AA

Diunggah oleh

Danish NawazHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

AA

Diunggah oleh

Danish NawazHak Cipta:

Format Tersedia

International Journal of Engineering & Technology IJET-IJENS Vol: 11 No: 06 55

Selection of Appropriate Ring Traveller Number for

Different Count of Cotton Hosiery Yarn

1

Jamal Hossen, 2 Subrata Kumar Saha

Department of Textile Engineering

Ahsanullah University of Science and Technology

141-142, Love Road, Tejgaon I/A, Dhaka-1208, Bangladesh

Abstract-- Traveller has a great impact on yarn quality respectively. Specific ring frame was selected and then any

parameters specially hairiness. Yarn quality varies due to specific 10 spindles of that frame were selected. Ten yarn cops

different traveller number. The traveller imparts twist to the were collected by using five different traveller number of

yarn and enables winding of the yarn on the cop. However, same manufacturing company (Kanai). Due to unavailability

cooperating assembly, the spindle is required for the winding of the traveller of brand name like Bracker, Carter, Reiners

operation. High contact pressure (up to 35 N/mm2) is generated

and Furst, only the Kanai brand was used. Unevenness

between the ring and traveller during winding, mainly due to

centrifugal force. This research was established according to percentage(U%), CVm%, hairiness (H), thin (-50%)/km, thick

yarn parameter of hairiness, U%, IPI, i.e. imperfection index and (+50%)/km, neps (+200%)/km were tested by Uster Tester-5.

end breakage rate per 1000 spindle-hr. It is very important for Imperfection index (IPI) was calculated and end breakage rate

the technologist to understand this and act on them to optimize (EBR) per 1000 spindle-hr also studied in each cases. Due to

the yarn production. Specific number of traveller should be used both lighter and heavier traveller end breakage rate vary and

for a particular count of yarn. quality of yarn decrease by increasing the EBR. Then test

results were analyzed for identifying suitable traveller number

Index Term-- Traveller number, carded yarn, combed yarn, for above mentioned counts.

Uster Tester, hosiery yarn.

I. INTRODUCTION

The ring and traveller combination is effectively a twisting

and winding mechanism [3]. Although it is very minute in

appearance, it plays an important role in spinning operation

[2]. Several investigations have been carried out on the

influence of the ring traveller [4]. For a given yarn count, the

longer the fibers, the fewer the number per unit length of a

given yarn count, and this is reflected in the yarn hairiness.

Consequently, there moving of short fibers by combing results

in combed yarns being much less hairy than carded yarns of

equivalent count [3]. In most cases, the limit to productivity of

the ring spinning machine is defined by the traveller in

interdependence with the ring, and yarn. The following shapes

are in use in the short-staple spinning mills: (i) C-traveller (ii)

Flat or oval traveller (iii) Elliptical traveller (iv) N-traveller

(v) SU-traveller [1]. Usually, C-traveller is used in short-staple

spinning mills. C-traveller and Kanai brand were used in this

work.

II. MATERIALS AND METHOD

Formerly in the United Kingdom, the term hosiery was used in

the generic sense of all types of knitted fabrics and goods

made up there from. Combed, super carded and carded yarns

are all used extensively for knitting [6]. In this study 26/1 Ne

and 30/1 Ne carded hosiery and 24/1 Ne and 34/1 Ne combed

hosiery yarn were made from roving of hank 0.75. For both

carded and combed yarns, twist multiplier were 3.6 and 3.5

111906-8585 IJET-IJENS @ December 2011 IJENS

IJENS

International Journal of Engineering & Technology IJET-IJENS Vol: 11 No: 06 56

Comparative chart of traveller weights [5]

Table A

R+F Bracker

Carter ISO-Nr. Kanai* ISO-Nr.

Travel. No. ISO-Nr. ISO-Nr.

Lighter 15/0 14.0 15.0 22.7 16.6

14/0 15.0 16.0 24.3 18.3

13/0 16.0 17.0 26 20.0

12/0 18.0 18.0 27.5 21.6

11/0 19.0 20.0 29 23.4

10/0 20.0 22.4 31 25.0

9/0 22.4 23.6 32 26.8

8/0 23.6 25.0 34 28.5

7/0 26.5 28.0 36 30.2

6/0 30.0 31.5 39 32.2

5/0 31.5 35.5 42 35.1

4/0 35.5 40 45 38.3

3/0 40 45 49 42.2

2/0 45 50 52 48.3

1/0 50 56 58 54.6

1 60 63 65 62.2

2 71 71 71 73.6

3 80 80 78 81.0

4 85 90 84 87.7

5 95 95 91 95.3

6 106 100 104 108.8

7 112 112 117 121.8

8 125 125 130 135.9

9 140 140 149 154.4

10 160 160 168 174.8

11 180 180 194 199.0

12 200 200 214 219.8

13 224 224 233 237.8

14 236 250 253 258.7

Heavier 15 250 265 272 277.1

* Weight series of the most important types (ISO No. = traveller weight in mg)

The following testing equipments were used for this study.

Uster HVI 1000, Wrap Reel, Uster Auto Sorter, Uster Tester 5

111906-8585 IJET-IJENS @ December 2011 IJENS

IJENS

International Journal of Engineering & Technology IJET-IJENS Vol: 11 No: 06 57

III. RESULTS AND DISCUSSION

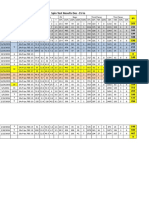

Count and traveller number wise Uster test report and end breakage rate per 1000 spindle-hr for 26/1 Ne carded hosiery yarn

Table I

Thin Thick Neps EBR/

Traveller CVm

U% Hairiness (-50%) (+50%) (+200%) IPI 1000

Number %

/Km /Km /Km spindle-hr

1 10.13 12.88 5.57 0.3 66.3 91.3 157.9 55

1/0 10.09 12.98 5.32 1.0 81.8 94.0 157.9 50

2/0 10.48 13.33 5.54 1.8 86.5 103.8 192.1 61

3/0 10.54 13.35 5.49 1.9 85.7 102.9 190.5 61

4/0 10.55 13.45 5.62 1.8 87.4 104.3 193.5 64

Fig. 1. Traveller number Vs U% Fig. 2. Traveller number Vs hairiness

Fig. 3. Traveller number Vs imperfection Fig. 4. Traveller number Vs

index (IPI) EBR/1000 spindle-hr

The figure 1 to 4 show that U%, hairiness, IPI and end 26/1 Ne carded hosiery yarn, traveller number 1/0 is

breakage rate are the lowest for traveller number 1/0. With appropriate.

respect to above four quality parameters the best result is in Count and traveller number wise Uster test report and end

this traveller number. So it can be concluded that in case of breakage rate per 1000 spindle-hr for 30/1 Ne carded hosiery

yarn.

111906-8585 IJET-IJENS @ December 2011 IJENS

IJENS

International Journal of Engineering & Technology IJET-IJENS Vol: 11 No: 06 58

Table II

Thin Thick Neps EBR/

Traveller CVm

U% Hairiness (-50%) (+50%) (+200%) IPI 1000

Number %

/Km /Km /Km spindle-hr

1 11.68 14.85 5.20 4.2 172.3 243.5 420.0 58

1/0 11.65 14.81 5.21 4.0 171.5 241.8 417.3 52

2/0 11.34 14.55 5.08 3.9 172.3 223.0 399.2 48

3/0 11.52 14.65 5.43 4.3 178.0 226.3 408.6 59

4/0 11.58 14.71 5.57 4.7 179.2 229.4 413.3 62

Fig. 5. Traveller number Vs U% Fig. 6. Traveller number Vs hairiness

Fig. 7. Traveller number Vs imperfection Fig. 8. Traveller number Vs

Index (IPI) EBR/1000 spindle-hr

The figure 5 to 8 show that U%, hairiness, IPI and end Count and traveller number wise Uster test report and end

breakage rate are the lowest for traveller number 2/0. With breakage rate per 1000 spindle-hr for 24/1 Ne combed hosiery

respect to above four quality parameters the best result is in yarn.

this traveller number. So it can be concluded that in case of

30/1 Ne carded hosiery yarn, traveller number 2/0 is

appropriate.

111906-8585 IJET-IJENS @ December 2011 IJENS

IJENS

International Journal of Engineering & Technology IJET-IJENS Vol: 11 No: 06 59

Table III

Thin Thick Neps EBR/

Traveller CVm

U% Hairiness (-50%) (+50%) (+200%) IPI 1000

Number %

/Km /Km /Km spindle-hr

2 7.82 9.88 5.07 0.0 8.5 19.0 27.5 54

1 7.65 9.64 5.63 0.0 7.3 17.8 25.1 47

1/0 7.65 9.64 5.02 0.0 6.0 15.8 21.8 43

2/0 7.79 9.71 5.92 0.0 7.8 16.5 24.3 49

3/0 7.77 9.59 5.89 0.0 8.5 17.4 25.9 53

Fig. 9. Traveller number Vs U% Fig. 10. Traveller number Vs hairiness

Fig. 11. Traveller number Vs imperfection Fig. 12. Traveller number Vs

Index (IPI) EBR/1000 spindle-hr

The figure 9 to 12 show that U%, hairiness, IPI and end breakage rate are the lowest for traveller number 1/0. With respect to

above four quality parameters the best result is in this traveller number. So it can be concluded that in case of 24/1 Ne combed

hosiery yarn, traveller number 1/0 is appropriate.

Count and traveller number wise Uster test report and end breakage rate per 1000 spindle-hr for 34/1 Ne combed hosiery yarn

111906-8585 IJET-IJENS @ December 2011 IJENS

IJENS

International Journal of Engineering & Technology IJET-IJENS Vol: 11 No: 06 60

Table IV

Thin Thick Neps EBR/

Traveller CVm

U% Hairiness (-50%) (+50%) (+200%) IPI 1000

Number %

/Km /Km /Km spindle-hr

1/0 8.99 11.48 4.78 0.0 10.4 33.7 44.1 53

2/0 9.04 11.38 4.65 0.0 10.5 32.3 42.8 52

3/0 8.95 11.27 4.52 0.3 7.0 24.0 25.0 47

4/0 8.95 11.27 4.54 0.3 9.0 25.3 34.6 54

5/0 9.98 11.35 4.54 0.5 9.9 29.6 40.0 55

Fig. 13. Traveller number Vs U% Fig. 14. Traveller number Vs hairiness

Fig. 15. Traveller number Vs imperfection Fig. 16. Traveller number Vs

index (IPI) EBR/1000 spindle-hr

The figure 13 to 16 show that U%, hairiness, IPI and end traveller number 3/0 is suitable for 34/1 Ne combed hosiery

breakage rate are the lowest for traveller number 3/0. With yarn. Because considering unevenness percentage, hairiness,

respect to above four quality parameters the best result is in imperfection index and end breakage rate per 1000 spindle-hr,

this traveller number. So it can be concluded that in case of it is clearly seen that above number of travellers are suitable

34/1 Ne combed hosiery yarn, traveller number 3/0 is for specific four different count of yarn. A spinning mill

appropriate. which is using the traveller of Kanai brand and looking for

good quality yarn should try to use above traveller number for

IV. CONCLUSION above mentioned count of yarn. Further study can be

This study shows that the traveller number 1/0 is suitable for examined by using the traveller, brand of Bracker, Carter and

26/1 Ne, traveller number 2/0 is suitable for 30/1 Ne carded Reiners and Furst for same count of carded, combed and

hosiery yarn and traveller number 1/0 is suitable for 24/1 Ne, compact cotton yarn. A comparative study can be done by

111906-8585 IJET-IJENS @ December 2011 IJENS

IJENS

International Journal of Engineering & Technology IJET-IJENS Vol: 11 No: 06 61

using the different traveller number of specific brand against

same count of carded, combed and compact cotton yarn.

REFERENCES

[1] Klein W., Manual of Textile Technology The Textile Institute.

ISBN 0900739916.

[2] Pattabhiram T. K., Essential Elements of Practical Cotton

Spinning Somaiya Publications Pvt. Ltd. Mumbai, New Delhi.

Fourth Edition 1997.

[3] Lawrence, Carl A. Fundamentals of Spun Yarn Technology

Library of Congress Cataloging-in-Publication Data. ISBN 1-

56676-821-7 (alk. paper).

[4] I. Usta, S. Canoglu, Influence of Ring Traveller Weight and

Coating on Hairiness of Acrylic Yarns University of Marmara

Faculty of Technical Education, Department of Textile Studies,

Gztepe, 81040 Istanbul, Turkey.

[5] Technical Manual of Reiners + Furst, Rings and Travellers

Reiners + Furst GmbH u. Co. KG.

[6] Starfish Quality Control Knit, Cotton Technology International,

Manchester U.K.

111906-8585 IJET-IJENS @ December 2011 IJENS

IJENS

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Astm F 30 - 96 R02 - RJMWDokumen5 halamanAstm F 30 - 96 R02 - RJMWphaindikaBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Splunk 7 Essentials Third EditionDokumen388 halamanSplunk 7 Essentials Third EditionHaripriya100% (1)

- tt130 Ultrasonic Wall Thickness Material Thickness Gauge Instruction Manual PDFDokumen20 halamantt130 Ultrasonic Wall Thickness Material Thickness Gauge Instruction Manual PDFelmek jayaBelum ada peringkat

- MS3XV30 Hardware 1.3Dokumen229 halamanMS3XV30 Hardware 1.3Colton CarmichaelBelum ada peringkat

- 2012 D61ex-15e0Dokumen1.239 halaman2012 D61ex-15e0Alex San Tana100% (3)

- Annual: Program Year 2 0 2 0Dokumen16 halamanAnnual: Program Year 2 0 2 0Danish NawazBelum ada peringkat

- U.S. Cotton Ten Year Sustainability Goals Pathways To ProgressDokumen12 halamanU.S. Cotton Ten Year Sustainability Goals Pathways To ProgressDanish NawazBelum ada peringkat

- CottonPaper 071021 TransformersFoundationDokumen137 halamanCottonPaper 071021 TransformersFoundationDanish NawazBelum ada peringkat

- True Neps - 2008Dokumen10 halamanTrue Neps - 2008Danish NawazBelum ada peringkat

- The Right Cotton. The Right Place. The Right Time.: Cotton Incorporated World HeadquartersDokumen4 halamanThe Right Cotton. The Right Place. The Right Time.: Cotton Incorporated World HeadquartersDanish NawazBelum ada peringkat

- ITL-PUR-F-001 - Supplier EvaluationDokumen6 halamanITL-PUR-F-001 - Supplier EvaluationDanish NawazBelum ada peringkat

- TowelDokumen4 halamanTowelDanish NawazBelum ada peringkat

- Spacer Results ! PolyDokumen1 halamanSpacer Results ! PolyDanish NawazBelum ada peringkat

- Sapphire Textile Mills LTD No 2: (70 DENIER)Dokumen19 halamanSapphire Textile Mills LTD No 2: (70 DENIER)Danish NawazBelum ada peringkat

- ITL-PUR-F-001 - Supplier EvaluationDokumen6 halamanITL-PUR-F-001 - Supplier EvaluationDanish NawazBelum ada peringkat

- Not All Natural Fibers Are Created Equal: The Truth About Viscose RayonDokumen4 halamanNot All Natural Fibers Are Created Equal: The Truth About Viscose RayonDanish NawazBelum ada peringkat

- Count Ring NR Ring Model Amp at 70-80 % Dof Min:Speed Speed at Which Amp CheckedDokumen2 halamanCount Ring NR Ring Model Amp at 70-80 % Dof Min:Speed Speed at Which Amp CheckedDanish NawazBelum ada peringkat

- Ccunl: Va CLSP L7Dokumen2 halamanCcunl: Va CLSP L7Danish NawazBelum ada peringkat

- Modle-O eDokumen1 halamanModle-O eDanish NawazBelum ada peringkat

- Machinery List of U#1 & 2Dokumen2 halamanMachinery List of U#1 & 2Danish NawazBelum ada peringkat

- USA Cotton Stock USA Cotton (Stocking Overview) : Received 500 Bales From Premium Mills NooriabadDokumen7 halamanUSA Cotton Stock USA Cotton (Stocking Overview) : Received 500 Bales From Premium Mills NooriabadDanish NawazBelum ada peringkat

- Count: Description Type YF N S L T CP CM CCP CCM Neps MV Thick MV Thin MV Group CVDokumen4 halamanCount: Description Type YF N S L T CP CM CCP CCM Neps MV Thick MV Thin MV Group CVDanish NawazBelum ada peringkat

- Simplex Actual Eff Report: CottonDokumen6 halamanSimplex Actual Eff Report: CottonDanish NawazBelum ada peringkat

- Spin Test Results Dec - 15 ToDokumen6 halamanSpin Test Results Dec - 15 ToDanish NawazBelum ada peringkat

- Year 2014 Hard Waste & B-Grade Percentage: AverageDokumen2 halamanYear 2014 Hard Waste & B-Grade Percentage: AverageDanish NawazBelum ada peringkat

- Book ListDokumen2 halamanBook ListDanish NawazBelum ada peringkat

- Acc Opening Terms N ConditionsDokumen4 halamanAcc Opening Terms N ConditionsDanish NawazBelum ada peringkat

- Spin Test Results Dec - 15 ToDokumen22 halamanSpin Test Results Dec - 15 ToDanish NawazBelum ada peringkat

- Daily Simplex Production & Efficiency Report: CottonDokumen9 halamanDaily Simplex Production & Efficiency Report: CottonDanish NawazBelum ada peringkat

- Application: Adm Spinning Count Balance Setting MenuDokumen6 halamanApplication: Adm Spinning Count Balance Setting MenuDanish NawazBelum ada peringkat

- 20 % 3 Years C19Dokumen1 halaman20 % 3 Years C19Danish NawazBelum ada peringkat

- Card Wire PriceDokumen2 halamanCard Wire PriceDanish NawazBelum ada peringkat

- Spin Test Results Dec - 15 ToDokumen6 halamanSpin Test Results Dec - 15 ToDanish NawazBelum ada peringkat

- TIL 1881 Network Security TIL For Mark VI Controller Platform PDFDokumen11 halamanTIL 1881 Network Security TIL For Mark VI Controller Platform PDFManuel L LombarderoBelum ada peringkat

- Student Manual of Damped & Un DampedDokumen3 halamanStudent Manual of Damped & Un DampedaqibBelum ada peringkat

- Design Procedure For Journal BearingsDokumen4 halamanDesign Procedure For Journal BearingsSwaminathan100% (1)

- Stainless Steel: Presented By, Dr. Pragati Jain 1 YearDokumen68 halamanStainless Steel: Presented By, Dr. Pragati Jain 1 YearSneha JoshiBelum ada peringkat

- .Preliminary PagesDokumen12 halaman.Preliminary PagesKimBabBelum ada peringkat

- Rheobuild 1100: A High Range Water Reducing Superplasticising Admixture For The Production of Rheoplastic ConcreteDokumen3 halamanRheobuild 1100: A High Range Water Reducing Superplasticising Admixture For The Production of Rheoplastic ConcreteFrancois-Belum ada peringkat

- Strength of Materials Basics and Equations - Mechanics of Materials - Engineers EdgeDokumen6 halamanStrength of Materials Basics and Equations - Mechanics of Materials - Engineers EdgeansarBelum ada peringkat

- A Simplified Two-Stage Method To Estimate The Settlement and Bending Moment of Upper Tunnel Considering The Interaction of Undercrossing Twin TunnelsDokumen32 halamanA Simplified Two-Stage Method To Estimate The Settlement and Bending Moment of Upper Tunnel Considering The Interaction of Undercrossing Twin TunnelsJianfeng XueBelum ada peringkat

- Excel CatDokumen132 halamanExcel Catjuanf_scribdBelum ada peringkat

- McLaren Artura Order BKZQG37 Summary 2023-12-10Dokumen6 halamanMcLaren Artura Order BKZQG37 Summary 2023-12-10Salvador BaulenasBelum ada peringkat

- Dex Stainless Steel Undermount Kitchen Sinks: Installation ManualDokumen18 halamanDex Stainless Steel Undermount Kitchen Sinks: Installation ManualRrsc RamsBelum ada peringkat

- YcivDokumen68 halamanYcivBelhassen Saddadi100% (2)

- CP 001 - 18 - PP - Eng - 00 - CP Umk450t (2018) 18VR5K01 (Eng)Dokumen52 halamanCP 001 - 18 - PP - Eng - 00 - CP Umk450t (2018) 18VR5K01 (Eng)Honda almagrorepuestosBelum ada peringkat

- Floor Plans & ElevationsDokumen6 halamanFloor Plans & Elevationsbryan cardonaBelum ada peringkat

- cjv30 Maintenance V10a PDFDokumen101 halamancjv30 Maintenance V10a PDFEdu100% (1)

- Lord!: KnowledgeDokumen161 halamanLord!: KnowledgeAsra Zafar khanBelum ada peringkat

- An Overview of Subspace Identification: S. Joe QinDokumen12 halamanAn Overview of Subspace Identification: S. Joe QinGodofredoBelum ada peringkat

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDokumen1 halamanTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliBelum ada peringkat

- Kaltreparatur-Textil WT2332 enDokumen20 halamanKaltreparatur-Textil WT2332 enFerAK47aBelum ada peringkat

- 2012 LFDDokumen943 halaman2012 LFDsergioBelum ada peringkat

- 2011 TH 18205 Awad Nassib PdfaDokumen95 halaman2011 TH 18205 Awad Nassib PdfahafosaamrBelum ada peringkat

- Renewsys India Pvt. LTD.: Form Factor - 18 Cells Reference Drawing Numbers: Bom For C06 - 5Wp With Elmex JB Per ModuleDokumen31 halamanRenewsys India Pvt. LTD.: Form Factor - 18 Cells Reference Drawing Numbers: Bom For C06 - 5Wp With Elmex JB Per Modulesandeep devabhaktuniBelum ada peringkat

- CPS 800 12 900 10 Parts List 2012 02 ENG 2205 6006 51 PDFDokumen51 halamanCPS 800 12 900 10 Parts List 2012 02 ENG 2205 6006 51 PDFMar SolBelum ada peringkat

- ICON Catalog LocationsDokumen16 halamanICON Catalog LocationsTools StuffsBelum ada peringkat

- Ceilcote 383 Corocrete: Hybrid Polymer Broadcast FlooringDokumen3 halamanCeilcote 383 Corocrete: Hybrid Polymer Broadcast FlooringNadia AgdikaBelum ada peringkat