3885019 (2)

Diunggah oleh

acere18Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

3885019 (2)

Diunggah oleh

acere18Hak Cipta:

Format Tersedia

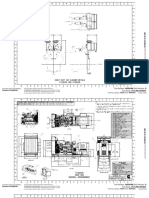

LTA10-G1

GENERATOR DRIVE

SPECIFICATIONS LTA10-G1 CPL: 1429 (Dry) Curve: FR-2237

4-Stroke Cycle, Turbocharged/Aftercooled, Fuel Consumption

In-Line, 6-Cylinder Diesel Engine.

U.S.Gallons/hour

1800 RPM Engine Output 20.0

Standby Power Rating 380 BHP [283 kWm*] 1500 RPM

Prime Power Rating 345 BHP [257 kWm*] 15.0

Continuous Power Rating 305 BHP [228 kWm*]

* Refers to gross power available from engine, not generator set.

10.0

Bore and Stroke 4.95x5.35 in. [125x136 mm]

Displacement 610 cu.in. [10 L]

5.0

**Lube System Oil Cap 9.6 U.S.gal. [36 L]

Coolant Capacity 3.38 U.S. gal. [12.8 L]

Net Weight with Std. 0.0

0 50 100 150 200 250 300 350 400

Accessories, Dry 1,995 lb. [906 kg]

Gross Engine Power Output - BHP

Approx. Overall Dimensions:

Width 34.1 in. [866 mm]

Length 52.0 in [1,321 mm] CONVERSIONS: (U.S. Gal = Litres x 0.2642)

Height 39.5 in. [1,003 mm] (Engine BHP = Engine kWm x 1.34)

**With combination full flow and bypass filter.

PERFORMANCE:

RATING GUIDELINES: Standard Conditions:

Standby Power Rating is applicable for supplying emergency electric Data Shown Above Are Based On:

power for the duration of the utility power outage. No overload capability is Engine operating with fuel system, water pump, lubricating oil pump, air

available for this rating. Under no condition is an engine allowed to operate cleaner and exhaust silencer; not included are battery charging alternator, fan

in parallel with the public utility at the Standby Power rating. and optional driven components.

Engine operating with diesel fuel corresponding to grade No. 2D per ASTM

Prime Power Rating is applicable for supplying electric power in lieu of D975.

commercially purchased power. Prime Power is the maximum power ISO-3046, Part 1, Standard Reference Conditions of: 29.53 in. Hg. [100 kPa]

available at variable load for an unlimited number of hours. A 10% overload barometric pressure (361 ft. [110m] altitude), 77 F [25 C] air temperature and

capability is available. a relative humidity of 30%.

OPERATION at ELEVATED TEMPERATURE and ALTITUDE: NOTES:

For Continuous Power or Base Power, Interruptible Power (Utility Power

The engine may be operated at:

Curtailment) and Peak Shaving, contact the local Cummins representative.

1800 RPM up to:

5000 ft. [1525m] and 104 F [40 C] without power deration.

For sustained operation above these conditions derate by: Cummins Engine Company recommends that Cummins engines be operated

4% per 1,000 ft.[300m] and 1% per 10 F [2% per 11 C]. at a minimum load of 30% of their respective Standby Power rating.

LTA10-G1

GENERATOR DRIVE

DESIGN FEATURES Gear Train: Timing gear and accessory drive gears are induction

hardened helical gears driven from crankshaft and located at

Aftercooler: Single pass, high flow aftercooler results in cooler,

front of block.

denser intake air for more efficient combustion and reduced

Lubrication: Gear pump provides pressure lubrication to all bear-

internal stresses for longer life. Aftercooler is located in

ings and oil supply for piston cooling. All pressure lines are

engine coolant system, eliminating need for special plumbing.

internal drilled passages in block and head. High capacity two

Bearings: Replaceable, precision type, steel backed tri-metal

pass unitized design oil cooler provides full flow oil cooling.

bearings.

Pistons: Aluminum alloy, designed to compensate for thermal

Camshaft: Design provides increased injection pressures for

expansion; assures precise fit at operating temperatures. Oil

improved performance. Large 2.83 in. (72 mm) diameter cam

cooled for rapid heat dissipation. Two compression and one

permits short, stiff injector train for precise fuel metering and

two-piece, dual-rail oil ring.

high injection pressures.

Piston Pins: Tubular steel retained by snap rings.

Camshaft Followers: Crowned cam follower rollers for long

Turbocharger: Holset exhaust gas driven turbocharger.

cam and cam follower life.

Turbocharging provides more power, improved fuel economy,

Connecting Rods: Drop forged, I-beam section 8.58 in.(218 mm)

altitude compensation, and lower smoke and noise levels.

center-to-center length. Rod is tapered on piston pin end to

provide stronger piston pin bore for increased durability. AVAILABLE EQUIPMENT

Cooling System: Gear driven centrifugal water pump. Modulating Cooling System:

bypass thermostat regulates coolant temperature. Spin-on cor- 1.Fan drive for radiator (1.0:1 drive ratio).

rosion resistor filter removes impurities and checks corrosion. 2.Remote cooling (engine water pump only).

Crankshaft: High tensile strength steel forging with induction Exhaust System:

hardened fillets and journals. Fully counterweighted and 1.Exhaust manifold, dry pulse type.

dynamically balanced. 2.Flexible exhaust connection.

Cylinder Block: Alloy cast iron with removable wet liners. Filters: Fleetguard. Lubricating oil: combination spin-on full flow

Cylinder Head: One-piece cylinder head reduces engine length and bypass paper element type. Fuel: spin-on paper element

and provides a rigid head-to-block fit. Ports are oriented to type.

provide free intake and exhaust flow; short exhaust ports for Flywheel: To fit SAE-514 (18.375 in. [467mm] diameter), generator

low heat rejection. Fuel rail passages are internally drilled. flexible drive disk - reference SAE standard J162.

Cylinder Liners: Replaceable wet liners dissipate heat faster Flywheel Housing: SAE No. 1, dry type, ref: SAE standard J617.

than dry liners and are easily replaced without reboring the Governor: Cummins EFC (electric fuel control) governor for

block. Mid-stop liner design significantly shortens the liner droop or isochronous operation.

cooling jacket resulting in reduced heat rejection. Starting System:

Fuel System: Cummins PT self-adjusting system. Integral 1. Electric starter (24 volt positive engagement).

dual flyweight governor provides overspeed protection inde- 2. Compressed air starter.

pendent of main governor. Camshaft actuated fuel injectors 3. Battery charging alternator (24 volt, 35 ampere).

give accurate metering and timing. Fuel lines are internal For other available equipment contact the local Cummins

drilled passages in cylinder head. representative.

AGENCY CERTIFICATION

Certification: Contact your local Cummins representative.

Cummins Engine Company, Inc.

Box 3005

Columbus, IN 47202-3005

U.S.A.

Cummins has always been a pioneer in product improvement. Thus, specifications may

change without notice. Illustrations may include optional equipment. Bulletin 3885019 Printed in U.S.A. Rev. 01/97

Anda mungkin juga menyukai

- DR PG: Be Used in Conjunction With The Standard Hydraulic Schematic in This Service ManualDokumen1 halamanDR PG: Be Used in Conjunction With The Standard Hydraulic Schematic in This Service Manualrayendra100% (1)

- Vebm090100 WF550-3 T-3Dokumen394 halamanVebm090100 WF550-3 T-3Baciu NicolaeBelum ada peringkat

- Katalog Mini Excavator BME-08Dokumen4 halamanKatalog Mini Excavator BME-08Chimuw ChimuwBelum ada peringkat

- Cylindrical Roller Bearings - 2 PDFDokumen52 halamanCylindrical Roller Bearings - 2 PDFcristinelbBelum ada peringkat

- SM PC300,350 Electrical DiagramsDokumen2 halamanSM PC300,350 Electrical DiagramsMelpi Norawati SimarmataBelum ada peringkat

- ULTIMA Series Hand Pump Model P-39 Repair Parts SheetDokumen4 halamanULTIMA Series Hand Pump Model P-39 Repair Parts SheetOAR INDUSTRIAL SASBelum ada peringkat

- NTB R9350 enGB-US PDFDokumen22 halamanNTB R9350 enGB-US PDFHarishBelum ada peringkat

- Marantz PM4200 AmpDokumen17 halamanMarantz PM4200 Ampffar1Belum ada peringkat

- Honda CRF250L Owners Manual EngDokumen114 halamanHonda CRF250L Owners Manual EngThomas Alecsson100% (1)

- Marantz Sr8200-9200 Service ManualDokumen145 halamanMarantz Sr8200-9200 Service ManualSaeid Pourfarzib100% (1)

- Hyd DiagramDokumen7 halamanHyd DiagramnurdinzaiBelum ada peringkat

- HISENSE PDH4239EU Service Manual V1.0Dokumen44 halamanHISENSE PDH4239EU Service Manual V1.0videosonBelum ada peringkat

- Enerpacp 141Dokumen4 halamanEnerpacp 141MARCO HernándezBelum ada peringkat

- Marantz SR8001 AV Surround Receiver Amplifier User ManualDokumen79 halamanMarantz SR8001 AV Surround Receiver Amplifier User Manualtrevor5409Belum ada peringkat

- Machine WeightsDokumen34 halamanMachine WeightsTrent BeckerBelum ada peringkat

- Hidro TransmisijaDokumen31 halamanHidro TransmisijaMaximus MaxisBelum ada peringkat

- TR-500EX: Tadano LTDDokumen6 halamanTR-500EX: Tadano LTDMuhammadFaridBelum ada peringkat

- Data Jenis Parts Dan HargaDokumen24 halamanData Jenis Parts Dan Hargaedy susantoBelum ada peringkat

- Every Ton.: Non-Certified Engines For Mining ApplicationsDokumen4 halamanEvery Ton.: Non-Certified Engines For Mining ApplicationsCarlos andres Revelo gomezBelum ada peringkat

- Tekiro Galaxy LTC CatalogDokumen37 halamanTekiro Galaxy LTC CatalogReza Kartadiwiria100% (2)

- 3-1. Hydraulic System PDFDokumen30 halaman3-1. Hydraulic System PDFmarcelo rojasBelum ada peringkat

- Marantz PM 66 Service Manual PDFDokumen15 halamanMarantz PM 66 Service Manual PDFretrueke1170Belum ada peringkat

- PM7000/8000 Service Manual Integrated Amplifier 276W Specs DiagramsDokumen29 halamanPM7000/8000 Service Manual Integrated Amplifier 276W Specs DiagramsDirk LindemansBelum ada peringkat

- Loading Capacity of 2.0 T and Bucket Capacity of 1.0 M: Product FeaturesDokumen2 halamanLoading Capacity of 2.0 T and Bucket Capacity of 1.0 M: Product FeaturesJ EquipBelum ada peringkat

- Full Air Brake SystemDokumen81 halamanFull Air Brake SystemMuhamad RifkyBelum ada peringkat

- SakaiDokumen2 halamanSakaiariBelum ada peringkat

- Bolt Size & Torque TableDokumen5 halamanBolt Size & Torque TableFirman andikaBelum ada peringkat

- Hydraulic Filter - Wheel Loader Komatsu Wa20-1 - Work Equipment Control System 777partsDokumen2 halamanHydraulic Filter - Wheel Loader Komatsu Wa20-1 - Work Equipment Control System 777partsashraf elsayedBelum ada peringkat

- Komatsu Pc200Dokumen2 halamanKomatsu Pc200Ananto Yusuf WBelum ada peringkat

- D8R Pruebas y AjustesDokumen109 halamanD8R Pruebas y AjustesMiguel Angel Garrido CardenasBelum ada peringkat

- Litronic Performance Liebherr Wheel Excavators Have Been DesignedDokumen20 halamanLitronic Performance Liebherr Wheel Excavators Have Been DesignedLiebherr100% (1)

- Tier 4 Emissions Standards ExplainedDokumen4 halamanTier 4 Emissions Standards ExplainedAmilton filhoBelum ada peringkat

- Matris ExcavatorDokumen17 halamanMatris ExcavatorPablo Rodriguez0% (1)

- NTB R9250 enGB-US PDFDokumen22 halamanNTB R9250 enGB-US PDFmuhammad febri faizin0% (1)

- Mst-800vd - 4001!1!1 - Manual de Partes 2Dokumen160 halamanMst-800vd - 4001!1!1 - Manual de Partes 2RAUL PEREZ NEGREIROSBelum ada peringkat

- 320C, 320C L, 320C LN Excavator: Service Repair ManualDokumen23 halaman320C, 320C L, 320C LN Excavator: Service Repair ManualPatricio OrdóñezBelum ada peringkat

- General Information: 018-001 SpecificationsDokumen10 halamanGeneral Information: 018-001 SpecificationsLaiqBelum ada peringkat

- Systems Operation 966G Series II Wheel Loader and 972G Series II Wheel Loader Power TrainDokumen20 halamanSystems Operation 966G Series II Wheel Loader and 972G Series II Wheel Loader Power TrainCarlos GonzálesBelum ada peringkat

- PC1250Dokumen106 halamanPC1250yonathan yonathan100% (1)

- DL550 - Specification Sheet - 20160502Dokumen27 halamanDL550 - Specification Sheet - 20160502AbdelrahmanBelum ada peringkat

- 11 SPS System Trouble ShootingDokumen36 halaman11 SPS System Trouble Shootingjuliocanel2009Belum ada peringkat

- Excavator MiniDokumen230 halamanExcavator Miniduongpndng100% (3)

- SHOP MANUAL SK330 8 PDF - 118Dokumen28 halamanSHOP MANUAL SK330 8 PDF - 118RiverPlaceBelum ada peringkat

- BD50 Crawler Dozer 67kW Engine Spur Gear TransmissionDokumen4 halamanBD50 Crawler Dozer 67kW Engine Spur Gear TransmissionAnsh MishraBelum ada peringkat

- JCB EscavadeiraDokumen16 halamanJCB EscavadeiraExperiencia oneBelum ada peringkat

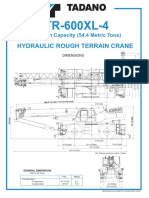

- TR-600XL-4 SpecificationsDokumen12 halamanTR-600XL-4 SpecificationsPTCBelum ada peringkat

- Catalouge Bucket Wearplate & AccessoriesDokumen18 halamanCatalouge Bucket Wearplate & Accessoriesaribawayuni16Belum ada peringkat

- R210 SMART - Medium Excavators - Hyundai Construction Equipment India Pvt. LTD PDFDokumen3 halamanR210 SMART - Medium Excavators - Hyundai Construction Equipment India Pvt. LTD PDFarfa ujiantoBelum ada peringkat

- EL-HKN 31021601e 01-9Dokumen114 halamanEL-HKN 31021601e 01-9KiranKumarReddy100% (1)

- BPW El W BW GW 05 01eDokumen38 halamanBPW El W BW GW 05 01ewoulkanBelum ada peringkat

- Alternator Parts DiagramDokumen50 halamanAlternator Parts DiagramFelipe Douglas da SilvaBelum ada peringkat

- ABS and speed sensors for Toyota Avanza and XeniaDokumen1 halamanABS and speed sensors for Toyota Avanza and XeniaSANTRI BLAMBANGANBelum ada peringkat

- All-Track Service: AT-80HD Operator ManualDokumen28 halamanAll-Track Service: AT-80HD Operator ManualDavid OrtegaBelum ada peringkat

- 02 Torque and Socket OptimizeDokumen26 halaman02 Torque and Socket OptimizeANDI SETIAWANBelum ada peringkat

- WipexDokumen20 halamanWipexflytorahulBelum ada peringkat

- RS8140 Single Drum CompactorDokumen4 halamanRS8140 Single Drum CompactorMartin Lee100% (2)

- Earthmovers in Scotland: Mining, Quarries, Roads & ForestryDari EverandEarthmovers in Scotland: Mining, Quarries, Roads & ForestryBelum ada peringkat

- Kta38 G5Dokumen2 halamanKta38 G5Patricio Andres Ibañez ConchaBelum ada peringkat

- Specifications KTA38 G DRIVEDokumen2 halamanSpecifications KTA38 G DRIVEMehdi ChakrouneBelum ada peringkat

- V28 Rebuild GuidelinesDokumen26 halamanV28 Rebuild Guidelinesacere18100% (1)

- DSE7110 Installation InstructionsDokumen2 halamanDSE7110 Installation Instructionscmaharaja25Belum ada peringkat

- Cummins Heavy Duty Air Cleaner DetailsDokumen6 halamanCummins Heavy Duty Air Cleaner Detailsacere18Belum ada peringkat

- Delphi DP210 Fuel Injection Pump CatDokumen3 halamanDelphi DP210 Fuel Injection Pump CatSilas F Pimenta89% (19)

- Steel Cargo GuideDokumen100 halamanSteel Cargo GuideBill Kelso100% (1)

- TSB-1158 M105R M110R Rotate Flange RelayDokumen2 halamanTSB-1158 M105R M110R Rotate Flange Relayacere18Belum ada peringkat

- Alternador s3.8 y x2.5 y x3.3 A115Dokumen2 halamanAlternador s3.8 y x2.5 y x3.3 A115acere18Belum ada peringkat

- DETROIT Model Serial NumberDokumen7 halamanDETROIT Model Serial NumberDave Barchugov67% (3)

- Installing 38mt 39mt Gear Reduction Heavy Duty Starting MotorsDokumen2 halamanInstalling 38mt 39mt Gear Reduction Heavy Duty Starting MotorsEduardo Hugo MelchorBelum ada peringkat

- BRO Doosan EngineDokumen9 halamanBRO Doosan Enginea.pilatis9140100% (1)

- DDC SVC Bro 0001 PDFDokumen45 halamanDDC SVC Bro 0001 PDFKaly7Belum ada peringkat

- Iims Btec HNC HND Application FormDokumen4 halamanIims Btec HNC HND Application Formacere18Belum ada peringkat

- Model Course 1.19 Personal Survival TechniquesDokumen63 halamanModel Course 1.19 Personal Survival Techniquesacere18100% (2)

- Lucas TVS Price List 2nd May 2011Dokumen188 halamanLucas TVS Price List 2nd May 2011acere18Belum ada peringkat

- Manual de Partes QSK19Dokumen17 halamanManual de Partes QSK19acere18100% (1)

- GL CL For Onboard MaintenanceDokumen2 halamanGL CL For Onboard Maintenanceacere18Belum ada peringkat

- Delphi DP210 Fuel Injection Pump CatDokumen3 halamanDelphi DP210 Fuel Injection Pump CatSilas F Pimenta89% (19)

- GL CL For Onboard MaintenanceDokumen18 halamanGL CL For Onboard Maintenanceacere18100% (1)

- Skipper On A Fishing Vessel: Model CourseDokumen277 halamanSkipper On A Fishing Vessel: Model Courseacere18100% (1)

- Model Course 1.21 Personal Safety and Social ResponsibilitiesDokumen97 halamanModel Course 1.21 Personal Safety and Social Responsibilitiesacere1888% (8)

- Model Course 1.08 Radar Navigation at Management Level (RADAR, ARPA, Bridge Teamwork and Search and Rescue)Dokumen89 halamanModel Course 1.08 Radar Navigation at Management Level (RADAR, ARPA, Bridge Teamwork and Search and Rescue)acere1883% (18)

- Model Course 1.24 Proficiency in Fast Rescue Boats Final DraftDokumen44 halamanModel Course 1.24 Proficiency in Fast Rescue Boats Final Draftacere18Belum ada peringkat

- PMB69 CPG CoolKit Distributor AnnouncementDokumen2 halamanPMB69 CPG CoolKit Distributor Announcementacere18Belum ada peringkat

- (Paul - A. - Harren) - Safe Operation and Maintenance of Dry Dock Facilities-2010Dokumen33 halaman(Paul - A. - Harren) - Safe Operation and Maintenance of Dry Dock Facilities-2010acere18Belum ada peringkat

- QSB5 G7Dokumen2 halamanQSB5 G7acere18Belum ada peringkat

- Power Generation Installation GuideDokumen30 halamanPower Generation Installation GuideAnonymous MDkp0hnb3l100% (8)

- Model Course1 33Dokumen130 halamanModel Course1 33acere18Belum ada peringkat

- Air Intake ComponentsDokumen5 halamanAir Intake Componentsacere18Belum ada peringkat

- GL CL For Onboard MaintenanceDokumen18 halamanGL CL For Onboard Maintenanceacere18100% (1)

- Datasheet 6125HF070Dokumen2 halamanDatasheet 6125HF070acere18Belum ada peringkat

- Electronic EngineDokumen4 halamanElectronic EngineSoumyadeep BhattacharyyaBelum ada peringkat

- Manual de Overhaul Tsio-520 Series Sandcast PDFDokumen437 halamanManual de Overhaul Tsio-520 Series Sandcast PDFomaclubaereo valparaiso y viña del mar100% (2)

- Ford Fiesta Se 1.6l DuratecDokumen735 halamanFord Fiesta Se 1.6l DuratecDavid Emmanuel Turcios CarrilloBelum ada peringkat

- 2007 Two Stroke PDFDokumen327 halaman2007 Two Stroke PDFfishhunter18100% (1)

- Gasturbine SGT5 8000h Poster PDFDokumen2 halamanGasturbine SGT5 8000h Poster PDFmyegnrBelum ada peringkat

- Test Plan 8443B250DDokumen2 halamanTest Plan 8443B250DЕвгенийBelum ada peringkat

- Technical Data TWD1240VE: GeneralDokumen6 halamanTechnical Data TWD1240VE: GeneraladiBelum ada peringkat

- Mini Stirling Engine ProjectDokumen6 halamanMini Stirling Engine ProjectGaurav Kumar50% (2)

- Introduction To Internal Combustion EnginesDokumen19 halamanIntroduction To Internal Combustion EnginesAkhilesh ChoudharyBelum ada peringkat

- Bendix BA-921 Compressor: DescriptionDokumen36 halamanBendix BA-921 Compressor: DescriptionEstebanMongeAlvaradoBelum ada peringkat

- BL Series Adelino Price ListDokumen6 halamanBL Series Adelino Price ListJaved Hasan100% (1)

- VOLVO EXCAVATOR SPECSDokumen12 halamanVOLVO EXCAVATOR SPECSمحمد عابدينBelum ada peringkat

- Form-04 Piston & Liner 2004Dokumen2 halamanForm-04 Piston & Liner 2004YeremiaBelum ada peringkat

- Design of Switched Reluctance Motor Using Ansys MaxwellDokumen5 halamanDesign of Switched Reluctance Motor Using Ansys Maxwellaman kumarBelum ada peringkat

- Activity 2Dokumen3 halamanActivity 2ron Joshua QuirapBelum ada peringkat

- 3029TFU20 44kw@1800Dokumen3 halaman3029TFU20 44kw@1800Kazim AlrefaiBelum ada peringkat

- Analysis Part ListDokumen500 halamanAnalysis Part Listharishgaikwad96Belum ada peringkat

- US9212603Separate-type Rotary EngineDokumen12 halamanUS9212603Separate-type Rotary Engine임학진Belum ada peringkat

- Fuel Injection Pumps, In-LineDokumen24 halamanFuel Injection Pumps, In-LineJose Luis CristanchoBelum ada peringkat

- 30kW Capstone MicroturbineDokumen2 halaman30kW Capstone MicroturbineMal KukuraBelum ada peringkat

- Camless PrincipleDokumen5 halamanCamless PrincipleSekhar ChallaBelum ada peringkat

- F3M2011 F4M2011Dokumen2 halamanF3M2011 F4M2011Javier CardonaBelum ada peringkat

- 4 Cylinder Loom Wiring Harness Information: SCS DeltaDokumen6 halaman4 Cylinder Loom Wiring Harness Information: SCS DeltaMuhamedomar Jojo JojoBelum ada peringkat

- SKI-DOO Engine Leak Test (SUMMIT X) - Shop Manual - 04cciLAAQ - SM11Y015S01 - enDokumen5 halamanSKI-DOO Engine Leak Test (SUMMIT X) - Shop Manual - 04cciLAAQ - SM11Y015S01 - enHannu LeinonenBelum ada peringkat

- AP05.30-B-0560F.fm Valve Lash Adjustment 19.06.98Dokumen4 halamanAP05.30-B-0560F.fm Valve Lash Adjustment 19.06.98LUKASBelum ada peringkat

- TD13-00019-02 Inlet Temp. Setting of LT F.W. Engine (Rev.2 Precaution Statement Edit)Dokumen2 halamanTD13-00019-02 Inlet Temp. Setting of LT F.W. Engine (Rev.2 Precaution Statement Edit)TimmyJuriBelum ada peringkat

- 6 Crank Gears: 6 .1 Crankshaft DriveDokumen34 halaman6 Crank Gears: 6 .1 Crankshaft DrivemoonBelum ada peringkat

- Codes List Cummins - TIER4fDokumen137 halamanCodes List Cummins - TIER4fM V BHASKARARAOBelum ada peringkat

- EngineDokumen367 halamanEngineHassan ZAFFA CISNEROS100% (1)

- Me7 Tuner Wizzard - XLSM - 0Dokumen81 halamanMe7 Tuner Wizzard - XLSM - 0lytoselputoamoBelum ada peringkat