Mod10 1ToothBending

Diunggah oleh

Mario AndradeJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Mod10 1ToothBending

Diunggah oleh

Mario AndradeHak Cipta:

Format Tersedia

MOD3_2.

XLS

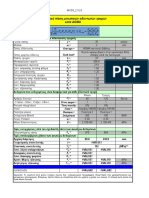

Module 10-1

Design Equation for

Bending of Spur Gear Teeth

Click here for

instructions on how to

use this spreadsheet. Pd K m K B s at Y N

Wt Ko Kv K s

Click here to learn more

F J SF K T K R

about this spreadsheet.

Given information that is common to both gears in the set:

= 25 degrees Pressure angle

Pd = 6 teeth/in Diametral pitch

Gear type = AGMA full depth Tooth type

Tooth load= HPSTC loading Type of tooth loading

F= 2.00 inches Face width

Wt = 430 lbf Transmitted load

vt = 1,527 ft/min Pitch line velocity

SF = 2.00 Factor of safety

Ko = 1.0 Overload factor

Qv = 6 Quality class of gear set

Ks = 1.0 Size factor

KB = 1.0 Rim thickness factor

YN = 1.0 Stress cycle factor

KT = 1.0 Temperature factor

KR = 1.0 Reliability factor

Given information that may be different for each gear in the set:

Pinion Gear

Ni = 14 17 teeth Number of teeth

Material = Bronze Steel HB200 Material type

grade = ASTMB148 Grade 1 Material grade

Values found from the above information and inserted by the designer:

sat = 23,600 28,260 psi Allowable stress

J= 0.33 0.36 Geometry factor

Values computed using the above information:

Kv = #VALUE! Dynamic factor

Km = #VALUE! Load distribution factor

st = #VALUE! #VALUE! psi Left-hand side of eqn.

RHS 11,800 14,130 psi Right-hand side of eqn.

Status #VALUE! #VALUE!

Source: AGMA Standard 2001-C95, Fundamental Rating Factors and

MOD3_2.XLS

Calculation Methods for Involute Spur and Helical Gear Teeth

with the permission of the publisher, American Gear Manufacturers

Association, 1500 King Street, Suite 201, Alexandria, VA 22314.

MOD3_2.XLS

MOD3_2.XLS

Anda mungkin juga menyukai

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987Dari EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonBelum ada peringkat

- Structural Health MonitoringDari EverandStructural Health MonitoringDaniel BalageasBelum ada peringkat

- Σχεδιασμός σε επιφανειακή πίεση μετωπικών οδοντωτών τροχών κατά AGMADokumen1 halamanΣχεδιασμός σε επιφανειακή πίεση μετωπικών οδοντωτών τροχών κατά AGMAkstayroskBelum ada peringkat

- AGMA Gear Design SpreadsheetDokumen1 halamanAGMA Gear Design SpreadsheetkstayroskBelum ada peringkat

- Various Hardening Processes of GearsDokumen32 halamanVarious Hardening Processes of GearsYash VermaBelum ada peringkat

- 0611 GearSolutionsDokumen72 halaman0611 GearSolutionspoorianaBelum ada peringkat

- Axisymmetric Shrink Fit Analysis and DesignDokumen10 halamanAxisymmetric Shrink Fit Analysis and DesignParag NaikBelum ada peringkat

- RENK Range of CouplingsDokumen2 halamanRENK Range of CouplingssurawutwijarnBelum ada peringkat

- A Procedure To Determine The Unknown Geometry of External Cylindrical Gears - Gear Solutions Magazine Your Resource To The Gear IndustryDokumen11 halamanA Procedure To Determine The Unknown Geometry of External Cylindrical Gears - Gear Solutions Magazine Your Resource To The Gear IndustryChetan PrajapatiBelum ada peringkat

- 02 Mechanical BasicsDokumen29 halaman02 Mechanical BasicsVLADIMIR YOLVIS CHOQUEHUANCA GALINDOBelum ada peringkat

- ISO Gear Standards GuideDokumen6 halamanISO Gear Standards GuideEslam YehiaBelum ada peringkat

- Design of Bevel and Worm Gear: Machine Element IIDokumen60 halamanDesign of Bevel and Worm Gear: Machine Element IIkibromgidey12Belum ada peringkat

- Gear DesignDokumen83 halamanGear DesignmuhammadaminjamalmutBelum ada peringkat

- Service Factor RatingsDokumen4 halamanService Factor Ratingschu42Belum ada peringkat

- Gearbox Design and Analysis - ProgramDokumen4 halamanGearbox Design and Analysis - Programمحمد نتعيBelum ada peringkat

- Alwasy Step Ahead in TechnologyDokumen6 halamanAlwasy Step Ahead in TechnologyDxFx100% (1)

- Assy Gear Box AgitatorDokumen1 halamanAssy Gear Box Agitatorer_winwibowoBelum ada peringkat

- Gear TechnologyDokumen52 halamanGear TechnologyJithinBelum ada peringkat

- Angrenaj Cilindric PDFDokumen17 halamanAngrenaj Cilindric PDFDiana Maria CozmaBelum ada peringkat

- Spur Gear, Helical Gear Design Step Final1Dokumen2 halamanSpur Gear, Helical Gear Design Step Final1Venkadesh ShanmugamBelum ada peringkat

- Flender - Ejes ParalelosDokumen49 halamanFlender - Ejes ParalelosYenny LaraBelum ada peringkat

- TGM Planetary GearboxDokumen8 halamanTGM Planetary GearboxOmar Ahmed ElkhalilBelum ada peringkat

- Design - Ring Gear MaterialsDokumen4 halamanDesign - Ring Gear Materialstushar11singhBelum ada peringkat

- Content PDF 1Dokumen15 halamanContent PDF 1jesbmnBelum ada peringkat

- Calculating Involute Gear Teeth ParametersDokumen3 halamanCalculating Involute Gear Teeth ParametersreinaldosidejuniorBelum ada peringkat

- High Speed Gearing: Design, Failure Analysis, Life Factors, Reconditioning/RepairDokumen16 halamanHigh Speed Gearing: Design, Failure Analysis, Life Factors, Reconditioning/RepairRamesh TimmanagoudarBelum ada peringkat

- Ansi Agma6010 f97 PDFDokumen62 halamanAnsi Agma6010 f97 PDFWilliam Noe100% (1)

- Gear 1Dokumen9 halamanGear 1Ariyant CreativeBelum ada peringkat

- A Method to Optimize Brass Synchronizer RingDokumen6 halamanA Method to Optimize Brass Synchronizer RingaravindhBelum ada peringkat

- Loading Factors Within The Strength Calculation Procedure For Involute Marine Gears With Parallel AxesDokumen12 halamanLoading Factors Within The Strength Calculation Procedure For Involute Marine Gears With Parallel AxesNenad VulićBelum ada peringkat

- Kisssoft Tut 003 E KeyDokumen11 halamanKisssoft Tut 003 E KeyJorge Ronald Cabrera ÑaupaBelum ada peringkat

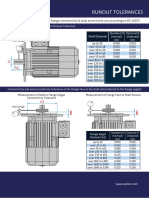

- IEC 60072 Shaft and Flange Runout TolerancesDokumen1 halamanIEC 60072 Shaft and Flange Runout Tolerancesbiranchi satapathyBelum ada peringkat

- Addendum Modified Gear For An All-Terrain Vehicle GearboxDokumen6 halamanAddendum Modified Gear For An All-Terrain Vehicle GearboxIJRASETPublicationsBelum ada peringkat

- Lista Base Instalada LATAM FLESANDokumen19 halamanLista Base Instalada LATAM FLESANWiliam SeguraBelum ada peringkat

- Kisssoft 0315 Product Description en PDFDokumen112 halamanKisssoft 0315 Product Description en PDFhrrypnBelum ada peringkat

- Semi-Topping Shaper CuttersDokumen4 halamanSemi-Topping Shaper CuttersalemarlonstosBelum ada peringkat

- Article - Experimental Characterization of Bending Fatigue Strength in GearDokumen8 halamanArticle - Experimental Characterization of Bending Fatigue Strength in Gearjavo0128Belum ada peringkat

- A Crowning Achievement For Automotive ApplicationsDokumen10 halamanA Crowning Achievement For Automotive ApplicationsCan CemreBelum ada peringkat

- Gear Coupling 2014Dokumen4 halamanGear Coupling 2014Dado Maja ArseninBelum ada peringkat

- SKF No Wear Coating - DLCDokumen6 halamanSKF No Wear Coating - DLCLLBelum ada peringkat

- Dynamic Factor FormulaeDokumen15 halamanDynamic Factor FormulaeShubham More0% (1)

- Install bevel gears for peak performanceDokumen3 halamanInstall bevel gears for peak performancejemanuelvBelum ada peringkat

- SEW Compact Constant Speed Reducer MC SeriesDokumen195 halamanSEW Compact Constant Speed Reducer MC SeriesDênis DáyolBelum ada peringkat

- STUEWE Katalog GB 2012Dokumen68 halamanSTUEWE Katalog GB 2012jorge arturo100% (1)

- Design II MDE 221 Mott CH 8 and CH 9 Spur GearsDokumen42 halamanDesign II MDE 221 Mott CH 8 and CH 9 Spur GearsThieroy PelendaBelum ada peringkat

- Isis DriveDokumen18 halamanIsis DriveTms ArnBelum ada peringkat

- Spiral Springs PDFDokumen18 halamanSpiral Springs PDFEngr Eze Chuklet ChukwumaBelum ada peringkat

- Tooth ThicknessDokumen9 halamanTooth ThicknessPraveen VundrajavarapuBelum ada peringkat

- Gear Hunting Tooth Recommendations-Frank Kushner - 0419Dokumen2 halamanGear Hunting Tooth Recommendations-Frank Kushner - 0419Rachel AustriaBelum ada peringkat

- KISSsoft ANSI B92.1 Involute Spline AnalysisDokumen6 halamanKISSsoft ANSI B92.1 Involute Spline AnalysisDaggupati PraveenBelum ada peringkat

- TechnicalData KGSTOCKGEARS PDFDokumen171 halamanTechnicalData KGSTOCKGEARS PDFChetan PrajapatiBelum ada peringkat

- Measurements & Metrology (English)Dokumen29 halamanMeasurements & Metrology (English)Kumar SubramanianBelum ada peringkat

- RKB Proper Lubricant Selection For Rolling Bearing Applications PDFDokumen8 halamanRKB Proper Lubricant Selection For Rolling Bearing Applications PDFJako MishyBelum ada peringkat

- New Developments in Gear HobbingDokumen8 halamanNew Developments in Gear HobbingpongerkeBelum ada peringkat

- Face WidthDokumen24 halamanFace WidthDipak100% (1)

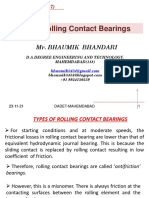

- Rolling Contact Bearings - DMEDokumen28 halamanRolling Contact Bearings - DMESumitBelum ada peringkat

- Contact Stress Analysis of Spur Gear Teeth Pair PDFDokumen6 halamanContact Stress Analysis of Spur Gear Teeth Pair PDFCan CemreBelum ada peringkat

- Maintenance Manual: Manufacturing Number GenericDokumen64 halamanMaintenance Manual: Manufacturing Number GenericManh PhamBelum ada peringkat

- 2 Gear BasicsDokumen6 halaman2 Gear BasicsMohamed Adel RizkBelum ada peringkat

- Design and Analysis Procedures For Shafts and Splines: Paul E. BurkeDokumen21 halamanDesign and Analysis Procedures For Shafts and Splines: Paul E. BurkeBalasrinivasan Murugan100% (3)

- Ger 3620n Heavy Duty Gas Turbine Operationg Maintenance ConsiderationsDokumen60 halamanGer 3620n Heavy Duty Gas Turbine Operationg Maintenance Considerationszomglolzscribd100% (3)

- 02 BoilDokumen18 halaman02 BoilWeb LogueandoBelum ada peringkat

- The Mystery of Nikola TeslaDokumen7 halamanThe Mystery of Nikola TeslaMario Andrade100% (1)

- Brevets Nicola Tesla CompletDokumen499 halamanBrevets Nicola Tesla CompletkozlhooBelum ada peringkat

- Turbo Gener AdoresDokumen141 halamanTurbo Gener AdoresMario AndradeBelum ada peringkat

- Corriente Alterna formulas potencia seccion cablesDokumen2 halamanCorriente Alterna formulas potencia seccion cablesMario Andrade100% (1)

- Pronombres Indefinidos - ActividadesDokumen2 halamanPronombres Indefinidos - ActividadesMario AndradeBelum ada peringkat

- GE90 Engine Data With 3D CutawayDokumen19 halamanGE90 Engine Data With 3D CutawayjauuulBelum ada peringkat

- The Four Humor Mechanisms 42710Dokumen4 halamanThe Four Humor Mechanisms 42710Viorel100% (1)

- Vocabulary and grammar practice for future technologyDokumen4 halamanVocabulary and grammar practice for future technologyRosa MartinezBelum ada peringkat

- SplunkCloud-6 6 3-SearchTutorial PDFDokumen103 halamanSplunkCloud-6 6 3-SearchTutorial PDFanonymous_9888Belum ada peringkat

- Qdoc - Tips Select Readings 2nd Pre IntermediateDokumen178 halamanQdoc - Tips Select Readings 2nd Pre IntermediateFarzana BatoolBelum ada peringkat

- JCL RefresherDokumen50 halamanJCL RefresherCosta48100% (1)

- A&P Book - Aeronautical Charts and CompassDokumen17 halamanA&P Book - Aeronautical Charts and CompassHarry NuryantoBelum ada peringkat

- Data Pre Processing in WEKADokumen5 halamanData Pre Processing in WEKAPrashant SunejaBelum ada peringkat

- Sap CRM Web - UiDokumen7 halamanSap CRM Web - UiNaresh BitlaBelum ada peringkat

- Question Notes On Production Management (Final)Dokumen63 halamanQuestion Notes On Production Management (Final)Vineet Walia100% (1)

- Chrome FlagsDokumen12 halamanChrome Flagsmeraj1210% (1)

- Lighthouse Case Study Solution GuideDokumen17 halamanLighthouse Case Study Solution Guidescon driumBelum ada peringkat

- Quality Policy Nestle PDFDokumen6 halamanQuality Policy Nestle PDFJonathan KacouBelum ada peringkat

- Loads Dead Loads Imposed Loads Floor Roof Determining Load Per M and m2 WindDokumen58 halamanLoads Dead Loads Imposed Loads Floor Roof Determining Load Per M and m2 Windwaheedopple3998Belum ada peringkat

- SW GDLoader GettingStarted v3-0 enDokumen41 halamanSW GDLoader GettingStarted v3-0 enEduardo QuispeBelum ada peringkat

- Aspen TutorialDokumen33 halamanAspen TutorialSarah RasheedBelum ada peringkat

- Sony Kdl-42w654a rb1g PDFDokumen100 halamanSony Kdl-42w654a rb1g PDFMihaela CaciumarciucBelum ada peringkat

- RSBACDokumen166 halamanRSBACtradersanBelum ada peringkat

- Pineapple Peel Extract vs Calamansi Extract Stain RemoverDokumen13 halamanPineapple Peel Extract vs Calamansi Extract Stain RemoverShebbah MadronaBelum ada peringkat

- Ranking Hospital - Do We Gain Reliability by Using Composite Rather Than Individual Indicators?Dokumen9 halamanRanking Hospital - Do We Gain Reliability by Using Composite Rather Than Individual Indicators?Robert CoffinBelum ada peringkat

- Pagdaragdag (Adding) NG Bilang Na May 2-3 Digit Na Bilang Na May Multiples NG Sandaanan Antas 1Dokumen5 halamanPagdaragdag (Adding) NG Bilang Na May 2-3 Digit Na Bilang Na May Multiples NG Sandaanan Antas 1Teresita Andaleon TolentinoBelum ada peringkat

- The STP Guide To Graduate Student Training in The Teaching of PsychologyDokumen101 halamanThe STP Guide To Graduate Student Training in The Teaching of PsychologyNeilermindBelum ada peringkat

- 7949 37085 3 PBDokumen11 halaman7949 37085 3 PBAman ChaudharyBelum ada peringkat

- PESTEL Team Project (Group)Dokumen9 halamanPESTEL Team Project (Group)Yadira Alvarado saavedraBelum ada peringkat

- Lesson Exemplar On Contextualizing Science Lesson Across The Curriculum in Culture-Based Teaching Lubang Elementary School Science 6Dokumen3 halamanLesson Exemplar On Contextualizing Science Lesson Across The Curriculum in Culture-Based Teaching Lubang Elementary School Science 6Leslie SolayaoBelum ada peringkat

- What Is A Political SubjectDokumen7 halamanWhat Is A Political SubjectlukaBelum ada peringkat

- Vblock® Systems Password ManagementDokumen22 halamanVblock® Systems Password ManagementVakul BhattBelum ada peringkat

- I-K Bus Codes v6Dokumen41 halamanI-K Bus Codes v6Dobrescu CristianBelum ada peringkat

- Guia de Manejo Sdra 2019Dokumen27 halamanGuia de Manejo Sdra 2019Jorge VidalBelum ada peringkat

- Instructional Module Training PlanDokumen5 halamanInstructional Module Training Planapi-246767803100% (1)

- Signal Sampling, Quantization, Binary Encoding: Oleh Albert SagalaDokumen46 halamanSignal Sampling, Quantization, Binary Encoding: Oleh Albert SagalaRamos D HutabalianBelum ada peringkat