Protection Relay Features 11 Protection FunctionsDokumen17 halamanASHIDA Numerical 3OC + EF Protection Relay Features 11 Protection FunctionsVishwanath TodurkarBelum ada peringkat

- CH1 - Circuit Variables PDFDokumen25 halamanCH1 - Circuit Variables PDFahmed ahmedBelum ada peringkat

- Electronic Service Manual PDFDokumen110 halamanElectronic Service Manual PDFvictor50% (2)

- RelayDokumen12 halamanRelaytai58Belum ada peringkat

- KYN61-40.5 Indoor Removable AC Metal-Clad SwitchgearDokumen1 halamanKYN61-40.5 Indoor Removable AC Metal-Clad SwitchgearCLAVOTBelum ada peringkat

- Homework 1Dokumen8 halamanHomework 1Yooncheul JeungBelum ada peringkat

- Introduction To Random Processes Handouts PDFDokumen116 halamanIntroduction To Random Processes Handouts PDFshaan76Belum ada peringkat

- RZ1-K Power CableDokumen5 halamanRZ1-K Power CablegarysBelum ada peringkat

- Lect 17 - Performance Parameters of Rectifier CircuitsDokumen40 halamanLect 17 - Performance Parameters of Rectifier CircuitsShumaila AltafBelum ada peringkat

- PRP NotesDokumen10 halamanPRP NotesBharath JojoBelum ada peringkat

- Three Phase ControlledDokumen9 halamanThree Phase ControlledSaif HassanBelum ada peringkat

- Digital Signal Processing NotesDokumen12 halamanDigital Signal Processing NotesDanial ZamanBelum ada peringkat

- Two Port Networks PPT 1 B TECH 3RDDokumen32 halamanTwo Port Networks PPT 1 B TECH 3RDEuthecas KipkiruiBelum ada peringkat

- 2 - 3 - 4-Wire RTD MeasurementDokumen9 halaman2 - 3 - 4-Wire RTD MeasurementtotovasiBelum ada peringkat

- 05 Convolution of CT and DTDokumen63 halaman05 Convolution of CT and DTBhaskarBelum ada peringkat

- Amp Capacity of Copper BusDokumen1 halamanAmp Capacity of Copper BusVIKRAM DESAIBelum ada peringkat

- Data Sheet: Diesel Generator 1500Kw 50HZ/1500RPM PERKINS MODEL: 4012-46TAG3ADokumen9 halamanData Sheet: Diesel Generator 1500Kw 50HZ/1500RPM PERKINS MODEL: 4012-46TAG3AmualiminBelum ada peringkat

- Introduction To Time Series Analysis, LecturesDokumen49 halamanIntroduction To Time Series Analysis, LecturesnumenoreBelum ada peringkat

- Neration of High DC Voltages - NEWDokumen15 halamanNeration of High DC Voltages - NEWMohammed MansoorBelum ada peringkat

- AC Voltmeters and AmmetersDokumen8 halamanAC Voltmeters and AmmetersrajivBelum ada peringkat

- Half Wave Rectifiers With Resistive and Inductive LoadDokumen5 halamanHalf Wave Rectifiers With Resistive and Inductive Loadluqman059Belum ada peringkat

- Power System Protection TrainingDokumen3 halamanPower System Protection TrainingVicBelum ada peringkat

- Introduction To Electrical Circuit Design: Instructor Manual 2015Dokumen10 halamanIntroduction To Electrical Circuit Design: Instructor Manual 2015arturo tuñoque effioBelum ada peringkat

- Cable Selection (Multi-Core)Dokumen1 halamanCable Selection (Multi-Core)Hùng Trần XuânBelum ada peringkat

- Pressure Transmitter Deltabar Pmd230 Pmd230 Endress HauserDokumen20 halamanPressure Transmitter Deltabar Pmd230 Pmd230 Endress HauserSonya HollandBelum ada peringkat

- Motion Controller BES-516-604, Typical Applications: Balluff Zero Speed Controller On A Grinding MachineDokumen8 halamanMotion Controller BES-516-604, Typical Applications: Balluff Zero Speed Controller On A Grinding MachinenorbertoBelum ada peringkat

- Switch Gear Functions and ComponentsDokumen6 halamanSwitch Gear Functions and ComponentsAdeel Mustafa100% (1)

- Using PIC Microcontrollers to Control Triacs PhaseDokumen22 halamanUsing PIC Microcontrollers to Control Triacs PhaseMarko Lukic100% (1)

- ARDUINO SPWM SINE INVERTER PROJECT GUIDEDokumen5 halamanARDUINO SPWM SINE INVERTER PROJECT GUIDEmaurilioctbaBelum ada peringkat

- Rtds - or Resistance Temperature Detectors - Are Temperature Sensors That Contain A Resistor ThatDokumen6 halamanRtds - or Resistance Temperature Detectors - Are Temperature Sensors That Contain A Resistor Thatmuhammad aliBelum ada peringkat

- RTDDokumen4 halamanRTDCss GaneshBelum ada peringkat

- Types of Signals, Their Properties & Energy/PowerDokumen9 halamanTypes of Signals, Their Properties & Energy/PowerMas ShariBelum ada peringkat

- Drum Level ControlDokumen17 halamanDrum Level ControlMourougapragash SubramanianBelum ada peringkat

- Combustion Ratio ControlDokumen8 halamanCombustion Ratio ControlMourougapragash SubramanianBelum ada peringkat

- Zero and Span CircuitsDokumen2 halamanZero and Span CircuitsMourougapragash Subramanian100% (1)

- Electronic ControllersDokumen9 halamanElectronic ControllersMourougapragash SubramanianBelum ada peringkat

- Electronic Pid Controller Design: Dr. Mourouga Pragash.SDokumen16 halamanElectronic Pid Controller Design: Dr. Mourouga Pragash.SMourougapragash SubramanianBelum ada peringkat

- Orifice Meter Design: DR - Mourouga Pragash Dept. of Eie Pondicherry Engineering CollegeDokumen8 halamanOrifice Meter Design: DR - Mourouga Pragash Dept. of Eie Pondicherry Engineering CollegeMourougapragash SubramanianBelum ada peringkat

- Liquid Level Measurement TechniquesDokumen6 halamanLiquid Level Measurement TechniquesMourougapragash SubramanianBelum ada peringkat

- Thermocouple Cold Junction Compensation GuideDokumen12 halamanThermocouple Cold Junction Compensation GuideMourougapragash SubramanianBelum ada peringkat

- PID Controller BasicsDokumen11 halamanPID Controller BasicsMourougapragash SubramanianBelum ada peringkat

- Variable Area Flowmeter (Rotameter) : DR - Mourouga Pragash Dept - of Eie Pondicherry Engineering CollegeDokumen6 halamanVariable Area Flowmeter (Rotameter) : DR - Mourouga Pragash Dept - of Eie Pondicherry Engineering CollegeMourougapragash SubramanianBelum ada peringkat

- Process Control System Components Test QuestionsDokumen2 halamanProcess Control System Components Test QuestionsMourougapragash SubramanianBelum ada peringkat

- Automobile Instrumentation Exam QuestionsDokumen2 halamanAutomobile Instrumentation Exam QuestionsMourougapragash SubramanianBelum ada peringkat

- Digital Control April 2018Dokumen4 halamanDigital Control April 2018Mourougapragash SubramanianBelum ada peringkat

- Advanced Control Systems Exam ReviewDokumen2 halamanAdvanced Control Systems Exam ReviewMourougapragash SubramanianBelum ada peringkat

- DP Transmitter WorkingDokumen7 halamanDP Transmitter WorkingMourougapragash Subramanian100% (1)

- RTDA Final R PDFDokumen33 halamanRTDA Final R PDFMourougapragash SubramanianBelum ada peringkat

- Introduction of Various PumpDokumen25 halamanIntroduction of Various PumpSajib Chandra RoyBelum ada peringkat

- DP Transmitter WorkingDokumen7 halamanDP Transmitter WorkingMourougapragash Subramanian100% (1)

- Study of Cro PDFDokumen11 halamanStudy of Cro PDFMourougapragash SubramanianBelum ada peringkat

- How Does A PLC OperateDokumen2 halamanHow Does A PLC OperateMourougapragash SubramanianBelum ada peringkat

- Approximate Flow Through An OrificeDokumen6 halamanApproximate Flow Through An OrificeMourougapragash SubramanianBelum ada peringkat

- Orifice Meter Is Type of Variable Head MeterDokumen2 halamanOrifice Meter Is Type of Variable Head MeterMourougapragash SubramanianBelum ada peringkat

- Types of TransducersDokumen30 halamanTypes of TransducersMourougapragash SubramanianBelum ada peringkat

- Once The Valve Type Is SelectedDokumen5 halamanOnce The Valve Type Is SelectedMourougapragash SubramanianBelum ada peringkat

- Laws of ThermocoupleDokumen3 halamanLaws of ThermocoupleMourougapragash SubramanianBelum ada peringkat

- 66 - 15575 - EC 732 - 2014 - 1 - 1 - 2 - Chapter 2 - ADokumen30 halaman66 - 15575 - EC 732 - 2014 - 1 - 1 - 2 - Chapter 2 - AMourougapragash Subramanian50% (2)

- Once The Valve Type Is SelectedDokumen5 halamanOnce The Valve Type Is SelectedMourougapragash SubramanianBelum ada peringkat

- Report Edm Die SinkerDokumen21 halamanReport Edm Die SinkerAwateff Al-Jefry II100% (8)

- Miele Coffee Maker Cva - 4070 - EncaDokumen6 halamanMiele Coffee Maker Cva - 4070 - EncaJim LawlerBelum ada peringkat

- Planning Norms-11 KVDokumen6 halamanPlanning Norms-11 KVnitin369Belum ada peringkat

- Fundamentals of Electronic Devices Exam QuestionsDokumen7 halamanFundamentals of Electronic Devices Exam QuestionsSakshi UpadhyayBelum ada peringkat

- E/m Experiment (Magnetron Method) : ObjectDokumen6 halamanE/m Experiment (Magnetron Method) : ObjectSandeep KumarBelum ada peringkat

- Analysis of Silicon Solar Cell Device PaDokumen9 halamanAnalysis of Silicon Solar Cell Device PaHoucine NaimBelum ada peringkat

- 2.7V 4-Channel/8-Channel 12-Bit A/D Converters With SPI Serial InterfaceDokumen41 halaman2.7V 4-Channel/8-Channel 12-Bit A/D Converters With SPI Serial InterfacecutoBelum ada peringkat

- E Series DX Uninterruptible Power System: Product BrochureDokumen4 halamanE Series DX Uninterruptible Power System: Product BrochureDania Luna SantanaBelum ada peringkat

- MA5002VZ SM 130446-1amplificator ManualDokumen140 halamanMA5002VZ SM 130446-1amplificator Manualtiganiada100% (1)

- Automatic Gearbox GA750/751/752 and GA851/852 Including VariantsDokumen51 halamanAutomatic Gearbox GA750/751/752 and GA851/852 Including Variantsesam PhilipeBelum ada peringkat

- Valve Catalogue General Imsubs Pvt. Ltd.Dokumen20 halamanValve Catalogue General Imsubs Pvt. Ltd.Spark MeditechBelum ada peringkat

- Vertex Standard Vx-351pmr446Dokumen30 halamanVertex Standard Vx-351pmr446Troy LarimerBelum ada peringkat

- Advance E-Bike-WPS Office-1 Hari Hari Hari Hari HariDokumen26 halamanAdvance E-Bike-WPS Office-1 Hari Hari Hari Hari HariVIJAYBelum ada peringkat

- Testbeds For Integrated Transmission and Distribution Networks: Generation Methodology and BenchmarksDokumen10 halamanTestbeds For Integrated Transmission and Distribution Networks: Generation Methodology and BenchmarksAbd Al7medBelum ada peringkat

- 3.expannded Battery Treatment Service Guide - TCS BatteryDokumen1 halaman3.expannded Battery Treatment Service Guide - TCS BatteryHICHAM el HAYAOUIBelum ada peringkat

- Local Control Stations For Electric Actuators: Key FeaturesDokumen8 halamanLocal Control Stations For Electric Actuators: Key Featuresrocket-vtBelum ada peringkat

- Canon 7161 Service ManuelDokumen346 halamanCanon 7161 Service ManuelkopisanBelum ada peringkat

- Geiger-Muller Tube (GM Tube)Dokumen12 halamanGeiger-Muller Tube (GM Tube)bdb6wxhyxfBelum ada peringkat

- Sample Problems and Solution - 2Dokumen6 halamanSample Problems and Solution - 2김동욱Belum ada peringkat

- Battery Charging Only Not Grid Connected: This Drawing Is For ReferenceDokumen1 halamanBattery Charging Only Not Grid Connected: This Drawing Is For ReferenceJesus VelascoBelum ada peringkat

- Mitsubishi Active Skid and Traction Control System PDFDokumen210 halamanMitsubishi Active Skid and Traction Control System PDFmanfred100% (1)

- AP Practice Test MC With KeyDokumen16 halamanAP Practice Test MC With KeyMichel G. RahalBelum ada peringkat

- Mtl7000 Series: Ultra-Slim Safety Barriers That Can Be Used Like TerminalsDokumen13 halamanMtl7000 Series: Ultra-Slim Safety Barriers That Can Be Used Like TerminalsDharmilBelum ada peringkat

- Exercises V1 Part2Dokumen8 halamanExercises V1 Part2Ahmed AlgadriBelum ada peringkat

- Chapter 3-3 Signal Processing Elemnt Part ThreeDokumen43 halamanChapter 3-3 Signal Processing Elemnt Part Threedan gBelum ada peringkat

- RelayDokumen5 halamanRelayNachimuthu LoganathanBelum ada peringkat