Analisis de Causas PDF

Diunggah oleh

miguelvelardeJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Analisis de Causas PDF

Diunggah oleh

miguelvelardeHak Cipta:

Format Tersedia

Causal Analysis Tree Rev.

0

START

HERE

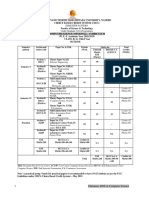

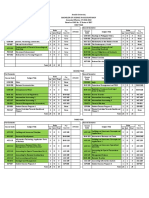

A1 Design / Engineering A2 Equipment / Material A3 Human PerformanceLTA A4 Management Problem A5 Communications LTA A6 Training Deficiency

Problem Problem

B1 MANAGEMENT METHODS B3 WORK ORGANIZATION & PLANNING LTA B1 NO TRAINING

B1 DESIGN INPUT LTA B1 CALIBRATION FOR B1 SKILL BASED ERROR B1 WRITTEN

C01 Check of work was LTA LTA C01 Insufficient time for worker to prepare task PROVIDED

C01 Design input cannot INSTRUMENTS LTA COMMUNICATIONS

C01 Management policy guidance/ C02 Insufficient time allotted for task C01 Decision not to train

be met C01 Calibration LTA C02 Step was omitted due to METHOD OF

expectations not well-defined, C03 Duties not well-distributed among personnel C02 Training requirements not

C02 Design input obsolete C02 Equipment found distraction PRESENTATION LTA

understood or enforced C04 Too few workers assigned to task identified

C03 Design input not outside acceptance criteria C03 Incorrect performance due to C01 Format deficiencies

C02 Job performance standards not C05 Insufficient number of trained or experienced workers C03 Work incorrectly

correct mental lapse C02 Improper referencing or

B2 PERIODIC / adequately defined assigned to task considered skill of the craft

C04 Necessary design C04 Infrequently performed steps branching

input not available CORRECTIVE were performed incorrectly C03 Management direction created C06 Planning not coordinated with inputs from C03 Checklist LTA

MAINTENANCE LTA B2 TRAINING METHODS

C05 Delay in time cause d LTA insufficient awareness of impact of Walk downs/ task analysis C04 Deficiencies in user aids LTA

B2 DESIGN OUTPUT LTA C01 Preventive actions actions on safety / reliability C07 Job scoping did not identify potential task interruptions (charts, etc.) C01 Practice or hands -on

C01 Design output scope maintenance for equipment C06 Wrong action selected based C04 Management follow-up or and / or environmental stress C05 Recent changes not made experience LTA

LTA LTA on similarity with other actions monitoring of activities did not C08 Job scoping did not identify special circumstances apparent to user

C02 Predictive maintenance C02 Testing LTA

C02 Design output not C07 Omission / repeating of steps identify problems and / or conditions C06 Instruction step / C03 Refresher training LTA

clear LTA due to assumptions for C05 Management assessment did not C09 Work planning not coordinated with all departments information in wrong

C03 Corrective C04 Inadequate presentation

C03 Design output not completion determine cause s of previous event or involved in task sequence

correct maintenance LTA known problem C10 Problem performing repetitive tasks and / or subtasks C07 Unclear / complex wording B3 TRAINING

C04 Inconsistent design C04 Equipment history B2 RULE BASED ERROR C06 Previous industry or in-house C11 Inadequate work package preparation or grammar MATERIAL LTA

output LTA C01 Strong rule incorrectly experience was not effectively used C01 Training objectives LTA

B4 SUPERVISORY METHODS LTA B2 WRITTEN

C05 Design input not chosen over other rules to prevent recurrence C02 Inadequate content

B3 INSPECTION / TESTING C01 Tasks and individual accountability not made clear to COMMUNICATION

addressed in design output C02 Signs to stop were ignored C07 Responsibility of personnel not C03 Training on new work

LTA worker CONTENT LTA

C06 Drawing, and step performed incorrectly well-defined or personnel not held methods LTA

C01 Start-up testing LTA C02 Progress / status of task not adequately tracked C01 Limit inaccuracies

specification, or data error C03 Too much activity was accountable C04 Performance standards

C02 Inspection / testing LTA C03 Appropriate level of in-task supervision not determined C02 Difficult to implement

C07 Error in equipment or occurring and error made in C08 Corrective action responses to a LTA

C03 Post-maintenance / Post- prior to task C03 Data / computations

material selection problem solving known or repetitive problem was

modification testing LTA C04 Direct supervisory involvement in task interfered with wrong / incomplete

C08 Errors not detectable C04 Previous success in use of untimely

rule reinforce d continued use of

overview role C04 Equipment identification A7 Other Problem

C09 Errors not recoverable B4 MATERIAL CONTROL C09 Corrective action for previously C05 Emphasis on schedule exceeded emphasis on LTA

LTA rule identified problem or event was not

B3 DESIGN / methods / doing a good job C05 Ambiguous instructions / B1 EXTERNAL PHENOMENA

C01 Material handling LTA C05 Situation incorrectly adequate to prevent recurrence

DOCUMENTATION LTA C06 Job performance and self-checking standards not requirements C01 Weather or ambient conditions LTA

C02 Material storage LTA identified or represented result ing

C01 Design / documentation B2 RESOURCE MANAGEMENT properly communicated C06 Typographical error C02 Power failure or transient

C03 Material packaging in wrong rule used

not complete LTA C07 Too many concurrent tasks assigned to worker C07 Facts wrong / requirements C03 External fire or explosion

LTA

C02 Design / documentation B3 KNOWLEDGE BASED C01 Too many administrative duties C08 Frequent job or task shuffling not correct C04 Other natural phenomena LTA

C04 Material shipping LTA

not up-to-date ERROR assigned to immediate supervisor C09 Assignment did not consider workers need to use C08 Incomplete / situation not

C05 Shelf life exceeded

C03 Design / documentation C01 Attention was given to wrong C02 Insufficient supervisory resources higher-order skills covered B2 RADIOLOGICAL / HAZARDOUS

C06 Unauthorized material

not controlled issues to provide necessary supervision C10 Assignment did not consider workers previous task C09 Wrong revision used MATERIAL PROBLEM

substitution

C02 LTA Conclusion based on C03 Insufficient manpower to support C11 Assignment did not consider workers ingrained work C01 Legacy contamination

C07 Marking / labeling LTA B3 WRITTEN

B4 DESIGN / sequencing of facts identified goal / objective patterns C02 Source unknown

INSTALLATION B5 PROCUREMENT C03 Individual justifie d action by C04 Resources not provided to assure C12 Contact with personnel too infrequent to detect work COMMUNICATION

VERIFICATION LTA CONTROL LTA focusing on biased evidence adequate training was provided / habit/attitude changes NOT USED

C01 Independent review of C01 Control of changes to C04 LTA review based on maintained C13 Provided feedback on negative performance but not on C01 Lack of written

design / documentation procurement specifications / assumption that process will not C05 Needed resource changes not positive performance communication

LTA purchase order LTA change approved / funded C02 Not available or Level A nodes are

B5 CHANGE MANAGEMENT LTA inconvenient for use

C02 Testing of design / C02 Fabricated item did C05 Incorrect assumption that a C06 Means not provided to assure underlined.

installation LTA not meet requirements correlation existed between two or procedures / documents / records were C01 Problem identification did not identify need for change

C03 Independent C03 Incorrect item received of adequate quality and up -to-date C02 Change not implemented in timely manner

B4 VERBAL Level B nodes are in

more facts COMMUNICATION LTA

inspection of design / C04 Product acceptance C06 Individual underestimated the C07 Means not provided for assuring C03 Inadequate vendor support of change

C01 Communication between

ALLCAPS.

installation LTA requirements LTA problem by using past events as adequate availability of appropriate C04 Risks / consequences associated with change not Level C nodes are in

work groups LTA

C04 Acceptance of basis materials / tools adequately reviewed / assessed

design / installation LTA B6 DEFECTIVE, FAILED C08 Means not provided for assuring C05 System interactions not considered

C02 Shift communications sentence case.

OR CONTAMINATED LTA

B4 WORK PRACTICES LTA adequate equipment quality, C06 Personnel / department interactions not considered

C03 Correct terminology not

LTA = Less than adequate

B5 OPERABILITY C01 Defective or failed part C01 Individual s capability to reliability, or operability C07 Effects of change on schedules not adequately addressed

C02 Defective or failed used

OF DESIGN / perform work LTA [Examples C09 Personnel selection did not assure C08 Change-related training / retraining not performed or not

ENVIRONMENT LTA material C04 Verification / repeat back

include: Sensory / perceptual match of worker motivations / job adequate

C01 Ergonomics LTA C03 Defective weld, braze not used

capabilities LTA, Motor / physical descriptions C09 Change-related documents not developed or revised

or soldering joint C05 Information sent but not

C02 Physical environment capabilities LTA, and Attitude / C10 Means / method not provided for C10 Change-related equipment not provided or not revised

LTA C04 End of life failure understood

psychological profile LTA.] assuring adequate quality of contract C11 Changes not adequately communicated

C05 Electrical or instrument C06 Suspected problems not

C03 Natural environment C02 Deliberate violation services C12 Change not identifiable during task

LTA noise communicated to supervision

C13 Accuracy / effectiveness of change not verified or not

C06 Contaminant C07 No communication

validated

method available

Anda mungkin juga menyukai

- Human Error Root Cause Analisys - HercaDokumen6 halamanHuman Error Root Cause Analisys - HercaSamuel Colaço100% (3)

- Audit Procedures - FCPA PDFDokumen356 halamanAudit Procedures - FCPA PDFJoud H Abu HashishBelum ada peringkat

- SSP 465 12l 3 Cylinder Tdi Engine With Common Rail Fuel Injection SystemDokumen56 halamanSSP 465 12l 3 Cylinder Tdi Engine With Common Rail Fuel Injection SystemJose Ramón Orenes ClementeBelum ada peringkat

- MAOH600 Ropu 48 Presentation Script and ReferencesDokumen10 halamanMAOH600 Ropu 48 Presentation Script and ReferencesFano AsiataBelum ada peringkat

- PMP Exam SimulatorDokumen5 halamanPMP Exam SimulatorJuan Pablo CortésBelum ada peringkat

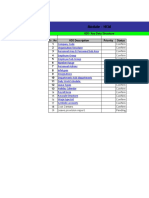

- Perspective Objective/Goals Ref. Code Perspective Weightage Ref. Code WeightageDokumen29 halamanPerspective Objective/Goals Ref. Code Perspective Weightage Ref. Code Weightagerevanth kumarBelum ada peringkat

- CIMA Suggested Study RoutesDokumen4 halamanCIMA Suggested Study RoutesjerryetcBelum ada peringkat

- Primera Prueba de ExamenDokumen5 halamanPrimera Prueba de Exameneduardo ordazBelum ada peringkat

- Raci Matrix: Project Deliverable (Activity)Dokumen20 halamanRaci Matrix: Project Deliverable (Activity)vikram khanna100% (2)

- 390012-Reynard-Loading OperatorDokumen3 halaman390012-Reynard-Loading OperatorATKBelum ada peringkat

- University of Calicut - Online ResultsDokumen1 halamanUniversity of Calicut - Online ResultsArjun SureshBelum ada peringkat

- Lab01 - Program Coding Phase Defects ChecklistDokumen1 halamanLab01 - Program Coding Phase Defects ChecklistIulia ThiraBelum ada peringkat

- India Post Payment Bank Recruitment 2023Dokumen11 halamanIndia Post Payment Bank Recruitment 2023Anwesha MukherjeeBelum ada peringkat

- Sap PP: Production PlanningDokumen10 halamanSap PP: Production PlanningNARESH SINGARAMBelum ada peringkat

- Department of Artificial Intelligence and Data ScienceDokumen2 halamanDepartment of Artificial Intelligence and Data Sciencemeenakshi singhBelum ada peringkat

- Skill Planning: 1.1 Lean OverviewDokumen12 halamanSkill Planning: 1.1 Lean Overview25aprilBelum ada peringkat

- Sem-1 Syllabus Distribution 2021Dokumen2 halamanSem-1 Syllabus Distribution 2021Kishan JhaBelum ada peringkat

- CE37L 3A Ambalong PlateNo-4-1Dokumen9 halamanCE37L 3A Ambalong PlateNo-4-1jestertapallaBelum ada peringkat

- Wrench Time Analysis: SeriesDokumen27 halamanWrench Time Analysis: Seriespradeep1987coolBelum ada peringkat

- Accounting Information Systems 2nd Edition Richardson Test BankDokumen25 halamanAccounting Information Systems 2nd Edition Richardson Test BankCassieYangiosx100% (56)

- Co-Requisite: Prerequisite: Data Book / Codes/Standards Course Category Course Designed by ApprovalDokumen3 halamanCo-Requisite: Prerequisite: Data Book / Codes/Standards Course Category Course Designed by ApprovalVidushi SoodBelum ada peringkat

- 6895-TemplateDokumen1 halaman6895-TemplateRaúl Fernández CuencaBelum ada peringkat

- Experiment No. 10Dokumen3 halamanExperiment No. 10Ubair Javaid 16 (Game Play)Belum ada peringkat

- Accounting Information Systems 2nd Edition Richardson Test BankDokumen35 halamanAccounting Information Systems 2nd Edition Richardson Test Banknubilegoggler.i8cm100% (13)

- Dwnload Full Accounting Information Systems 2nd Edition Richardson Test Bank PDFDokumen35 halamanDwnload Full Accounting Information Systems 2nd Edition Richardson Test Bank PDFga437yboyd100% (15)

- Industrial Technology SBA Mark Schemes 220915 084022Dokumen6 halamanIndustrial Technology SBA Mark Schemes 220915 084022wafiyyah AliBelum ada peringkat

- Assignment of Strategic HRMDokumen1 halamanAssignment of Strategic HRMJyoti YadavBelum ada peringkat

- Oil and Natural Gas Corporation LimitedDokumen12 halamanOil and Natural Gas Corporation LimitedSagar SharmaBelum ada peringkat

- LAB 1-WP Evaluation SheetDokumen1 halamanLAB 1-WP Evaluation SheetHasham SohailBelum ada peringkat

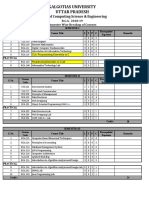

- Galgotias University Uttar Pradesh: School of Computing Science & EngineeringDokumen3 halamanGalgotias University Uttar Pradesh: School of Computing Science & EngineeringTushant ChakravartyBelum ada peringkat

- IT ITM Curriculum IT 2015Dokumen6 halamanIT ITM Curriculum IT 2015Black noirBelum ada peringkat

- BA2 Transition GuideDokumen4 halamanBA2 Transition GuideBrilliantBelum ada peringkat

- University of Calicut - Online ResultsDokumen1 halamanUniversity of Calicut - Online ResultsAnzil For pubgBelum ada peringkat

- Current File IndexesDokumen16 halamanCurrent File IndexesSQBelum ada peringkat

- HRM301Dokumen2 halamanHRM301RaviBelum ada peringkat

- Amandy, Arjay S. Bsit 2CDokumen4 halamanAmandy, Arjay S. Bsit 2CArjay S. AmandyBelum ada peringkat

- BA3 Transition Guide PDFDokumen4 halamanBA3 Transition Guide PDFMuhammad MuzammilBelum ada peringkat

- COBOL Basic Programming ConceptsDokumen8 halamanCOBOL Basic Programming ConceptsNagfaceBelum ada peringkat

- BMTC Kds FinalDokumen66 halamanBMTC Kds FinalragininikamBelum ada peringkat

- Board of Technical Examinations, BangaloreDokumen17 halamanBoard of Technical Examinations, BangaloreSanjay PatilBelum ada peringkat

- University of Calicut - Online ResultsDokumen1 halamanUniversity of Calicut - Online ResultsAdithya AdhiBelum ada peringkat

- Bsc-Ty 2019-20Dokumen15 halamanBsc-Ty 2019-20nrdhakshinBelum ada peringkat

- University of Calicut: Examination ResultsDokumen1 halamanUniversity of Calicut: Examination ResultsJustine JustineBelum ada peringkat

- Cbarbcm007 PDFDokumen1 halamanCbarbcm007 PDFJustine JustineBelum ada peringkat

- Edmil - Production Team LeaderDokumen3 halamanEdmil - Production Team LeaderATKBelum ada peringkat

- Scet HRM Mid Ii QBDokumen5 halamanScet HRM Mid Ii QBSai PrabhasBelum ada peringkat

- HeritageDokumen5 halamanHeritageSai PrabhasBelum ada peringkat

- COBIT 5-Self-Assessment Templates-06May2013-drDokumen114 halamanCOBIT 5-Self-Assessment Templates-06May2013-drDian Razak BastianBelum ada peringkat

- Transaction ProcessingDokumen59 halamanTransaction ProcessingK KUMAR JENABelum ada peringkat

- Lean Audit Checklist 9aug20Dokumen160 halamanLean Audit Checklist 9aug20synkan100% (1)

- M. S. Ramaiah University of Applied Sciences: Faculty of Engineering & TechnologyDokumen5 halamanM. S. Ramaiah University of Applied Sciences: Faculty of Engineering & TechnologyShyam BhatBelum ada peringkat

- Rubric Project RC2Dokumen1 halamanRubric Project RC2Ummi Suraya100% (1)

- Cont. Table 5.1 Updated Risk Register For Time.: Arab Academy For Science and Technology and Maritime TransportDokumen2 halamanCont. Table 5.1 Updated Risk Register For Time.: Arab Academy For Science and Technology and Maritime Transportjish161Belum ada peringkat

- TVET Business and FinanceDokumen19 halamanTVET Business and FinancefatbehBelum ada peringkat

- BS Accountancy 1Dokumen2 halamanBS Accountancy 1Jana May Faustino MedranoBelum ada peringkat

- Assignment Cover Sheet Qualification Module Number and TitleDokumen8 halamanAssignment Cover Sheet Qualification Module Number and Titleoshada chaturaBelum ada peringkat

- Syllabus For Bcom StudentsDokumen2 halamanSyllabus For Bcom StudentssainipreetpalBelum ada peringkat

- 4 - IPS - ZamanDokumen1 halaman4 - IPS - ZamanS A ZamanBelum ada peringkat

- 4 - IPS - ZamanDokumen1 halaman4 - IPS - ZamanS A ZamanBelum ada peringkat

- 5 - IPS For AllDokumen1 halaman5 - IPS For AllS A ZamanBelum ada peringkat

- 7.1.3 - PMP - Appendix7.1.3 - Register of Controlled Documents - B1Dokumen19 halaman7.1.3 - PMP - Appendix7.1.3 - Register of Controlled Documents - B1SA023Belum ada peringkat

- Jurnal SOL MeningiomaDokumen6 halamanJurnal SOL MeningiomaConnie SianiparBelum ada peringkat

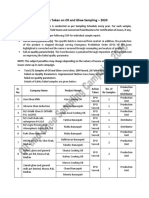

- Action Taken On Oil and Ghee Sampling - 2020Dokumen2 halamanAction Taken On Oil and Ghee Sampling - 2020Khalil BhattiBelum ada peringkat

- Essay Type ExaminationDokumen11 halamanEssay Type ExaminationValarmathi83% (6)

- TM - 1 1520 237 10 - CHG 10Dokumen841 halamanTM - 1 1520 237 10 - CHG 10johnharmuBelum ada peringkat

- Lesson 49Dokumen2 halamanLesson 49Андрій ХомишакBelum ada peringkat

- Glycolysis Krebscycle Practice Questions SCDokumen2 halamanGlycolysis Krebscycle Practice Questions SCapi-323720899Belum ada peringkat

- BS 65-1981Dokumen27 halamanBS 65-1981jasonBelum ada peringkat

- L04-課文單片填空 (題目) (Day of the Dead)Dokumen3 halamanL04-課文單片填空 (題目) (Day of the Dead)1020239korrnellBelum ada peringkat

- Campus Sexual Violence - Statistics - RAINNDokumen6 halamanCampus Sexual Violence - Statistics - RAINNJulisa FernandezBelum ada peringkat

- Lesson Plan PPEDokumen3 halamanLesson Plan PPEErika Jean Moyo ManzanillaBelum ada peringkat

- Active Contracts by Contract Number Excluded 0Dokumen186 halamanActive Contracts by Contract Number Excluded 0JAGUAR GAMINGBelum ada peringkat

- Đề ANH chuyên 5Dokumen7 halamanĐề ANH chuyên 5Phạm Ngô Hiền MaiBelum ada peringkat

- Earth Loop ImpedanceDokumen5 halamanEarth Loop ImpedanceKaranjaBelum ada peringkat

- A.8. Dweck (2007) - The Secret To Raising Smart KidsDokumen8 halamanA.8. Dweck (2007) - The Secret To Raising Smart KidsPina AgustinBelum ada peringkat

- Endothermic Gas Production Overview: Tmosphere Ngineering OmpanyDokumen6 halamanEndothermic Gas Production Overview: Tmosphere Ngineering OmpanyJhon ChitBelum ada peringkat

- Aromatic Electrophilic SubstitutionDokumen71 halamanAromatic Electrophilic SubstitutionsridharancBelum ada peringkat

- Unit-7 (EVS)Dokumen32 halamanUnit-7 (EVS)g6614134Belum ada peringkat

- BV DSG eDokumen18 halamanBV DSG eIulianIonutRaduBelum ada peringkat

- Hubungan Body Image Dengan Pola Konsumsi Dan Status Gizi Remaja Putri Di SMPN 12 SemarangDokumen7 halamanHubungan Body Image Dengan Pola Konsumsi Dan Status Gizi Remaja Putri Di SMPN 12 SemarangNanda MaisyuriBelum ada peringkat

- Cyber Safety PP Presentation For Class 11Dokumen16 halamanCyber Safety PP Presentation For Class 11WAZ CHANNEL100% (1)

- Aluminium - Hull Structure in Naval ApplicationsDokumen6 halamanAluminium - Hull Structure in Naval ApplicationsStefano CostaBelum ada peringkat

- Key ScientificDokumen4 halamanKey ScientificGarrettBelum ada peringkat

- Universal ING - LA.Boschi Plants Private LimitedDokumen23 halamanUniversal ING - LA.Boschi Plants Private LimitedAlvaro Mendoza MaytaBelum ada peringkat

- Week5 6 2Dokumen2 halamanWeek5 6 2SAMANIEGO BERMEO DAVID SEBASTIANBelum ada peringkat

- Schematic Diagram For Pharmaceutical Water System 1652323261Dokumen1 halamanSchematic Diagram For Pharmaceutical Water System 1652323261Ankit SinghBelum ada peringkat

- Biodegradable Plastic Bag Manufacturing Industry-800655 PDFDokumen68 halamanBiodegradable Plastic Bag Manufacturing Industry-800655 PDFAryanBelum ada peringkat

- Chapter FourDokumen9 halamanChapter FourSayp dBelum ada peringkat

- CFPB Discount Points Guidence PDFDokumen3 halamanCFPB Discount Points Guidence PDFdzabranBelum ada peringkat