A283GrC VS A36 Comparison

Diunggah oleh

Khalilahmad KhatriJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

A283GrC VS A36 Comparison

Diunggah oleh

Khalilahmad KhatriHak Cipta:

Format Tersedia

COMPARISON BETWEEN ASTM A36 AND ASTM A283 GRADE C

1. MATERIAL SCOPE

ASTM A283 Gr. C consists of four grade of material (A, B, C, & D) of Carbon Steel Plate of Structural

Quality for General Application.

ASTM A36 covers Carbon Steel plate, shape, and bar of Structural Quality for use in riveted,

bolted or welded construction of bridges and building and for General Structural purpose.

From material scope, both ASTM A 36 and ASTM A 283 are the Carbon Steel of Structural Quality for

General Application.

2. CHEMICAL COMPOSITION (Thickness up to 19 mm)

Chemical Composition (%)

Material

C Mn P S Si Cu

A36 0,25 - 0,04 0,05 0,4 0,2

A283 Gr. C 0,24 0,9 0,035 0,04 0,4 0,2

The chemical composition between ASTM A36 and ASTM A 283 Gr. C differ only on Mn content.

The effect of Mn and other element to the weld ability can be known by Carbon Equivalent (CE)

calculation

The formula for CE = C + Si/24 + Mn/6 + Ni/40 + Cr/5 + Mo/4 + V/4 where the element in % weight

ASTM A36 CE = 0.25 + 0.4 / 24 =

0.266 %

ASTM A 283 Gr. C CE = 0.24 + 0.4/24 + 0.9/6 + 0 + 0 + 0 + 0 = 0.406 %

It seems that CE of A283 Gr. C is higher than ASTM A36. Base on this A 283 Gr. C is little bit difficult to

weld compare to A 36.

Referring to ASME IX the weld ability of material is classified in to P-Number. Both A 283 Gr. C and A36

is group in to the same P number 1. It mean that once we make the WPS/PQR with A-36, it also valid

for A 283 Gr. C

3. MECHANICAL PROPERTIES

Yield Strength Tensile Elongation Elongation

Material Strength ksi

ksi (Mpa) 8 inch 2 inch

(Mpa)

58-80 (400-

A 36 36 (250) 20 23

550)

55-75 (380-

A 283 Gr. C 30 (205) 22 25

515)

The mechanical properties between A 36 and A 283 Gr. C are almost the same which mean the

mechanical properties range are not big different.

4. CONCLUSION

Base on the above explanation, it can consider that A36 can be used to alternative substitution of A283 Gr. C for

patch plate of tank bottom.

5. REFERENCE

5.1. ASTM A36 & ASTM A283 Gr. C (ASME Sec II A 2015)

5.2. Introduction to the Physical Metallurgy of Welding, Kenneth Easterling, Butterworth Heinemann, 1992

5.3. ASME IX Code: Welding and Brazing Qualification, Edition 2015

Anda mungkin juga menyukai

- Response To RFPDokumen8 halamanResponse To RFPRohan JadhavBelum ada peringkat

- EN 13480-3 Straight Pipes PDFDokumen1 halamanEN 13480-3 Straight Pipes PDFmasatusBelum ada peringkat

- PVP2016 Final ProgramDokumen76 halamanPVP2016 Final Programthaivinhtuy100% (1)

- Method Statement of Proof Load Test For Anchor BoltDokumen1 halamanMethod Statement of Proof Load Test For Anchor BoltMorris KwokBelum ada peringkat

- A741Dokumen3 halamanA741solrac4371100% (1)

- First Aid Emergencies: Call/DialDokumen5 halamanFirst Aid Emergencies: Call/DialKhalilahmad Khatri100% (1)

- Power System Loss Analysis-EngDokumen5 halamanPower System Loss Analysis-EngRatana KemBelum ada peringkat

- A10 Bare Metal Lib3.3Dokumen38 halamanA10 Bare Metal Lib3.3George JR BagsaoBelum ada peringkat

- Atlas Copco - Scooptram ST18 (18t) PDFDokumen4 halamanAtlas Copco - Scooptram ST18 (18t) PDFДмитрий АсташонокBelum ada peringkat

- Material Requisition For Overhead Crane: Page. 1 of 30Dokumen30 halamanMaterial Requisition For Overhead Crane: Page. 1 of 30Mohammad SadatBelum ada peringkat

- HIGH CARBON 35Cr-45Ni-1Nb: Alloy TypeDokumen2 halamanHIGH CARBON 35Cr-45Ni-1Nb: Alloy TypeSaravanan Pitchandi100% (1)

- ASTM A194 NutsDokumen13 halamanASTM A194 NutsDan ClarkeBelum ada peringkat

- Stainless Steel AISI 630-17-4PHDokumen1 halamanStainless Steel AISI 630-17-4PHwillyBelum ada peringkat

- 304 Stainless Steel Technical Data SheetDokumen4 halaman304 Stainless Steel Technical Data SheetMani KannaBelum ada peringkat

- UI 9252-02 Site-Welded EquipmentDokumen18 halamanUI 9252-02 Site-Welded EquipmentAnonymous nLMJGuBelum ada peringkat

- Abdalla - Desing and Fabrication of Low Cost Filament Winding MachineDokumen6 halamanAbdalla - Desing and Fabrication of Low Cost Filament Winding MachineAndrés MercadoBelum ada peringkat

- PEC EN STN C 13619 17 Mar 2014Dokumen169 halamanPEC EN STN C 13619 17 Mar 2014Raja RamBelum ada peringkat

- D953 1714809-1Dokumen6 halamanD953 1714809-1NitinBelum ada peringkat

- DNV Design ConsiderationsDokumen36 halamanDNV Design Considerationskogi3075100% (1)

- JIS SectionDokumen2 halamanJIS SectionthakrarhitsBelum ada peringkat

- Asme Section II Part A - Sa 283-Sa 283mDokumen4 halamanAsme Section II Part A - Sa 283-Sa 283mSaulo RoseiraBelum ada peringkat

- Hinge DesignDokumen2 halamanHinge Designpare222Belum ada peringkat

- Principal of DPTDokumen5 halamanPrincipal of DPTAkshith SulliaBelum ada peringkat

- Fastener Connection To Structure - ExampleDokumen12 halamanFastener Connection To Structure - ExamplekingdbmBelum ada peringkat

- Manual Tank 2016Dokumen159 halamanManual Tank 2016stiglatBelum ada peringkat

- Rules For Reusing BoltsDokumen4 halamanRules For Reusing Boltsaataylor83Belum ada peringkat

- AWS D1.1-D1.1M-2015 - Pagina-110Dokumen1 halamanAWS D1.1-D1.1M-2015 - Pagina-110Gedalías MartínezBelum ada peringkat

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 122, - , - : Pressure Vessel Plate, Low Alloy Steel, MoDokumen3 halamanMCGB - Data Sheet For Suppliers Old MAT Nos.: 122, - , - : Pressure Vessel Plate, Low Alloy Steel, Mobaskaran ayyapparajBelum ada peringkat

- ASME B16 - Gasket Color CodeDokumen2 halamanASME B16 - Gasket Color CodeGonçalo CortezBelum ada peringkat

- PVC CPVC Physical Properties and Astm Specifications For Piping PDFDokumen1 halamanPVC CPVC Physical Properties and Astm Specifications For Piping PDFShahfaraz AhmadBelum ada peringkat

- Lifting Lug CalculatorDokumen5 halamanLifting Lug CalculatorJOHNBelum ada peringkat

- Recommended Design Model Beam Welds Design Check No 1 Design Capacity of Flange Welds To Beam - DG11Dokumen6 halamanRecommended Design Model Beam Welds Design Check No 1 Design Capacity of Flange Welds To Beam - DG11perdhana2000Belum ada peringkat

- Ameron FRP Fittings 7000MDokumen8 halamanAmeron FRP Fittings 7000MNatchimuthu Durai BalanBelum ada peringkat

- En10028 2Dokumen12 halamanEn10028 2Patilea Daniela100% (1)

- ACI 347-04 Guide To Formwork For ConcreteDokumen3 halamanACI 347-04 Guide To Formwork For ConcreteAlpin MaulidinBelum ada peringkat

- Equivalent GradesDokumen37 halamanEquivalent GradesUmesh SakhareliyaBelum ada peringkat

- Bar / Wire Wrapped Steel Cylinder Pipes With Mortar Lining and Coating (Including Specials) - SpecificationDokumen22 halamanBar / Wire Wrapped Steel Cylinder Pipes With Mortar Lining and Coating (Including Specials) - SpecificationPratik KharmateBelum ada peringkat

- Field Fresh Foods PVT LTD Design For Anchor Bolts in Moment ConditionDokumen2 halamanField Fresh Foods PVT LTD Design For Anchor Bolts in Moment Condition4geniecivilBelum ada peringkat

- Barrier GateDokumen12 halamanBarrier GatewillysketchBelum ada peringkat

- Timco TDS Drywall ScrewDokumen2 halamanTimco TDS Drywall ScrewNajeeb AhmedBelum ada peringkat

- Q235 Steel, Q235A Q235B Q235C Q235D Specification, Chemical Composition, Properties & EquivalentDokumen4 halamanQ235 Steel, Q235A Q235B Q235C Q235D Specification, Chemical Composition, Properties & EquivalentWaqas WaqasBelum ada peringkat

- Overhead Crane Governing Bodies and Specs PDFDokumen1 halamanOverhead Crane Governing Bodies and Specs PDFscofiel1Belum ada peringkat

- Galvanizing High Strength BoltsDokumen9 halamanGalvanizing High Strength BoltsMikeBelum ada peringkat

- Bearing Pad - AASHTO Grade: Hohmann & Barnard, IncDokumen1 halamanBearing Pad - AASHTO Grade: Hohmann & Barnard, IncRiyuRazeBelum ada peringkat

- Valve Weight PDFDokumen10 halamanValve Weight PDFPrabha KaranBelum ada peringkat

- Asme Sec Viii D2 Art D-2 PDFDokumen10 halamanAsme Sec Viii D2 Art D-2 PDFDieguitoOmarMoralesBelum ada peringkat

- Wind Calculation According To Bs Cp3 CH V Part 2Dokumen5 halamanWind Calculation According To Bs Cp3 CH V Part 2SAMER OSMANBelum ada peringkat

- Industries: The Manila'S Expert EngineersDokumen12 halamanIndustries: The Manila'S Expert EngineersJohn Carlos Moralidad CriticaBelum ada peringkat

- Butterfly ValvesDokumen27 halamanButterfly ValvesИгорьBelum ada peringkat

- Corrugated Web BeamDokumen67 halamanCorrugated Web BeampsewagBelum ada peringkat

- Csa G40.21 PDFDokumen4 halamanCsa G40.21 PDFmecano1Belum ada peringkat

- Interconnecting Pipe Rack - TF1-PRK-510Dokumen68 halamanInterconnecting Pipe Rack - TF1-PRK-510Khac Hoang PhamBelum ada peringkat

- Astm A194-A194m-13 PDFDokumen12 halamanAstm A194-A194m-13 PDFjhonnyBelum ada peringkat

- Final 175T Crane Spec DT 11.1.16 PDFDokumen57 halamanFinal 175T Crane Spec DT 11.1.16 PDFRohan KulkarniBelum ada peringkat

- Gasket BrochureDokumen8 halamanGasket BrochureKumar JbsBelum ada peringkat

- VMH - Mounded Bullet Foundation Guidance PDFDokumen5 halamanVMH - Mounded Bullet Foundation Guidance PDFMauricio R Morales100% (1)

- Hilti-Fischer Anchor BoltDokumen2 halamanHilti-Fischer Anchor Boltpavitrakedar100% (1)

- Design Charts For Bolts With Combined Shear and Tension: MechanicalfastenerswhicharesubjecttoacombinedDokumen4 halamanDesign Charts For Bolts With Combined Shear and Tension: MechanicalfastenerswhicharesubjecttoacombinedcmkohBelum ada peringkat

- A283GrC Vs A36 ComparisonDokumen2 halamanA283GrC Vs A36 ComparisonKhalilahmad KhatriBelum ada peringkat

- Comparison Between Astm A 36 and Astm A 283 Grade C 1. Material ScopeDokumen1 halamanComparison Between Astm A 36 and Astm A 283 Grade C 1. Material ScopeLalit Bom MallaBelum ada peringkat

- Comparison A36 & A283 GR.CDokumen1 halamanComparison A36 & A283 GR.CAchmad Roghib100% (20)

- Chloride Threshold For Various Reinforcement Steel TypesDokumen21 halamanChloride Threshold For Various Reinforcement Steel Typesshameeka100% (1)

- ASTM A738 Grade B: General Product DescriptionDokumen2 halamanASTM A738 Grade B: General Product DescriptionhealgoseBelum ada peringkat

- Astm A516Dokumen11 halamanAstm A516Kokoh Aji LesmanaBelum ada peringkat

- Data Sheet ASTM A36Dokumen1 halamanData Sheet ASTM A36vn_hung3137Belum ada peringkat

- Smart Ketosis Weight Loss On Auto Pilot by Ken Roberts FREE Keto E-BookDokumen13 halamanSmart Ketosis Weight Loss On Auto Pilot by Ken Roberts FREE Keto E-BookKhalilahmad KhatriBelum ada peringkat

- Azsft (Bjfô: VC, ( ) GGT J HDFVT D:,S (VFC, F CHZTDokumen48 halamanAzsft (Bjfô: VC, ( ) GGT J HDFVT D:,S (VFC, F CHZTKhalilahmad KhatriBelum ada peringkat

- EQUIPMENT: Tube Bundle For Shell &tube HX Titile: Inspection Test Plan Item: 6112-E-02Dokumen6 halamanEQUIPMENT: Tube Bundle For Shell &tube HX Titile: Inspection Test Plan Item: 6112-E-02Khalilahmad KhatriBelum ada peringkat

- Bharuch inDokumen2 halamanBharuch inKhalilahmad KhatriBelum ada peringkat

- Edu - Excellance Award 2019-Application FormDokumen2 halamanEdu - Excellance Award 2019-Application FormKhalilahmad KhatriBelum ada peringkat

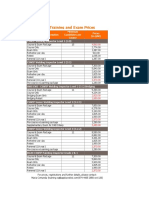

- 2019 Training Prices v1Dokumen1 halaman2019 Training Prices v1Khalilahmad KhatriBelum ada peringkat

- Plant Inspector CV.Dokumen7 halamanPlant Inspector CV.Khalilahmad KhatriBelum ada peringkat

- Outlet ListDokumen10 halamanOutlet ListKhalilahmad KhatriBelum ada peringkat

- 6D ScienceDokumen2 halaman6D ScienceKhalilahmad KhatriBelum ada peringkat

- Examinations Are Available At:: Cswip/Examvenues/2019Dokumen1 halamanExaminations Are Available At:: Cswip/Examvenues/2019Khalilahmad KhatriBelum ada peringkat

- Grade 1 - Entrance SyllabusDokumen1 halamanGrade 1 - Entrance SyllabusKhalilahmad KhatriBelum ada peringkat

- 101 Ahadith - Radd e Bad Mazhab-1Dokumen49 halaman101 Ahadith - Radd e Bad Mazhab-1Khalilahmad Khatri100% (1)

- Defensive Driving: " A Better Use of Mirrors"Dokumen9 halamanDefensive Driving: " A Better Use of Mirrors"Khalilahmad KhatriBelum ada peringkat

- The Greatest Bus Ever Built!Dokumen13 halamanThe Greatest Bus Ever Built!Khalilahmad KhatriBelum ada peringkat

- 2019-02-03 - SERVETECH Daily Progress ReportDokumen11 halaman2019-02-03 - SERVETECH Daily Progress ReportKhalilahmad KhatriBelum ada peringkat

- India: "Truth Alone Triumphs"Dokumen32 halamanIndia: "Truth Alone Triumphs"Khalilahmad KhatriBelum ada peringkat

- قانون شریعت مکملDokumen528 halamanقانون شریعت مکملKhalilahmad Khatri93% (15)

- 5 Important Qualities of Aayathul QurziDokumen7 halaman5 Important Qualities of Aayathul QurziKhalilahmad KhatriBelum ada peringkat

- Api-1169 Pipeline Construction Inspector: Body of KnowledgeDokumen9 halamanApi-1169 Pipeline Construction Inspector: Body of KnowledgeKhalilahmad KhatriBelum ada peringkat

- Family Must KnowDokumen16 halamanFamily Must KnowKhalilahmad Khatri83% (6)

- Mehmudaben Gulamnabi Ishakji Khatri: X BMNDokumen2 halamanMehmudaben Gulamnabi Ishakji Khatri: X BMNKhalilahmad KhatriBelum ada peringkat

- User Guide: Health & Safety ModuleDokumen24 halamanUser Guide: Health & Safety ModuleKhalilahmad KhatriBelum ada peringkat

- Ensemble Clapet Et VanneDokumen4 halamanEnsemble Clapet Et VannegwinnruBelum ada peringkat

- OPA335Dokumen32 halamanOPA335Mafer Ruiz EstudilloBelum ada peringkat

- 01 - IDoc Adapter PDFDokumen24 halaman01 - IDoc Adapter PDFFábio PantojaBelum ada peringkat

- Internship FormDokumen6 halamanInternship FormHOD Department of Mechanical EngineeringBelum ada peringkat

- MontessoriDokumen9 halamanMontessoriRaphael Sierra CalsinaBelum ada peringkat

- 1105 & 06 Samsung MagazineDokumen60 halaman1105 & 06 Samsung Magazinemiksan1975Belum ada peringkat

- FM5300 User Manual V2.7Dokumen105 halamanFM5300 User Manual V2.7Alex CanBelum ada peringkat

- The Role of A Construction ManagerDokumen9 halamanThe Role of A Construction Managermy_sydgal100% (1)

- Image Processing - AL Computer ScienceDokumen6 halamanImage Processing - AL Computer ScienceSarah HussainBelum ada peringkat

- GSM Gateway 252236Dokumen16 halamanGSM Gateway 252236muddogBelum ada peringkat

- Susan P Downson Sound Level Meter Calibration and VerificationDokumen6 halamanSusan P Downson Sound Level Meter Calibration and VerificationEduardo Mejía RomeroBelum ada peringkat

- Nginx Modules Reference r3Dokumen243 halamanNginx Modules Reference r3No NameBelum ada peringkat

- Electrical Machine DesignDokumen5 halamanElectrical Machine DesignsharmiladevyBelum ada peringkat

- AlabangClearance 12618Dokumen13 halamanAlabangClearance 12618Joseph Gene LalasBelum ada peringkat

- Unit 2Dokumen58 halamanUnit 2Venkatesh Arumugam100% (1)

- Map Info Pro Install GuideDokumen77 halamanMap Info Pro Install Guidececil tivaniBelum ada peringkat

- Low Voltage Alternators - 4 Pole: Installation and MaintenanceDokumen28 halamanLow Voltage Alternators - 4 Pole: Installation and MaintenanceElinton De Jesus SarmientoBelum ada peringkat

- Cyber Hunter-InstallerDokumen20 halamanCyber Hunter-InstallerMax CyberBelum ada peringkat

- Academic Integrity in Research and StudyDokumen19 halamanAcademic Integrity in Research and Studysurvanity wilsonBelum ada peringkat

- Performance Evaluation of Multimedia Streams Over Wireless Computer Networks (Wlans)Dokumen14 halamanPerformance Evaluation of Multimedia Streams Over Wireless Computer Networks (Wlans)Edy BudimanBelum ada peringkat

- Compresor Up6-50pe-125Dokumen208 halamanCompresor Up6-50pe-125AngelBelum ada peringkat

- ATEX ComplianceDokumen2 halamanATEX ComplianceEfari BahchevanBelum ada peringkat

- Astm D 570-1998Dokumen4 halamanAstm D 570-1998Anonymous ntZm8aUSuBelum ada peringkat

- Astm A324-73 (1992)Dokumen2 halamanAstm A324-73 (1992)FeteneBelum ada peringkat

- FABRIANO Catalogo2010 - Ing PDFDokumen72 halamanFABRIANO Catalogo2010 - Ing PDFS Antoni De RotiBelum ada peringkat

- Jonathan Robinson - Scoring Rubric Iep Case StudyDokumen11 halamanJonathan Robinson - Scoring Rubric Iep Case Studyapi-356383591Belum ada peringkat