Acceptance API 1104 PDF

Diunggah oleh

TijieichSuprihanto0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

93 tayangan2 halamanJudul Asli

Acceptance API 1104.pdf

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

93 tayangan2 halamanAcceptance API 1104 PDF

Diunggah oleh

TijieichSuprihantoHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

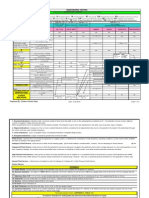

API STD1104, ASME/ANSI B31.4, ASME/ANSI B31.

8

Table 3-1 is applicable in determining the size and type of discontinuities when viewing

radiographs for final acceptance in accordance with API STD 1104, ASME/ANSI

B31.4, Paragraph 434.8.5, and ASME/ANSI B31.8.

Table 3-1 Acceptance Criteria for API STD 1104

Indication/Defect Unacceptable if any of the following conditions exist:

1. Length of an individual indication of IP exceeds 25.4 mm (1.0").

2. The aggregate length of indications of IP in any continuous 304.8 mm (12")

Inadequate Penetration length of weld exceeds 25.4 mm (1.0").

(IP) (without high-low)

3. The aggregate length of indications of IP exceeds 8% of the weld length in any

weld less than 304.8 mm (12") in length.

1. Length of an individual indication of IPD exceeds 50.8 mm (2.0").

Inadequate Penetration

2. The aggregate length of indications of IP in any continuous 304.8 mm (12")

due to High-Low (IPD)

length of weld exceeds 76.2 mm (3.0").

1. Length of an individual indication of IF exceeds 25.4 mm (1.0").

2. The aggregate length of indications of IF in any continuous 304.8 mm (12")

Incomplete Fusion (IF) length of weld exceeds 25.4 mm (1.0").

3. The aggregate length of indications of IF exceeds 8% of the weld length in any

weld less than 304.8 mm (12") in length.

1. Length of an individual indication of IFD exceeds 50.8 mm (2.0").

Incomplete Fusion due to 2. The aggregate length of indications of IFD in any continuous 304.8 mm

Cold Lap (IFD) (12") length of weld exceeds 50.8 mm (2.0").

3. The aggregate length of indications of IFD exceeds 8% of the weld length.

Any length of IC is acceptable provided the density of the radiographic image of

the IC does not exceed that of the thinnest adjacent base metal. For areas that exceed

Internal Concavity (IC) the density of the thinnest adjacent base metal, the criteria for burn through are

applicable.

Pipe OD 2-3/8" Pipe OD < 2-3/8"

1. Maximum dimension exceeds 1. Maximum dimension exceeds

6.35 mm (") and the density of the BT's 6.35 mm (") and the density of

image exceeds that of the thinnest the BT's image exceeds that of

adjacent base metal the thinnest adjacent base metal

2. Maximum dimension exceeds the thinner 2. Maximum dimension exceeds the

of nominal wall thicknesses joined, and thinner of nominal wall

the density of the BT's image thicknesses joined, and the

exceeds that of the thinnest density of the BT's image

Burn-Through (BT)

adjacent base metal exceeds that of the thinnest

3. Sum of maximum dimensions of separate adjacent base metal

BTs whose image density exceeds that of 3. More than one BT of any size is

the thinnest adjacent base metal exceeds present and the density of more

12.7 mm (") in 304.8 mm (12") of weld or than one of the images exceeds

the total weld length, whichever is less. that of the thinnest adjacent base

metal.

Table 3-1 Acceptance Criteria for API STD 1104 (Cont'd)

Indication/Defect Unacceptable if any of the following conditions exist:

Slag Inclusions Pipe OD 2-3/8" Pipe OD < 2-3/8"

Elongated(ESI) Unacceptable if: Unacceptable if:

Isolated (ISI) 1. ESI length > 2" 1. ESI > 3 X nominal WT of the

Note: ESI indications 2. ESI width > 1/16" thinner thickness joined.

separated by approx. 3. Sum of the lengths of ISI > " in 2. ESI width > 1/16"

width of root bead 12" of weld. 3. Sum of ISI lengths > 2 X nominal

(wagon tracks) to be WT of thinner thickness joined

considered as a single 4. Width of ISI > 1/8"

and ISI width > nominal WT of

indication unless the 5. > 4 ISI with maximum width of thinner thickness joined.

width of either > 1/32". 1/8" in any 12" of weld.

4. Aggregate length of ESI & ISI >

In that event, they 6. Sum of the lengths of ESI & ISI > 8% of weld length.

shall be considered as 8% of weld length.

separate indications.

Porosity - individual / Unacceptable if:

Scattered (P) 1. Size of individual pore > 1/8"

Note: Size based on 2. Size of individual pore > 25% of thinner WT joined

maximum dimensions

3. Distribution of Porosity exceeds API STD 1104 Porosity Charts.

Unacceptable if:

1. CP dia. > "

Porosity - Cluster (CP)

2. Aggregate length of CP > " in any continuous 12" of weld

3. An individual pore within a cluster > 1/16" in size.

Unacceptable if:

1. Length of individual HB > "

Porosity - Hollow-Bead (HB) 2. Sum of HB lengths > 2" in any continuous 12" of weld

3. Individual HB > " separated by < 2"

4. Sum of HB lengths > 8% weld length.

Any size or location of cracks are unacceptable except for shallow crater or

Cracks (C) star cracks. Shallow crater or star crack length > 5/32" is unacceptable.

Undercutting Unacceptable if:

Adjacent to cover pass 1. Any combination EU & IU length > 2" in any continuous 12" of weld.

(EU) Adjacent to root pass 2. Sum of EU & IU lengths in any combination > 1/6 of weld length.

(IU)

Tungsten Inclusions Individual tungsten inclusions are be evaluated as rounded indications

(Porosity). Elongated or aligned tungsten inclusions are unacceptable.

Accumulation of Unacceptable if:

Discontinuities 1. Sum lengths of indications > 2" in any continuous 12" of weld.

Excluding IPD, EU & IU

2. Sum lengths of indication > 8% of weld length.

Arc burns, long seam discontinuities and other discontinuities in the pipe or

Pipe / Fitting Discontinuities fittings detected by RT shall be recordable.

Anda mungkin juga menyukai

- API STD1104 acceptance criteria table radiograph discontinuitiesDokumen2 halamanAPI STD1104 acceptance criteria table radiograph discontinuitiesdownloadBelum ada peringkat

- Saudi Aramco: Company General UseDokumen8 halamanSaudi Aramco: Company General UseMasudhBashaBelum ada peringkat

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsDari EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsPenilaian: 4 dari 5 bintang4/5 (1)

- NDT ACC CriteriaDokumen6 halamanNDT ACC Criteriavsnaiduqc100% (1)

- Plasma Etching Processes for CMOS Devices RealizationDari EverandPlasma Etching Processes for CMOS Devices RealizationNicolas PossemeBelum ada peringkat

- NDT ACC. CriteriaDokumen6 halamanNDT ACC. CriteriaBalakumar100% (5)

- Shielding of Electromagnetic Waves: Theory and PracticeDari EverandShielding of Electromagnetic Waves: Theory and PracticeBelum ada peringkat

- NDT AcceptanceDokumen62 halamanNDT Acceptancebommakanti srinivasBelum ada peringkat

- Solution Manual for 100 Genesys Design Examples: Second EditionDari EverandSolution Manual for 100 Genesys Design Examples: Second EditionBelum ada peringkat

- E e C 2 3 XC S 2: 9.3.8.3 Mall Diameter PipeDokumen1 halamanE e C 2 3 XC S 2: 9.3.8.3 Mall Diameter PipeAnonymous t0r2yT4Belum ada peringkat

- Cylindrical Compression Helix Springs For Suspension SystemsDari EverandCylindrical Compression Helix Springs For Suspension SystemsBelum ada peringkat

- NDT Code Book Made EasyDokumen398 halamanNDT Code Book Made Easydiaccessltd_17172961100% (2)

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingDari EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghBelum ada peringkat

- API 1104 Defects Acceptance Criteria FinalDokumen9 halamanAPI 1104 Defects Acceptance Criteria Finalazizieh5701Belum ada peringkat

- RT Acceptance CriteriaDokumen3 halamanRT Acceptance CriteriaAndry Rimanov89% (18)

- Tabla D-5 DNV ST-F101 2021Dokumen2 halamanTabla D-5 DNV ST-F101 2021Gabriel HernándezBelum ada peringkat

- VT Acceptance Criteria PDFDokumen10 halamanVT Acceptance Criteria PDFKalaivel ThandavarayanBelum ada peringkat

- NDT Code Book Made Easy For AsmeDokumen398 halamanNDT Code Book Made Easy For AsmeJosé Pablo Espinoza SolísBelum ada peringkat

- RT Acceptance CriteriaDokumen3 halamanRT Acceptance CriteriaSalman KhanBelum ada peringkat

- DNVGL-ST-F101 Submarine Pipeline Systems-415-416 PDFDokumen2 halamanDNVGL-ST-F101 Submarine Pipeline Systems-415-416 PDFJeganeswaranBelum ada peringkat

- API 1104 RT AcceptanceDokumen1 halamanAPI 1104 RT Acceptancemohamed.eldesouky9120Belum ada peringkat

- API 1104 Defects Acceptance Criteria FinalDokumen3 halamanAPI 1104 Defects Acceptance Criteria FinalAbdul Wajid AliBelum ada peringkat

- Acceptance Criteria For RTDokumen3 halamanAcceptance Criteria For RTrajeshmohana100% (2)

- Weld Evaluation Guide - RADIOGRAFIA - PDFDokumen20 halamanWeld Evaluation Guide - RADIOGRAFIA - PDFCharly Teodoro BrownBelum ada peringkat

- API 1104 Acceptance CriteriaDokumen2 halamanAPI 1104 Acceptance CriteriaEngr Arfan Ali Dhamraho79% (14)

- Section Defect Page Welding Imperfections StandardsDokumen4 halamanSection Defect Page Welding Imperfections Standardsjegathesmsjs86% (44)

- Radiographic Testing of Weld Joints: (As Per API-1104, 20 Edition & EWPL100-P30-J00-505)Dokumen2 halamanRadiographic Testing of Weld Joints: (As Per API-1104, 20 Edition & EWPL100-P30-J00-505)aamirapiBelum ada peringkat

- Type of Discontinuity Cheat SheetDokumen13 halamanType of Discontinuity Cheat SheetIvanJoseVelasquezBelloBelum ada peringkat

- API 1104 Defects Acceptance Criteria FinalDokumen4 halamanAPI 1104 Defects Acceptance Criteria FinalHendry AriosBelum ada peringkat

- Radiographic Acceptance Criteria: (This Table Contains Maximum Discontinuity Size Allowed)Dokumen7 halamanRadiographic Acceptance Criteria: (This Table Contains Maximum Discontinuity Size Allowed)Alzaki AbdullahBelum ada peringkat

- RT Acceptance Para. 9.4Dokumen4 halamanRT Acceptance Para. 9.4Yan Ferizal100% (1)

- Acceptance Criteria for WeldsDokumen7 halamanAcceptance Criteria for WeldsAnilBelum ada peringkat

- Radiographic Acceptance Criteria ChartDokumen6 halamanRadiographic Acceptance Criteria ChartSana Alzaki100% (1)

- AWS D1.i/Di.iM:2010 Clause 6 inspection criteriaDokumen1 halamanAWS D1.i/Di.iM:2010 Clause 6 inspection criteriagigiphi75% (8)

- ASME B31 3 Acceptance Criteria Tab 341-3-2ADokumen2 halamanASME B31 3 Acceptance Criteria Tab 341-3-2Aadel100% (1)

- Attachment ADokumen13 halamanAttachment AVitthal DeokateBelum ada peringkat

- API 1104 SummaryDokumen7 halamanAPI 1104 Summarymohamedqc100% (1)

- Acceptance Criteria Radiography Test 2018 PDFDokumen7 halamanAcceptance Criteria Radiography Test 2018 PDFSigit Pratikno100% (1)

- RT Acceptance Criteria For Welder Test According To ASME Sec IX (QW 191 1.2)Dokumen20 halamanRT Acceptance Criteria For Welder Test According To ASME Sec IX (QW 191 1.2)Oscar Iván Duque DiazBelum ada peringkat

- Instrumentation Cables PDFDokumen4 halamanInstrumentation Cables PDFhaisamsarwarBelum ada peringkat

- Tolerance As Per AWS D1.1Dokumen3 halamanTolerance As Per AWS D1.1milind bedarkarBelum ada peringkat

- A L F I: Cceptance Imit OR MperfectionsDokumen29 halamanA L F I: Cceptance Imit OR MperfectionsDavid MacatangayBelum ada peringkat

- API 1104 Welding Defect GuideDokumen48 halamanAPI 1104 Welding Defect GuidesbmmlaBelum ada peringkat

- Preheat Welding Document For Truck Bodies PDFDokumen10 halamanPreheat Welding Document For Truck Bodies PDFCarlos LoboBelum ada peringkat

- Astm B 33Dokumen6 halamanAstm B 33Kamer Bibuçukvolt SemerciogluBelum ada peringkat

- Acceptance Craiteria of API1104, ASME B31.3 and AWS D.1.1Dokumen7 halamanAcceptance Craiteria of API1104, ASME B31.3 and AWS D.1.1MJ Magdy100% (1)

- Specifying Bolt Length of High strength BoltsDokumen12 halamanSpecifying Bolt Length of High strength BoltsUpadrasta HarishBelum ada peringkat

- Wireway Selection Size Calculator 03132011Dokumen6 halamanWireway Selection Size Calculator 03132011Bandi ThaguruBelum ada peringkat

- Aws Table 8.1 MT PTDokumen1 halamanAws Table 8.1 MT PTSugianto Tan Lok AnBelum ada peringkat

- Busduct Welds - Acceptance StandardDokumen3 halamanBusduct Welds - Acceptance StandardSURENDRA NARAYANBelum ada peringkat

- ASME IX Acceptance StandardsDokumen1 halamanASME IX Acceptance Standardsmohamed.eldesouky9120Belum ada peringkat

- IS 1538:1993 - Pipe Fitting Dimensions and TolerancesDokumen1 halamanIS 1538:1993 - Pipe Fitting Dimensions and TolerancesAkshat JainBelum ada peringkat

- Manual Ultrasonic Inspection of Thin Metal Welds: Capucine - Carpentier@twi - Co.ukDokumen16 halamanManual Ultrasonic Inspection of Thin Metal Welds: Capucine - Carpentier@twi - Co.ukdarouichBelum ada peringkat

- Welded FinDokumen7 halamanWelded FinNatarajan RavisankarBelum ada peringkat

- Acceptance Criteria Asme B31 3Dokumen1 halamanAcceptance Criteria Asme B31 3Hadi Allouche100% (9)

- AWS D1.1 Acceptance StandardsDokumen2 halamanAWS D1.1 Acceptance StandardsAlper Çakıroğlu92% (12)

- If There Is More Than 1Dokumen3 halamanIf There Is More Than 1riffdBelum ada peringkat