Cu Ni 18 ZN 19 PB 1

Diunggah oleh

Isa CatJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Cu Ni 18 ZN 19 PB 1

Diunggah oleh

Isa CatHak Cipta:

Format Tersedia

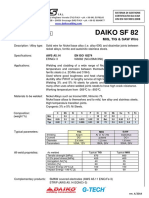

UNS C76300 EN CW408J DIN 2.

0790 - CuNi18Zn19Pb1

General Characteristics

German silver (or nickel silver) with high toughness, good corrosion resistance, and medium cold formability. Lead is Machinability -

added for improved machinability. Quench hardening no

The alloy is mainly used in jewelry and for spectacle frames. Polishing +

The electrical conductivity is 6% IACS.

Magnetic no

Age hardening no

Welding

MIG,TIG,WIG yes

Arc yes

Resistance yes

Autogenous no

Laser yes

Chemical composition (ASTM) [wt.%]

Cu Fe Ni Pb AT Zn

60.5-63.5 < 0.25 16 - 20 0.8 - 1.4 < 0.5 Balance

Physical properties

Density Electrical resistivity Specific heat Thermal conductivity

r [kgm-3] r [Wm] Cp [Jkg-1K-1] l [Wm-1K-1]

8750 0.286 at 20 C 420 33

Coefficient of thermal expansion Elastic modulus

a [10-6C-1] between 20C and E [GPa]

100 C 200 C 300 C 400 C 500 C 600 C 700 C 130 at 20C

17.0

Mechanical properties

Yield strength Tensile Elongation Vickers

State Rp0.2 [MPa] strength Hardness

20C 100C 200C 300C Rm [MPa] A5 [%] [HV]

Annealed 160 420 40 90

Full hard 540 640 5 200

Thermal treatment

Type Temperature Time Protective atmosphere Cooling

[C] [minutes]

Annealing 620 - 700 15 - 60 Air, argon or N2 + H2 not critical

Stress relief 300 - 400 240 Air, argon or N2 + H2 not critical

Surface treatment

Type Solution Remarks

Pickling H2SO4 4 - 15% during 0.5 to 15 minutes RT or at 60C

Pickling HCl 40 - 90 % during 1 to 3 minutes RT

Fabrication characteristics

Cold formability is good, but not as good as that of CuNi18Zn20. Hot forming is not recommended.

Annealing in air requires subsequent pickling to remove the surface oxide layer. Annealing can also be done in a neutral (Argon) or reducing (cracked

ammoniac, N2 + H2) atmosphere. The most

performant microstructures and mechanical properties are achieved with annealing temperatures to the lower bound of the temperature interval given

above. Machinability is good, estimated at

30% on a scale with the free cutting brass CuZn35.5Pb3 at 100%

Welding, brazing and soldering

This alloy is easily soldered and brazed.

Gaz and resistance point welding give good results.

MIG and continuous resistance welding are possible.

Welding with mantled electrodes is not recommended.

Available products

Sheets, ribbons, wires, profiles, tubes, dimensions and tolerances on request.

The indications are basically founded on our actual know-how. This technical data sheet is without

commitment and not contracted.

Anda mungkin juga menyukai

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDokumen1 halamanThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedRemo StortiniBelum ada peringkat

- Aisi 420 PDFDokumen1 halamanAisi 420 PDFJusril HidayatBelum ada peringkat

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDokumen1 halamanThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedsreckoBelum ada peringkat

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDokumen1 halamanThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not Contractedlijojose1Belum ada peringkat

- Grade 2 Titanium Characteristics and PropertiesDokumen1 halamanGrade 2 Titanium Characteristics and PropertiesLucho de BarBelum ada peringkat

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDokumen1 halamanThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedRavindra ErabattiBelum ada peringkat

- Cuzn37-Pna 243 enDokumen2 halamanCuzn37-Pna 243 enAbrahan Tinco PariBelum ada peringkat

- Carbon Steels - Data Sheet Grade: U1004: Chemical Composition (% by Weight)Dokumen7 halamanCarbon Steels - Data Sheet Grade: U1004: Chemical Composition (% by Weight)alvida pramudiantiBelum ada peringkat

- CuZn10-PNA 222 - ENDokumen2 halamanCuZn10-PNA 222 - ENjurreijndersBelum ada peringkat

- Hussey Copper Electrolytic Tough Pitch CDA Copper C 110 00Dokumen1 halamanHussey Copper Electrolytic Tough Pitch CDA Copper C 110 00Michael DoyleBelum ada peringkat

- Cucrzr c18160 Pna 372 - enDokumen2 halamanCucrzr c18160 Pna 372 - enSulistyo widiatmokoBelum ada peringkat

- Cunisi-Pna 290 enDokumen2 halamanCunisi-Pna 290 enJdjoBelum ada peringkat

- Cu Etp c11000 Pna - 211 sm0008 - enDokumen2 halamanCu Etp c11000 Pna - 211 sm0008 - enNitin KumarBelum ada peringkat

- CuFe2p - AurubisDokumen2 halamanCuFe2p - AurubisJan NoscilBelum ada peringkat

- Datasheet Sandvik Saf 2205 en PDFDokumen12 halamanDatasheet Sandvik Saf 2205 en PDFYuriy NesterovBelum ada peringkat

- (UNS N08825) : NAS High Corrosion Resistant Nickel AlloyDokumen4 halaman(UNS N08825) : NAS High Corrosion Resistant Nickel AlloySunil Kumar GoudaBelum ada peringkat

- CuZn30-PNA 226 - ENDokumen2 halamanCuZn30-PNA 226 - ENNHadesBelum ada peringkat

- Cu Ofe c10100 Pna 203 - enDokumen2 halamanCu Ofe c10100 Pna 203 - enNitin KumarBelum ada peringkat

- Datasheet-Sandvik-253-Ma-En-V2019-08-19 09 - 46 Version 1Dokumen12 halamanDatasheet-Sandvik-253-Ma-En-V2019-08-19 09 - 46 Version 1mini p shendeBelum ada peringkat

- 16 MN CR 5Dokumen2 halaman16 MN CR 5bd54Belum ada peringkat

- Interlloy Grade 8620 Case Hardening SteelDokumen3 halamanInterlloy Grade 8620 Case Hardening Steelajitchavan2150Belum ada peringkat

- kme_STOL76_C19010_enDokumen1 halamankme_STOL76_C19010_enMattia Terri TerrandoBelum ada peringkat

- NAS 660 Heat-Resistant Stainless Steel PropertiesDokumen4 halamanNAS 660 Heat-Resistant Stainless Steel Propertiessafat parBelum ada peringkat

- Steel Grade: Material Data SheetDokumen3 halamanSteel Grade: Material Data Sheetreza amiriniaBelum ada peringkat

- Steel Grade: Material Data SheetDokumen5 halamanSteel Grade: Material Data Sheetdan howsBelum ada peringkat

- DS Mold 4140Dokumen3 halamanDS Mold 4140reza prasetiaBelum ada peringkat

- CuSn6-PNA 282 - ENDokumen2 halamanCuSn6-PNA 282 - ENasatcholidBelum ada peringkat

- CuZn10-PNA 222 - ENDokumen2 halamanCuZn10-PNA 222 - ENYulwido AdiBelum ada peringkat

- Datasheet Sandvik Saf 2507 en PDFDokumen15 halamanDatasheet Sandvik Saf 2507 en PDFShesharam Chouhan100% (1)

- Quenched and Tempered Alloyed Engineering Steel DINDokumen2 halamanQuenched and Tempered Alloyed Engineering Steel DINkazdoelahBelum ada peringkat

- Datasheet Sanicro 72hpDokumen2 halamanDatasheet Sanicro 72hpphillipskincaidBelum ada peringkat

- 20Mncr5: Steel GradeDokumen4 halaman20Mncr5: Steel GradeAhmad ShujaBelum ada peringkat

- Material Datasheet Cuzn30Dokumen2 halamanMaterial Datasheet Cuzn30alex94kgBelum ada peringkat

- SMAW E9018-G electrode for welding CrMo steelDokumen1 halamanSMAW E9018-G electrode for welding CrMo steelSai PrasathBelum ada peringkat

- SAE 1018 - Data Sheet PDFDokumen1 halamanSAE 1018 - Data Sheet PDFHari SuthanBelum ada peringkat

- 02 Asae 101892Dokumen1 halaman02 Asae 101892raviteja036Belum ada peringkat

- 100crmnsi6-4: Steel GradeDokumen3 halaman100crmnsi6-4: Steel GradeSama UmateBelum ada peringkat

- SISTEMA DI GESTIONE CERTIFICATO DA ICIMDokumen1 halamanSISTEMA DI GESTIONE CERTIFICATO DA ICIMRhyan EdwinBelum ada peringkat

- Cusn10-Pna 292 enDokumen2 halamanCusn10-Pna 292 enRissi CHBelum ada peringkat

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10225Dokumen2 halamanEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10225farshid KarpasandBelum ada peringkat

- 42 CR Mo 4Dokumen3 halaman42 CR Mo 4lucasBelum ada peringkat

- Technical Datasheet PNA290Dokumen3 halamanTechnical Datasheet PNA290nelson9746Belum ada peringkat

- 601-UK-Use of Toolox in Engineering ApplicationsDokumen6 halaman601-UK-Use of Toolox in Engineering Applicationsplj0001Belum ada peringkat

- 30crnimo8: Steel GradeDokumen2 halaman30crnimo8: Steel GradewemersonsrBelum ada peringkat

- Cusn8-Pna 283 enDokumen2 halamanCusn8-Pna 283 enRahul BiradarBelum ada peringkat

- Steel PropertiesDokumen22 halamanSteel PropertiesMOHD SALMANBelum ada peringkat

- Material data sheet for steel grades SB-C45, 047 and Imatra 4MDokumen2 halamanMaterial data sheet for steel grades SB-C45, 047 and Imatra 4Mabu asiyahBelum ada peringkat

- Raffmetal: UNI EN 1676 and 1706Dokumen2 halamanRaffmetal: UNI EN 1676 and 1706Martin DuarteBelum ada peringkat

- CuZn30 Brass Sheet: Properties and Applications of 70/30 Copper Zinc AlloyDokumen2 halamanCuZn30 Brass Sheet: Properties and Applications of 70/30 Copper Zinc Alloyavinashchauhan2695Belum ada peringkat

- AmuDokumen2 halamanAmuavinashchauhan2695Belum ada peringkat

- UNION ER90S-B3 TIG rodDokumen1 halamanUNION ER90S-B3 TIG rodbrayanBelum ada peringkat

- Raffmetal: UNI EN 1676 and 1706Dokumen2 halamanRaffmetal: UNI EN 1676 and 1706Raj RajeshBelum ada peringkat

- 1.7225 en PDFDokumen2 halaman1.7225 en PDFTheodoros AtheridisBelum ada peringkat

- C2700Dokumen6 halamanC2700Andrew TanBelum ada peringkat

- Electric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesDari EverandElectric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesBelum ada peringkat

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantDari EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryDari EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryBelum ada peringkat

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDari EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsBelum ada peringkat

- Heat Treatment - Manufacturing Engineering Questions & Answers - SanfoundryDokumen13 halamanHeat Treatment - Manufacturing Engineering Questions & Answers - SanfoundryBrown Mesh0% (1)

- European Steel and Alloy Grades: About Us EN 10248-1Dokumen2 halamanEuropean Steel and Alloy Grades: About Us EN 10248-1farshid KarpasandBelum ada peringkat

- ASM Material Data Sheet 430 AnnealedDokumen2 halamanASM Material Data Sheet 430 AnnealedKarthick DuraiBelum ada peringkat

- Astm B139Dokumen5 halamanAstm B139Jamil SalmanBelum ada peringkat

- ElectrodosDokumen20 halamanElectrodosRuben Dario Mamani ArellanoBelum ada peringkat

- Data Table For Grades Tool Die Steels SKD-11Dokumen3 halamanData Table For Grades Tool Die Steels SKD-11Adhi candra irawanBelum ada peringkat

- Anastasia YoungDokumen8 halamanAnastasia YoungInterweave46% (13)

- PWHT Case StudiesDokumen5 halamanPWHT Case Studiestbmari100% (1)

- Strengthening Mechanisms in Solid Solution Aluminum AlloysDokumen8 halamanStrengthening Mechanisms in Solid Solution Aluminum AlloysJavier HerediaBelum ada peringkat

- Everything You Need to Know About 4140 High Tensile SteelDokumen3 halamanEverything You Need to Know About 4140 High Tensile SteelJean Paulo SalvatiBelum ada peringkat

- 05 - Titanium and Titanium AlloysDokumen78 halaman05 - Titanium and Titanium AlloysMiaCat100% (1)

- Aisi 9254 - Spring SteelDokumen2 halamanAisi 9254 - Spring SteelSergio100% (1)

- BronzeDokumen4 halamanBronzeGaurav Kumar SinghBelum ada peringkat

- Property Manipulation of Steels With Variation in %C-Fracture Toughness vs. Yield StrengthDokumen5 halamanProperty Manipulation of Steels With Variation in %C-Fracture Toughness vs. Yield StrengthSaumya SuyalBelum ada peringkat

- Data Sheet VDM Alloy 59Dokumen16 halamanData Sheet VDM Alloy 59Iniyan Thiruselvam Navaladi KarthikeyanBelum ada peringkat

- 304 304h Data SheetDokumen4 halaman304 304h Data SheetHuỳnh Thanh TrườngBelum ada peringkat

- 01-SAMMS-046 Stainless PipeDokumen11 halaman01-SAMMS-046 Stainless PipesureshBelum ada peringkat

- Measurement of Decarburization PDFDokumen6 halamanMeasurement of Decarburization PDFnayefamkBelum ada peringkat

- M4-NF High Speed Steel Metaux-SolutionsDokumen2 halamanM4-NF High Speed Steel Metaux-SolutionsLaurent MorgeBelum ada peringkat

- Astm A803-12Dokumen7 halamanAstm A803-12Артем ТитовBelum ada peringkat

- Welding, Brazing & Cutting - 11-21-2007Dokumen7 halamanWelding, Brazing & Cutting - 11-21-2007Jimmy ClavelBelum ada peringkat

- Re CrystallizationDokumen476 halamanRe CrystallizationThaiThanh PhanBelum ada peringkat

- Fti Vhssm50 InglesDokumen2 halamanFti Vhssm50 InglesAntonio Melgaço da SilvaBelum ada peringkat

- Additive Manufacturing Stainless Steel Alloy (UNS S31603) With Powder Bed FusionDokumen9 halamanAdditive Manufacturing Stainless Steel Alloy (UNS S31603) With Powder Bed FusionRaj Rajesh100% (1)

- Boiler Welding ElectrodesDokumen24 halamanBoiler Welding Electrodesjohnknight000Belum ada peringkat

- Böhler WeldingDokumen32 halamanBöhler WeldingszizaBelum ada peringkat

- Grade 410 Stainless Steel Properties UsesDokumen5 halamanGrade 410 Stainless Steel Properties UsesGangsar DwikaBelum ada peringkat

- Machinability of BS S132Dokumen2 halamanMachinability of BS S132goggerBelum ada peringkat

- Sa 961 PDFDokumen10 halamanSa 961 PDFaruntpeBelum ada peringkat

- DocxDokumen110 halamanDocxAizel Jeong Aizel JeongBelum ada peringkat