Operation V N P T I 74

Diunggah oleh

Dhiraj SatyamJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Operation V N P T I 74

Diunggah oleh

Dhiraj SatyamHak Cipta:

Format Tersedia

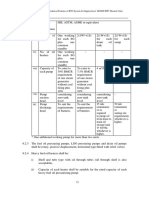

Sudden tripping of one or more Control the furnace pressure by adjusting I.D.

mills or choking of mills/raw coal fan vanes. Simultaneously try to start stand by

feeder pipe mill. Remove the chocking of affected mill/raw coal

feed pipe.

Partial flame failure Take the oil gun into service to establish flame at

that locations/corner.

Accidental closing of secondary See the proper functioning of secondary air path

air path damper.

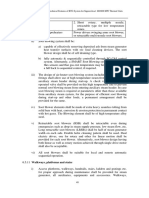

2.11.3.Drum Level Low

Mai-operation of Feed Auto Control Take feed control valve on hand and increase

or Feed Regulator or Scoop auto. feeding rate. Take scoop tube control on hand and

increase scoop tube position. Check that feed

water flow through each pump does not exceed }ts

capacity. Check feed water control valve and scoop

tube control linkages.

Tripping of one of working feed Start reserve feed pump on tripping of running

pump (standby pump does not start) feed pump, if auto starting fails.

Sudden reduction of load Try to increase the load if not possible reduced

firing irate accordingly to control drum pressure.

Sudden increase in firing e.g. Reduce firing rate by suitably adjusting the feeding

starting of mills having rate of running mills.

sufficient coal left before previous

stopping.

Tube rupture/puncture Check water flow and compare with previous

feeding rate and steam flow. High feed flow

indicates tube failure. Inspect water wall and econ-

omiser or any tube leakage. If tube leakage is

observed stop the boiler as soon as possible.

Inadvertent opening of low point Check drum drains and low point drain for tight

drain valves or Emergency drum closing.

drain valve.

Note :

If drum level goes below gauge glass and low drum level trip protection fails, trip boiler at once.

2.11.4.High Drum Level

Mal-operation of feed water control Take feed control valve on manual and reduce the

feeding rate.

Sudden increase in load resulting Try to decrease the load as far as possible.

in drum pressure drop.

70

Anda mungkin juga menyukai

- Super Critical Power - Part83Dokumen1 halamanSuper Critical Power - Part83Dhiraj SatyamBelum ada peringkat

- Super Critical Power - Part91Dokumen1 halamanSuper Critical Power - Part91Dhiraj SatyamBelum ada peringkat

- Chapter-10 Electrostatic Precipitator: 10.1 Design DataDokumen1 halamanChapter-10 Electrostatic Precipitator: 10.1 Design DataDhiraj SatyamBelum ada peringkat

- Super Critical Power - Part92Dokumen1 halamanSuper Critical Power - Part92Dhiraj SatyamBelum ada peringkat

- Super Critical Power - Part88Dokumen1 halamanSuper Critical Power - Part88Dhiraj SatyamBelum ada peringkat

- Super Critical Power - Part81Dokumen1 halamanSuper Critical Power - Part81Dhiraj SatyamBelum ada peringkat

- Standard Technical Features of BTG System for Supercritical Thermal UnitsDokumen1 halamanStandard Technical Features of BTG System for Supercritical Thermal UnitsDhiraj SatyamBelum ada peringkat

- Super Critical Power - Part81Dokumen1 halamanSuper Critical Power - Part81Dhiraj SatyamBelum ada peringkat

- Super Critical Power - Part86Dokumen1 halamanSuper Critical Power - Part86Dhiraj SatyamBelum ada peringkat

- Super Critical Power - Part62Dokumen1 halamanSuper Critical Power - Part62Dhiraj SatyamBelum ada peringkat

- Super Critical Power - Part80Dokumen1 halamanSuper Critical Power - Part80Dhiraj SatyamBelum ada peringkat

- Super Critical Power - Part79Dokumen1 halamanSuper Critical Power - Part79Dhiraj SatyamBelum ada peringkat

- Super Critical Power - Part78Dokumen1 halamanSuper Critical Power - Part78Dhiraj SatyamBelum ada peringkat

- Super Critical Power - Part77Dokumen1 halamanSuper Critical Power - Part77Dhiraj SatyamBelum ada peringkat

- Suitable For Remote Manual OperationDokumen1 halamanSuitable For Remote Manual OperationDhiraj SatyamBelum ada peringkat

- Super Critical Power - Part76Dokumen1 halamanSuper Critical Power - Part76Dhiraj SatyamBelum ada peringkat

- Super Critical Power - Part71Dokumen1 halamanSuper Critical Power - Part71Dhiraj SatyamBelum ada peringkat

- Super Critical Power - Part52Dokumen1 halamanSuper Critical Power - Part52Dhiraj SatyamBelum ada peringkat

- Super Critical Power - Part61Dokumen1 halamanSuper Critical Power - Part61Dhiraj SatyamBelum ada peringkat

- Standard Technical Features of BTG System for Supercritical Thermal UnitsDokumen1 halamanStandard Technical Features of BTG System for Supercritical Thermal UnitsDhiraj SatyamBelum ada peringkat

- BTG System Technical Features for 660/800 MW Thermal UnitsDokumen1 halamanBTG System Technical Features for 660/800 MW Thermal UnitsDhiraj SatyamBelum ada peringkat

- Technical Features BTG Thermal UnitsDokumen1 halamanTechnical Features BTG Thermal UnitsDhiraj SatyamBelum ada peringkat

- Super Critical Power - Part54Dokumen1 halamanSuper Critical Power - Part54Dhiraj SatyamBelum ada peringkat

- Super Critical Power - Part57Dokumen1 halamanSuper Critical Power - Part57Dhiraj SatyamBelum ada peringkat

- Super Critical Power - Part53Dokumen1 halamanSuper Critical Power - Part53Dhiraj SatyamBelum ada peringkat

- Super Critical Power - Part50Dokumen1 halamanSuper Critical Power - Part50Dhiraj SatyamBelum ada peringkat

- Super Critical Power - Part56Dokumen1 halamanSuper Critical Power - Part56Dhiraj SatyamBelum ada peringkat

- Super Critical Power - Part49Dokumen1 halamanSuper Critical Power - Part49Dhiraj SatyamBelum ada peringkat

- Standard Technical Features of BTG System for Supercritical Thermal UnitsDokumen1 halamanStandard Technical Features of BTG System for Supercritical Thermal UnitsDhiraj SatyamBelum ada peringkat

- Super Critical Power - Part48Dokumen1 halamanSuper Critical Power - Part48Dhiraj SatyamBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Lab 1 Heat PumpDokumen17 halamanLab 1 Heat PumpZack MalikBelum ada peringkat

- 17V10 Johnson How To Collect Form and Ship SulfurDokumen43 halaman17V10 Johnson How To Collect Form and Ship SulfurabderrahimnBelum ada peringkat

- Compressor Filters Price ListDokumen5 halamanCompressor Filters Price ListSurajPandeyBelum ada peringkat

- Aurora Fire Pump SpecsDokumen16 halamanAurora Fire Pump SpecsJosé Martín Meza CabillasBelum ada peringkat

- VTG Firetube Condensing Boilers Technical DataDokumen6 halamanVTG Firetube Condensing Boilers Technical DatajrodBelum ada peringkat

- Topic: Reheat, Regenerative & Other Steam Power CycleDokumen17 halamanTopic: Reheat, Regenerative & Other Steam Power CycleMurvin VillarosaBelum ada peringkat

- Pneumatic & Hydraulic Circuit DiagramsDokumen6 halamanPneumatic & Hydraulic Circuit DiagramsRyan Jay Busabos100% (1)

- 7FA GT Classic Re Imagined - GEA17911Dokumen20 halaman7FA GT Classic Re Imagined - GEA17911Christina Paul100% (2)

- Chiesa, Paolo_ Lozza, Giovanni - [ASME ASME 1998 International Gas Turbine and Aeroengine Congress and Exhibition - Stockholm, Sweden (Tuesday 2 June 1998)] Vol (1998, American Society of Mechanical Engineers) [10.1115_98-Gt-38 - Libgen.liDokumen8 halamanChiesa, Paolo_ Lozza, Giovanni - [ASME ASME 1998 International Gas Turbine and Aeroengine Congress and Exhibition - Stockholm, Sweden (Tuesday 2 June 1998)] Vol (1998, American Society of Mechanical Engineers) [10.1115_98-Gt-38 - Libgen.liDS ManojBelum ada peringkat

- Six Stroke EngineDokumen36 halamanSix Stroke EngineAmandeep Tanwar100% (2)

- MEC7110: Solar Energy TechnologyDokumen3 halamanMEC7110: Solar Energy TechnologyNkugwa Mark WilliamBelum ada peringkat

- ME-458 Turbomachinery: Review of Basic Laws and Design AspectsDokumen113 halamanME-458 Turbomachinery: Review of Basic Laws and Design AspectsAneeq Raheem0% (1)

- The Jet Engine, 5th EditionDokumen306 halamanThe Jet Engine, 5th Editionmilad100% (3)

- Pressure Relief Valves HenryDokumen7 halamanPressure Relief Valves HenryOSCAR ASIAINBelum ada peringkat

- Nuclear Marine PropulsionDokumen106 halamanNuclear Marine PropulsionJosue Carpio100% (1)

- Chem 4922Dokumen2 halamanChem 4922sieausBelum ada peringkat

- Centrifugal Compressor SealsDokumen4 halamanCentrifugal Compressor SealsHadi ShahsavanBelum ada peringkat

- S (G2) Series Datasheet-3.22Dokumen2 halamanS (G2) Series Datasheet-3.22Carlos CruzBelum ada peringkat

- Sugar - Fluid Flow VelocitiesDokumen4 halamanSugar - Fluid Flow VelocitiesOmar Ahmed ElkhalilBelum ada peringkat

- Operating Instructions: Preparation For Start-UpDokumen8 halamanOperating Instructions: Preparation For Start-UpMiliani AhmedBelum ada peringkat

- Handouts PPE Day 3Dokumen4 halamanHandouts PPE Day 3terrence miguel balitaBelum ada peringkat

- Submittal FCQ36MVJU - RZQ36MVJU 07-06 - DaikinDokumen1 halamanSubmittal FCQ36MVJU - RZQ36MVJU 07-06 - Daikinedward sabedraBelum ada peringkat

- Renewable Energy Resources - Lecture 5Dokumen29 halamanRenewable Energy Resources - Lecture 5Kifayat UllahBelum ada peringkat

- Boiler Draft SystemDokumen56 halamanBoiler Draft SystemAmit Chauhan78% (9)

- Technical Data Sheet MX21TG 200-220/230V 50/60Hz 1 R404A: Compressor Model Voltage RefrigerantDokumen5 halamanTechnical Data Sheet MX21TG 200-220/230V 50/60Hz 1 R404A: Compressor Model Voltage RefrigerantCarlos SilvaBelum ada peringkat

- Ch2 - Gas TurbinesDokumen37 halamanCh2 - Gas TurbinesShaktivell Letchumanan100% (1)

- The Relay Protection Coordination For PHDokumen6 halamanThe Relay Protection Coordination For PHgrigore mirceaBelum ada peringkat

- 200TR Modern Air ChillerDokumen14 halaman200TR Modern Air ChillerJhon LewisBelum ada peringkat

- GTG-1 GTG-2: A-Shift B-Shift C-Shift A-Shift B-Shift C-ShiftDokumen3 halamanGTG-1 GTG-2: A-Shift B-Shift C-Shift A-Shift B-Shift C-Shiftcksharma68Belum ada peringkat

- Project 1 - Parsing NASA Thermodynamic Data - Skill-LyncDokumen9 halamanProject 1 - Parsing NASA Thermodynamic Data - Skill-LyncShlok DixitBelum ada peringkat

![Chiesa, Paolo_ Lozza, Giovanni - [ASME ASME 1998 International Gas Turbine and Aeroengine Congress and Exhibition - Stockholm, Sweden (Tuesday 2 June 1998)] Vol (1998, American Society of Mechanical Engineers) [10.1115_98-Gt-38 - Libgen.li](https://imgv2-1-f.scribdassets.com/img/document/605752054/149x198/cebe8cc676/1667824590?v=1)