How To Erect Access Frame Scaffolding. Scaffolding - Poster - Erect

Diunggah oleh

Gutha BabuJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

How To Erect Access Frame Scaffolding. Scaffolding - Poster - Erect

Diunggah oleh

Gutha BabuHak Cipta:

Format Tersedia

How to Erect Access Frame Scaffolding Before erecting access frame scaffolding

Requirements for access frame scaffolding

What will the scaffold be used for? For example, light duty (one or two workers;

A scaffold must be erected, altered, and dismantled by qualified workers or under the Erecting access frame scaffolding painting a wall), or heavy duty (several tradespersons, with large and heavy

direct supervision of a qualified person. The qualified person must ensure that the materials on the platform)?

erection is carried out according to acceptable practices in compliance with any drawings Scaffolds should be erected by two or more people. One person should be knowledgeable in erecting scaffolding to supervise the work. These step-by-step instructions

and the manufacturers or suppliers instructions, and that the correct components and are only a general guide. You must always first follow the manufacturers and/or suppliers specifications. The following example is based on building a scaffold that is How high will the scaffold be? Will it be erected in one operation or as the work

materials are being used. progresses?

2.1 x 1.5 m (7 x 5 ft.) x 1 frame high.

All equipment must be inspected before use to ensure that it is in good repair and Is the ground firm? Can it support the loads from the scaffold, workers, and

suitable for the intended use. materials on it?

The base must be firm and level enough to support the load of scaffolding, workers, and Will the scaffold need to be tied in? How will this be done? Will the ties be moved

materials. Sills and base plates are required on any soil or unstable ground condition, or as the work progresses?

where any levelling adjustment is needed. The sill must be sound, rigid, and capable of Is the scaffold likely to be covered or enclosed as a protection against the

supporting the maximum loads without settlement or deformation. elements? Is there provision for adding additional ties to the adjoining structure?

Adjustable base plates must be adjusted within the limits specified by the manufacturer What will be the method of access and egress? For example, a sloping ladder,

or supplier. vertical ladder, built-in stairway, or direct from the floors of the building structure?

The frames must be plumb and level and spaced to adequately support the loads. On a multi-level scaffold, how many levels will be loaded with materials at one

If uplift could cause the components to separate, locking pins must be used and the time? Will an engineer be required to make the calculations for the total

components secured. Uplift might be caused by the action of wind on a secured deck or anticipated loading and possibly design the scaffold and the sills?

by the leverage action of a cantilever side bracket on the scaffold. All joints must be

pinned on rolling scaffolds and free-standing towers.

With a rolling scaffold or free-standing tower, the platform height must not exceed three

1 5 If a rolling scaffold is required, consider ground surface, height restriction (3 to 1

rule), hazards when moving (such as power lines, projections from the building,

and potholes).

times its smallest base dimension (3 to 1 rule). Select and prepare the ground area. Place suitable sills and make sure there are no holes Install the decking, which may be metal or wood planks or the aluminum and plywood

under the sills. Select the equipment you need and place it near the work area. Put the decking units. If you are using wooden planks, they must extend beyond the supporting Equipment inspection

A scaffold built above the 3 to 1 rule must be effectively guyed or secured to a building or adjustable base plates on the sills in the location that matches your scaffold dimensions. cross-members at least 15 cm (6 in.) but not more than 30 cm (12 in.) Secure the decking so

structure to prevent overturning. The guying of a scaffold may require the direction of a Do not secure the bases to the sills at this time. it cannot move. You must inspect the equipment you plan to use to make sure that it is in good repair

professional engineer. Other methods of tying the scaffold should be of a push-and-pull- and suitable for the job. Check the following:

type mechanism and located no more than 6 m (20 ft.) vertically and 6.4 m (21 ft.)

horizontally, after the first tie has been installed to comply with the 3 to 1 rule. Sills: Suitable size and strength for the loads. Not split or rotten.

Guardrails must be installed on all open sides of the platform where a person could fall a Adjustable bases: No thread damage, no curling or warping of the base plate.

distance of 3 m (10 ft.) or more. The top rail must be placed 102112 cm (4044 in.)

above the work surface. An intermediate rail must be placed halfway between the top rail Frames: No cracks in the welded joints. No kinks or dents in the top or bottom

and the toeboard, if one is provided, or halfway between the top rail and the work surface cross-members. Legs plumb and square with the cross-members. Brace locks in

if no toeboard is provided. The guardrail must be able to withstand a load of 550 N good working order. Coupling pins in place and secured to the frame.

(125 lb.) applied at any point on the top rail.

Cross-braces and plan brace (gooser): Straight with no bent ends. Pivot

Toeboards must be installed on all the open sides of a platform where it is possible for connection in good working order. No excessive rust.

tools and or materials to roll off. The top of the toeboard must be at least 10 cm (4 in.)

above the platform. If loose materials are to be stacked above the height of the toeboard, Planks: No split ends, saw cuts, notches, protruding nails, excessive warping. No

then the toeboard must be increased in height or mesh panels must be installed to contamination that may affect the integrity of the plank, such as oil, chemicals, and

prevent materials from falling off the scaffold. burns. (If you have any doubts about the strength of the plank you may need to

have it load-tested).

Ladder access may be vertical or sloping. Ladders must be secured at the point of

support and must extend approximately 1 m (3 ft.) above the landing. A vertical ladder

must have a clear space of at least 15 cm (6 in.) behind each rung.

2 6 Plywood decks: Not misshapen or cracked. Locks working. All bolts and screws

in place. No burns or broken ends. If upper surface has non-skid coating, no rot or

plywood separation on underside.

Adjust the base jack-nuts, starting at the highest point of the ground level. The jack-nut at the Select the equipment for the guardrail system. Purpose-made, wood, or tube and clamp

highest ground level should be set 7.515 cm (36 in.) from the top of the sill, depending on could all be used. The following instructions are for purpose-made. Install the guardrail post Side or end brackets: Hook-on attachment not distorted. No cracks in welds. No

the slope. Place the first frame onto the base plates at the high point. Connect the first cross- onto the vertical coupling pins seated in the top of the frames. Put a lock pin through the top dents, kinks, or any signs of abuse.

brace to the frame. Allow the frame to lean slightly forward and rest on the sill while you and bottom of each vertical coupling pin to avoid any separation.

Guardrails: Straight, with no kinks, dents, or excessive rust.

prepare for the next frame to be installed.

Vertical ladders and brackets: Clamp on bracket is right size and works

properly. No cracks in welds on ladder rungs. Ladder straight with coupling pins

secured.

Casters: Same size and from same manufacturer. Wheel rotates well and the

swivel below the stem is working. Brake mechanism works properly. Wheel tread

has no damage.

Screw jacks: No cracks in weld where screw jack is attached to the top of the

caster. No thread damage. Adjusting nut is a tight fit.

Other equipment: Inspect any other equipment in the frame structure.

Damaged equipment should be tagged and marked as not fit for use. Inform the

supervisor so that others do not use it. If a supplier sends damaged equipment, make

sure it is returned. A supplier must ensure that equipment is safe to use.

3 7

Attach the guardrails to the posts on all the exposed sides.

Install the second frame onto the base plates. Secure the first cross-brace to the second

frame.

How to Erect Access

9

4 Install a suitable means of access, such as a sloping or vertical ladder secured to the

Frame Scaffolding Install the second cross-brace to both the frames. Next you need to level and plumb the

scaffold. Start at the high point of the scaffold. If possible, use the jack-nut to bring the

8

Install toeboards as required. The gap between the bottom of the toeboard and the top of the

scaffold at the landing point. The ladder must extend 1 m (3 ft.) above the landing.

Note: The diagram does not show a way to get on or off the platform because

there are many possible variations on access.

highest corner down closer to the sill. Next bring all four corners up to that point. If the bottom

platform must not be more than 13 mm (1/2 in.).

cross-members of each frame are level with each other, the frames should also be plumb.

Install the plan brace (gooser bar) at this time to keep the scaffold square. Check the level

again and plumb if necessary. Fasten the base plates to the sills with either nails or screws. If you have questions on workplace safety, call the WCB Prevention Line at 604-276-3100

in the Lower Mainland, or toll-free 1- 888 621-SAFE (7233) for the rest of B.C.

For scaffolding and other health and safety information, visit the Health and Safety Centre

www.worksafebc.com on www.worksafebc.com and click on Construction.

To order this poster (number 0207), phone 1 800 661-2112, local 3068

0207

Anda mungkin juga menyukai

- SOP For Use of Grinder Machines in WorkshopDokumen8 halamanSOP For Use of Grinder Machines in WorkshopFaisal RajaBelum ada peringkat

- Fall Protection and Ladder SafetyDokumen56 halamanFall Protection and Ladder SafetyKAii Magno GuiaBelum ada peringkat

- Ladder Guide PortableDokumen2 halamanLadder Guide PortableakilshaikhBelum ada peringkat

- Ladder Safety PDFDokumen24 halamanLadder Safety PDFRusihan RehanBelum ada peringkat

- SAFETY AND HEALTH RULES FOR CONSTRUCTION WORKDokumen9 halamanSAFETY AND HEALTH RULES FOR CONSTRUCTION WORKVholts Villa VitugBelum ada peringkat

- Scaff and Mewp and HeightDokumen24 halamanScaff and Mewp and HeightRmr ReyesBelum ada peringkat

- Test Method For Earthwork Compaction Control by Nuclear GaugeDokumen29 halamanTest Method For Earthwork Compaction Control by Nuclear GaugeLennieCartujanoLuceñoBelum ada peringkat

- Permit Working at HeightDokumen4 halamanPermit Working at HeightkinaBelum ada peringkat

- A Complete Guide To Working at Height Regulations by At-HeightDokumen6 halamanA Complete Guide To Working at Height Regulations by At-Heightat-height0% (1)

- Aagsc Traffic Management Plan TemplateDokumen13 halamanAagsc Traffic Management Plan TemplateGutha BabuBelum ada peringkat

- Patrick Dampier Wharf Traffic Management Plan Rev 0 For UseDokumen23 halamanPatrick Dampier Wharf Traffic Management Plan Rev 0 For UseGutha BabuBelum ada peringkat

- HIRAC - Work - at - Height - Template PDFDokumen8 halamanHIRAC - Work - at - Height - Template PDFRohma Desi ThirtasariBelum ada peringkat

- Tower Scaffolds: What You Need To DoDokumen3 halamanTower Scaffolds: What You Need To DoEdwin Maglapid RamosBelum ada peringkat

- Scaffolding Safety Guideline: KAS-Scaffolding - Fast Then. Fast NowDokumen9 halamanScaffolding Safety Guideline: KAS-Scaffolding - Fast Then. Fast Nowfaizal4yaBelum ada peringkat

- Working at Height EbookDokumen14 halamanWorking at Height EbookSubhi El Haj SalehBelum ada peringkat

- Stack Safety ProceduresDokumen7 halamanStack Safety ProceduresBhaskar ShuklaBelum ada peringkat

- HSEP 13 8 A1 Fall Prevention System Requirement Rev 5Dokumen5 halamanHSEP 13 8 A1 Fall Prevention System Requirement Rev 5mojgfdBelum ada peringkat

- Tips On: Ladder SafetyDokumen4 halamanTips On: Ladder SafetyGutha BabuBelum ada peringkat

- Frames Erection ProcDokumen18 halamanFrames Erection Procrobby_hipBelum ada peringkat

- Safe Work Procedure TemplateDokumen2 halamanSafe Work Procedure TemplateAmirulAkmalBelum ada peringkat

- Safe Ladder Use RefresherDokumen22 halamanSafe Ladder Use RefresherKheireddine AounallahBelum ada peringkat

- Safety Management: Scaffolds and BarricadesDokumen25 halamanSafety Management: Scaffolds and BarricadesIrene Pudiquet SilvaniaBelum ada peringkat

- Welding PPE GuideDokumen9 halamanWelding PPE Guidecyrelle rose jumentoBelum ada peringkat

- Daily Progress Report: M/s Shapoorji Pallonji Real Estate M/s Shapoorji Pallonji Engineering & ConstructionDokumen24 halamanDaily Progress Report: M/s Shapoorji Pallonji Real Estate M/s Shapoorji Pallonji Engineering & ConstructionBenadict JoshuaBelum ada peringkat

- Safe Working PracticesDokumen7 halamanSafe Working PracticesDiana ParkerBelum ada peringkat

- 3200 MCQ CeDokumen12 halaman3200 MCQ Cesivadhanu100% (1)

- SG11 - 15 NoiseDokumen6 halamanSG11 - 15 NoiseHolly Brigstocke100% (1)

- Presentation On Cable Car ProjectDokumen23 halamanPresentation On Cable Car ProjectAshiq Hossain100% (6)

- Toolbox Safety Talks - Fall ProtectionDokumen3 halamanToolbox Safety Talks - Fall ProtectionHtoo Htoo KyawBelum ada peringkat

- Ladder SafetyDokumen10 halamanLadder SafetysachinoakBelum ada peringkat

- 01-Ppe Eng PDFDokumen17 halaman01-Ppe Eng PDFZaki AdamouBelum ada peringkat

- 000-Za-E-09303 - 0 Packing and Marking ProcedureDokumen251 halaman000-Za-E-09303 - 0 Packing and Marking Procedurealinor_tnBelum ada peringkat

- 004 Hirac Confined SpaceDokumen3 halaman004 Hirac Confined Spaceeunice.pacerstradings100% (1)

- Sap MM TutorialDokumen190 halamanSap MM TutorialRobraggamofBelum ada peringkat

- Dry Bulk Product Safety SOPDokumen14 halamanDry Bulk Product Safety SOPWan Sek ChoonBelum ada peringkat

- Rigging Safety TipsDokumen2 halamanRigging Safety Tipspruncu.alianmBelum ada peringkat

- Seminar ReportDokumen31 halamanSeminar ReportPAWAN TIWARI57% (7)

- Construction - Scaffold Checklist - HSEDokumen6 halamanConstruction - Scaffold Checklist - HSEtarek_bouzayaniBelum ada peringkat

- Scaffolds: OSHA Office of Training & Education 1Dokumen34 halamanScaffolds: OSHA Office of Training & Education 1khaan1830Belum ada peringkat

- Unloading of EWPs From ContainersDokumen10 halamanUnloading of EWPs From ContainersPirashanth SathananthanBelum ada peringkat

- Tool Box Talk #10: Working at Heights 3. Tower ScaffoldsDokumen1 halamanTool Box Talk #10: Working at Heights 3. Tower ScaffoldsRomanuSBelum ada peringkat

- Job Safety Analysis FormDokumen2 halamanJob Safety Analysis FormAbhaySngh100% (1)

- Index: Cv. Dira Utama SejahteraDokumen12 halamanIndex: Cv. Dira Utama SejahteraFreshop SurabayaBelum ada peringkat

- Basic Scaffolding VOCDokumen1 halamanBasic Scaffolding VOCSaging GiriBelum ada peringkat

- SOP For Abrasive WheelsDokumen7 halamanSOP For Abrasive WheelsShreedharBelum ada peringkat

- Library of PD&T QMS Project HSE Moments: Presented By: On DateDokumen8 halamanLibrary of PD&T QMS Project HSE Moments: Presented By: On DateSyahril Aizal AhmadBelum ada peringkat

- Is 4912-1978Dokumen12 halamanIs 4912-1978Deboline MitraBelum ada peringkat

- Scaffolder Erector Medical ExaminationDokumen6 halamanScaffolder Erector Medical ExaminationZulqarnain RamliBelum ada peringkat

- 3.ceiling Installation JSA ADokumen2 halaman3.ceiling Installation JSA APijah AhmadBelum ada peringkat

- HIRAC Work at HeightDokumen7 halamanHIRAC Work at HeightMitchRappBelum ada peringkat

- Operate Portalifts and Econolifts SafelyDokumen7 halamanOperate Portalifts and Econolifts SafelyMuhammad Zefrian SyahputraBelum ada peringkat

- MWR 135Dokumen20 halamanMWR 135Philip Bautista TotanesBelum ada peringkat

- Power AscenderDokumen6 halamanPower AscenderApriliando KurniawanBelum ada peringkat

- TSTI FormDokumen2 halamanTSTI FormJinu ThomasBelum ada peringkat

- RFSSB-EHS-P-004 HIRARC Procedure PDFDokumen4 halamanRFSSB-EHS-P-004 HIRARC Procedure PDFNajman HamdiBelum ada peringkat

- Window Cleaning Safety GuidelineDokumen4 halamanWindow Cleaning Safety Guidelinejhunvalencia1203Belum ada peringkat

- Working at Height PresentationDokumen11 halamanWorking at Height PresentationAbdul Hameed OmarBelum ada peringkat

- Work at Heights Self Assessment SheetDokumen4 halamanWork at Heights Self Assessment SheetBalogun IsaacBelum ada peringkat

- SOP Module Unloading & StorageDokumen1 halamanSOP Module Unloading & StorageRahul SahaBelum ada peringkat

- Standard Operating ProcedureDokumen55 halamanStandard Operating Procedureboy tryadi100% (1)

- Topic For TBMDokumen19 halamanTopic For TBMdauxomBelum ada peringkat

- SWMS Bored PilingDokumen17 halamanSWMS Bored PilingnaraBelum ada peringkat

- Working at Height On 25.03.2021Dokumen80 halamanWorking at Height On 25.03.2021AMAN GUPTABelum ada peringkat

- Safety of LaddersDokumen13 halamanSafety of LadderssalekojicBelum ada peringkat

- Work at Height Checklist PDFDokumen1 halamanWork at Height Checklist PDFDEEPAKBelum ada peringkat

- Machine Safety in ConstructionDokumen27 halamanMachine Safety in ConstructionSawyu Nandar100% (1)

- MSDS - Asada Threading Oiil Red - ENDokumen7 halamanMSDS - Asada Threading Oiil Red - ENnghiaBelum ada peringkat

- No ParkingDokumen1 halamanNo ParkingGutha BabuBelum ada peringkat

- Keep LockedDokumen1 halamanKeep LockedGutha BabuBelum ada peringkat

- Warning / 警告: By Order Bartley Ridge Site ManagementDokumen1 halamanWarning / 警告: By Order Bartley Ridge Site ManagementGutha BabuBelum ada peringkat

- English Lets Report Template PDFDokumen17 halamanEnglish Lets Report Template PDFGutha BabuBelum ada peringkat

- Elect - Danger High VoltageDokumen1 halamanElect - Danger High VoltageGutha BabuBelum ada peringkat

- The Factories Act: - Administered by Ministry of ManpowerDokumen69 halamanThe Factories Act: - Administered by Ministry of ManpowerGutha BabuBelum ada peringkat

- Excavation Zone - Keep Away Swing AreaDokumen5 halamanExcavation Zone - Keep Away Swing AreaGutha BabuBelum ada peringkat

- Danger of Falling ObjectsDokumen1 halamanDanger of Falling ObjectsGutha BabuBelum ada peringkat

- Overhead Load Warning Sign Ref St601344917270Dokumen1 halamanOverhead Load Warning Sign Ref St601344917270Gutha BabuBelum ada peringkat

- Electrical SignDokumen2 halamanElectrical SignGutha BabuBelum ada peringkat

- English Lets Report TemplateDokumen4 halamanEnglish Lets Report TemplateGutha BabuBelum ada peringkat

- Electrical SignDokumen2 halamanElectrical SignGutha BabuBelum ada peringkat

- MM Quiz53Dokumen18 halamanMM Quiz53Gutha BabuBelum ada peringkat

- Zika MOM MOH AdvisoryDokumen1 halamanZika MOM MOH AdvisoryGutha BabuBelum ada peringkat

- SAP MM Certification QuestionDokumen43 halamanSAP MM Certification QuestionGutha BabuBelum ada peringkat

- NEA Chinese Tamil ZikaDokumen1 halamanNEA Chinese Tamil ZikaGutha BabuBelum ada peringkat

- Electrical SignDokumen2 halamanElectrical SignGutha BabuBelum ada peringkat

- Zika MOM MOH AdvisoryDokumen1 halamanZika MOM MOH AdvisoryGutha BabuBelum ada peringkat

- Flu PosterDokumen1 halamanFlu PosterGutha BabuBelum ada peringkat

- Always Tie Off - Work at Heights SafetyDokumen1 halamanAlways Tie Off - Work at Heights SafetyGutha BabuBelum ada peringkat

- Unsafe TagDokumen1 halamanUnsafe TagGutha BabuBelum ada peringkat

- Battery SafetyDokumen11 halamanBattery SafetyDhanushka SamarakoonBelum ada peringkat

- Always Tie Off - 100% Tie Off Safety HarnessDokumen1 halamanAlways Tie Off - 100% Tie Off Safety HarnessGutha BabuBelum ada peringkat

- Warning: No Alcohol, Drugs & Fighting Allowed Within The Premises Fine $2000 & Hand Over To PoliceDokumen1 halamanWarning: No Alcohol, Drugs & Fighting Allowed Within The Premises Fine $2000 & Hand Over To PoliceGutha BabuBelum ada peringkat

- Noise Regulations For Construction SiteDokumen3 halamanNoise Regulations For Construction SiteGutha BabuBelum ada peringkat

- Do Not TouchDokumen1 halamanDo Not TouchGutha BabuBelum ada peringkat

- Spec Schedule40 Pipe Galvanized PDFDokumen2 halamanSpec Schedule40 Pipe Galvanized PDFSahil SharmaBelum ada peringkat

- Guide For International Students Studying in Glagow For Mca Masters OralsDokumen3 halamanGuide For International Students Studying in Glagow For Mca Masters OralsVinil GuptaBelum ada peringkat

- 003 Kinematics-Relative MotionDokumen2 halaman003 Kinematics-Relative MotionAnant KumarBelum ada peringkat

- PSP5000BDokumen1 halamanPSP5000BOdair SilvaBelum ada peringkat

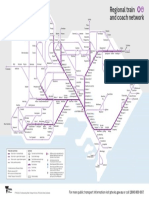

- PTV Regional-Train-Coach Network Map 2017Dokumen1 halamanPTV Regional-Train-Coach Network Map 2017Muhammad Akbar PradiktoBelum ada peringkat

- 2014 Bluebook 14th Edition (1) MBTA StatisticsDokumen114 halaman2014 Bluebook 14th Edition (1) MBTA StatisticsKira HoffmanBelum ada peringkat

- Route 19 From Perris - Moreno ValleyDokumen5 halamanRoute 19 From Perris - Moreno ValleyBenson TautalaBelum ada peringkat

- System: Fort Worth Central StationDokumen2 halamanSystem: Fort Worth Central StationbenBelum ada peringkat

- Chaplin PDFDokumen24 halamanChaplin PDFSandeep DewanganBelum ada peringkat

- Flash on English for Transport and Logistics Answer key and TranscriptsDokumen7 halamanFlash on English for Transport and Logistics Answer key and TranscriptsPeter Kova'csBelum ada peringkat

- NPC Report Details US Oil and Gas Transportation InfrastructureDokumen208 halamanNPC Report Details US Oil and Gas Transportation InfrastructureAshrafHussainBelum ada peringkat

- Accommodation Student VersionDokumen4 halamanAccommodation Student Versionleh.mo9315Belum ada peringkat

- Kenworth C500 Truck Brochure.Dokumen2 halamanKenworth C500 Truck Brochure.scribdadiddlyBelum ada peringkat

- Orange Line Improvements Project PresentationDokumen25 halamanOrange Line Improvements Project PresentationMetro Los AngelesBelum ada peringkat

- Evolution of Transportation in the Philippines from Pre-Industrial to Modern EraDokumen2 halamanEvolution of Transportation in the Philippines from Pre-Industrial to Modern EraAntonio Andres AlabaBelum ada peringkat

- Transportation - ShinkansenDokumen5 halamanTransportation - ShinkansenDandi4xBelum ada peringkat

- TCS Placement Paper On 12th Feb 2010Dokumen13 halamanTCS Placement Paper On 12th Feb 2010Jannathul Firdous MohamedBelum ada peringkat

- GRP1000 en Datasheet Survey BasicDokumen2 halamanGRP1000 en Datasheet Survey BasicandrewgeorgecherianBelum ada peringkat

- How Skyscrapers Can Save The CityDokumen4 halamanHow Skyscrapers Can Save The CitySeraMa JambuiBelum ada peringkat

- Case Study2: History of Indian Railways Electrification and Policy ObjectivesDokumen16 halamanCase Study2: History of Indian Railways Electrification and Policy ObjectivesDarshan ParmarBelum ada peringkat

- Route 10 Folkestone - AshfordDokumen7 halamanRoute 10 Folkestone - AshfordNathan AmaizeBelum ada peringkat

- 24th Bza MasDokumen1 halaman24th Bza MasGowri Sankara Rao UritiBelum ada peringkat

- Cadrail 9 ManualDokumen184 halamanCadrail 9 ManualMaverickMk11Belum ada peringkat