Thermostatic Steam Traps BK With Duo Stainless Steel (Bimetallic) Regulator PN 40 - PN 630

Diunggah oleh

hamid vahedil larijaniDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Thermostatic Steam Traps BK With Duo Stainless Steel (Bimetallic) Regulator PN 40 - PN 630

Diunggah oleh

hamid vahedil larijaniHak Cipta:

Format Tersedia

Thermostatic Steam Traps BK with Duo Stainless Steel

(Bimetallic) Regulator PN 40 PN630

Features of the BKseries

Robust regulator for roughest o perating Stainless steel internals

conditions (unaffected by waterhammer and frost)

Repairable in-line

Suitable for superheated steam

Base bushing ensures positive metal-to-metal

applications

sealing between body and regulator.

Automatic air-venting

Up to p 275 bar g

(steam trap can be used for thermal

air-venting in steam systems) Optional extra: Integrated steam trap monitoring

for BK 45 (temperature or steam loss)

Installation in any position

(horizontal and vertical lines)

Stage nozzle acts as non-return valve

Application

For open-loop controlled heating processes.

L

Draining of

saturated steam lines

BK 45, BK 46 superheated steam lines

DN 15, 20, 25

steam tracers

Can also be used for thermal air-venting

Air-venting

Steam trap for thermostatic air-venting with bimetallic regulator

The thermostatic steam traps with corrosion-resistant Duo S.S. (bimetallic) regulator of the BK series can also be

used for air-venting.

Application

Thermostatic steam trap for automatic air-venting and discharge of non-condensable gases and

steam/air mixtures from steam lines and heat exchangers.

Special adjustment might be required.

Pressure/Temperature Ratings

Type PN / Class PMX Material Max. Pressure /Temp. Rating1)

EN ASTM PMA TMA p/T

[bar] [bar] [C] [bar/C]

BK 45, BK 45U3) PN 40 22 1.0460 A105 40.0 450 27.6 / 300 13.1 / 450

L

BK 45, BK 45U3) Class 300 22 1.0460 A105 51.1 425 39.8 / 300 28.8 / 425

BK 15, DN 40, 50 BK 45-LT Class 300 22 SA350 LF2 51.1 425 51.1 / 464) 28.8 / 4254)

BK15 DN40, 50 PN 40 22 1.0460 A105 40.0 450 27.6 / 300 13.1 / 450

BK15 DN40, 50 Class 300 22 1.0460 A105 51.1 425 39.8 / 300 28.8 / 425

BK 46 PN 40 32 1.5415 A182-F12) 40.0 450 39.0 / 250 27.6 / 450

BK 46 Class 300 32 1.5415 A182-F12) 51.7 450 41.1 / 250 29.8 / 450

BK 37 PN 63/100 45 1.5415 A182-F12) 100.0 5304) 100.0 / 4504) 30.9 / 5304)

BK 27N DN40, 50 PN 63 45 1.5415 A182-F12) 63.0 500 47.6 / 300 25.8 / 500

BK 28 PN 100 85 1.5415 A182-F12) 181.04) 5304) 100.0 / 4504) 30.9 / 5304)

BK 29 PN 160 110 1.7335 A182-F12 201.04) 5404) 131.5 / 4504) 44.5 / 5404)

BK212 PN 630 275 1.7383 A182-F22 630.04) 5404) 447.0 / 5004) 261.0 / 5404)

BK 212-F91 275 1.4903 A182-F91 775.04) 5804) 607.0 / 5004) 205.0 / 5804)

BK 212-S PN 630 275 1.7383 A182-F22 630 580 289.0 / 5404) 163.0 / 5804)

BK 212-F91-S 275 1.4903 A182-F91 775 625 473.0 / 5754) 255.0 / 6254)

BK 212-1.4901 275 1.4901 A182-F922) 800 650 418.0 / 6004) 207.0 / 6504)

BK 37-ASME Class 400/600 45 A182-F12 103.44) 5004) 85.7 / 3004) 42.8 / 5004)

BK 28-ASME Class 600 85 A182-F12 103.44) 5004) 85.7 / 3004) 50.6 / 5004)

BK 29-ASME Class 900 110 A182-F12 155.04) 5404) 101.4 / 4504) 43.6 / 5404)

BK212-ASME Class 2500 275 A182-F22 430.94) 5934) 235.0 / 5004) 63.0 / 5934)

1) Limits for body/cover. Functional requirements may restrict the use to below the limits quoted.

For full details on limiting conditions depending on end connection and type of regulator see data sheet.

2) Material complies with EN and ASTM requirements.

3) Opening undercooling approx. 30 K.

4) Only applicable for traps with butt-weld (BW) or socket-weld (SW) ends DN 25. Note that limits will

be lower for traps with other dimensions or flanged end connections.

Thermostatic Steam Traps BK with Duo Stainless Steel

(Bimetallic) Regulator PN 40 PN630

Available End Connections and Overall Lengths in mm

DN 15 DN 20 DN 25 DN 40 DN 50

Type Connection

[1/2"] [3/4"] [1"] [11/2"] [2"]

BK 45 Flanged EN PN 40 150 150 160 230 230

Flanged ASME1501) 150 150 160 230 230

DN15 25 Flanged ASME 3001) 150 150 160 230 230

BK 15 Screwed sockets 95 95 95 130 230

DN 40, 50 Socket-weld (SW) 95 95 95 130 230

Butt-weld (BW) 200 200 200 250 250

BK 46 Flanged EN PN 40 150 150 160

Flanged ASME 300 150 150 160

Screwed sockets 95 95 95

Socket-weld (SW) 95 95 95

L

BK 27N Flanged EN PN 40 230 230

BK 27N, DN 40, 50

DN40,50 Flanged EN PN 63 260 300

Flanged ASME 400/600 241 292

Socket-weld (SW) 180 180

Butt-weld (BW) 180 180

BK 37 Flanged EN PN 63/100 210 230 230

BK 28 Socket-weld (SW) 160 160 160

Butt-weld (BW) 160 160 160

BK 29 Flanged EN PN 160 210 230

Socket-weld (SW) 160 160 160

Butt-weld (BW) 160 160 160

L BK 212... Butt-weld (BW) 330 330 330

BK 37, BK 28, BK 29, DN 15, 20, 25 Series Socket-weld (SW) 330 330 330

BK 37-ASME Flanged ASME 400/600 230 230 230

Socket-weld (SW) 160 160 160

Butt-weld (BW) 160 160 160

BK 28-ASME Flanged ASME 400/600 230 230 230

Socket-weld (SW) 160 160 160

Butt-weld (BW) 160 160 160

BK 29-ASME Flanged ASME 900/1500 230 230 254

L Socket-weld (SW) 200 200 200

BK 212, DN 15, 20, 25 Butt-weld (BW) 200 200 200

1) BK 45 with ASME flanges: overall length 172 mm available on request.

Capacity Charts

The charts show the maximum hot condensate capacities. BK 27N DN 40 and 50 PMX 45 bar (Curve 1)

BK 45 DN 15-25 PMX 22 bar (Curve 1) BK 37 DN 15-25 PMX 45 bar (Curve 3)

BK 46 DN 15-25 PMX 32 bar (Curve 1) BK 28/BK 28 ASME PMX 85 bar (Curve 2)

[lb/h] [kg/h] BK 15 DN 40 and 50 PMX 22 bar (Curve 2) BK 29/BK 29 ASME PMX 110 bar (Curve 2)

BK 212/BK 212 ASME PMX 250 bar (Curve 4)

10000

8000 4000

2

6000 3000

4000 2000

3000

2000 1000

600 1

1000

800 400

600 300

400 200

300

100 4

60

100

80 40

60 30

Durchfluss

20

Capacity

40

Capacity

Capacity

30

20 10

1 2 3 4 5 6 8 10 22 32 [bar]

[psi]

20 30 40 60 80 100 200 300 465

Differential pressure

Differential pressure

Differenzdruck

Differential pressure

Anda mungkin juga menyukai

- Materials Data for Cyclic Loading: Low-Alloy SteelsDari EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsPenilaian: 5 dari 5 bintang5/5 (2)

- A01CDokumen6 halamanA01CsaravootBelum ada peringkat

- Fte S F & T S T: Eries Loat Hermostatic Team RapsDokumen4 halamanFte S F & T S T: Eries Loat Hermostatic Team RapsAlvaro Yaciel Rodríguez LagunesBelum ada peringkat

- Steam TrapsDokumen24 halamanSteam Trapsiran1362Belum ada peringkat

- Unidades Trane PDFDokumen12 halamanUnidades Trane PDFARN18Belum ada peringkat

- UBAN Catalogue EDokumen12 halamanUBAN Catalogue EErcan YilmazBelum ada peringkat

- Tsa 2Dokumen6 halamanTsa 2Amit SurtiBelum ada peringkat

- Thermodynamic Steam Traps DK PN 40, PN 63/class 600: Features of The DK SeriesDokumen2 halamanThermodynamic Steam Traps DK PN 40, PN 63/class 600: Features of The DK Serieshamid vahedil larijaniBelum ada peringkat

- Ebara 3d SeriesDokumen45 halamanEbara 3d SeriesqmqsBelum ada peringkat

- Technical Data Sheet Ecotrol Control Valve TD - 6HDokumen6 halamanTechnical Data Sheet Ecotrol Control Valve TD - 6HFrancisco SanchezBelum ada peringkat

- Technical DrawingDokumen6 halamanTechnical DrawingRosyad AminBelum ada peringkat

- Ball Valves: For SteamDokumen8 halamanBall Valves: For SteamcontorrresjulianBelum ada peringkat

- FK 30.70 (3) GB NAF-Check Tilting Disc Check Valves: CharacteristicsDokumen6 halamanFK 30.70 (3) GB NAF-Check Tilting Disc Check Valves: CharacteristicsNguyen KhaBelum ada peringkat

- Highlight of IBRDokumen15 halamanHighlight of IBRAnonymous XBq5J84Belum ada peringkat

- Alloy Guide 2011Dokumen12 halamanAlloy Guide 2011bbmoksh100% (1)

- High Pressure Over Pressure Slam Shut Nominal Diameter " & 1"Dokumen2 halamanHigh Pressure Over Pressure Slam Shut Nominal Diameter " & 1"hon choong chongBelum ada peringkat

- Una45 GestraDokumen6 halamanUna45 Gestra123456jodaBelum ada peringkat

- Staal 40: Swing Check ValvesDokumen4 halamanStaal 40: Swing Check ValvesEric LarrondoBelum ada peringkat

- Pipes and TubesDokumen16 halamanPipes and TubesDaniel Sandoval FernándezBelum ada peringkat

- Specification Sheet: Customer Name PO Number Vendor Name Vendor Reference Document Title Revision NoDokumen13 halamanSpecification Sheet: Customer Name PO Number Vendor Name Vendor Reference Document Title Revision NoAmit SurtiBelum ada peringkat

- Flange Adapters: Used Throughout The WorldDokumen4 halamanFlange Adapters: Used Throughout The WorldfrdnBelum ada peringkat

- Asco Dust Collector Main Pulse Valves DC CatalogDokumen4 halamanAsco Dust Collector Main Pulse Valves DC CatalogFelipe SalvatierraBelum ada peringkat

- Dust Collector Main Pulse Valves: FeaturesDokumen4 halamanDust Collector Main Pulse Valves: FeaturesQuân TrịnhBelum ada peringkat

- TESCCOOM 54-52: SpecificationsDokumen4 halamanTESCCOOM 54-52: SpecificationsMFERRBelum ada peringkat

- VTV Butterfly ValveDokumen1 halamanVTV Butterfly Valveryando fernandaBelum ada peringkat

- FS - Stainless Steel (SS40)Dokumen3 halamanFS - Stainless Steel (SS40)Marcos KlaynBelum ada peringkat

- Welding ProcessesDokumen28 halamanWelding ProcessesAnaswarpsBelum ada peringkat

- Bermad: FP/FS 400Y Torrent Valve Engineering DataDokumen12 halamanBermad: FP/FS 400Y Torrent Valve Engineering Dataeitan-daliaBelum ada peringkat

- Brair Compressed Air Drain Trap: DescriptionDokumen2 halamanBrair Compressed Air Drain Trap: DescriptionWinter FreireBelum ada peringkat

- Asco Series 210 Gas Shutoff No CatalogDokumen2 halamanAsco Series 210 Gas Shutoff No CatalogManuel ParraBelum ada peringkat

- Steel AsiaDokumen109 halamanSteel AsiaHieu Do TatBelum ada peringkat

- Split System Cooling Product Data: 4TTB3018-060 1 - 5 TonsDokumen12 halamanSplit System Cooling Product Data: 4TTB3018-060 1 - 5 TonsFernando CabreraBelum ada peringkat

- 77Vds 04 18Dokumen7 halaman77Vds 04 18Allen RichardBelum ada peringkat

- Air and Water Solenoid Valves: NC NODokumen4 halamanAir and Water Solenoid Valves: NC NODevinBelum ada peringkat

- Catalog Series 226 Miniature Valves Proportional Asco en 6775570Dokumen2 halamanCatalog Series 226 Miniature Valves Proportional Asco en 6775570r.ashokskpBelum ada peringkat

- Gestra Steam Trap - Thermostatic Steam Trap BK 29: Class Rating: ANSI 900 Available SizesDokumen2 halamanGestra Steam Trap - Thermostatic Steam Trap BK 29: Class Rating: ANSI 900 Available SizesdcarunchioBelum ada peringkat

- Asco Series 042 Gas Shutoff CatalogDokumen4 halamanAsco Series 042 Gas Shutoff CatalogRoqueNetBelum ada peringkat

- Full Lift Spring Loaded Open PDFDokumen4 halamanFull Lift Spring Loaded Open PDFVenkatespatange RaoBelum ada peringkat

- Asco Valve 8298a002 ReplacementDokumen4 halamanAsco Valve 8298a002 ReplacementAugusto Leudo AngelBelum ada peringkat

- Butterfly Valve Series 240Dokumen6 halamanButterfly Valve Series 240Chaitanya DattaBelum ada peringkat

- Data Sheet Purgador PT65-40Dokumen2 halamanData Sheet Purgador PT65-40Douglas Tondello100% (1)

- Ar A Prova de ExplosãoDokumen2 halamanAr A Prova de ExplosãoMailthon Ritter GilBelum ada peringkat

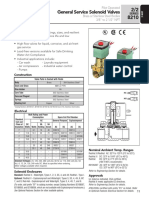

- General Service Solenoid Valves: FeaturesDokumen6 halamanGeneral Service Solenoid Valves: FeaturesIgnacio FranBelum ada peringkat

- TechnipFMC - Pipeline StrainersDokumen6 halamanTechnipFMC - Pipeline StrainersYadir SánchezBelum ada peringkat

- Solenoid Valves With CoilsDokumen3 halamanSolenoid Valves With Coilsron68xBelum ada peringkat

- Stainless Steel Solutions For The Aerospace Industry: UgitechDokumen4 halamanStainless Steel Solutions For The Aerospace Industry: UgitechMarkBelum ada peringkat

- Flanges General - Pressure-Temperature Ratings ASTM and ASMEDokumen5 halamanFlanges General - Pressure-Temperature Ratings ASTM and ASMEkuku kukuBelum ada peringkat

- Pipe SolutionsDokumen28 halamanPipe SolutionsAlvaro VicenteBelum ada peringkat

- VAL Team: Inverted Bucket Steam Traps IB30S (Carbon Steel / Stainless Steel) IB30SS (All Stainless Steel)Dokumen2 halamanVAL Team: Inverted Bucket Steam Traps IB30S (Carbon Steel / Stainless Steel) IB30SS (All Stainless Steel)Mohammed AbdelsalamBelum ada peringkat

- Ductile Iron PipesDokumen8 halamanDuctile Iron Pipesᕨᖆᕢᘙᖱ ᒸᕢᖽᐸᓎBelum ada peringkat

- XANIKDokumen6 halamanXANIKYOMAIRABelum ada peringkat

- Catalog Series 44 2300 Single Stage Backpressure Regulator Tescom en 5322280Dokumen4 halamanCatalog Series 44 2300 Single Stage Backpressure Regulator Tescom en 5322280Corneliu ZavadovschiBelum ada peringkat

- ADCA TSS22 Thermostatic Steam TrapDokumen1 halamanADCA TSS22 Thermostatic Steam TrapedlistiantoBelum ada peringkat

- TSS22HDokumen1 halamanTSS22HAntonio VelardeBelum ada peringkat

- Pipeline Strainer - SpecsDokumen6 halamanPipeline Strainer - SpecsCristhian AyanomeBelum ada peringkat

- Catálogo Válvula DirecionalDokumen20 halamanCatálogo Válvula DirecionalcristianoclemBelum ada peringkat

- NAF-Check Tilting Disc Check Valves FK 30.70 (11) GB: CharacteristicsDokumen8 halamanNAF-Check Tilting Disc Check Valves FK 30.70 (11) GB: CharacteristicsRobovenBelum ada peringkat

- Flexible Metalic Hose Braid & AssembliesDokumen44 halamanFlexible Metalic Hose Braid & AssembliesiJordanScribdBelum ada peringkat

- 2010 Master Parts Book Rain BIrdDokumen190 halaman2010 Master Parts Book Rain BIrdguinnessBelum ada peringkat

- Van Duijn GerritDokumen19 halamanVan Duijn Gerrithamid vahedil larijaniBelum ada peringkat

- Purolite C100Dokumen1 halamanPurolite C100hamid vahedil larijaniBelum ada peringkat

- Desmet Ballestra - Waste Water Steam GenerationDokumen2 halamanDesmet Ballestra - Waste Water Steam Generationhamid vahedil larijaniBelum ada peringkat

- Ion Exchange Separation of ChromiumDokumen3 halamanIon Exchange Separation of Chromiumhamid vahedil larijaniBelum ada peringkat

- Zero Liquid Discharge (ZLD) System Case StudyDokumen2 halamanZero Liquid Discharge (ZLD) System Case Studyhamid vahedil larijaniBelum ada peringkat

- MyProje خرمشهر 3 مرحل85Dokumen3 halamanMyProje خرمشهر 3 مرحل85hamid vahedil larijaniBelum ada peringkat

- Reverse Osmosis System Analysis For Filmtec™ Membranes Rosa 9.1 Configdb U399339 - 282 Project: Myproject Case: 1, 7/28/2017Dokumen5 halamanReverse Osmosis System Analysis For Filmtec™ Membranes Rosa 9.1 Configdb U399339 - 282 Project: Myproject Case: 1, 7/28/2017hamid vahedil larijaniBelum ada peringkat

- 818438Dokumen2 halaman818438Hosein MousaviBelum ada peringkat

- Mambrane ComparisionDokumen1 halamanMambrane Comparisionhamid vahedil larijaniBelum ada peringkat

- Una25 PK Ps - enDokumen1 halamanUna25 PK Ps - enhamid vahedil larijaniBelum ada peringkat

- Ball-Float Traps For Draining Condensate From Compressed-Air and Other Gas Lines UNADokumen1 halamanBall-Float Traps For Draining Condensate From Compressed-Air and Other Gas Lines UNAhamid vahedil larijaniBelum ada peringkat

- Thermodynamic Steam Traps DK PN 40, PN 63/class 600: Features of The DK SeriesDokumen2 halamanThermodynamic Steam Traps DK PN 40, PN 63/class 600: Features of The DK Serieshamid vahedil larijaniBelum ada peringkat

- Moist Air PropertiesDokumen12 halamanMoist Air PropertiesLily DianaBelum ada peringkat

- Select The Best Fitting Pressure Loss CorrelationDokumen4 halamanSelect The Best Fitting Pressure Loss Correlationpal_stephenBelum ada peringkat

- Shumatt 320D C7C9C-9 Spare Parts 2023-7-10 ListDokumen3 halamanShumatt 320D C7C9C-9 Spare Parts 2023-7-10 ListHéctor MujicaBelum ada peringkat

- Turbine FundamentalsDokumen2 halamanTurbine FundamentalsSajjad AhmedBelum ada peringkat

- Piping Design Info (Version 2)Dokumen279 halamanPiping Design Info (Version 2)MANIKANDABelum ada peringkat

- Supercritical Steam GeneratorDokumen2 halamanSupercritical Steam Generatorrr1819Belum ada peringkat

- Exercise Lec-05 PDFDokumen5 halamanExercise Lec-05 PDFaustin00012Belum ada peringkat

- Water Velocity Swiming Pool PIPE-IPCDokumen1 halamanWater Velocity Swiming Pool PIPE-IPCKrishna PATELBelum ada peringkat

- Sop For Dry Ash Vacuum Conveying SystemDokumen8 halamanSop For Dry Ash Vacuum Conveying SystemSonratBelum ada peringkat

- Kidde Engineered Fire Suppression System: 3-Inch Discharge ValveDokumen2 halamanKidde Engineered Fire Suppression System: 3-Inch Discharge ValveEDUARDOBelum ada peringkat

- Cat 330D2L Hydraulic&Elec - Diagram.pdf Versión 1Dokumen29 halamanCat 330D2L Hydraulic&Elec - Diagram.pdf Versión 1José Lopez100% (3)

- PN06CB1S01 PDFDokumen5 halamanPN06CB1S01 PDFpololamkaBelum ada peringkat

- Vdu Fire StarinerDokumen6 halamanVdu Fire StarinerkrishnanshwetaBelum ada peringkat

- 1 1/ Itel: Jsolm../ With Hinge & DavitDokumen17 halaman1 1/ Itel: Jsolm../ With Hinge & DavitTechnical A-Star Testing & Inspection MalaysiaBelum ada peringkat

- Data Sheet Pompa PDFDokumen19 halamanData Sheet Pompa PDFamamBelum ada peringkat

- Grease Fitting PDFDokumen12 halamanGrease Fitting PDFhadiBelum ada peringkat

- FFS 0217 2015 Franklin Fueling Systems Price ListDokumen208 halamanFFS 0217 2015 Franklin Fueling Systems Price ListpogisimpatikoBelum ada peringkat

- FM Question Bank Unit 4Dokumen3 halamanFM Question Bank Unit 4cbeprabhugmailBelum ada peringkat

- Raw Water Inlet: LegendDokumen1 halamanRaw Water Inlet: LegendsugiantoBelum ada peringkat

- P C (PVC) P P F W S: Specification Sheet: 1. 1. 1. 1. 1. P P P P PDokumen3 halamanP C (PVC) P P F W S: Specification Sheet: 1. 1. 1. 1. 1. P P P P PEngr. Mehadi Hassan NahidBelum ada peringkat

- 5 - ### Quotation FormatDokumen1 halaman5 - ### Quotation FormatSiddharth JainBelum ada peringkat

- Fluid Kinetic Energy As A Selection Criteria For Control ValvesDokumen9 halamanFluid Kinetic Energy As A Selection Criteria For Control ValvesVijay KabboorBelum ada peringkat

- Rig Lin 2015Dokumen9 halamanRig Lin 2015Sukuna PrideBelum ada peringkat

- Alum Dosing PumpDokumen2 halamanAlum Dosing PumpBassamBelum ada peringkat

- 165D6 - Thermo King 2000 Hose System: 3/8/14Dokumen75 halaman165D6 - Thermo King 2000 Hose System: 3/8/14Elliot WuBelum ada peringkat

- HydacDokumen4 halamanHydacmarkoBelum ada peringkat

- Manuals 1098 Egr 1098h Egr Pressure Reducing Regulators Instruction Manual Fisher en en 5969474Dokumen44 halamanManuals 1098 Egr 1098h Egr Pressure Reducing Regulators Instruction Manual Fisher en en 5969474TitoBelum ada peringkat

- Split Range ControllersDokumen3 halamanSplit Range Controllersashirwad shetty100% (2)

- Pipe IDokumen40 halamanPipe IMegelJoshuaRamiterre100% (1)

- Hydrotest ProcedureDokumen6 halamanHydrotest ProcedureIkhsan Hj SiratBelum ada peringkat

- Specification of Grouting EquipmentDokumen6 halamanSpecification of Grouting EquipmentBimal BosmiaBelum ada peringkat