Tooling and Tabletting Cycle Poster

Diunggah oleh

pradeep281001Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Tooling and Tabletting Cycle Poster

Diunggah oleh

pradeep281001Hak Cipta:

Format Tersedia

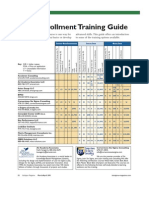

TA B L E T C O M P R E S S I O N T O O L I N G

PharmaGrade Steel Properties

Durability, Productivity, Longevity.

This chart explains the principles of the tabletting cycle and key

considerations for tablet tooling. HPG - S

Resistance to Fracture

The tabletting process is very demanding. Delicate punch tips have

to withstand many forces such as high cyclic loading, high speed

frictional forces and aggressive granules.

The Tabletting Cycle HPG - SS

HPG - P HPG - MP

HPG - MD

Tablet Terminology Filling Compression Ejection

Shaped Tablets Round Tablets 01 02 05 06 07 10 11

The lower punch is allowed The lower punch is then The upper punch Pre-compression The powder The lower punch begins to The tablet is then removed

Oval Tablets Capsule Tablets Flat Bevelled Bisect Line Quadrisect Line Embossing/

Edge Engraving to descend to its lowest raised to a predetermined is lowered into the gives the powder is fully rise in the bore of the die, from the punch into the take-

point and the bore of the die point so that excess powder bore of the die. an inital pinch compressed. lifting the tablet until its base off chute by passing under a

Major Axis

is filled with granule. is expelled. to remove is level with the top of the die. static take-off blade.

excess air.

Minor End Radius Minor Axis

HPG - TC

Major Side Radius

Land

Cup Depth

Wear Resistance

Wall

Minor Axis Radius Major Axis Radius Cup End Radius

Typical Tablet Shapes

03 04 08 N.B. For guidance 09 12 PharmaCote tool coatings

The powder is then This ensures that the bore The correct on compression The upper punch The lower punch then moves

levelled by passing under of the die is filled with the pressure levels for each is then raised out to its lowest point ready for

a scraper blade. exact volume of product to is reached. tablet profile, refer of the way, filling and the entire process

be used and the next stage to the maximum ready for tablet is repeated.

Overcome Common Tooling Problems with PharmaCote Treatments and Coatings.

can begin. pressure chart. ejection.

Flat Faced Flat Bevelled Edge Shallow Convex Normal Convex Deep Convex Extra Deep Convex Ball or Pill Double Radius

Feed Paddles Feed Frame Upper Punch Hopper Take-off Chute Ejection Station Take-off Blade

Ensures that the granule Fed by the hopper to The upper punch is Contains the granulated The chute down which This is the station where Fitted in front of the feed

is kept agitated for hold the granule as it is lowered in and lifted out material which is to be the tablet passes the tablet leaves the die frame this deflects the

Bevel and Convex Ring Capsule Oval Ellipse Square Triangle Polygon

correct filling of the fed into the die. of the die. tabletted. for collection and for take off. tablet down the

die bore. packaging. take-off chute. Pitting Sticking Wear Corrosion

Die Ejection Cam

Punch Tip Pressure Guide

Diamond Rectangle Side-Wall Bisect Side-Wall Quadrisect Fish Bear Star Heart

The punch moves This forms the lower

within the die to form punch guide during the

the compression ejection stage and is

adjustable to ensure Punch Tip

Punch & Die Terminology

chamber within which

140

Load (kN)

the tablet is formed. smooth ejection without

damaging tablets.

130

SHALLOW CUP

Upper Punch Die Multi-Tip 120

Universal Seal Groove

Lower Punch Compression Station

Head Flat Outside Head

Where full 110

Radius/Angle Die Bore Chamfer The lower punch

remains within compression of the NORMAL CUP

the bore of the die tablet is achieved. 100

Inside Head

Angle

Taper during the

Depth entire cycle. 90

Anti-Turn Key F.B.E CUP

(Optional on Height Taper

rounds, 80

standard on

shapes Groove

and multi For Seal 70

punches)

Groove Cam Tracks Direction of Rotation

Outside Diameter These lift and lower This diagram shows

For Bellows 60

Barrel to

Stem

Undercut the upper and lower the tabletting process DOUBLE RADIUS CUP

For Drip cup punches as requried. from left to right.

Chamfer

50

On an actual machine

Lower Punch Die Segment Punch Tip Blended Land Rota Head this will be determined

by the direction in 40 DEEP CUP

Tip Straight which the entire turret

Land rotates in reaction to 30

Stem

the fixed items, such

Barrel to Stem as the fill hopper etc. BALL/PILL CUP

Radius 20

This direction may

Draw-down Cam Weight control Cam Fill Station Pre-Compression Main Compression vary from machine

Barrel Barrel to 10

Neck Blended This guides the lower This guides the lower punch during the latter part of The point where the die Rollers Rollers to machine but as a

Radius punch during the first the fill stage, adjustable to ensure that as the punch has been correctly filled. This roller gives the Applies full pre- general rule British and

Chamfer part of the fill stage, rises, the correct quantity of granule remains within the granule an initial pinch determined pressure to American machines 0

adjustable to ensure that die and therefore the tablet dosage is correct. to remove as much the punches for the final rotate in a clockwise 3 5 7 9 11 13 15

Neck to

Head the die bore is overfilled air as possible before formation of the direction, whilst

Neck Radius intially to allow accurate full compression takes tablet - see punch tip European machines

Diameter (mm)

Head adjustment at weight place. pressure guide. rotate anti clockwise.

Head O/D control.

FOR FURTHER INFORMATION PLEASE CONTACT:

I Holland Limited

COMMITTED TO OUR CUSTOMERS Meadow Lane, Long Eaton, Nottingham NG10 2GD England.

SHARING OUR KNOWLEDGE. T: +44 (0)115 972 6153 F: +44 (0)115 973 1789

E: info@iholland.co.uk

I Holland Ltd 2014 www.iholland.co.uk

I Holland Tooling A1 Poster March 14.indd 1 24/07/2014 16:25

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- LD 50 Techbull - LiquinoxDokumen2 halamanLD 50 Techbull - Liquinoxpradeep281001Belum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Audit Checklist For Purified Water SystemDokumen2 halamanAudit Checklist For Purified Water Systempradeep28100171% (7)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Responding To Regulatory InspectionsDokumen5 halamanResponding To Regulatory Inspectionspradeep281001Belum ada peringkat

- NCBI Article For Chlorine Di OxideDokumen3 halamanNCBI Article For Chlorine Di Oxidepradeep281001Belum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Chlorine Di-OxideDokumen56 halamanChlorine Di-OxideRamachandran Venkatesh100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Cleaning For Bio-FoulingDokumen2 halamanCleaning For Bio-Foulingpradeep281001Belum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Dockweiler Bpe DirectDokumen52 halamanDockweiler Bpe Directpradeep281001Belum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Compressed AirDokumen7 halamanCompressed Airpradeep281001Belum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- ORP SpecDokumen12 halamanORP Specpradeep281001Belum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Dockweiler Bpe DirectDokumen52 halamanDockweiler Bpe Directpradeep281001Belum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- 2810Dokumen1 halaman2810pradeep281001Belum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- ProcessDokumen4 halamanProcesspradeep281001Belum ada peringkat

- Technical DiaryDokumen24 halamanTechnical Diarypradeep281001Belum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Long - ArtiDokumen8 halamanLong - Artipradeep281001Belum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Clinical ResearchDokumen40 halamanClinical Researchpradeep281001Belum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- FDA Compliance Program for Sterile Drug Product Manufacturing InspectionsDokumen54 halamanFDA Compliance Program for Sterile Drug Product Manufacturing InspectionsantonygamalpharmaBelum ada peringkat

- Kimball Six Sigma Training ScheduleDokumen3 halamanKimball Six Sigma Training Schedulepradeep281001Belum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- MilliDokumen6 halamanMillipradeep281001Belum ada peringkat

- iSixSigma Magazine March-April 2011 52 Product GuideDokumen4 halamaniSixSigma Magazine March-April 2011 52 Product Guidewawawa1Belum ada peringkat

- World Class Training. World Class Consulting. World Class ResultsDokumen17 halamanWorld Class Training. World Class Consulting. World Class Resultspradeep281001Belum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Certificate Program in Regulations For Biologics and Pharmaceutical Product (6months)Dokumen3 halamanCertificate Program in Regulations For Biologics and Pharmaceutical Product (6months)pradeep281001Belum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- WHO Guidelines For Drinking Water PDFDokumen564 halamanWHO Guidelines For Drinking Water PDFshekharvkate100% (3)

- Quality PressDokumen56 halamanQuality PressEddie Kuang100% (1)

- MagaDokumen44 halamanMagapradeep281001Belum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Certificate Program in Regulations For Biologics and Pharmaceutical Product (6months)Dokumen3 halamanCertificate Program in Regulations For Biologics and Pharmaceutical Product (6months)pradeep281001Belum ada peringkat

- Spyn Audio Catalog-1589913182Dokumen28 halamanSpyn Audio Catalog-1589913182Jose Gregorio Ortega CarrilloBelum ada peringkat

- FMDC HEC PAST PAPERS BY PrepareHOWDokumen121 halamanFMDC HEC PAST PAPERS BY PrepareHOWSaad Hassan KheraBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Covid-19 and Crises Management Strategies of Hospitality Industry: A Descriptive ResearchDokumen8 halamanCovid-19 and Crises Management Strategies of Hospitality Industry: A Descriptive ResearchIAEME PublicationBelum ada peringkat

- CM4-1 - (Newtons Laws)Dokumen38 halamanCM4-1 - (Newtons Laws)Joseph TabulinaBelum ada peringkat

- Name - AP Calculus BC Date - Approximation ProjectDokumen4 halamanName - AP Calculus BC Date - Approximation ProjectzombielibraryBelum ada peringkat

- "Just The Maths" Unit Number 1.4 Algebra 4 (Logarithms) by A.J.HobsonDokumen11 halaman"Just The Maths" Unit Number 1.4 Algebra 4 (Logarithms) by A.J.HobsonNguyen Linh TrangBelum ada peringkat

- Marcom Opc ProductsDokumen8 halamanMarcom Opc ProductsMARCOM SRLBelum ada peringkat

- Interplast UPVC Pipe SpecificationDokumen4 halamanInterplast UPVC Pipe SpecificationJOSEPH APPIAHBelum ada peringkat

- Jawaban Soal BahlDokumen2 halamanJawaban Soal Bahlayu irsalinaBelum ada peringkat

- Crystalloid-Colloid: Body FluidsDokumen1 halamanCrystalloid-Colloid: Body FluidsgopscharanBelum ada peringkat

- Mapeo ComputoDokumen20 halamanMapeo ComputoGuillermo Santiago Robles RangelBelum ada peringkat

- Polypyrrole-Palladium Systems Prepared in PDCL Aqueous SolutionsDokumen10 halamanPolypyrrole-Palladium Systems Prepared in PDCL Aqueous SolutionsemzzBelum ada peringkat

- Determining Moment of Inertia Using Falling Weight MethodDokumen3 halamanDetermining Moment of Inertia Using Falling Weight MethodSaad AliKhanBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Sage Erp X3 V7: Development Part 1 Exercises Level 2Dokumen21 halamanSage Erp X3 V7: Development Part 1 Exercises Level 2Yahya Chiguer100% (1)

- Airplane Dimensions and Areas - Description and Operation 1. GeneralDokumen17 halamanAirplane Dimensions and Areas - Description and Operation 1. GeneralKEVINBelum ada peringkat

- The Design of Reinforced Earth Walls DGS 28-11Dokumen32 halamanThe Design of Reinforced Earth Walls DGS 28-11paulombatista100% (1)

- Robot Localization Ias13 Revised PDFDokumen6 halamanRobot Localization Ias13 Revised PDFKamal NathanBelum ada peringkat

- List of DrawingsDokumen58 halamanList of DrawingsVijay RajBelum ada peringkat

- 0.0.0.0 Lab - Configuring Devices For Use With Cisco Configuration Professional (CCP) 2.5 - InstructorDokumen12 halaman0.0.0.0 Lab - Configuring Devices For Use With Cisco Configuration Professional (CCP) 2.5 - InstructorSalem TrabelsiBelum ada peringkat

- Money WiseDokumen62 halamanMoney Wisejei liBelum ada peringkat

- Acoustic Doppler Effect With Universal Counter: (Item No.: P2150405)Dokumen7 halamanAcoustic Doppler Effect With Universal Counter: (Item No.: P2150405)Muhammad IshfaqBelum ada peringkat

- 4024 w08 Ms 2Dokumen9 halaman4024 w08 Ms 2mstudy123456Belum ada peringkat

- Measure Theory Kaminski8Dokumen2 halamanMeasure Theory Kaminski8AgusBelum ada peringkat

- Cre Technology ParallelingDokumen6 halamanCre Technology ParallelingduaBelum ada peringkat

- FEM Matlab ProgramDokumen4 halamanFEM Matlab ProgramleaBelum ada peringkat

- Nokia Networks: VoLTE Optimization GuideDokumen20 halamanNokia Networks: VoLTE Optimization GuideKamil KocBelum ada peringkat

- Study Scheme & Syllabus Of: IK Gujral Punjab Technical UniversityDokumen28 halamanStudy Scheme & Syllabus Of: IK Gujral Punjab Technical UniversityvijiBelum ada peringkat

- EPayments Merchant Web Service (V. 0.3) - EngDokumen25 halamanEPayments Merchant Web Service (V. 0.3) - EngRadusi ViorelBelum ada peringkat

- Joinson 2008Dokumen10 halamanJoinson 2008PaulShapiroBelum ada peringkat