Raft Foundation Design

Diunggah oleh

mihai_serban13Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Raft Foundation Design

Diunggah oleh

mihai_serban13Hak Cipta:

Format Tersedia

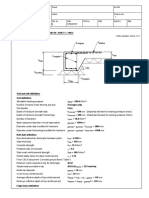

RAFT FOUNDATION DESIGN (BS8110 : PART 1 : 1997)

TEDDS calculation version 1.0.05;

A s e d g e to p

A s s la b to p

A h s la b

s e d g e lin k

hedge h h c o r e s la b

aedge

h h c o r e th ic k

A s e d g e b tm

bedge

Soil and raft definition

Soil definition

Allowable bearing pressure; qallow = 400.0 kN/m2

Number of types of soil forming sub-soil; One type only

Soil density; Firm

Depth of hardcore beneath slab; hhcoreslab = 150 mm; (Dispersal allowed for bearing pressure

check)

Depth of hardcore beneath thickenings; hhcorethick = 150 mm; (Dispersal allowed for bearing pressure

check)

Density of hardcore; hcore = 20.0 kN/m3

Basic assumed diameter of local depression; depbasic = 1500mm

Diameter under slab modified for hardcore; depslab = depbasic - hhcoreslab = 1350 mm

Diameter under thickenings modified for hardcore; depthick = depbasic - hhcorethick = 1350 mm

Raft slab definition

Max dimension/max dimension between joints; lmax = 20.000 m

Slab thickness; hslab = 150 mm

Concrete strength; fcu = 40 N/mm2

Poissons ratio of concrete; = 0.2

Slab mesh reinforcement strength; fyslab = 500 N/mm2

Partial safety factor for steel reinforcement; s = 1.15

From C&CA document Concrete ground floors Table 5

Minimum mesh required in top for shrinkage; A142;

Actual mesh provided in top; A393 (Asslabtop = 393 mm2/m)

Mesh bar diameter; slabtop = 10 mm

Cover to top reinforcement; ctop = 50 mm

Average effective depth of top reinforcement; dtslabav = hslab - ctop - slabtop = 90 mm

Minimum effective depth of top reinforcement; dtslabmin = dtslabav - slabtop/2 = 85 mm

Edge beam definition

Overall depth; hedge = 450 mm

Width; bedge = 450 mm

Angle of chamfer to horizontal; edge = 45 deg

Strength of main bar reinforcement; fy = 500 N/mm2

Strength of link reinforcement; fys = 500 N/mm2

Reinforcement provided in top; 4 T12 bars (Asedgetop = 452 mm2)

Reinforcement provided in bottom; 4 T12 bars (Asedgebtm = 452 mm2)

Link reinforcement provided; 2 T12 legs at 300 ctrs (Asv/sv = 0.754 mm)

Bottom cover to links; cbeam = 50 mm

Effective depth of top reinforcement; dedgetop = hedge - ctop - slabtop -edgelink - edgetop/2 = 372 mm

Effective depth of bottom reinforcement; dedgebtm = hedge - cbeam - edgelink - edgebtm/2 = 382 mm

Internal slab design checks

Basic loading

Slab self weight; wslab = 24 kN/m3 hslab = 3.6 kN/m2

Hardcore; whcoreslab = hcore hhcoreslab = 3.0 kN/m2

Applied loading

Uniformly distributed dead load; wDudl = 0.0 kN/m2

Uniformly distributed live load; wLudl = 7.0 kN/m2

Internal slab bearing pressure check

Total uniform load at formation level; wudl = wslab + whcoreslab + wDudl + wLudl = 13.6 kN/m2

PASS - wudl <= qallow - Applied bearing pressure is less than allowable

Internal slab bending and shear check

Applied bending moments

Effective span of slab; lslab = (depslab + dtslabav)/2 = 720 mm

Ultimate self weight udl; wswult = 1.4 wslab = 5.0 kN/m2

Approximate self weight cantilever moment at edge; Mesw = (wswult lslab2) (lslab/3) / (2 lslab) = 0.4kNm/m

Self weight shear force at edge; Vsw = wswult lslab / 2 = 1.8 kN/m

Moments due to applied uniformly distributed loads

Ultimate applied udl; wudlult = 1.4 wDudl + 1.6 wLudl = 11.2 kN/m2

Approximate cantilever moment at edge; Meudl = (wudlult lslab2) (lslab/3) / (2 lslab) = 1.0 kNm/m

Shear force at edge; Vudl = wudlult lslab / 2 = 4.0 kN/m

Resultant moments and shears

Total moment at edge; Me = 1.4 kNm/m

Total shear force; V = 5.8 kN/m

Reinforcement required in top

K factor; Kslabtop = Me/(fcu dtslabav2) = 0.004

Lever arm; z slabtop = dtslabav min(0.95, 0.5 + (0.25 - Kslabtop/0.9)) = 85.5 mm

Area of steel required for bending; Asslabtopbend = Me/((1.0/s) fyslab zslabtop) = 38 mm2/m

Minimum area of steel required; Asslabmin = 0.0013 hslab = 195 mm2/m

Area of steel required; Asslabtopreq = max(Asslabtopbend, Asslabmin) = 195 mm2/m

PASS - Asslabtopreq <= Asslabtop - Area of reinforcement provided in top to span local depressions is adequate

Shear check

Applied shear stress; v = V/dtslabmin = 0.069 N/mm2

Tension steel ratio; = 100 Asslabtop/dtslabmin = 0.462

Design concrete shear strength; vc = 0.842 N/mm2

PASS - v <= vc - Shear capacity of the slab is adequate

Internal slab deflection check

Basic allowable span to depth ratio; Ratiobasic = 7.0

Moment factor; Mfactor = Me/dtslabav2 = 0.173 N/mm2

Steel service stress; fs = 2/3 fyslab Asslabtopbend/Asslabtop = 32.015 N/mm2

Modification factor; MF slab = min(2.0, 0.55 + [(477N/mm2 - fs)/(120 (0.9N/mm2

+ M factor))])

MFslab = 2.000

Modified allowable span to depth ratio; Ratioallow = Ratiobasic MFslab = 14.000

Actual span to depth ratio; Ratioactual = lslab/dtslabav = 8.000

PASS - Ratioactual <= Ratioallow - Slab span to depth ratio is adequate

Edge beam design checks

Basic loading

Hardcore; whcorethick = hcore hhcorethick = 3.0 kN/m2

Edge beam

Rectangular beam element; wbeam = 24 kN/m3 hedge bedge = 4.9 kN/m

Chamfer element; wchamfer = 24 kN/m3 (hedge - hslab)2/(2 tan(edge)) = 1.1 kN/m

Slab element; w slabelmt = 24 kN/m3 hslab (hedge - hslab)/tan(edge) = 1.1 kN/m

Edge beam self weight; wedge = wbeam + wchamfer + wslabelmt = 7.0 kN/m

Edge beam bearing pressure check

Effective bearing width of edge beam; bbearing = bedge + (hedge - hslab)/tan(edge) = 750 mm

Total uniform load at formation level; wudledge = wDudl+wLudl+wedge/bbearing+whcorethick = 19.4 kN/m2

PASS - wudledge <= qallow - Applied bearing pressure is less than allowable

Edge beam bending check

Divider for moments due to udls; udl = 10.0

Applied bending moments

Span of edge beam; ledge = depthick + dedgetop = 1722 mm

Ultimate self weight udl; wedgeult = 1.4 wedge = 9.8 kN/m

Ultimate slab udl (approx); w edgeslab = max(0 kN/m,1.4wslab((depthick/23/4)-

- (b edge+(hedge- hslab)/tan(edge))))

wedgeslab = 0.0 kN/m

Self weight and slab bending moment; Medgesw = (wedgeult + wedgeslab) ledge2/udl = 2.9 kNm

Self weight shear force; Vedgesw = (wedgeult + wedgeslab) ledge/2 = 8.5 kN

Moments due to applied uniformly distributed loads

Ultimate udl (approx); wedgeudl = wudlult depthick/2 3/4 = 5.7 kN/m

Bending moment; Medgeudl = wedgeudl ledge2/udl = 1.7 kNm

Shear force; Vedgeudl = wedgeudl ledge/2 = 4.9 kN

Resultant moments and shears

Total moment (hogging and sagging); Medge = 4.6 kNm

Maximum shear force; Vedge = 13.3 kN

Reinforcement required in top

Width of section in compression zone; bedgetop = bedge = 450 mm

Average web width; bw = bedge + (hedge/tan(edge))/2 = 675 mm

K factor; Kedgetop = Medge/(fcu bedgetop dedgetop2) = 0.002

Lever arm; zedgetop = dedgetop min(0.95, 0.5 + (0.25 - Kedgetop/0.9)) = 353

mm

Area of steel required for bending; Asedgetopbend = Medge/((1.0/s) fy zedgetop) = 30 mm2

Minimum area of steel required; Asedgetopmin = 0.0013 1.0 bw hedge = 395 mm2

Area of steel required; Asedgetopreq = max(Asedgetopbend, Asedgetopmin) = 395 mm2

PASS - Asedgetopreq <= Asedgetop - Area of reinforcement provided in top of edge beams is adequate

Reinforcement required in bottom

Width of section in compression zone; bedgebtm = bedge + (hedge - hslab)/tan(edge) + 0.1 ledge = 922 mm

K factor; Kedgebtm = Medge/(fcu bedgebtm dedgebtm2) = 0.001

Lever arm; zedgebtm = dedgebtm min(0.95, 0.5 + (0.25 - Kedgebtm/0.9)) = 363

mm

Area of steel required for bending; Asedgebtmbend = Medge/((1.0/s) fy zedgebtm) = 29 mm2

Minimum area of steel required; Asedgebtmmin = 0.0013 1.0 bw hedge = 395 mm2

Area of steel required; Asedgebtmreq = max(Asedgebtmbend, Asedgebtmmin) = 395 mm2

PASS - Asedgebtmreq <= Asedgebtm - Area of reinforcement provided in bottom of edge beams is adequate

Edge beam shear check

Applied shear stress; vedge = Vedge/(bw dedgetop) = 0.053 N/mm2

Tension steel ratio; edge = 100 Asedgetop/(bw dedgetop) = 0.180

From BS8110-1:1997 - Table 3.8

Design concrete shear strength; vcedge = 0.425 N/mm2

vedge <= vcedge + 0.4N/mm2 - Therefore minimum links required

Link area to spacing ratio required; Asv_upon_svreqedge = 0.4N/mm2 bw/((1.0/s) fys) = 0.621 mm

Link area to spacing ratio provided; Asv_upon_svprovedge = Nedgelinkedgelink2/(4svedge) = 0.754 mm

PASS - Asv_upon_svreqedge <= Asv_upon_svprovedge - Shear reinforcement provided in edge beams is adequate

Corner design checks

Basic loading

Corner bearing pressure check

Total uniform load at formation level; wudlcorner = wDudl+wLudl+wedge/bbearing+whcorethick = 19.4 kN/m2

PASS - wudlcorner <= qallow - Applied bearing pressure is less than allowable

Corner beam bending check

Cantilever span of edge beam; lcorner = depthick/(2) + dedgetop/2 = 1141 mm

Moment and shear due to self weight

Ultimate self weight udl; wedgeult = 1.4 wedge = 9.8 kN/m

Average ultimate slab udl (approx); wcornerslab = max(0 kN/m,1.4wslab(depthick/((2)2)-(bedge+(hedge-

-h slab)/tan(edge))))

wcornerslab = 0.0 kN/m

Self weight and slab bending moment; Mcornersw = (wedgeult + wcornerslab) lcorner2/2 = 6.4 kNm

Self weight and slab shear force; Vcornersw = (wedgeult + wcornerslab) lcorner = 11.2 kN

Moment and shear due to udls

Maximum ultimate udl;wcornerudl = ((1.4wDudl)+(1.6wLudl)) depthick/(2) = 10.7 kN/m

Bending moment; Mcornerudl = wcornerudl lcorner2/6 = 2.3 kNm

Shear force; Vcornerudl = wcornerudl lcorner/2 = 6.1 kN

Resultant moments and shears

Total design moment; Mcorner = Mcornersw+ Mcornerudl = 8.7 kNm

Total design shear force; Vcorner = Vcornersw+ Vcornerudl = 17.3 kN

Reinforcement required in top of edge beam

K factor; Kcorner = Mcorner/(fcu bedgetop dedgetop2) = 0.003

Lever arm; z corner = dedgetop min(0.95, 0.5 + (0.25 - Kcorner/0.9)) = 353 mm

Area of steel required for bending; Ascornerbend = Mcorner/((1.0/s) fy zcorner) = 57 mm2

Minimum area of steel required; Ascornermin = Asedgetopmin = 395 mm2

Area of steel required; Ascorner = max(Ascornerbend, Ascornermin) = 395 mm2

PASS - Ascorner <= Asedgetop - Area of reinforcement provided in top of edge beams at corners is adequate

Corner beam shear check

Average web width; bw = bedge + (hedge/tan(edge))/2 = 675 mm

Applied shear stress; vcorner = Vcorner/(bw dedgetop) = 0.069 N/mm2

Tension steel ratio; corner = 100 Asedgetop/(bw dedgetop) = 0.180

From BS8110-1:1997 - Table 3.8

Design concrete shear strength; vccorner = 0.417 N/mm2

vcorner <= vccorner + 0.4N/mm2 - Therefore minimum links required

Link area to spacing ratio required; Asv_upon_svreqcorner = 0.4N/mm2 bw/((1.0/s) fys) = 0.621 mm

Link area to spacing ratio provided; Asv_upon_svprovedge = Nedgelinkedgelink2/(4svedge) = 0.754 mm

PASS - Asv_upon_svreqcorner <= Asv_upon_svprovedge - Shear reinforcement provided in edge beams at corners

is adequate

Corner beam deflection check

Basic allowable span to depth ratio; Ratiobasiccorner = 7.0

Moment factor; Mfactorcorner = Mcorner/(bedgetop dedgetop2) = 0.140 N/mm2

Steel service stress; fscorner = 2/3 fy Ascornerbend/Asedgetop = 41.773 N/mm2

Modification factor; MF corner=min(2.0,0.55+[(477N/mm2-fscorner)/(120(0.9N/mm2+Mfactorcorner))])

MFcorner = 2.000

Modified allowable span to depth ratio; Ratioallowcorner = Ratiobasiccorner MFcorner = 14.000

Actual span to depth ratio; Ratioactualcorner = lcorner/ dedgetop = 3.066

PASS - Ratioactualcorner <= Ratioallowcorner - Edge beam span to depth ratio is adequate

Anda mungkin juga menyukai

- Raft Foundation DesignDokumen5 halamanRaft Foundation Designafiq100% (2)

- Raft DesignDokumen8 halamanRaft Designomolewa joshuaBelum ada peringkat

- Raft DesignDokumen8 halamanRaft Designramesh_madkatte1082Belum ada peringkat

- Slab Bridge Eg Han - 2 - 150321122706Dokumen10 halamanSlab Bridge Eg Han - 2 - 150321122706Ebisa AdamuBelum ada peringkat

- Analysis & Design of Multi Storeyed Buildings V.M.RAJAN, M.E. (Struct), FIE, Former CE/Civil/TANGEDCODokumen25 halamanAnalysis & Design of Multi Storeyed Buildings V.M.RAJAN, M.E. (Struct), FIE, Former CE/Civil/TANGEDCOV.m. RajanBelum ada peringkat

- Eccentric Footing Design 4Dokumen10 halamanEccentric Footing Design 4Murthy Guna100% (1)

- RCC RAFT FOUNDATION DESIGNDokumen33 halamanRCC RAFT FOUNDATION DESIGNUma Mahesh100% (1)

- Slab Design As Per IS 456Dokumen7 halamanSlab Design As Per IS 456RitaBiswas100% (1)

- RCD Course Work PDFDokumen60 halamanRCD Course Work PDFSaciid LaafaBelum ada peringkat

- Raft Foundation DesignDokumen6 halamanRaft Foundation DesignstructuralengBelum ada peringkat

- Concrete slab stress analysis reportDokumen3 halamanConcrete slab stress analysis reportprabhu_civil20Belum ada peringkat

- Ware House DesignDokumen8 halamanWare House DesignJay-Jay JapsBelum ada peringkat

- Combined FootingDokumen31 halamanCombined Footingalbert_pathBelum ada peringkat

- Summary of Structural Calculation of 1-Barrel Box CulvertDokumen30 halamanSummary of Structural Calculation of 1-Barrel Box CulvertTony Hartono BagioBelum ada peringkat

- NOTES SeviceabilityDokumen81 halamanNOTES Seviceabilitydileep 443Belum ada peringkat

- 20d-Stepped Masonry Retaining Wall-Stability CheckDokumen6 halaman20d-Stepped Masonry Retaining Wall-Stability CheckParthiban Arivazhagan100% (1)

- Calculation of Pile Bearing CapacityDokumen3 halamanCalculation of Pile Bearing Capacityhayder1974Belum ada peringkat

- Sachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997Dokumen14 halamanSachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997sitheeqBelum ada peringkat

- Design of Underground Water TankDokumen6 halamanDesign of Underground Water TankAlfred PatrickBelum ada peringkat

- Wind Load Calculation (Parking-1 Monoslope)Dokumen2 halamanWind Load Calculation (Parking-1 Monoslope)Partha Roy/Engineering/HO Noida/InterarchBelum ada peringkat

- Design of Retaining WallDokumen8 halamanDesign of Retaining WallLeena RodricksBelum ada peringkat

- Repport Steel Structure PDFDokumen111 halamanRepport Steel Structure PDFAnonymous fxqnhfKBelum ada peringkat

- Design of Multi-Cell Box Culvert (Side Walls & Bottom Slab)Dokumen4 halamanDesign of Multi-Cell Box Culvert (Side Walls & Bottom Slab)Berry Umpola100% (2)

- Isolated footing design example step-by-step guideDokumen6 halamanIsolated footing design example step-by-step guidetopukuet100% (1)

- Fence Type-3: Design Calculation Sheet HYD-121 FenceDokumen18 halamanFence Type-3: Design Calculation Sheet HYD-121 FenceAbhilash KowndinyaBelum ada peringkat

- Crack Width Calculation for ColumnDokumen3 halamanCrack Width Calculation for ColumnNadira PervinBelum ada peringkat

- Isolated FootingDokumen59 halamanIsolated Footingsrinivasa raoBelum ada peringkat

- Design of AquaductDokumen76 halamanDesign of AquaductGaurav Sharma100% (1)

- Calculation For 1.4m X 1.5m RCC Box CulvertDokumen4 halamanCalculation For 1.4m X 1.5m RCC Box Culvertrupesh417Belum ada peringkat

- Design Shear Resistance (Beams EC2)Dokumen2 halamanDesign Shear Resistance (Beams EC2)dhanya1995Belum ada peringkat

- 5-Design of Raft FoundationDokumen2 halaman5-Design of Raft FoundationheshamBelum ada peringkat

- Design of FootingDokumen31 halamanDesign of FootingAbhinav100% (1)

- Special Moment Resisting FrameDokumen1 halamanSpecial Moment Resisting FrameJester AbucayBelum ada peringkat

- Reference Calculations Output: N/A Project CalculationDokumen2 halamanReference Calculations Output: N/A Project CalculationRyan De LeonBelum ada peringkat

- Design of ColumnDokumen6 halamanDesign of ColumnShivsagar YadavBelum ada peringkat

- SEO Structural Design of Box CulvertsDokumen8 halamanSEO Structural Design of Box CulvertscoreteamBelum ada peringkat

- Design of Pile CapDokumen3 halamanDesign of Pile CapHaris Lee100% (2)

- Design Two Way Slab ReinforcementDokumen5 halamanDesign Two Way Slab ReinforcementVinod RevankarBelum ada peringkat

- StaircaseDokumen2 halamanStaircaseMAGED MOHMMED AHMED QASEMBelum ada peringkat

- Retaining Wall Design CalculationsDokumen25 halamanRetaining Wall Design CalculationsAmit Patel100% (1)

- Design of pile cap reinforcement for 4-pile groupDokumen13 halamanDesign of pile cap reinforcement for 4-pile groupShabbir OsmaniBelum ada peringkat

- Retaining Wall Design CalculationsDokumen6 halamanRetaining Wall Design Calculationsdocument123456789100% (1)

- RCC Stair Case Design for Residential BuildingDokumen14 halamanRCC Stair Case Design for Residential BuildingVictor OmotoriogunBelum ada peringkat

- Steel Connection DesignDokumen68 halamanSteel Connection DesignPushkar KokaneBelum ada peringkat

- Design of 8x10m grid floor slab with M25 concrete and Fe415 barsDokumen3 halamanDesign of 8x10m grid floor slab with M25 concrete and Fe415 barsHarini RameshBelum ada peringkat

- Calculation Notes for Luxury Villa Development ProjectDokumen29 halamanCalculation Notes for Luxury Villa Development ProjectShanil BussooaBelum ada peringkat

- UNDER-REAMED PILES: KEY FACTS ABOUT CONSTRUCTION AND DESIGNDokumen7 halamanUNDER-REAMED PILES: KEY FACTS ABOUT CONSTRUCTION AND DESIGNAnonymous nwByj9LBelum ada peringkat

- Admin Block: Pile Cap (3pile Group) Design by Bending Theory To Bs 8110 Part 1Dokumen3 halamanAdmin Block: Pile Cap (3pile Group) Design by Bending Theory To Bs 8110 Part 1Saifulazreen Mahyan100% (1)

- Design of Simply Supported One Way SlabDokumen15 halamanDesign of Simply Supported One Way SlabNikhil100% (2)

- Beam to beam design with landingsDokumen10 halamanBeam to beam design with landingsUmesh ChamaraBelum ada peringkat

- Raft Foundation Design (Bs8110: Part 1: 1997) : SslabtopDokumen2 halamanRaft Foundation Design (Bs8110: Part 1: 1997) : SslabtopafiqBelum ada peringkat

- Slab Foundation Design 1Dokumen6 halamanSlab Foundation Design 1Renato ZanescoBelum ada peringkat

- Raft Foundation DesignDokumen7 halamanRaft Foundation DesignperundingtsteohgmailcomBelum ada peringkat

- RC Raft FoundationDokumen6 halamanRC Raft FoundationNaziemi AhmadBelum ada peringkat

- Project foundation design calculationsDokumen10 halamanProject foundation design calculationsGautam PaulBelum ada peringkat

- Design of RC Rectangular Section NSCP ACI 318Dokumen5 halamanDesign of RC Rectangular Section NSCP ACI 318Nicko Jay BajaoBelum ada peringkat

- RC SLAB DESIGN CALCULATION REPORTDokumen35 halamanRC SLAB DESIGN CALCULATION REPORTျမတ္ သူ ေအာင္Belum ada peringkat

- RDSODokumen8 halamanRDSOVikasBelum ada peringkat

- JPPJ Calcs for Raft Foundation DesignDokumen1 halamanJPPJ Calcs for Raft Foundation DesignHimura_100% (1)

- Element Location: Subject: Made by Design Code: Loading On Slab Value Units JamesDokumen5 halamanElement Location: Subject: Made by Design Code: Loading On Slab Value Units JamesJames AswaBelum ada peringkat

- Fursecuri Vegane Boost MetabolismDokumen1 halamanFursecuri Vegane Boost Metabolismmihai_serban13Belum ada peringkat

- Highline 179 - o Punte La Înălțime Și L..Dokumen1 halamanHighline 179 - o Punte La Înălțime Și L..mihai_serban13Belum ada peringkat

- Influence of Headed Anchor Group Layout On Concrete Failure in TensionDokumen8 halamanInfluence of Headed Anchor Group Layout On Concrete Failure in TensionMoe Oo HtunBelum ada peringkat

- Top 10 Recipes KetoDokumen23 halamanTop 10 Recipes Ketomihai_serban13100% (4)

- Gluten Free & Keto Chocolate Chip Cookies - Just 1Dokumen2 halamanGluten Free & Keto Chocolate Chip Cookies - Just 1mihai_serban13Belum ada peringkat

- Tables of Structural Steel Sections1Dokumen107 halamanTables of Structural Steel Sections1MichaelBelum ada peringkat

- Spec. HVAC DesignDokumen7 halamanSpec. HVAC Designmihai_serban13Belum ada peringkat

- Gluten Free & Keto Cinnamon Toast Crunch Cereal ? Now Extra Crunchy! PDFDokumen2 halamanGluten Free & Keto Cinnamon Toast Crunch Cereal ? Now Extra Crunchy! PDFmihai_serban13Belum ada peringkat

- Specification For Air-Cooled Packaged Computer Ac UnitDokumen7 halamanSpecification For Air-Cooled Packaged Computer Ac Unitmihai_serban13Belum ada peringkat

- Tank FoundationDokumen9 halamanTank Foundationmihai_serban13Belum ada peringkat

- (15-Minute!) Keto Pizza Crust - Gnom-Gnom PDFDokumen2 halaman(15-Minute!) Keto Pizza Crust - Gnom-Gnom PDFmihai_serban13Belum ada peringkat

- Keto Mozzarella Dough Bagels - Only 2Dokumen1 halamanKeto Mozzarella Dough Bagels - Only 2mihai_serban13Belum ada peringkat

- Anc DesignDokumen9 halamanAnc Designmihai_serban13Belum ada peringkat

- Top 10 Recipes KetoDokumen23 halamanTop 10 Recipes Ketomihai_serban13100% (4)

- Gluten Free & Keto Cinnamon Toast Crunch Cereal ? Now Extra Crunchy!Dokumen2 halamanGluten Free & Keto Cinnamon Toast Crunch Cereal ? Now Extra Crunchy!mihai_serban13Belum ada peringkat

- Dynamic Analysis and Structural Design of Turbine Generator FoundationsDokumen12 halamanDynamic Analysis and Structural Design of Turbine Generator FoundationsGowrishankar1987100% (1)

- Gluten Free & Keto Chocolate Chip Cookies - Just 1Dokumen2 halamanGluten Free & Keto Chocolate Chip Cookies - Just 1mihai_serban13Belum ada peringkat

- Breakfast Sanatosx4Dokumen4 halamanBreakfast Sanatosx4mihai_serban13Belum ada peringkat

- Performance Run - L65ADokumen1 halamanPerformance Run - L65Amihai_serban13Belum ada peringkat

- HighwayDokumen48 halamanHighwaymihai_serban13Belum ada peringkat

- Salzburg Si LacuriDokumen4 halamanSalzburg Si Lacurimihai_serban13Belum ada peringkat

- Desig - Floor Slabs On Grade - 1Dokumen61 halamanDesig - Floor Slabs On Grade - 1mihai_serban13Belum ada peringkat

- Tabel AlcalinitateDokumen17 halamanTabel Alcalinitatemihai_serban13100% (1)

- Anc DesignDokumen9 halamanAnc Designmihai_serban13Belum ada peringkat

- Bracing For Stability - Yura - Another VersionDokumen144 halamanBracing For Stability - Yura - Another Versionmihai_serban13Belum ada peringkat

- Connessione Controvento 2UPN EC3 IngleseDokumen15 halamanConnessione Controvento 2UPN EC3 Inglesemihai_serban13Belum ada peringkat

- Lap & Splice Lengths ACI 318-02Dokumen3 halamanLap & Splice Lengths ACI 318-02mihai_serban13100% (1)

- Connessione A Taglio EC3 IngleseDokumen15 halamanConnessione A Taglio EC3 Inglesemihai_serban13Belum ada peringkat

- Dynamic Analysis and Structural Design of Turbine Generator FoundationsDokumen12 halamanDynamic Analysis and Structural Design of Turbine Generator FoundationsGowrishankar1987100% (1)

- Proceedings of The Third Balkan Symposium On Archaeometry 2012Dokumen107 halamanProceedings of The Third Balkan Symposium On Archaeometry 2012Lucian RatoiuBelum ada peringkat

- New wind tunnel tests boundary layersDokumen9 halamanNew wind tunnel tests boundary layerslmjBelum ada peringkat

- Head Loss in TunnelsDokumen16 halamanHead Loss in TunnelsSai Charan RajuBelum ada peringkat

- Math8 3rdquarter (Week 1-7)Dokumen8 halamanMath8 3rdquarter (Week 1-7)Angelie ButalidBelum ada peringkat

- 1-Ion Channels-08!06!2022 (08-Jun-2022) Material II 08-06-2022 Goldman EquationDokumen21 halaman1-Ion Channels-08!06!2022 (08-Jun-2022) Material II 08-06-2022 Goldman Equationfiseha tadesseBelum ada peringkat

- DGA - TANGEDCO's procedure for transformer oil analysisDokumen7 halamanDGA - TANGEDCO's procedure for transformer oil analysischandranmuthuswamyBelum ada peringkat

- Test Bank For College Physics 5th Edition Alan GiambattistaDokumen24 halamanTest Bank For College Physics 5th Edition Alan Giambattistaalexiscastillorbtjcdazng100% (46)

- Ap Calculus Ab-Bc Cheat SheetDokumen25 halamanAp Calculus Ab-Bc Cheat SheetticoninxBelum ada peringkat

- ASTM D430 06 - Standard Test Methods For Rubber Deterioration-Dynamic FatigueDokumen10 halamanASTM D430 06 - Standard Test Methods For Rubber Deterioration-Dynamic FatigueAndre Rodriguez SpirimBelum ada peringkat

- Estimation Theory EngDokumen40 halamanEstimation Theory EngVe EKBelum ada peringkat

- Module 4 Em222 2023 SC1Dokumen8 halamanModule 4 Em222 2023 SC1GARCIA, Maron Mark C.Belum ada peringkat

- Experiment 2A: Kirchhoff's Rules, Light Bulbs in Series and in ParallelDokumen7 halamanExperiment 2A: Kirchhoff's Rules, Light Bulbs in Series and in ParallelWalking Mozart RaquelBelum ada peringkat

- Catalogo TeufelbergerDokumen32 halamanCatalogo TeufelbergerFernando Mario Montes de Oca CaballeroBelum ada peringkat

- 1st Year Syllabus 23-24 - New CompressedDokumen183 halaman1st Year Syllabus 23-24 - New Compressedmsyashwanth432005Belum ada peringkat

- NT Developments in Eca Methods For PipelinesDokumen16 halamanNT Developments in Eca Methods For Pipelineskatfy1Belum ada peringkat

- PMT Handbook v3aE-Chapter2Dokumen8 halamanPMT Handbook v3aE-Chapter2Lateral verticalBelum ada peringkat

- Plane and Spherical TrigonometryDokumen1 halamanPlane and Spherical TrigonometryJeff LaycoBelum ada peringkat

- Free Vibration Part-A: Dynamics of MachineryDokumen3 halamanFree Vibration Part-A: Dynamics of MachineryMonojit KonarBelum ada peringkat

- Analysis of GearsDokumen14 halamanAnalysis of GearsShamma AlBlooshiBelum ada peringkat

- Thermographic TestingDokumen14 halamanThermographic TestingArluky NovandyBelum ada peringkat

- Ideal Gas Law: PV NRT PV NRTDokumen7 halamanIdeal Gas Law: PV NRT PV NRTMJTBelum ada peringkat

- Making Clocks Workshop GuideDokumen65 halamanMaking Clocks Workshop GuideGOUTHAM RATHINAM100% (1)

- Ecss e ST 32c Rev 1Dokumen134 halamanEcss e ST 32c Rev 1Bishwajyoti DuttaMajumdarBelum ada peringkat

- TR 47-180 Floor Deck Profile Data Sheet 9-12-14 PDFDokumen3 halamanTR 47-180 Floor Deck Profile Data Sheet 9-12-14 PDFAkhil VNBelum ada peringkat

- Selection. 1. To Learn About RM Calculation 2. To Learn About Load Calculation 3. To Learn The Selection of Wire Based On LoadDokumen15 halamanSelection. 1. To Learn About RM Calculation 2. To Learn About Load Calculation 3. To Learn The Selection of Wire Based On LoadWakeeBelum ada peringkat

- Branch CutsDokumen9 halamanBranch CutsFernando LópezBelum ada peringkat

- 26.3 - Mass Defect and Nuclear Binding EnergyDokumen8 halaman26.3 - Mass Defect and Nuclear Binding EnergyDellaBelum ada peringkat

- Science 7 4th QuarterDokumen5 halamanScience 7 4th QuarterBOBBY MAGNOBelum ada peringkat

- Laboratory Experiment 1 - Precision MeasurementDokumen8 halamanLaboratory Experiment 1 - Precision MeasurementEthan Duncan F. NEPUNANBelum ada peringkat

- Final Test PlannerDokumen6 halamanFinal Test PlannerYash RaoBelum ada peringkat